ALICYCLOBACILLUS DETECTION AGAR CAT Nº: 2002 Alicyclobacillus

advertisement

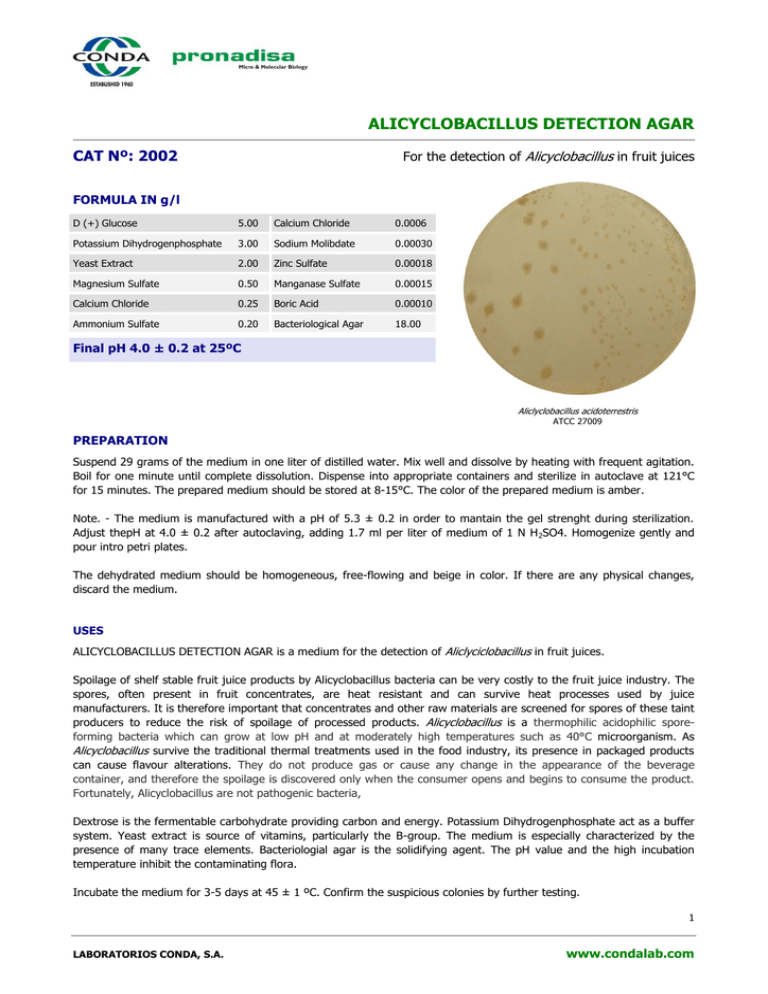

ALICYCLOBACILLUS DETECTION AGAR CAT Nº: 2002 For the detection of Alicyclobacillus in fruit juices FORMULA IN g/l D (+) Glucose 5.00 Calcium Chloride 0.0006 Potassium Dihydrogenphosphate 3.00 Sodium Molibdate 0.00030 Yeast Extract 2.00 Zinc Sulfate 0.00018 Magnesium Sulfate 0.50 Manganase Sulfate 0.00015 Calcium Chloride 0.25 Boric Acid 0.00010 Ammonium Sulfate 0.20 Bacteriological Agar 18.00 Final pH 4.0 ± 0.2 at 25ºC Aliclyclobacillus acidoterrestris ATCC 27009 PREPARATION Suspend 29 grams of the medium in one liter of distilled water. Mix well and dissolve by heating with frequent agitation. Boil for one minute until complete dissolution. Dispense into appropriate containers and sterilize in autoclave at 121°C for 15 minutes. The prepared medium should be stored at 8-15°C. The color of the prepared medium is amber. Note. - The medium is manufactured with a pH of 5.3 ± 0.2 in order to mantain the gel strenght during sterilization. Adjust thepH at 4.0 ± 0.2 after autoclaving, adding 1.7 ml per liter of medium of 1 N H 2SO4. Homogenize gently and pour intro petri plates. The dehydrated medium should be homogeneous, free-flowing and beige in color. If there are any physical changes, discard the medium. USES ALICYCLOBACILLUS DETECTION AGAR is a medium for the detection of Aliclyciclobacillus in fruit juices. Spoilage of shelf stable fruit juice products by Alicyclobacillus bacteria can be very costly to the fruit juice industry. The spores, often present in fruit concentrates, are heat resistant and can survive heat processes used by juice manufacturers. It is therefore important that concentrates and other raw materials are screened for spores of these taint producers to reduce the risk of spoilage of processed products. Alicyclobacillus is a thermophilic acidophilic sporeforming bacteria which can grow at low pH and at moderately high temperatures such as 40°C microorganism. As Alicyclobacillus survive the traditional thermal treatments used in the food industry, its presence in packaged products can cause flavour alterations. They do not produce gas or cause any change in the appearance of the beverage container, and therefore the spoilage is discovered only when the consumer opens and begins to consume the product. Fortunately, Alicyclobacillus are not pathogenic bacteria, Dextrose is the fermentable carbohydrate providing carbon and energy. Potassium Dihydrogenphosphate act as a buffer system. Yeast extract is source of vitamins, particularly the B-group. The medium is especially characterized by the presence of many trace elements. Bacteriologial agar is the solidifying agent. The pH value and the high incubation temperature inhibit the contaminating flora. Incubate the medium for 3-5 days at 45 ± 1 ºC. Confirm the suspicious colonies by further testing. 1 LABORATORIOS CONDA, S.A. www.condalab.com MICROBIOLOGICAL TEST The following results were obtained from type cultures in the performance of the medium after incubation at a temperature of 45 ± 1.0 C, under anaerobic conditions, and observed after 3-5 days hours. Microorganisms Growth Alicyclobacillus acidocaldarius ATCC 27009 Good Alicyclobacillus acidoterrestris ATCC 49025 Good Escherichia coli ATCC 25922 Inhibited BIBLIOGRAPHY BAUMGART, J. and MENJE, S.: The Impact of Alicyclobacillus acidoterrestris on the Quality of Juices and Soft Drinks. Fruit Processing 7; 251- 254 (2000) IFU Working Group Microbiology: First Standard IFU-Method on the Detection of Alicyclobacillus in Fruit Juices. (April 2003) Jensen Nancy, Evaluation of detection methods for alicyclobacilli in fuit juice concentrates in Australia. Food Science, Australia Akira Yokota, Tateo Fujii, Keiichi Goto, Alicyclobacillus: Thermophilic Acidophilic Bacilli. Springer (2008) STORAGE 25ºC Once opened keep powdered medium closed to avoid hydration. 2ºC 2 LABORATORIOS CONDA, S.A. www.condalab.com