A STUDY OF D}NAMIC BEHAVIOUR OF PROTON

advertisement

of the lSth Symposilun

of Malaysid ChemlcalElaileeB

Proceedings

A STUDY OF D}NAMIC BEHAVIOUR OF PROTON

EXCHANGE MEMBRANE FUEL CELL STACK

RoslinaAbdullah', Hxmdani Saidi

Unit,Udvelsili TeknologiMalaysia,Ciiy Campuq

Membrane

Reseaxch

54100KualaLumpur,Nlalaysia.

'Co(espondingauthor.Phone:+603-26154598,Fa{: +603'26945021

Emailiaroslina@ur'nkl.utm.my

ABSTR-{CT

The proton erchange membran€tue1 cell (PEMFC) stack has shown promise as the

leading candidatefof use as a non-polluting power source.lt dischaxg€swater as wrste,

opemtesat low temperaturesfor quick start-up,andusesa solid Pol]'ner as an €lectrolyte

which reducesboth consLrclion and safetycomplications.In order io study the dynamic

b€haviow of PEMFC stack, dynamic model is d€veloped using MATLAB, a high

performanceteclmicat computing sofilvareThe model is basedon pbysical laws having

cl€ar significant in replicating the tuel ceil system and can easily be used lo set up

differefi operationalsiralegi€s-It consistsof several submodelswhich are integnted to

€ach other. The periomances of the tuel cell stack such as thermodvnamicefficiency,

pressure and humidity profile afe also d€scrib€d As a whole, the outpul from the

aswell as

canbe variedto meettheneedsof individualinvestigations

modelingtechnique

for the disiribution results.

K€ywordsrBehaviourOf PEMFC,DynamicMode| lnt€grationOf SeveralSubmodels,

Performance,Individual lnvestigationAnd Dist.ibuiion Results.

I lNl RoDt ( Tlo\

Fuel cel1sconstit te lhe most efficient energytransducersknown to modem technology;

they arc rwice as €fficient as batte es.Fu€l cells are electrochemicaldeviceslhat convef

a tueL'senergydirectly to elect.ical ene.gy,operaiingmuch like coniinuousbatlerieswhen

suppliedwith ftel to the anode(negativ€elecirode)and oxidant (e.9, ai) to the cathode

(positive electode). Forhrnately, fliel cells do not follow the naditionai extraction of

energyin the form of combuslionheat, conversionof heat energyto mechanicalenergy,

and finally tuming mechanicalenergyinto electricity- Instead,th€y chemically combine

the moleculesof a tuel and oxidizer without buming, directly producingelecrricitv and

dispensingwith the inefficienciesandpollution offiaditional combustiotr.

The dev€lopmentof tuel cell technologyis catatyzedby the fact that the global energv

use is ircreasing steadjly and eNironnenlal problems related to energyproduction and

transportationare growing.At the same time, the efficienci€s of conventional energy

conv€rsion process€s are approaching their thermodynamic limils. Morc efficient

solutionsarc thus needed.

The efficiency of tuel cels is not limited by the Camoi limitations of heat engines

High efficiency makes fuel cells attractive for a iarge variety of applications,inchding

pow€r production,residentialenergysyst€msandpossibly

road vehicles,decentralised

compactsu€

In matryapplicalions,

like pofiableelectronics.

even smallerapplications

andthe lack of1ocal emissionsalso increasethe attractivenessoffuel cells

Chemical

Engineers

Proce€dhgs

orlhe18thS)dposlunofMalaysia!

2 METHODOLOGY

2.1DYNAMIC SIMULATION

To study the dynamic performance of tuel cell stack, the modeling methodology

incoiporates an explicit finite difference scheme.For lhis puryose,lhetuel cell stack is

divided ilto elementswhos€ size is determinedby the desiredaccuacy ofxhe resultsand

the num€rica1stability of the calculations.Thepropefiies ol each computationalelement

are assumedbe spatialty unifom and changewith time. The finite differcnce schemeis

usedio calculate the temperatureonly.The remainingpropediesar€ calculaledusing ihe

temperatureand various relationships.This requiresthal the electrochemicalkiletics and

gasdlnamic be treatedwith st€adystatefonnulations.Assumptionis madelo simplify the

resulting equaiionsand reduc€the computationalrequLremenlsofmodel developedrlsing

thismethodologyThe srability citerion, an expressionusedto detenninethe sizerangefor the el€ments

and time stepsneededfor numerical stability, is derived using an energybalanceon an

is

element.Theexpression

At :!

ioVC) iil

Irn c" ): rm(,r. -Il ,

R) l

wiih At is the time slep usedfor the finite differenc€calc lations.pis the averagedensity

ofthe elementma1erial,V is the voiume of the elemed while C is the themai capacitance

ofthe elementmatenals. C" and m are the specific heat at constantpressureand mass

flow rate respectivelyofthe fluids in the elementand R representlhe thennal resNtances

As seenin equation(1), L'restabilityofthe fidte dif€rence

of the thennalandsurface.s.

caiculationsdependson material properiies,fluid proPedies(if any existsin the element),

elemelr.andr'r,e

ot l\e sunourding

lhe es,sunce

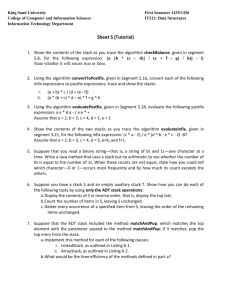

2.2 FUEL CELL SYSTEMMODEL

It r€q.rires four flow systems(figure l) which are hy&ogen supply system,airsupply

system,cooling systemandhumidificalion system. To simplified the model,it is assumed

that the siack tempemtureis constant.A11the variablesassociatedwith the lumped anode

volume are denotedwith a subscripi(an.).The cathodesupply manifold (sm) lumps a1lthe

volumes associatedwith pipes and connection between the compressorand the stack

cathode(ca) flow field. The cathoderetum manifold (1m)representsthe llunped votune

ofpipes downstreamof the stack cathode.Another assumplionis that the properliesof the

flow €xiting a volume are the sameas lhoseofthe easinside the volume. Subscripts(cp)

ard (cm) denote variables associatedwi$ the compressor and compressor motor,

rcspectivelY.

fonrt]l5d

I cP,

!rumdrns

I \\',;,,,,

FIGTIR! 1. Componentsandvoiumesin tuel ce11rcaciantsupply system

The power of ihe tuel ce1] stack dependson cunent drawn from th€ stack and stack

voltage. The tuel cell voltage is a tunction of currenl, reactan! partial pressule,

.1-5l

:ii

Chemical

Engineeis

Proceedlngs

offie 18thSymposnu!

of Malaysian

lemperatureand membranehumidity. As the curaentis drawr ftom the tuel c€11,oxygen

andhydrogenareusedin the r€action.Waterandhe3t are also generated.

2,3 FIIEL CELL STACKMODEL

The ftel cel stack model containsfour interacting sub-modelswhich are stack voltage

mod€I, anode flow model, cathodeflow modei and membranehydration mode1.It is

assumedthat the stack temperatureis constantat 80"C (353.15 K). The voltage model

containsan equationto calculatestackvoltage basedon fue] cel1pressure,temperature,

reactantgas partial pressureand membranehumjdity. The dynamically varying pressure

andrelative humidiry of the reactantgasflow inside the stackflow channelsare calculated

in the cathodeand th€ anodeflow models.

2.3.1StackYoltageModel

The stackvoltage is calculatedas a functior of stack current, cathodepressure,reactani

pafial Fessures,tuel cell temperatureandmembranehumidily. Fuel cell voltageis

Vfc =E-Vact-Vohm

(:2)

Vconc

ohmicand

wilh E is the opetrcircuitcircuitwhileVact, Vdhm and Vconcareactivation,

overvoltages,

which reprcsentlossesdue to variousphysicalor chemical

concenirarion

factors.

2.3.1.1ActivationOvervoltage

It arisesffom the need to move elecfons, to break , and to form chemical bond at the

cathodeand anode - The relation between the activation ovewoltage and the cunent

density is describedby rhe Tafel equationwhich is however not valid for small curent

d€nsiry.Therefore,the Tafel equationis approximatedby expression

vacr:vo

Va (l - e-cri)

(3)

The calculationfor Vo and Va is basedon eiectrochenical,kinetics and therrnodlnamic

2.3.1.2Olmic Overvoliage

It arises&om the rcsistanceof the polymer membraneto the 'transfer of protons' and the

ofthe electlodes

andconaollerplatesto the 'tansfer ofelectrons'.Th€voltage

resistance

drop that conespondsto the otmic resistanceis proponional to the cu(ent density

( 1)

v *,=i & m

with i is curent andR.bnis ohmic resistance

2.3.1.3 Concentration

Overvotag€

It resultslrom the increasedloss at high curent density)€.g., a sigificant &op in reaclant

concentation due to both hig:hreacrantconsumptionand he3d loss ar high flow laie. An

equalionthat approximatesthe voltagedrop from concentrationlossesis given by

vconc = i ( c2 x i,/i ,"")"r

(5)

This ierm is ignored is some models,becauseil is not desirableto operatethe stack at

regionswhere Vconc is high. However, this term needsto be included, if the siack will

operateat high cunent density. c2, c3 and i.", are constantsthat d€pendon temperature

andreactantpartial pressure.

+54

ChemicalEnsineen

of the l EthSynposiunof Nlalaysian

Proceedinss

2.3.2Cathode

Flow Mod€i

Thjs model capturesthe cathode air flow behavior, and is deveiop€dusing the mass

conveffationprinciple and the thernodlnamic and psychometricpropertiesof air. Several

assumptionsare made.First, all gasesobey ideai gas law and the temperatur€ofthe air

insidethe cathodeis equalto the stackt€mpemturewhich is 80oC.Ii shouldbe noted that

lhe propeniesofthe flow exiiirg the cathodesuch as temperature,presiule and humidiiy

are assumedto be the sameas those inside the cathode.Fufhermore, wh€n the relative

humidity of the gasexceeds100%,vapor condens€sinto ihe liquid for,n The iiquid water

doesnot leav€the siack andwill either evapoGtewhen the humidiry dropsbelow 100%or

accumulatein the cathode.

2.3.3AnodeFiow Model

This nod€l is qrite similar to the cathodeflow model. First assumptionis pure hydrogen

gasis assumedto be suppliedto rhe anodefrom a hy&ogen tank. Nexi, the inlel hyihogen

flow is assumed ro have 100% relative hunidiry. Hy&ogen flowmte can be

instanraneouslyadjusled by a valve while maintaining a minimum pressue difference

acrossthemembrane.

2.3.4Membrane

HydmtionModel

The water transportaffoss membraneis achiv€dthrough two distinct phenomenalirst,

the €lectro-osmolic drag phenomenonis rcsponsible for the water molecules dragg€d

acrossthe membmneftom anodeto cathodeby the hydrogenproton. Second,the gadient

of water concentrationacrossthe membran€due to differencein humidity in anodeand

cathodegasescauses"back-diffllsion"ofwater from the cathodeto anode2.4PERFORMANCE

The calculaiion for themodynamic efficiency of the tuel cell is accomplishedby dividing

the net electrical energyproducedby the energy value of the tuel used ro produce the

electricity. The ner eiectdcalenergyis calculatedby numericallyintegratingihe net power

with respectwith time. The modeling allows for €ither the higher or lower haeling value

of thefuel to be usedfor rhiscaiculation.

n=

{P

dt

(6)

with rl is the themodlnamic efficiency of the stack,P is ihe net power prcducedby ihe

stack,lry is the heatingvalu€ of the fuel andm is the massofrhe fuel usedto producethe

2.5PROPERTIES

Pressureandhumidiry plofiles are computedusing the design of the bipolarplates,output

from the at flow, the ideal gas equationand psychometricrelationship The bipolar plate

desigrl output fiom xhe air flow and the ideal gas equation are used to calculate ihe

densit and velocity of the gasesin the flow channei; both of which are required to

calculatethe pressuredrop.

2.6 CONTROLSYSTEM

The pueose of control systemis io regulalesthe enxirestack system lt determinesthe

amounlof processgasrequiredto meetpaticular load as well as calculalesthe amountof

eneryyusedto deliver the gasto the tuei cells. It is also calculatesthe amounl ofcooling

flow requiredby the stackto maintain the desirediemperaturc.If the stackis pressurized,

th€ energyrequted to pressurizethe syslemwili be calculated.The amountofthe process

gas requircd and the amount ol the water producedby the tuel cell stack is calculated

using the electrochemicalequalions

..rl

olMalavsianChemicalEn_qneds

of the lSth Svmposium

Proceedings

3 RESULT

*g**g*''*r**e**+*

#F{*r{*trtil1#':tx*r'h

resuLl

showsan exampleof distribuhon

sf:!qI}91!9ll!9q

T AB IE l . Stn e l e \a | u ere suLtfromrhemodel

Result

r'-l

- Pl- r t "1r l

1.6381L/s

0.40631L/s

4't.2%

en' c ler c v

7.468 kW

AmP

155.99

\l J \i 1 r 4 c t re rt

*

''

C 1,,.

A mor

a'

l'{GLtu 2 Drsnrbrror esJ'I HearoLrDuL

rnclionofcunerL

4 CONCLUSION

j*#

l",tJjj:,'di

;!$ii:Ir'lrur#r*ll$ji:r

t::"ili'*Hi:i""ffff

l,|"""'"'ti!'l:[#ft]r',"".TH";ir*i;"*

1r1'l:::ii:T:liJ",'iJii:

I

ydc,e'r,ae

e,enruJ,'

1";,,

:"T,l::.ff

f,ft :' Jll: ;:J:;T:""l,i

",,,

wnic-Xi,5.1TTl:":;,'""Jilli

.e'r.)5'ern

tue'

.p"i:'n.""""'

f.?T:lTi,;

"i,

cost elll

be

noi

may

it

Since

oo*".

"vtt"-. ,r'" r'"1

i.*"'"r"\v".t.

rnodelwill prove to be verv usetul

".11

BIBLIOGR-A.PHY

!3iJsi'ii"3'h"t':#Ti"qi:3]-:i:'#'fr:

B:*::,H:1,',;:?1,,'+:.T#[:ff

4-56

Chemical

Eryiree6

Proceedings

ol the18thSymposium

of Malaysjan

Pol)'technic Institute and State University, Mechanical Engineering Depadment,

Blacksburg,

Virginia24061-0238.

JayT Pukmshkan,Huei Peng, Alnu G Stefanopolou.(2002)."Simulation ar1danalysisof

tansient fuel cell system perfonnance based on a dynamic reactant flow

Deparbnent

ofMechanicalEngin€ering,

University

Research

Cenxer,

model.'Automotive

ofMichigan, Ann Arbor, Michigan.

for the development

of nathematicalmodels

JamesHowardLee.(1996).A methodology

B.S.,Califomia

Pollechnic

StateUniversity,

and

desigr

oftuel

cell

stacks

for simulation

,

M.S.,TexasA&M University.

JamesLarminie.(2001)."FuelCel1SystemExplain."OxfordBtookesUniversity,United

Kjngdom.

J. M. Ogden,M. M. SteinbuglerandT. G. Leutz. (1998)."4ConparisonOf Hydrosen,

MeihanolAnd CasolineAs Fuels For Fuel Cell VehiclesrImplicationsFor Vehicle

DesignAnd InftastruciureDevelopment."Joumal Power Soulces.

(?000). "PropulsionSystemStrategi€sfof Fuel Cel1vehicles."

KaushikRajashekara.

Energenix Center Delphi Automotive System, SAE 2000 World Congress.Detroit,

Michigan

MichaelJamesOgbum(2000)."SystemsIntegration,Modeling,andValidationofa Fuel

Blacsburg.Virgina.

Ce i H)bridE ec-ricVehicle."

DouglasJ. Nelson,MichaelW. Ellis, BenoitOlsommerand

MichaelR. von Spakovsky,

MichaelJ. Ogbum(2000)."A Multi- Inter'DisciplinaryApproachTo Fuel Cell System

Development:The U.S. DoE GATE CenterFor AutomoiiveFuel Cell SystemsAt

Virginia Tech." MechanicalEngineerlngDept.,VirginiaPolytechnicInsliluteand Slate

Inc.

Univ., Socieq,of AutomotiveEngin€els,

SeongW. L€e. (2003)."FeasibilityShrdyof a Fuel Cell Technologyin Automobile

Appiication." Depatmeni of Industrial Engineering,Schoolof Engineeriry, Morgan State

University.

,ii