Study of Scale Formation in Oil Reservoir During ...

advertisement

February22 - 23,2047

Marine Science & Technologt Seminar 2007

Study of Scale Formation in Oil Reservoir During Water fnjection-A review

Amer Badr Bin MerdhzhrUniversiti TeknologiMalaysia

amer0227@tahoacom

Abu Azam Mohd Yassin, Universiti TehnologiMaleysia

abuazo@fkhksautm.ny

Scale deposition is one of the most important and serious poblems which water injection systems are generally

engaged in Scqle sometimes limits or hlocks oil cnd gasproduction b pIuSgW the oil-pra&tcingformation matrix

or frac,tures and peforoted intervals. Scale slso deposited in down-hole pump& tubing, casing flow-lines, heater

treaters, tanks and other production equipment andfacilities- Scsle c6m occur at /or dawnstream af arry point in the

production yystem, at which super-sduratian is generated. Srper-saturation cun be generated in single water fu

changing the pressure and temperature conditions or by mixing two incompatible waters. The most coinmon oilfield

scales deposited are calcium carbonate, calcium sulfate, strontium sulfate qnd barium sulfate. This paper describes

overview formation damage, scale deposition mechanisms and source af oil field scale, scale formation along the

iryjection-water poth in water-food operations, scaling problens encotmtered in oil fields, salubility of scale,

oilfield Scale types, scale control chemicols and laboratory bwestigatians of scale in different media and

procedures used to predict scale are presented

Keywords: formation damage, scale deposition mechanisms, scaling problems, solubility of scale

1. Introduction

The injection of seawaterinto oilfield reservoirsto maintainreservoirpressureand improve secondaryrecoveryis a

well-established,mature, operation. Moreover, the degree of risk posed by depositionof mineral scalesto the

injection and production wells during such operationshas beenmuch studied. Scaledeposition is one of the most

seriousoil field problemsthat inflict water injecfion systemsprimarily when fwo incompatiblewatersare involved.

Two waters are called incompatible if they interact chemically and precipitate minerals when mixed. Typiq{

examplesare seawat6r, with high concentrationof SOa-2and formation waters,with high concentrationsof Ca*2,

Ba*2and Sr*2. Mixing of thesewaters,therefore,could causeprecipitationof CaSOa,BaSO+and/orSrSOaThere are

otherreasonswhy scaleforms, and the amountand location of which are influencedby severalfactors. Yet, superis the primary causeof scale

saturationis the most important reasonbehind mineral precipitation. A supersaturated

formation and occurs when a solution contains dissolvedmaterials which are at higber concentrationsthan their

equilibrium concentration. The degreeofsuper-saturation, also known as the scaling index, is the driving force

for the precipitation reaction and a high super-saturation,therefore, implies high possibilities for salt

pH, and CO2III2Spartial pressurecould also conrlbute in forming a

precipitation. Changesin temperature,pressurre,

(Mackay

et

al2003a).

et al,Z}O3,Moghadasi

scale

l.l CommonOil Field Scales

The most common oil field scalesare listed in Table l, along with the primary variablesthat affect their solubility

(Moghadasiet aI,2A03a). Thesescalesare sulfates such as calcium sulfate (anhydrite, glpsum), barium sulfate

(barite),and Strontiumsulfate(celestite)and calcium carbonate.Other lesscommonscaleshavealso beenreported

suchas iron oxides,iron sulfidesand iron carbonate.Lead and zinc sulfide scalehasrecentlybecomea concernin a

numberof North Seaoil andgasfields (CollinsandJordan,2001).

1.2ScaleDeposition

oil and gasproductionequipmenthasbeenrecognized.Scaledeposition

Scaledepositionin surfaceand subsurface

is one of the most importantand seriousproblemsthat inflict oil field water injectionsystems.Scalelimits and

sometimesblocks oil and gas productionby plugging the oil-producing formation matrix or fractures and

could

perforatedintervals. It can alsoplug production lines and equipmentand impair fluid flow. The consequence

failure, emergencyshutdown,increasedmaintenancecost, and overall decreasein

be production-equipment

productionefficiency. The failure of theseequipmentscould result in safetydangers. In caseof water injection

systems,scale could plug the pores of the formation and resultsin injectivity declinewith time (Todd and Yuan,

AsghariandKharrat,1995;Andersenet aL,2000;Pauloet al,200l; Voloshinet a|.,2003).

1992;Bayona,1993;

February22 - 23, 2007

Marine Science& Technologt Seminar 2007

Scaledepositioncan occurfrom onetype of water becauseof super-saturationwith scale-formingsaltsattributable

to changesin the physical conditions under which the rvaterexists. Scalealso can depositu'hen two incompatible

watersare mixed and super-saflrationis reached(Nassiveraand Essel, 1979;Readand Ringen, 1982;Yellet, et al.,

1982;ToddandYuan, 1992;Moghadasiet a1.,2003b;Moghadasiet aL,2A04}

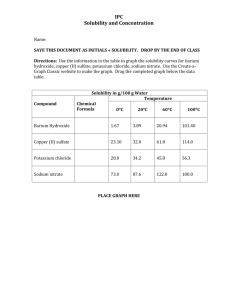

Table 1: Most commonoilfield scales

Name

ChemicalFormula

Primarv Variables

CalciumCarbonate

CaOOI

Partialpressureof CO:,

temp€rature,total dissolvedsalts,

nH

CalciumSulfate:

Gypsum

CaSO4.2H2O

Hemihydrate

CaSOq.U2HzO

Anhydrite

CaS0a

Barium Sulfate

BaS0a

Strontium Sulfate

SrSOq

Temperature,total dissolved

salts,pressure

Temnerafure.Dressure

prcssure,total

Ternperature,

dissolvedsalts

Iron Cornpounds:

FerrousCarbonate

FeCq

FerrousSulfide

FeS

FerrorxH1'droxide

F{OID,

FerrousHydroxide

F{OH)3

Corrosion,dissolvedgases,pH

1.3 Sourceof Oil Field Scate

The chief sourceof oil field scaleis mixing of incompatible waters. Two waters are called incompatible if they

interact chemically and precipitate minerals when mixed. A t]"jcal exampleof incompatiblewatersare seawater

with hish concentrationof SO.r-'and low concentrationsof Ca", Ba-"/Sr", and formation waters with very lorv

of Ca*2,Ba*2 and Sr*2. Miring of thesewaters,therefore,causes

of SOa-2but high concentrations

"orr."otiutiorrs

precipitation

of CaSOa,BaSO+,and/or SrSOq. Field producedwater (disposalwater) can also be incompatible

with seawater. In caseswhere disposal *ater is mixed with seawaterfor re-injection,scaledepositionis possible

@ayona,1993;Andersenet al,20O0 Bedrikovistskyet a|.,2001;'Stalkeret al.,20[3;' Pauloet al,2A0\.

During the productiorL the rvater is drained to the surface and suffers from significant pressuredrop and

temperaturevariations. The successi\€pressuredrops lead to releaseof the carbondioxide with an increasein pH

value of the producedwater and precipitationof calcium carbonate(Mackay,2003).

Zinc sulfide scaleis more likely that the zinc ion sourcemixes with the hydrogen sulfide-rich sourcewithin the

near well-bore or the production tubing during fluid extraction. Lead and zinc sulfide scales have recently

becomea concernin a numberoil and gasfields. Thesedepositshaveoccurredwithin the productiontubing and

topsideprocessfacilities (Collins and Jordan,2003).

2. Scale Formation along the Injection-Water Path in Water-Flood Operations

is us:ally muchlower than reservoirtemperature.When it travels

At theinjectionwellheadinjectionwat€rternperature

down the rnjectionwell-string,the water coolsthe surroundingformations-and its temperanreand pressureincrease.

with increasingtemperatures(e.g.

If the water is saturatedat surfaceconditiorsrriith saftswhosesolubilitydecreases

anhydrite),scalemay form alongthe well-string.

of temperatureand

Scaleprecipitationfrom the injection ryatermay happenbehindthe mixing zoneasa consequence

with increasing

containing

salts

w'hose

decreases

particularly

rvaters

solubility

of

This

is

true

prs$re dranges

(rvith

present

in the rock

zone

resen'oir

is

mixing

only

brine

oil)

pressure.

of

the

Fonvard

temperatueand decreasing

pores.Betundthe mixing zone,onl.vinjectedwaler in equilibrium at local temperanreand pressure(with residualoil)

Marine Science & Technologt Seminor 2007

February 22 - X, 2407

of insohrblesaftsmay ocqn due to the interactio4 at local temperatureand

exists.In the mixing zone,precipiuation

pressure,of chemicalspecies

containedin the injectionwaterwith chemicalspeciespresentin the reservoirbrine.

Nevertheless,at a differentpressurqthe remainingclearwatermovesaheadmix againwith reseryoirbrine and scale

precipitationmay againake place. This cycle is repeateduntil the remainingclear water reachesa produclion well.

alongthe flow suing up to drc surfacein the prodtrctionwell, andfirrdrerchangesin

Pressureandtemperaturedecrease

thermodynamicconditionsoccw in the surfrce equipment. This may againresult in scale formation. Nonrnlly, these

scalesdo the most damagein the well-borewhentherearemajo'rftlls in pressurebut hardly any temperaturechanges

(Khelil et al,1979).

Therearethreeprincipal mechanismsby which scalesform in both offshore and onshoreoil field system(Mackay,

2005;Jordm andMackay,2005):

a) Decreasein pressue and/or incre'asein temperatweof a b,rine,goesto a reduction in the solubility of the

salt (mostcommonlytheseleadto precipitationof cartronatescales,suchas CaCOr).

Ca (HCO,), <+ CaCO3+ CO2+ H2O

(l )

b) Mixing of two incompatible brines (most commonly formation water rich in cations such as bariunr,

calcium and/orstrontium,mixing with sulftte rich seawater,goesto the precipitation of sulfatescales,such

asBaSOa).

Ba2"(or Sr2* or Ca2*) + SO42- <+ BaSOo (or SrSOn or CaSOo)

Q)

Other fluid incompatibilitiesinclude sulfide scalewhere hydrogensulfide gasmixes with iron, zinc or lead

rich formation \vaters:

(3)

7.n2*+HrS <+ ZnS+2gzn

c) brine evaporation,resulting in salt concentrationincreasingabove the solubility limit and goes to salt

precipitation (as may occur in HP/HT gas wells where a dry gas streammay mix with a low rate brine

streamresulting in dehydrationand most commonlythe precipitationofNaCl).

3. The ScalingProblem in Oil Fields

Scaling depositionis one of the most important and seriousproblemswhich water injection systemsare generally

engagedin. Oil field scalescostsare high due to intenseoil and gasproductiondecline,frequentlypulling of downhole equipment for replacement,re-perforation of the producing intervals, re-drilling of plugged oil wells,

stimulation of plugged oil-bearing formations, and otherremedial workovers through production and injection

wells. As scaledepositsaround the well-bore, the porous media of formation becomesplugged and may be

renderedimpermeableto any fluids.

Many casehistoriesof oil well scaling by calcium carbonate,calcium sulfate, strontium sulfate and barium

sulfatehave beenreported(Mitchell et al, 1980;Lindlof and Stoffer 1983;Vetter et al,1987; Shuleret aI,l99l).

Problems in connectionto oil well scaling in the Russia where scale has seriously plugged wells and are

similar to casesin North Seafields have beenreported(Mitcheli et aL,7980).

Oilfields scaleproblemshave occurredbecauseof water flooding in Saudi oil fields, Algeria, Indonesiain

south Sumatraoilfields, and Egypt in el-Morgan oilfield where calcium *6 su'safinmsulfate scaleshave been

found in surfaceand subsurfaceproduction equipment(El-Hattab,l982).The following is a brief explain of

scalingcasesreportedin the literature.

Mitchell et al. (1980) describedscaleproblems occurring in the forties field could be attributedtwo major

factors:

a) Commingling of forties formation and injection waters could precipitateboth barium and strontium

sulfates.

b) Precipitation of calcium carbonate scale from formation water due to variations in pressure and

temperaturein production systems.

ToddandYuan(199) describedbarium sulfate scaleoccurrencewas a severeproductionproblem in North Seaoil

operations. Barium sulfate is often accompaniedby shontium sulfateto form a completelymixed scalecalled @4

Sr) SOr solid solution. Sulfate-anion-richseawaterinjected into the reservoir formation subsequentlymixed with

formation water,which containsexcessivebarium and strontium.

Bayona(1993) reportedtwo major problemswith seawaterinjection in the norttr Uthmaniyahsectionof the

Ghawarfield in SaudiArabia. The first is maintenanceof acceptablewater quality to preventexcessivelossesof

well injectivity and the secondis control of plugging in the pores and corrosion at a reasonablelevel in the

eguipmentdue to which excessivelossesof well injectivity occur. The only cause of these losses is the

depositionof scalesdue to the presenceof saltsin the injectionwater.

February22 - 23,2007

Marine Science& TechnologtSeminar2007

Salmanet al. 11999)conductedto predict the possibility of scaleformation when seawaterwas injected into the

northemKuwaiti oilfields for reservoir pressuremaintenance.Resultsindicatedthat the seawaterwas likely to be

self-scalingwith respectto calcium carbonateunder productionreservoirconditionscould becomea problem when

the systemunderwenttemperatureandpressurechanges.

Paulo et al. QO0l'l described Sulfate scaledepositionis a common problem in the Alba field in the North Sea

resulted from injected seawatermixing with aquifer brines. The problem is most severein and aroundthe

injection and production well bores and can causeconsiderabledisruption to hydrocarbonproduction after water

breakthrough.

Moghadasiet al. Q003a) described scale formation in the Iranian oilfields has been recognizedto be a major

operational problem causing formation damage either at injection or producing wells. Scale contributes to

equipmentwear and corrosionand flow restrictions,thus rtsulting in a decreasein oil and gasproduction.

4. Solubility of Scales

"solubility" is definedas the limiting amountof solutethat can dissolvein a solventundera given set of physical

conditions. Factors that affect scale precipitation, deposition and crystal growth can be summarizedas: supersaturation,temperature,pressurq ionic strength,evaporation,contacttime and pH. Eflective scalecontrol shouldbe

one of the primary objectivesof any efficient water injection and normal production operationin oil and gas fields.

Therearetwo solubilities of scales:

4.1 Calcium, Strontium, Barium Sulfatesand Calcium Carbonate Solubilities

The solubility of calcium sulfate is an order of magnitudelarger than that of strontium sulfate,with in turn is about

one and one- half ordersof magnitudelarger than that of barium sulfate Figure l For example,Figure I indicates,

that the solubility of strontium sulfate can be larger than 950 mg/I. This solubility, however,is true only when the

solution is stoichiometricallybalanceGi.e., when the numberof strontiumions equalsthe numberof sulfate ions. If

an excessof either ion is introduce4 the solubility is depressedmarkedly. This is known as the "common ion

effecf' (Lindlof and Stoffer 1983). The solubility reachesa maximumin highly concentratedbrinesAccording to Oddo et al, (1991), calcium carbonatesolubility has an inverse relationship with temperatureor

statedmore simply, CaCO:scalebecomesmore insoluble with increasingtemperatureand a solution at equilibrium

wifh CaCO3will precipitatethe solid as the temperatureis increased. The tendencyto form CaCOgalso increases

with increasingpH (as the solution becomesless acid). The decreasein total pressurearoundthe purnpsallows

dissolvedcarbondioxide to escapefrom solution as a gas causingan increasein pH with a subsequentincreasein

the tendencyto form solid.

4.2 Zinc Sulfide,Lead Sulfide and fron Sulfide Solubilities

Lead and zinc sulfide solubility is much lower even than iron sulfide, which is the common sulfide in oil field

environments. For example in a lM (mole/dm3)NaCl brine solution are presentedin Figure 2 at pH: 5 the

solubility of iron sulfide is 65 ppm, whereaslead and zinc sulfides are 0.002 ppm and 0.063 ppm respectively.

Dependingon the exact brine conditions,the solubility of zinc sulfide is between30 and 100 times more soluble

than lead sulfide. As with iron sulfide, the solubility of both lead and zinc sulfide increaseswith increasingsolution

pH (CollinsandJordan,200l).

5. ScaleControl Chemicals

In oil and gaswell operations,water- insoluble scaleis formed in tubing casings,and associatedequipment,as well

as in the well bore and the formation itselt which carq/, at least in part, water or brine waters. Thesewaters can

containinsolublecalcium,barium, strontium,magnesium,and iron salts.

Scaleinhibitors are chemicalswhich delay, reduce or prevent scale fonnation when addedin small amountsto

normallyscalingwater. Accordingto Bezemerand Bauer(1969),the most commonclassesof inhibitor chemicals

compormdsand organicpolymers.

are inorganicphosphates,organophosphorous

acid) @ETPMP) are

Polyphosphonocarboxylicacid @PCA) and Diethylenetriaminepenta(methylenephosphonic

two common commercialscale inhibitors used in the oil and gas industry. Normally, PPCA is regardedas

nucleationinhibitor and DETPMP as a growth inhibitor (Chenel al,2004).

Severalcombined scale removal and inhibition systemscould be consideredin order to meet thesechallenges.

Hydrochloricacid (HCl) may be the most cost effectivetreatmentto remove calcium carbonate,but corrosion

control, systemcompatibility and inhibitor adsorptionmay all be difficult in a combinedtreatrnent. Conversely,

scaledissolversmay offer better corrosion control and scaleinhibitor compatibility when spent,but will be higher

to be met.

cost. Organicacidscould offer a compromisewhich allowsmostof the systemrequirements

February22 - 23,2007

Marine Science& TechnologtSeminar2007

|J

a

r,

(\l

q0l

tJ

!

G

lr,

d-

g ro e

t

F

7

s

3

J

8 rsl

itsCl

SOLUTtOfi

loHE STHEFTGTH

Figure 1: Relative solubilities of three sulfates in brine

itcEs0

lRr&

E

3

E

;

E

E

rtrn

rug

(4

5! - i :

t

E

zls

=.

N,

s

\

I

$

tr6

5

o

at?

il.tl

0,001

Ailr. pH

Figure 2: Comparisonof zinc, leadandiron sulfidesolubilityin lM NaCl brineat 25"C.

6. Laboratory Evaluation

Scaleformation can be predictedby laboratory experiments. Severalexperimentalstudieshave beenconductedto

determinethe scalingpotentialin different oil-fields. ln experimentalstudies,the extentof permeabilitydamage

February22 - 23, 2007

Marine Science & Technologt Seminar 2M7

causedby flowing precipitatesin coresand sandpackswas investigated. Severalinvestigatorstestedincompatible

watersfrom oilfields in the North Sea(Mitchell et al.,1980),the Middle EastandEl-Margon(El-Hattab,1982)that

producedbarium, calcium and strontium precipitates. They reportedthat l5-20-pm-sized crystalsblocked tlre pare

throatsin glassbeadpacksand in alumina cores,by size exclusionand bridging mechanisms-Crystalsoften grew

perpendicularto the pore walls, and that somecrystal aggregatesalso had the form of "books" and rosettes. Todd

and Yuan (1992) also conductedlaboratory investigationsusing North Seareseryoir brines that producedbarirun

and strontium scales.Crystals depositingalong and growing perpendicularto the pore surfacescausedmost of the

ratio of both barium and strontium

reductionin core permeability. They observedthat doubling the super-saturation

producedan increasein the quantity of scaleformed insidethe poresand a changein the morphologyof the crystals.

Both changesincreasethe rate of permeabilitydecline.

7. Modeling Development

Along with laboratoryexperiments,scaleformationcan be predictedby severalmodelsto determinethe scaling

potentialin differentoil-fields. Ceochemicalflow modelsweredeveloped(Shenand Corsby,1983;Yeboaher c/.,

1993;Khatib,1994) for both mineral dissolutionand precipitationprocessesduring convectivetransport. These

modelswere basedon the assumptionof local thermodynamicequilibrium and negligible dispersion. They did not

include solids migration, an assumption, which was severely limiting because many experimental studies

demonstratedthat precipitatedsolids could migratewithin the porousmatrix-

8. Summary

Fromthe abovesurveyofthe literatune,permeabilitydeclinecausedby scaleformation in the porousbed rangedfrom

lessthan 30Votomore than 90% of the initial permeability,dependingon solution composition,initial permeability,

temperature,flow rate and solution injection period. The pattem of permeabilitydecline in a porousmedium due to

scaling injection was characterizedby a steep initial decline which gradually slowed down to a lower. Several

factors influencing scaleformation had beenexamined.Increasingtemperature,super-saturationand flow rate had a

derimental effect on the permeabilityreduction. Pressurehad a slight effecton scaleformation precipitation.

9. References

T. and Ostbye,O. N. *Water Managementin a Closed

Andersen,I. K-, Halvorsen,8., Saelensminde,

Loop - Problems and Solutions at Brage Field." The SPEEuropeanPetroleumConference.October 2425,2000.p.l-12.

Asghari, K. and Kharrat, R. "Alteration of Permeabilityby Fine Particle Movement-A Water Injectivity

Problem."The SPEInternationalSymposiumon Oilfield Chemistry-February14-17,1995.p. 655-665.

J.

Bayon4 G.H. "A Review of Well Injectivity Performancein Saudi Arabia's Ghawar Field Seawater

Injection Program."The SPE Middle East Oil TechnicalConferenceand Exhibition. April 3-6, 1993-p20t-214.

4. Bedrikovistsky,P., Marchesin,D., ShecairqF., Serr4 L. A., Marchesin,A., Reszende,E. and Hime, G.

"Well Impairment During Sea/ProducedWater Flooding: Treatrnentof Laboratory Data." The SPE Latin

March 25-28,2001.p. l-9.

AmericanandCaribbeanPetroleumEngineerinsConference.

5. Bezemer,C- and Bauer,A. K. "Preventionof CarbonateScaleDeposition:A Well-PackingTechniquewith

Journalof PetroleumTechnolos.v.

1969.p.505-514.

ControlledVolubility Phosphates."

6. Chen, T., Neville, A. and Yuan, M- "Effect of PPCA and DETPMP Inhibitor Blends on CaCO3Scale

Formation."The 66 IntemationalSymposiumon Oilfield Scale.May26-27,2A04-p. l-7.

7. Collins,R. I. and Jordan,M. M. "Occurrence,Predictionand Preventionof Zinc Sulfide Scalewithin Gulf

Coast and North Sea High TemperatureiHighSalinity Production Wells." The SPE Third International

on Oilfield Scale.January30-31,2001.p. 1-17.

Synrposium

8. Collins, R. I. and Jordan,M. M. "Occurrence,Predictionand Preventionof Zinc SulfideScalewithin Gulf

and High-Salinityfields." SPEProductionand Facilities.20A3.p.

Coastand North SeaHigh-Temperature

200-209.

9. El-Hattab,I. M. *GUPCO'S Experiencein TreatingGulf of Suez Seawaterfor Water flooding the El

MorganOil Field." Journalof PetroleumTechnology.1982.p. 1449-1460.

10 .Jordan,M. M. andMackay,J. E. "IntegratedField Developmentfor EffectiveScaleControlThroughoutthe

Water Cycle in Deep Water SubseaFields." The SPE EuropeclEAGEAnnual Conference.June 13-16,

2005.o. l-9.

l.

6

Mmine Science& TechnologtSeminsr2407

February 22 - 2i, 2007

I l. Lindlof, C. J. and Stoffer,G. K. '? casestudy of seawater injection incornpatibility." Joumal of Petroleum

Technology.I 983.p. 1256-1262.

12. Khatib, I. Z. *Prediction of ForrnationDamageDue to SuspendedSolids: Modeling Approach of Filter

CakeBuildup in Injectors." The SPE8fth Annual TechnicalConferenceand Exhibition. September25*78,

1994.p. 263-273.

*Water Injection in Algeria-Problemsand Solutions." The

13. Khelil, C., Harouaka,A. and Delhoume, A.

Middle EastOil TechnicalConferenceof the Societyof PetroleumEneineers.March 25-29, 1979.p.97 *

106.

14. Mackay, J. E. *Modeling In-Situ Scale Deposition: The Impact of Reservoir and Well Geometriesand

Kinetic ReactionRates." SPEProductionaqd Facilities 2003. p. 45-56.

15. Mackay, J. E" "Scale Inhibitor Application in Injection r$ells to Protect Against Damageto Production

May25-27,2005. p. t-9.

FormAtionDamaseConference.

Wells." The SPEEuro'pean

t6- Mitchell, W.R., Gris! M. D. andBoyle,J. M. "ChemicalTreatmentsAssociatedWith North SeaProjects."

1980.p.90a -912.

Technoloe.v.

Journalof Petroleum

H., Sharif,A., Ghalambor,A., Izadpanah,

R. M. and

M., Muller-Steinhagen,

t7. Moghadasi,J., Jamialahmadi,

Motaie, E. "Scale Formation in Iranian Oil Reservoirand ProductionEquipmentduring Water Injection."

The 5th IntemationalQilfield ScaleSymoosiumand Exhibition. January29*30,2003a. p. I - 14.

lE. Moghadasi,J., Jamialatrmadi,M., Muller-Steinhagen,H. and Sharif, A. "Scale Formation in Oil Reservoir

and FroductionEquipmentduring Water Injection (Kinetics of CaSOoand C&O3 Crystal Growth and

Effect on FormationDamage)."The SPEElnopeanFormationDamaseConference.May l3-14,2003b. p.

1-12.

19. Moghadasi,J., Muller-steinhagen,H., Jamialatrmadt,M. and Sharif, A. "Model study on the kinetics of oil

field formation damage due to salt precipitation from injection." Joumal of Petroleum Science and

Engineering.2O44.p. 2Ol* 217.

20. Nassivera"M. and Esseln.d sFateh field sea water iqiection - Water Treatrnent Corrosion, And scale

control.'oThe Middle East Oil TechnicalConferenceof the Societyof petroleumEneineers.March 25-29,

1979.p.r33- r38.

zt. Oddo,E. J., Smit[ P. J. and Tomason,B. M. *Analysis of and Solutionsto the CaCOrand CaSOrScaling

Problems Encountered in Wells Offshore Indonesia." The 66& Annual Technical . ConferEnceand

Exhibitionof the Sociewof PetroleumEneineerins.OctoberG-9,1991.p. 1-10.

)) Paulo, J., Mackay, J. E., Menzies,N. and Poynton,N. "Implications of Brine Mixing in the Reservoirfor

ScaleManagementin the Alba Field." The 2001 SPE lnternational Symposiumon Oilfield scale.January

p. l-13.

30*31,2001.

23. Rea4 A. P. and Ringen,K. J. (1982). "The Use of LaboratoryTeststo EvaluateScaling Problemsduring

Water Injection." The SPE Sixth InternationalSymposiumon Oilfield and GeothermalChemisfiy. January

-17.

25-27,1982.p.7

24. Salman,M. Al-Hashem,A. and Carew, J. "Prediction of Scaling for the SeawaterInjection Systemat the

NorthemKuwaiti Oil Fields."The 1999SPEMiddle EastOil Show.February20-23,1999.p. l-5.

25. Shen, J- and Corsby, C.C. *Insight into Strontium and Calcium Sulfate Scaling Mechanismsin a Wet

Producer."JournalofPetroleumTechnoloey.1983.p. 1249-1255.

26. Stalker, R., Collins, R. I. and Graham,M. G. *The lmpact of Chemical Incompabilities in Commingled

Fluids on the Efficiency of a Produced Water Reinjection System: A North Sea Example." The SPE

InternationalSymposiumon Oilfield chemistry.February5-:7,2003.p. l-13.

27. Shuler,J. P., Freitas,A. E. and Bowker,A. K. "Selectionand Applicationof BaSO+ScaleInhibitorsfor a

CO2Flood,RangelyWeberSandUnit, Colorado."Societvof PetroleumEngineers.1991.p. l-8.

28. Tod4 C. A. and Yuan, D. M. "Barium and SbontiumSulfateSolid-SolutionScaleFormationat Elevated

Temperafures."SPEProdrrtionEngineering.1992.p. 85-92.

29. Vetter, J. O., Farone,A. W., Veith, E. and Lankford, S. "Calcium CarbonateScaleConsiderations:A

PracticalApproach."The SPEproductionTechnologySvmposium.November76- 17, 1987. p. l-14.

30. Vetter, J. O., Kandarpq V. and Harouaka, A. *Prediction of Scale Problems Due To Injection of

IncompatibleWaters." Journalof PetroleumTechnology.1982.p. 273 -284.

31. Voloshin,I. A., Ragulin,V. V., Tyabayeva,E. N., Diakonov,L I. and Mackay,J. E."Scaling Problemsin

WestemSiberia."The SPEfifth InternationalSymoosiumon Qilfield scale.January29 -30,2003. p. l-8.

32. Yeboah,D. Y., Somuah,K. S. and SaeedR. M. "Anew and ReliableModel for PredictingOilfield Scale

Formation."The SPElnternationalSvmposiumon Oilfield Chemistry.March 2 - 5, 1993.p. l-10.