DATA VALIDATION FOR REAL TIME OPTIMISATION CYCLE

advertisement

Proceedirgs

oftir€ l3th SymposilmofMaldysiAnChefricalEnglnee.s

DATA VALIDATION FOR REAL TIME

OPTIMISATION CYCLE

H. w. L€e' and A. Ahmad

Laboratoryof PrccessContol, Fac lty of ChemicalandNatural ResourcesEngineering,

Udveffiry TeknologiMalaysia,81310Sludai,Johor,Malaysia.

'Corespondingaurhor.Phone:+607'5535877.

Fax:+607'5581463

Email:leehw_78@hotrnail.com

ABSTRACT

for RTO implementation,

daiacollectedfrom a processplant mustbe

As a prerequisite

lrcated by three importanldata validationstages,i.e.. steadystate detection,data

andgrosserrordetection

to eliminaleerro$ andinconsistencres.

rcconciliation

This paper

discusses

thed€velopment

of tbedatavalidationsiagefor realtine optimizationin a fatty

acid fraciionation process.To evaluatethe proposeddala validation sysl€m,single and

multiple gross errols in the fom1 of leakagesin processstream were imposed to the

prccess.The resultsproved the capabilityof the proposedlool in identifyingand

reciirying all the grossenors introducedto the process.

Ke)ryords: Data Validation,SteadyStateDetection,Data Reconciliation,

GrossElTor

Detection.

1 INRODUCTION

Processindustneshave beell undergoingsubstantialchangesin order to cop€ with new

challenges fesultiq from high en€rgy and manpower costs, slrict safety and

enviromrenral regulaiions, siringenr product specification and scarcity of reduced

as well as stiffcompetitionfrom new players. Due to thesereasons,

variationfeedstock

real time optimisation (RTO) has been bfought forward for chemical industdes as

potentialsolutionsto the increasinglyinlenseproduction challenge.

Genichi et al. (1994) proposesthat the second stage jn the real iime optimisation

(RTO)cycleis datavalidation.Datavalidationis consisted

of threemajorcomponents,

which are steadystated€tection,datareconciliationand grosserror detection.

RTO moves processesfrom one steady siate operaling condilion to anothersetting

that are more profiiable. Therefore,st$dy siate detectionis required to detenninethe

conditionof the proc€ssand the tlme requiredfof an optimisationcycle. RTO is only

implemeniedif the plant is al sleadystateandthe plant must thereforebe allowedto settle

so thatthe desiredconditionjs obtained.DarbyandWlite (1988)proposed

thatrhetime

period betweentwo real time optimisationexecutionsmust be much longerthan the

processsettling time to ensurethat the processr€tums to steady state operationbefore

optimisation

is conducted

agaln.

Measurcmentsof process variables such as flow lates, pressurcs,levels,

concentations

andtemperatures

in a chemicalplocessare subjectto enor, bothrandom

and gross. These enors are ofien umvoidable and they may foul signals during

processingand lransmissionstages. Randomand grossenors can leadto

measurements,

deteriomtionin the performanceofihe control syst€ms. At the Limil larger eross error

canevennullify gainsachievable

throughprocessopiimisation.Theseenoneous

datacan

evendrlvethe processto unecoromicor unsafeoperatingrcgime. As a result,m€asures

to eliminate lhese effects must therefore be in place to ensure the successof any

optimisation tasks. Data Leconciliation and gross error detection were requir€d to

accomplishlheseimportanttasks.

Data reconciliation is developed to improve the accuracy of measurementsby

reducing the efect of elTorin the daia. Meanwhile, thesefteasurementsafe adjustedto

satisfylhe conservation

laws and rhe balanceconst.ainis(e.g.energy,mass,etc.).This

3- 168

Engineers

Chemical

of Malavsi.n

of theI8thSymposiun

Proceedings

lo .enove any glosseror lrom

by a grosselaordetectionmechanism

was accompanied

2 DATA VALIDATION

2,1STEADY STATEDETECTIONMETHOD

A number of methodshave been proposedto certify lhal the required steady state

conditionis alfeadyachievedpnor to the executionof the oplimisationcvcle ln this

re.tprooosed

re.rdri'ricdr

,nd\.r,'or.ehoasr.Fcorsde,Fd lhefif'r sas 'hecornDo'

qa'

rca'

r'e

m"

hern'

|

hc

1/

r/

lo8or

-heorlol etidence

ui \ar".rrnla,

'econc

"1o

(1q8-)

a/

Nalas]mhan

bl

{MTE)slrsaested

"/

c de'jned

I rn';per' Iendrfer rar'(dl'heoqo e\idFnLe'MTI-''r'ed I\evlf

in rhefollowinge$ationl

'

(1 )

(5'+s )

where ri, is the randon variableswhich obevingthe Hotteling's/ distributionwith

degrcesof freedom2'V-2 A level of

numeratordegreesof freedom1, anddenominator

{x is chosen,and 1i:"-. (o) is calculaiedto be lhe uppervalue of the C

significance,

to be at sleadvslalewith respectto the

distribution.lf tir:7ir,\ r, tireplant is assumed

variablei. If /ir>Ii,r ,, theplantis takenasnot beingal a steadyslatecondiiion'

2.2DATA RECONCILIATION

Data reconciliation is developedto improve the accuracyof measu€menlsby leduclng

areadjustedio satisfythe

the effectof elror in the dala Meanwhile,thesemeasurenents

(eg

rnass) Nonr1al1v,dala

energv,

conse ation laws and the balanceconstraints

that

reconciliaiion

tvpe

ofdata

problen

The

minimisalion

is a conslrained

reconclliation

process

when

only

process

units

involved

is requir€d dependson the problem and

flowates are ieconciled, a linear data reconciliation probiem is applied On the other

alongwith

arereconciled

measur€ments

or pressure

temp€rature

hand,whencomposilion,

nonlinear-data

this

case,

requir€d

In

is

scheme

data

r€conciliation

nowiates,a noniinear

reconciliationis requiredbecauseit is dealing wilh processnonlinearitvsuch as

thermodynamicequilibrium relationshipand complex correlation for the thermodvnamlc

problemcan be

andotherphysicaiproperties.The generalnonlineardatareconclliation

2000):

rbnnulatei asa weightealeastsquareminimisaiion (Narasimlan,

Mi" v(r, i)r t-r(.v - x)

(2J

Subjectto

f (x) =t

c6)<o

.ec'oro equalrl cor'LrJiflsg i( q \ \ecro ofireaualrycon\rmrrht

$fere/isn\

n:,rix,.t i' n r | \elror ol mea'uea !afiable'J' i( n \ I

;. n

16r'ff6..qsrdriance

^'n

measurementsof variables r and t' is n x 1 vector oi

vailles

of

vector of m€asured

of variablest

of

measurements

weighting factor

2.3 GROSSERRORDETECTION

The most comnonly usedmelhod for detectinggrosserror is statisticalhpothesis tesling

a sul.(li. lor'he te'Lwith 'r kno$'roi'r ibtron jnd pe{orndrce

Lh.rreoui.e,e.ec.ine

q

.e5lJaIr'r;Le\ceed'J cri' cal

il he comprrreo

ch,j'acterinic.. gioqse-or 's oec,dred

the statisticalhypoihesistests

others'

Among

value selectedfton a table of disldbuiion

l- r69

Pro.e€dings

oflhe l8tbSymposlun

ofMalarsidChenlcllEnsimers

likelihoodratio test

test (NT), generalized

includeglobaltest (CT), nodalor consrrain!

testO{I),

(GLR),boundedCenetalized

likelihoodmrio (BGLR)merhod,measurements

(MIMT)

test

iterativetneasuremenltesr(IMT) and modified ilerative measuremeni

ii is suitablefor

In this work, the Measwemen!

Test(MT) methodwasusedbecause

(3)

below:

RTO application.Thetestslatisticis asgivenin Equalion

Equation(3) alsocanbe *ritten as:

erors, tris ihe

enors,er is the measurement

measurenenl

Here,:.! is the standafdised

data

and

irr

is

the

measuremenls.

is

the

reconciled

ofmeasurementsJ

deviatiotr

standard

I'

3 PI,ANT SIMULATION

C6,c,i, Cj

L,C

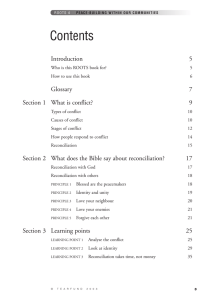

Figure 1. SchemaricdiBgralnof a fany acid fractionationplant

The fatty acid fractionation (FAF) plant considercdin this paper is consistedof tl(ee

of the columnsis illustratedin

packeddistillationcolun s. The sequence

connecting

throughlhree columns,

into

its

components

fatty

acids

arc

separated

Figure L Here, clude

i.e..Pre-cutColumn(PC).Light-culColumn(LC) andMiddle-cutColumn(MC). ln t\e

pi€-cul column, light products(C6,Cs and Cro falry acids) are recoveredjn the overheadThe botlom strealnis then led to the lightcut columr whererhe Cr, falty acid is separated

from ihe rest ofthe fatq?acids. The botlom producl ofthis colurnnthen entersthe middlecut colnn wherethe Crr fatty acid is recovercdleaving$e Cr6and Cls fatty acidsas

by a dynamicsimulationmodel

In this study, the FAF plant was represented

purpose

the

FoI

the

ofRTO inplementarion,

simulaior.

developed

usingHYSYS.PlantrM

The

ibrmer

iook

using

the

same

simulalor.

model

llas

also

developed

requled steadyslale

conditionsif the plant

the role ofthe actuaiplantwhilst the latlerprovidedthe expected

was actllally at a sieadystare.At the sane tiine, the steadystatemodel neededlo provide

sysrenatic search for processoptimisation especially in data reconciliation. Since the

qualiiy ofboth nodels playspivotal role in producingthe jtrtended€nd-results,the models

mnst thereforebe accurateandrobust.

To ensurethe consistencyof the model output,rhe steadystatemodel must therefore

be validated against the dynamic model. The results reveal€d lhat close agreement

betweenthe modelswith an overall diifercnce of lessthan3% lvas obtainedandiherefore

consideredadequarefor this study.

4 EFFf,CT OF GROSSERROR

in this section,$oss elrors were createdby simulating processleak in pipeiines. Ii *as

implem€ntedby le3king the flowrate for the distillale stream at 60 minutes after the

processin steadystate condition. The goss elror was detectedas the disiillate flowrate

was one ofthe variables in d1edala r€conciliation. The amo nts of th€ leakagewere

3-t?0

Elgrneen

Chemical

ofMalavsian

Proceedings

of thel3thSynposium

highly dependenton the dislillate flowrate During implementation'carewas takennot to

letthe disiillateflowrateio dry out. Theamountsofleakagewer€shownintablebelow:

strerm

Table L.Tfe smorntofrhe Leakage

(Ks/h)

41.6519

301.1?80

t24.16-t0

MC L.akase

Ihere weretwo waysof implementalionsThe first involvedcreatinga singLegross

eror by leaking the distillate stream either in PC, LC oL MC colunln The second

approachintroducedmlLitipl€ gross errors by lealdng all the distillate stueamsin the PC,

oflhese bothcasesweresimilar,eitherin

Lt anrtMC columns.The dyrlamicresponses

2 illusfates the dlnamic rcsponseofthe

gross

Figurc

errors situation

single or multiple

1othepla t

gloss

were

introduced

erroN

proaess

whenmuftipie

ofleakageanddistillatesteams

Figure2. The dlaurnicrcsponse

,1.I STEADYSTATEDETECTION

were selected,ie' tbe llowrateof lhe PC distillate

ln this case,6 key measurements

stread, PC botlom siream, LC distillate stream,LC bottom slr€am' MC distillate stream

was collectedover a pedodof30 minutes

and MC bottomsiream. Eachmeasuremenl

theory of evidencemethodwas

mathenatical

The

(dynamic

model)

from the plant oodel

was

used to iest the difference

Hotteling

t'

and

the

iask

Lr"

i"tended

*"J to Ju..v o"t

at 0 05% and the

specified

d

was

significance.

leveL

of

The

the

two

m€ans.

beiween

of r,l, for each

1.

The

value

Equation

iom

r;.--? (a) is 47.04 as determined

is lowerthanthe 7l', , (o). FAf processachievedsleadvstatecondition

measurem€nt

wilhin th€ period of 30 minutes. Therefore' a l0 mi11ltesor bigger cycle time can

thereforeus€tuIfor RTO.

4.2 DATA RECONCILIATION

It is important io reitera!€here tliat the purposeof data reconciliation in this stldy is to

supportthe RTO implementationwhere measureddatamust be reconciledto satisli mass

is at a tue steadystalecoMition

This is doneonly whentheprocess

andenergybalaaces.

be

and any;djustmentrequir€dto the process&!a would madeas smallas possibl€to

3- l l l

Prcce.dings

ofthe1StISyi'tosinmofMalaysian

Chenicet

Elgineeis

guaranieethat lhe reconciledconditionsarc still accuraretyrepresentingrhe rfte operating

condilion.Resultsofthis inplemertarionar€shownin Tabte2.

Table2. Theresultofleakagestudybeibreandafrerdatareconciliation

BeforeDataReconciliarion

402.E6

]l 64.]0

t 78.92

l 952.ti

Alter DataReconciliation

16:1.04

t071.77

816.03

i ri65.t 0

The valueof the objectiveftnction beforedatarcconcitiarion

$.ashightydepenitent

to lhe amountof the distillareiost. It was provenfrom l|e rable 2. The value of the

objectivetunction was large when all d1edisti[ate steamswere ]eakedbefore data

reconciliaiion

is cafied our Ir is thenfollowedby the teat(age

of rheLc_disrinatesteanr.

It is dueto rheamountof rhedisrillaretostwerc grearerifconpared to the losrofpc and

MC distillatestreans.The d-ata

reconciliarion

problem\l,assolved sins the Successive

OrdorarrcP ogrrmn-nCr\QP, dtgo.irhmo o\ ded o\ H\ Sys ;p imi.e". Ddrd

reconciliation

was ableto feducerhesegrossenors and the detectionol the qrcsseffor

wascaniedout by grosselTorderector.

1.3 GROSSERRORDETECTION

Thesame6 measurements

fiar usedin thesreadysatederedionwereadoDted

in thissrudv

.gr n. Tl e pla"rld. ruo f- e.J'rofrnedlrare.oncrtdr:on$ereconpdredba.edor

rr;

"

cnticaivalue C The critical value,C was deteminedbasedon the overa[ siqnificarl!

Ievel,o whichwasspecifiedas 0.05(e.g.95%ot confidentialinte al). andthe v;he was

2.8044from the standardnomal disrribulionwirh accumrtated

probabilityar 0.9989.If

the value test staiistic, ] z, j I exceedsthe citicat value C, then rhis measurementis said

to contain gross €1ror. Ofieruise, this measufemen!is consideredftee of gross en'or.

Measuremenrs

containing

srosserrorarenufkedunderline.

LC-Le.kaee

(Ke/h)

PCBottom

PCDistillate

fC Bo$om

LC Distiuate

MC Bottom

MC Distillate

9400.81

9i3998

r,89.91

9t00.8i

9139.98

61753

446t.71

589.91

448i .59

4904.59

6175l

4461.71

4890.82

29E2.89

l:r94.16

)961.+9

9:100.83

9186.46

622.39

4 4 3 i .i 9

4904.59

2 9 8 2 .8 9

i 4 9 4 .3 6

4890.81

2967.19

r174.77

1414.77

MC-L€akAse

(Kdh)

PCBoton

PCDistdlJte

LC Boftom

lC D i s ti l l a t€

9400.81

637.59

448i.49

4 9 0 4 .1 0

MC Bottod

2983.42

MC Distillate

.lll!.04

9i86.46

622.39

4175.74

4826.07

2959.09

r47|.62

637.59

4181.49

490410

293102

4475.71

1826.07

2959.09

1.170.04

147t.62

ln thePc,leakage

case,one€uor,i.e.,thepC distillateflowrarewasdeteded.On the

otherhand.LC distillateflowratelvasdetecred

containingelTorin the Lcleakage case.

Similarly,fie lvlc distiilateflowratewasidentifiedin Mcjeakage case.On the contrary,

all the distiilareslreamswere detededto containgrosserror whenthese

*"i"

"tthe

"u-s

subJected

to leakage.By compadryto the threesingiegrosserror cases,

distillate

sireamsafter leakagewere the sameas the caseof muliiple grosserror.Alt the gross

enorsin distlllatestreams

wercdetected

eitherin sineleor in D ltjole situarions.

Tle din ll. e

01

e-ch.oll|mn

srs ioer.fied.o, d,r;nggjo". enoruher rhe

'uedn

leakagevalveofthe colunrnwasopened.As menrioned

earti€r,whenihe leakag€vaLve

3,172

ofMalaysian

ftoceedings

ofde lSthSymposium

ChenicaL

Engineers

was opened,th€ leakage strcam started to flow causing lhe redlrction in the distitlate

in the distillat€

flowrat€. The effectof$oss enor causedby the leakagewas detecred

5 CONCLUSIONS

Data validation is crucial to the succ€ssof the rca1 time optimisation. Steady state

detection

hadbe€nappliedto detectthepfocesscondirionbasedon 6 keysneasuements.

hadbeenapplied

Wtrenlhe processachievedits steadysiatecondition,datareconciliation

in orderto tulfil massand energybalances.

to adjustand reconcilethe measurcments

Gross elTor detection was used to identify ihe ristlng of the goss elTor jn th€

measuf€ments.As expected,gross errof was deiectedin the distillate streamwhen the

leakageof the distillationsteam was occrmed.Theseresultsexposedthe abillty of the

dalar€conciliationand grossenors in the neasurements.

ACKNOWLEDGMENTS

This project is tundedby the Ministy of Science,Technologyand the Environment

ttrougl IRPA researchgrant. Our headiest appreciaiionsare for everybody who has

to thesuccess

ofthisproject.

directlyor indirectlycontribute

REFERENCES

Uni!."

ofComplexProcess

Da$y, M. L., andWhite,D. C. (1988)."On line Optimization

Progress,

84(i0), 51 59.

ChenicalEngineering

Cenichi,E., Yodhinori,O., Hitoshi,M., Morinusa,O., Doughlas,B., Rosalyn,F. P., and

John, S. A. (1994). "IntegratedAdvancedControl and Closed-LoopReal-Time

Optimizationof an OlefinsPlant."Proceedi4 of IIAC AdvancedCootroiof Chemical

Processes,

Kyoto,Japan,95 100.

Narasimllan,S., Chen,S. K., and Mah, R. S. H. (1987).DetectingChangesof Steady

TheoryofEvidence.AICHEJaumal.33(lI): 1930 1932.

StateUsingtheMalhematical

Narasinrlun,S. and Haril:umar,P. (1993).'A Methodio lncoryorateBoundsin Data

Problem."

andGrossE1Tor

Detection L TheBoundedDataReconciliatioD

Reconciliation

l7(11), 1115-1120.

Compuie$andChemicalEngineering,

An

& GrossEror Detection:

S. andJordache,

C. (2000).Datareconciliation

Na.rasinlhan,

Comp3ny,

Texas.

Inteiligen!Us€ofprocessData.CulfPublishing

3 1,73

j