REHOBOTH SOLAR PROJECT FINAL REPORT Calvin College Engineering W83-A

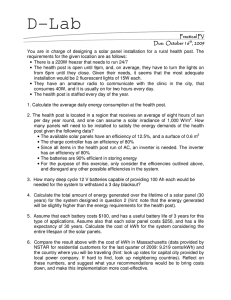

advertisement