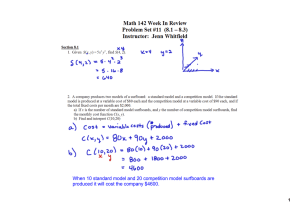

JOHN BALL ZOO SOLAR INTEGRATION PROPOSAL Interim 2015 ENGR W80 Class A

advertisement