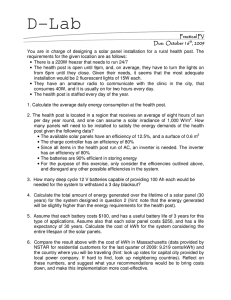

SOLAR PV PROJECT CALVIN COLLEGE INTERIM 2015 ENGINEERING W-80 A

advertisement