c 9 A e

advertisement

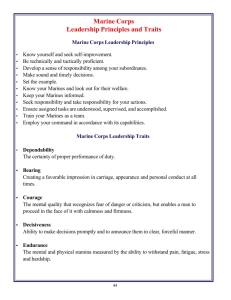

Chapter 9 A da p t i n g E x p e d i t i o n a ry C a pa b i l i t i e s to E n e rg y C h a l l e n g e s 287 Colonel Edward (Ted) Smyth Thus far, we have had three previous roundtable discussions on the subject of energy and energy challenges, so at this stage of the game, you might wonder what sets this particular roundtable Colonel Edward (Ted) Smyth is the Supervisor of the Analysis, Modeling, and Simulation Branch and a Fellow within the National Security Analysis Department (NSAD) at JHU/APL. He is also a Fellow and former President of the Military Operations Research Society (MORS) and a former Marine Corps Colonel with 30 years of active service, during which he commanded Marine Corps units at the company/ battery, battalion, and regimental levels. His primary military occupational specialty was artillery/fire support with subspecialties as a military operations analyst and historian. Since joining JHU/APL, he has served as the Director, Land Attack Warfare Studies and as Supervisor of the Ground Operations Section of NSAD. He has also coordinated efforts in support of Office of the Chief of Naval Operations Sea Strike analyses, served as the Supervisor of the Joint Effects Based Operations Group, developed and organized a 3-day symposium sponsored by MORS on the subject of “Analysis of Urban Warfare,” and served as the Senior JHU/APL Analyst in support of the National Security Agency’s Signals Intelligence Requirements Office. His most recent activities include active contributions to the Johns Hopkins University Symposia on Unrestricted Warfare and the 2010 Climate and Energy Symposium. He also provided leadership and/or major contributions to the following projects and analyses: a MORS Special Meeting on the subject of “Wargaming and Analysis”; an Analysis of Alternatives on the Joint Effects Targeting System (JETS); a study of the implications of economic and financial issues and actions on U.S. national security; an analysis of DoD and interagency coordination in support of homeland defense; and the Quadrennial Defense Review-directed study on a comprehensive review of the Reserve Component. Colonel Smyth also serves on the faculty of The Johns Hopkins University’s Whiting School of Engineering. 288 Climate and Energy Proceedings 2011 discussion apart. In my view there are really two factors. First, we are going to dwell almost exclusively on expeditionary capabilities and the energy challenges created by being expeditionary. Second, this roundtable consists of folks who day to day are either serving in the Marine Corps on active duty or in a civilian capacity. So this is, in effect, our Marine Corps panel for this symposium. I am not an energy expert per se. I will leave it to the panel members to provide those details, but what I thought I might do in the way of introducing this particular panel is attempt to put the term “expeditionary” in context. To do that, I will offer a definition or at least provide you with a set of characteristics that are normally used by the Marine Corps and others in describing expeditionary. I will also briefly touch upon the types of missions Marine expeditionary forces conduct and capabilities that they possess, and then I will touch briefly on how we link some of those expeditionary capabilities to some of the emerging energy challenges that we face. At that point, I will pass it off to the experts to describe some of the solutions that they are working on. My initial effort to find an accepted definition of the term “expeditionary” took me to Joint Publication 1-02, the Dictionary of Military and Associated Terms. [1] Unfortunately, I did not find a great deal of help there. The term “expeditionary” does not appear in that document. What you will find is a definition of the term “expeditionary force,” which, in my view, does not fill the need of defining what a true expeditionary force is all about. Accordingly, I chose to expand my research and consulted a number of Navy and Marine Corps sources. Please note that the Marine Corps sources frequently describe “expeditionary” in terms of being a state of mind, one that drives the way in which the Marine Corps organizes, trains, and equips its forces. These sources also serve to describe “expeditionary” in a number of different ways and provide characteristics that include rapidly deployable, self-sustainable, adaptive to mission requirements, scalable, and agile. These same sources also frequently provide a comprehensive overview of the types of missions that naval expeditionary forces have recently supported as well as information on the numbers of Marine Corps forces that have been involved. As we Chapter 9 Adapting Expeditionary Capabilities 289 well know, these types of operations are continuing today. Below is a summary of some of the important points from my research: • Expeditionary Force: “An armed force organized to accomplish a specific objective in a foreign country.” [1] • The Navy and Marine Corps describe “expeditionary” as a state of mind that drives the way their forces are organized, trained, and equipped. Forces are described as possessive of a high state of readiness, scalable and agile, self-sustainable, capable of rapid deployment, and able to begin operating immediately upon arrival, even in the most austere environments. [2] • During 2010, naval expeditionary forces participated in combat operations in Afghanistan, successfully completed their mission in Iraq, conducted humanitarian assistance/disaster relief operations in Pakistan, Haiti, and the Philippines, and conducted antipiracy missions off the Horn of Africa. • At the end of 2010 there were approximately 20,700 Marines in Afghanistan, 6,200 at sea in Marine Expeditionary Units, and 1,600 engaged in various other missions, operations, and exercises. An additional 18,000 Marines were also assigned to garrison locations outside the continental United States. Figure 1. Marine Corps Operations 290 Climate and Energy Proceedings 2011 Turning now to Marine Corps operations (Figure 1), I am sure that most of you are aware that the Marines are routinely organized into Air-Ground Task Forces to meet designated mission requirements and are capable of rapid deployment and employment from the sea, land, and air. In recent years, Marine expeditionary forces have been deployed frequently alongside their Navy shipmates. The list below highlights a number of other key points regarding the Marine Corps: • Contributions: –– A versatile “middle-weight” capability to respond across the range of military operations –– Inherent crisis response speed and agility buys time for national leaders –– An enabling and partnering capability in joint and combined operations • America’s return on investment: –– 8.5% of the proposed FY2012 DoD budget –– 31% of DoD ground operating forces (combat, combat support, and combat service support) –– 12% of the DoD’s fixed wing tactical aircraft –– 19% of the DoD attack helicopters The Marines are now characterizing themselves as a middleweight force: a force that is much lighter than the U.S. Army yet possesses considerable combat power. The projected Marine Corps mission focus as identified by Secretary Robert M. Gates in his February 2011 speech at West Point clearly requires the continuance of Marine Corps expeditionary capabilities. At the same time, I think everyone recognizes that the Marine Corps of the future will be somewhat smaller than today’s Marine Corps. As forces are withdrawn from Afghanistan, Marine Corps force structure is almost certain to be reduced. In addition, I have noted the Marine Corps’ own description of the current and future contributions it will make to the nation in terms of national security. As indicated, these capabilities come at what I think is a very reasonable cost. Chapter 9 Adapting Expeditionary Capabilities 291 In short, the Marine Corps provides the American taxpayer with an excellent return on investment. It is this expeditionary combat power that we are going to focus on this morning because as Marine Corps combat power has become more lethal, it has also become increasingly dependent on fossil fuel. Along with the substantial increase in Marine Corps combat power, the number of tactical vehicles, radios, computers, and other equipment organic to Marine Corps units has increased threefold over the past decade. This increase has obviously contributed to increased fuel requirements. Daily Marine Corps fuel consumption in Afghanistan, for example, is estimated to be in excess of 200,000 gallons. According to General Jim Amos, the current Marine Corps Commandant, this dependency on fuel puts both Marines and expeditionary capabilities at risk. The photograph in Figure 2 shows a typical fuel convoy in Afghanistan. This convoy reflects today’s efforts to sustain forces in the field. In addition to the challenges posed by the terrain and a fairly limited road network, relying on such convoys in a hostile threat environment necessitates extensive use of security forces, forces which become another target for the adversary along with the fuel and supplies that are being protected. Figure 2. Energy Challenges 292 Climate and Energy Proceedings 2011 So what is the Marine Corps doing about it? As you will soon learn, the Marines are currently working hard to reduce both the size and the amount of equipment that they use as well as the energy demands associated with that equipment. When implemented, these changes will reduce the demand for fuel and thus there will be fewer fuel convoys and fewer personnel in harm’s way. I will leave it to my roundtable colleagues to describe the important initiatives that are underway. REFERENCES 1. Joint Chiefs of Staff, Joint Publication 1-02, Department of Defense Dictionary of Military and Associated Terms, 2010, http://www.dtic.mil/doctrine/new_pubs/jp1_02.pdf. 2. General James F. Amos, The 2011 Posture of the United States Marine Corps, 2011, http://www.quantico.usmc.mil/MCBQ PAO Press Releases/CMC 2011 Posture Statement-bm.pdf. 293 Colonel Robert Charette, Jr. Colonel Ted Smyth’s introduction proves that I am not an expert in energy but only an expert in burning energy. It is an honor to be here. This was one of the first forums I addressed Colonel Robert Charette, Jr., enlisted in the Marine Corps Reserves in 1985. He then attended Officer Candidate School and was commissioned in 1986. He has a B.S. degree in chemistry from Delaware Valley College, a master of business administration degree from the University of Phoenix, and a master of national security strategy degree from the National War College. He has attended numerous major professional schools. He has served as the VMFA-235 Embarkation and Pilot Training Officer, Third Battalion/Third Marines Air Officer and Operations Officer, VMFA-312 Admin Officer and Pilot Training Officer, VMFA451 Aircraft Maintenance Officer and Operations Officer, Marine Aviation Weapons and Tactics Squadron-1 FA-18 Instructor, Director of Safety and Standardization, Tactical Aircraft Department Head, I Marine Expeditionary Force G-5 CENTCOM Planner, Task Force-58 Air Officer, VMFA-314 Executive Officer, VMFA-323 Commanding Officer, Marine Aircraft Group-11 Operations Officer, Joint Staff J8, Chief Joint Requirements Oversight Council Secretariat, and the USMC Representative to the Joint Chief of Staff Working Group. He is currently Director, Expeditionary Energy Office. Colonel Charette participated directly in the following combat operations: Operation Desert Storm, Operation Southern Watch, Operation Deliberate Force, Operation Enduring Freedom, and Operation Iraqi Freedom. His personal decorations include the Defense Meritorious Service Medal with two gold stars, Air Medal with combat distinguishing device, Air Medal Strike/ Flight Award numeral six, Navy and Marine Corps Commendation Medal with combat distinguishing device and two gold stars, Navy and Marine Corps Achievement Medal, and seven Sea Service Deployment ribbons. He has earned “Top Ten” honors with Carrier Air Wing 8 and Carrier Air Wing 9. He was awarded the 1996 Alfred A. Cunningham Award for being selected as the Marine Corps’ Aviator of the Year. 294 Climate and Energy Proceedings 2011 last year after getting my orders pulled to go to Miramar and fly again. So this reminds me of last year’s horrible experience. But I will tell you, it has been a fascinating journey; it has really been about watching and helping develop cultural change in the Marine Corps. Commandant James Conway started the process a year ago, and Commandant James Amos has put the pedal to the metal and has continued it. It has been fascinating to watch what the Commandant’s leadership can do. So what did the Commandant do? How did we get here? Several years ago, Commandant Conway, working with General Amos, at the time the Director of Combat Development and Integration down in Quantico, conducted the Marine Corps Vision and Strategy 2025 Study. They looked at the war after the next war, how we need to be positioned for it, and how it will be affected by resource constraints around the world. They considered the fact that a lot of people live near the world’s oceans and the fact that a lot of people live in urban areas. The next war could well be over oil or it could be over water. The world is changing rapidly. Populations in Europe and Japan are decreasing, while those in Asia and Africa are increasing dramatically. The price of oil has once more begun to rise as you can see on the left-hand side of Figure 1. Figure 1. Rising Energy Demand: Increasing Fiscal and Combat Risks Chapter 9 Adapting Expeditionary Capabilities 295 If we have learned just one thing from the last 10 years of combat, it is that if one man can build it, another man can destroy it. You do not need a Mine Resistant Ambush Protected (MRAP) if you are not on the road. The impact of that, however, is that you cannot require fuel or water. So, that is the issue that the Commandant was looking at. There is an obvious danger in putting a fiscal concern next to a mortal combat concern; they are not the same. Obviously, the reason we are attacking this problem is to reduce the risks incurred by our Marines. However, the fiscal issue is also important. You can see that fuel prices spiked between 2000 and 2001. Congress passed an emergency supplemental during that timeframe that authorized $1.56 billion to account for the cost of fuel. The operation and maintenance (O&M) accounts in the Marine Corps and the other services had been totally disrupted. If we did not do something about that rise, the Marines would not have been able to train. When we lose money in our O&M accounts, we can have Marines at risk because they cannot complete the required training. So we have to address the fiscal issue head on. The bottom line is we cannot afford to do business as usual. It is not in our best interest fiscally, and it is definitely not in our best interest combat wise; that is what got us going. As a follow-up to Strategic Vision 2025, the Commandant set up my office and put this great team together over the last year. When you take a look at it in real terms, the Marine Corps is burning over 200,000 gallons of fuel per day (Figure 2). The price per gallon that we pay in the Helmand Province is $7 even. We do not pay the Defense Logistics Agency price of $2.80 in Afghanistan; we pay the NATO price of $7.05. What does that come down to? Well, it adds up to $1.4 million per day, or a little over $500 million per year. Right now it costs about a billion dollars to operate the Marine Corps for a year in Afghanistan. That is half of the Marine Corps’ entire annual procurement budget; so that is significant. Then you take a look on the right side of Figure 2. We have been running about 5 million barrels a year. Most of that is consumed by aviation, and as you have already heard, the Navy is working on 296 Climate and Energy Proceedings 2011 that challenge. There are things we can do in training and simulation that we are looking into. Figure 2. Marine Corps (USMC) Energy Use What we are really getting after though are the things that we can affect today on the battlefield. One of the principal components of Marine Corps battlefield energy consumption is batteries. The Marine Corps spends $22 million a year just on batteries, and a large share of those batteries power our radios. We do not need to get into the jammers that Marines carry, or the sights or night vision goggles. Let us just take a look at the number of radios in a Marine infantry company, like the one depicted in Figure 3. Prior to September 11, 2001, each of our infantry companies had a couple of radios, which required a total of about 160 watts of power. At that time, the total weight of the batteries required for a 3-day company-level patrol amounted to 122 pounds, and it only cost us about $4000. Today in Afghanistan, some 10 years later, that same company requires about 1255 watts of power because now every Marine has a radio. The batteries to provide that power weigh 586 pounds and cost $117,000. We just cannot afford to do business like this. We are going to price ourselves out of the warfighting business. General Joseph Dunford, the Assistant Commandant of the Marine Chapter 9 Adapting Expeditionary Capabilities 297 Corps, has told us that we are out of money. We have got to start thinking. Figure 3. The Company Pre-2001 versus The Company Today So General Amos has raised the bar in his latest planning guidance. He told us to do something about our energy consumption. Fortunately, we have had an 8-month head start. The Expeditionary Energy Strategy provides a baseline for our current energy use on the battlefield. [2] While the Marines are frequently deployed in different places around the world, we also spend a lot of our time at home, which means that Marines have to train and think at home so they are prepared to do the things they need to do when they get to the battlefield. Prior to the 1990s—and I joined the Marine Corps in the mid1980s—the Marines were very much a resource-limited force. When we landed an F/A-18, we called the radio room to find out how many flight hours we should log because we were concerned about fuel use. When we went to the fueling pits, we had shut down our left motor—the right motor was connected to all the important hydraulics—because we were worried about burning gas on the ground. When a Marine woke up in the morning on a patrol, he had two canteens and a couple of iodine tablets. You made do with what you had, but over the last 20 years, we have become resource spoiled. We now drink only bottled water on the 298 Climate and Energy Proceedings 2011 battlefield; Marines do not carry canteens anymore. They expect to have bottled water. I was a battalion operations officer (OPSO) some years ago. As penance for flying too much, they gave me an OPSO tour. I started as a forward air controller and then they made me the battalion OPSO. We went to Lowe’s and bought a little Honda generator because we did not have a generator at the battalion headquarters. We ran it all night to power our stuff so we were not wasting money on batteries. If you go to Helmand Province today, you will find that there are generators everywhere. We have Marines starting up 60-kilowatt generators to charge their iPods. By the way, those kids have guns, so I am not going to say anything to them, but they need maybe a couple microwatts. We have gotten completely spoiled over the last 10 or 20 years because post-Desert Storm, we stopped thinking about our fuel bill. We stopped thinking on the battlefield about water because water was always going to be there. Our logisticians have done heroic work supplying a battlefield where consumption is out of control. Figure 4. 35th CMC’s Planning Guidance [2, 3] We have to turn the corner. Fast, lethal, austere—those are the attributes of expeditionary operations. The infantry company that goes out today is magnitudes more lethal than an infantry company was in 2001. We have learned a lot. While we are definitely Chapter 9 Adapting Expeditionary Capabilities 299 more lethal, we still have to be able to fit back on ship. We have to be able to get back to our austerity and our speed. We have probably lost some of that, and so what we are figuring out right now in working with the Marine Corps Systems Command and the Office of Naval Research (ONR) is how we lighten our load and how we power that load in a smart way that is less costly. We have to think ourselves out of this. We are not going to be able to pay our way out of it. The triangle on the right-hand side of Figure 4 shows how we are going to compress ourselves back to the center. One of our goals is to end up getting some of our energy from renewable sources. As you will see shortly, we are well along the way to doing that. We are also going to increase the efficiency of our current gear as we reset and recapitalize. Then we have to make sure that our requirements documents capture that and move forward so when our requirements community sends a document to the Marine Corps Systems Command, it includes energy efficiency Key Performance Parameters (KPPs). I would actually like those KPPs to be designated energy performance KPPs, but we have not made that change yet; but I am floating that idea. More importantly, the anchors for our whole approach are leadership and training. We have to have Marines thinking about resource constraints. We need our Marine Lieutenant Colonels and Colonels and some of the old guys to think hard about this. Colonel Eric Smith, a friend of mine, just took over RTC-8 in Northern Helmand Province. He is working very hard to get his Marines off bottled water by the end of the year. They get it, and thanks to our leadership it is starting to echo throughout the Corps. Earlier this week, we sent a Marine out to Twentynine Palms to show an infantry battalion how to use one of the small solar blankets we have given them. Forty Marines and their Lieutenant Colonel sat through that training session. It is starting to spark; that ethos is going to be our biggest driver, and it does not cost us a lot of money. Today in Helmand Province we are burning about 8 gallons of fuel per Marine per day. In Vietnam I think we were using about a gallon or so per Marine per day. Moreover, we are projected to 300 Climate and Energy Proceedings 2011 continue this climb. The equipment we are buying is heavier, and it is more power dependent. Still, we have to turn the corner. Our plan calls for us to reduce the fuel required by that same force that is in Helmand Province by half by the year 2025. The only fuel that will be on that battlefield is that needed by mobility systems. Generators are going to disappear. We are going to have more power-efficient equipment. We are going to have Marines that think differently about their resources. We are going to harvest as much solar energy as we can. We are going to store it using some technologies we do not know about today, and we are going to use our vehicles in ways that we are not even thinking about. We are going to harvest energy from our vehicles, whether it is heat energy or kinetic energy. Our vehicles will micro grid and will become backup power sources. Figure 5. Strategy and Timeline Our strategy has been signed out (Figure 5). What is different about it is that we have backed it up with an official requirements document, which identifies 112 specific energy-efficiency-related shortfalls. We believe that that requirements document is the intellectual foundation for getting us where we want to go. It will inform both the acquisitions community and the training community. We have also stood up a new power-and-energy (P&E) future naval Chapter 9 Adapting Expeditionary Capabilities 301 capability (FNC); so we now have our own tier in the FNC process. That FNC will guide the work that is going on at ONR, with the other services, with the agencies, and with the labs. By having a strategy that flows through a requirements document, everyone will be able to understand what the end state is for the warfighter and see the linkages. We also hope that this approach will improve our ability to successfully transition programs from the research and development and science and technology worlds. We recognize, of course, that such programs involve risk, but we want to see if we can improve the transition rate. We believe that our requirements document will help us do that. We have also asked our operational analysis division at Quantico to build a methodology so we can figure out if making these investments makes sense. We believe they do, but we want to back it up with rigor. Figure 6. Expeditionary Energy Goals Breakdown Figure 6 shows the breakdown of that 50%. Figure 6 does not appear in our strategy, because we do not want anybody in the system gaming it. I do not want anyone to say that we can just get our 25% from the ethos change and that we do not need to build new solar panels. So, I am sharing it with you in confidence. The point is that when we wrote the strategy we invited individuals from academia and the venture capital community to come in and provide a red team review. Based on their feedback, we 302 Climate and Energy Proceedings 2011 ended up with the numbers I have shown above. We believe they are reasonable. We believe they are executable. When we briefed the Commandant on our strategy, he said that he wanted it faster. I said, “Sir, right now we have over 112 things we have to get closed before we can get there, and that is going to cost a significant amount of money. We are going to get there, and we are dedicated to doing it, but it is going to take time.” So let me switch gears from the strategic level where we have been focused down to the tactical level. Obviously our most important thing is to protect the Marines who are in harm’s way. A year ago, Colonel David Karcher, Mr. Cody Reese, and I were in the field down at Quantico trying to figure out what we were doing with our Experimental Forward Operating Base (ExFOB). At the time, our charter was to develop and deploy an 80% solution vice spending several years working on the 100% solution. So, in January 2010, we went out to industry with a request for information (RFI) and asked for their best technologies in solar, water, and efficient shelter design. We ended up looking at products from over 200 different companies. Figure 7. The Ground Renewable Expeditionary Energy Network (GREEN) System and the SPACES System Chapter 9 Adapting Expeditionary Capabilities 303 We invited 16 of those companies to bring their products to Quantico, and we ended up buying about six of them. Figure 7 shows two of them. The solar panels that appear in front of these Marines make up what is called the Ground Renewable Expeditionary Energy Network (GREEN) System. On the wall is the SPACES system that we have been working on since 1996. Following our first two ExFOBs, we approached India Company of the 3rd Battalion, 5th Marine Regiment (3/5). In September 2010, they went into the Sangin Valley in Afghanistan’s Helmand Province—one of the hardest combat areas in modern history. We sent these solutions in with them. When we first approached them in June 2010, they wanted nothing to do with this gear. I begged them to take it. I told them that if they did not, I would be fired and that I really need this job because the economy’s not good. So, they somehow found it in their hearts to train with these systems and carry them into combat. When they came back, they provided feedback on how they had used these items. In the process they told us things that we had not even thought about. As a result, we are now accelerating our effort to bring them to the rest of the Marine Corps. They are getting prepared to come home. We hope to have a couple of their folks come to Washington and talk about what they did in their own words. We are particularly interested in learning about their combat operations because they went into a tough area, and we hope to talk a little bit about how they used the energy efficiency systems we gave them. So what is the ExFOB team? It is organized under Lieutenant General George Flynn, the Deputy Commandant for Combat Development and Integration. The team includes the Marine Corps War Fighting Laboratory (MCWL), the ONR, the Marine Corps Systems Command, our Training and Education Command (TECOM), the Capabilities Development Directorate (CDD) from the Marine Corps Combat Development Command, and finally my Expeditionary Energy Office (E2O). We meet weekly; our Executive Board meets every quarter, and we run ExFOB annually. Our next one will be held August 11–19 at Twentynine Palms. 304 Climate and Energy Proceedings 2011 The neat thing about this is we never intended for it to turn out this way. It was one of those things where you just rush to the field to get things to the front because we were told to do so. When the Commandant gets interested in something, we get rather fascinated, and so we ran to the field and did this. Along the way, we found that it became a process. The things we learned helped inform our requirements. We also started investing differently, and when we did our Program Objective Memorandum (POM) drill, we started changing investments around based on what we could get from industry and what we thought was possible. At the end of the day, we gained confidence that some of the stuff can actually work, and we built confidence in our young Marines by getting this new technology out to them. When I was in college if you talked about environmental stuff, you got beat up by guys like me, but today when you talk about environmental stuff with young Marines, they are all over it. Their school systems are apparently different than mine; they embrace this technology. So while it was confidence building with us old guys, the youngsters got it right away and ran with it. Figure 8. ExFOB Process Chapter 9 Adapting Expeditionary Capabilities 305 Figure 8 will just give you an idea of the scope of our efforts to date. We did Phases 1 and 2 at Quantico and in the process evaluated the commercial-off-the-shelf (COTS) options. Phase 3 was accomplished during the deployment of India 3/5. We conducted Phase 4 last August at Twentynine Palms; we are in the process of purchasing the solution concepts identified there right now. Colonel Karcher and his folks are doing tremendous work coordinating that. If those systems pass the evaluation that we have planned for this coming May at Twentynine Palms, we will take them to Afghanistan this summer. Now we are really amping up the ante. We are looking at getting a battalion-level Combat Operations Center (COC) off the net entirely if possible or, at the very least, saving a significant amount of fuel. When we conduct ExFOB 2011 this summer, we are going to look at concentrated solar power, and we are going to look at stationary vehicle exportable power. We are really trying to wrap our minds around how we can make our vehicles better. The RFI for bringing solution options to ExFOB 2011 closes at the end of April. The neat thing about ExFOB 2011 is that we have partnered very closely with the Army to do the evaluation. We really want to make sure that we share everything we are doing. Let us get into specific solutions from ExFOB, and the reason I want to bring this up is because I think it is fascinating. Figure 9 shows the SPACES system; it is a small solar blanket that you can roll up in your pack. It comes with an inverter that you can use to charge up a couple of batteries while you keep marching on patrol. The system was first tested by the Marine Corps in 1996. The requirements document was not written for it until 2004. It did not deploy to the field until 2010. At that point, it went viral. We have no more on the shelf. India 3/5 got it in their hands last October; they were the only battalion we asked to use this. We never mentioned it to the other nine infantry battalions or the Marine Expeditionary Units. The word went out virally. It went from Marine to Marine; we never advertised this. We were a little hesitant because we did not know how it was going with 3/5. Now, thanks to word-of-mouth advertising, we have no more left. We 306 Climate and Energy Proceedings 2011 are trying to get an additional $9 million to buy some more; hopefully we will get them soon. Figure 9. Fleet Demand for Renewable Energy Increasing The success of this system was demonstrated effectively during one of the unit’s 3-week patrols. The platoon commander was very skeptical when we first gave him this gear. By accident, the Marines filmed a video following the patrol that has provided excellent advertis­ing for the system; we had nothing to do with it. The platoon commander told Combat Camera that his patrol used no batteries whatsoever during the entire 3-week duration of their patrol. Instead, they used the SPACES blan­ket. Normally, batteries for an infantry patrol have to be resupplied every 2 to 3 days. So, doing without that resupply is significant. It increased the patrol’s operational reach. They were less at risk, and they were able to operate all their systems on the move. There is a link on our website at Marines.mil. A couple of videos are posted there, including the one with the platoon commander’s comments. There are some limits to this system. Amorphous silicon does not do well in clouds and rain. We sent it to the Philippines recently to test it. It did okay when the sun was shining, but it did not do well in clouds and rain. We have provided three systems to the Chapter 9 Adapting Expeditionary Capabilities 307 Naval Research Lab so they can tell us how to make it better. We know this has applicability, but we need to make it better. Shown in Figure 10 is the complete set of capabilities that we provided to 3/5. I have talked about the GREEN System. The zerobased system was a commercial-off-the-shelf product we bought from Raytheon; it has done really well. The LED lights have done well; the Marines love them because it is really easy to go to blackout mode when necessary. Figure 10. ExFOB Capabilities Deployed with India Company 3/5 in September 2010 We also tested the solar shade and the solar light poles. We found that one of the issues with the solar shade on a forward operating base (FOB) is that the silicon is woven into the top. To keep it clean you have to send Marines up there once in a while. They had to get in full battle rattle and were sniper targets, so we withdrew it back to Camp Leatherneck, our major base in Afghanistan. We are not really sure what we are going to do with the solar shade idea; we are working our way through that. The solar light poles worked out okay, but the Marines on the forward edge did not like them because they obviously helped the enemy target the Marine position. So, we moved them back to Camp Leatherneck too. They may ultimately have some applicability. 308 Climate and Energy Proceedings 2011 The Marines set up two patrol bases that operated exclusively on renewable energy. I was a little concerned when I heard that because by then the gear had been out there for a while. Some of it was commercial off the shelf, and some of it was homemade stuff. When we tried to get it back a couple weeks ago, I asked my liaison officer in Helmand to bring it back, and he said: “Sir, 3/5 will not give it back. All they have is renewable energy.” I was really concerned that they were using gear full time that we had not fully developed. So, we have some generators moving out there to back it up. But, they have really become dependent on renewable energy. The Phase 4 options that are going to be deployed to Afghanistan this summer are shown in Figure 11. We have direct current (DC)powered air conditioners and DC-powered refrigeration. We think we are going to make large cuts in the load at the company level, and we are adding the liners and the lights. Figure 11. ExFOB Phase 4 Follow-On Deployment for Summer 2011 So it is clear that our multifunctional team can move out quickly when we work together. The key is our written requirements documents. We did not just talk about it as a science experiment. We put our money where our mouth was. We have increased our Chapter 9 Adapting Expeditionary Capabilities 309 funding for these systems by over 67% from the President’s Budget for FY2011 to the President’s Budget for FY2012 and have the flexibility to get the right stuff in Marines’ hands. Figure 12. Key Technology Focus Areas This is what we are doing on the science and technology side (Figure 12). Figure 13. Changing Ethos 310 Climate and Energy Proceedings 2011 Beyond just buying better toys, we are working hard to get energy efficiency into the Marine Corps ethos (Figure 13). Toward that end, we have just added a liaison officer in our shop who works with the Marines Training and Education Command; I believe that organization is one of the keys to our success. If we train our young leaders, and if we train our young Marines, the rest of it will take care of itself. Figure 14. Nawa Renewable Energy Project: Providing Opportunities As my final point, I think it is important to note that we have not just been thinking about ourselves in this. We are also thinking about the local Afghanis; we have looked at a lot of different approaches for helping them. To be sure, not everything has worked. We could not get the Afghanis interested in biofuels, for example. While they do not have a lot of clean water or good food, they do have a lot of cell phones. When we went to their markets to see how we might help, we found out that they are very familiar with solar power; they use it to charge their cell phones. So, after a 6-month negotiation, we started a renewable solar-energy project that is under construction right now. Interestingly, there is a Nawa renewable energy company in Kabul, Afghanistan. We asked them to come out to Helmand and meet with the local shura Chapter 9 Adapting Expeditionary Capabilities 311 in Nawa. So now, we have an Afghan energy company helping local Afghans (Figure 14). When it is completed, we will be providing renewable energy in a distributed environment; we will be helping the local Afghanis in the same manner that we are helping our Marines. The costs for transporting fuel and building infrastructure are simply too high for the local Afghanis. This approach will allow them to avoid those expenses. We really believe this has a lot of opportunity throughout Helmand Province. REFERENCES 1. Department of the Navy, Marine Corps Vision and Strategy 2025, http://www.marines.mil/news/publications/Documents/ Vision%20Strat%20lo%20res.pdf. 2. The Marine Corps Expeditionary Energy Office, United States Marine Corps Expeditionary Energy Strategy and Implementation Plan—Bases-to-Battlefield, http://www.marines.mil/unit/hqmc/ cmc/Documents/USMC Expeditionary Energy Strategy.pdf. 3. Department of the Navy, 35th Commandant of the Marine Corps Commandant’s Planning Guidance, 2010, http://www.marines. mil/unit/hqmc/cmc/Documents/CMC 35 Planning Guidance FINAL.pdf. 312 Colonel David Karcher As Colonel Robert Charette, Jr., noted, the Commandant has said go faster and gain and maintain momentum. You have seen some of the things that we have done. But, it is with your help that we are going to gain and maintain the momentum that we need Colonel David Karcher recently retired after more than 31 years as a United States Marine. A U.S. Naval Academy graduate, he served in various command, staff, and instructor positions across the Marine Corps. Primarily a field artilleryman, with secondary specialties in acquisition and joint operations, he deployed to operations including Urgent Fury in Grenada, security operations and humanitarian evacuations in Lebanon, Sharp Edge evacuation operations in Liberia, Desert Shield/Desert Storm in Kuwait, United Nations Operation in Somalia II (UNOSOM II) with Joint Task Force Somalia, Operation Iraqi Freedom (OIF) in Iraq, and Operation Enduring Freedom (OEF) in Afghanistan. His acquisition tours included acquisition of command and control systems (Advanced Field Artillery Tactical Data System, Tactical Combat Operations system, Intelligence Operations Workstation, and Global Command and Control System) and tactical software (Command and Control Personal Computer) and serving as Director of the DoD Joint Non-Lethal Weapons Program and Chief of Staff of the Marine Corps’ Acquisition Command. Colonel Karcher retired in December 2009. He returned to government service in 2010 and is currently the Director, Energy and C-IED Systems, Marine Corps Systems Command in Quantico, Virginia. Colonel Karcher graduated from the U.S. Naval Academy with a B.S. in engineering, holds a master’s degree in business from Oklahoma City University, and earned a master of science degree from the Industrial College of the Armed Forces. He is a graduate of the Amphibious Warfare School, the Command and General Staff College, the Armed Forces Staff College, the Defense Systems Management College, the Defense Acquisition University, and the National Defense University. He is a Lean Six Sigma Black Belt and is Defense Acquisition Workforce Improvement Act Level III certified in program management. Chapter 9 Adapting Expeditionary Capabilities 313 to reach the goals we have set for the future. Colonel Charette did a nice job of laying out our strategy. How are we going to put this into action? How are we going to have long-term enduring solutions that the Marines and the other services can use? I will show you some of the challenges that we have; those faced by the Army are very similar. The Marine Corps Systems Command (MCSC), where I work, provides support to both the acquisition community and the requirements community. One of the things we have done to gain and maintain momentum is to put a multifunction team together. It has worked very well. That team is addressing the capabilities that we want to have in the Marine Corps given our limited resources. While some of our challenges are the same as those for the other services, some are different. Thus, we have to get the requirements right. The bullet points below provide some background: • MCSC provides long-term material solutions • We meet the requirements • We provide life cycle support • The warfighter must be, and is, an integral part of process • Materiel solutions must be integrated into the larger Expeditionary Energy Strategy Earlier, Colonel Ted Smyth took a shot at defining the term “expeditionary” from the Marine Corps perspective. I want to expand that a bit by looking at “expeditionary” from the energy perspective. In my view, it is a mindset, but it is also more than that. We have to be able to go at any time to any place, and we have to win the battles that the country calls on us to fight. So, the first thing that comes to mind when I hear the word “expeditionary” is that whatever piece of gear that Marine takes with him has to work exactly as he expects it to the first time he uses it and every time thereafter. Obviously, we have to make trades when we consider energy efficiencies. We have to be very careful when we make those trades because our material solutions still have to provide desired 314 Climate and Energy Proceedings 2011 capabilities. Thus, we have a bit of a challenge, particularly on the engineering side. Our systems have to be rugged, and they have to work. We have to be able to train on them and be able to do so in a way that does not add to the existing training burden. Then, we have to be able to use them. They have to work. They have to fit into our mission profiles. When necessary, we have to be able to repair them or get parts for them. In some ways, the energy efficiency community is fairly new. While many things have been going on for years, a lot of the interesting work is still being done by small companies with great ideas. Managing the supply chain and providing long-term support are not necessarily their strong suit; so, we have to work our way through that. When we build something, we want it to be as lightweight as possible. We want it to be agile. And we have to be able to test and prove that it works, and we have to do all this preferably by this afternoon, and if not, by tomorrow morning. In short, it has to be worth taking to “every clime and place.” It has to be useful to our individual Marines and to their units. It has to make them better in combat and also in secondary missions such as those providing humanitarian assistance. It also has to operate in a Marine Air-Ground Task Force organization (transportability, training, mission profile, supply chain, weight/space, testing, etc.). So, we have to be prepared to do all those things, but when it gets aboard that ship or aboard that aircraft, we have to make very tough choices. We already have too much of what we sometimes refer to as GLOP—gear left on pier—because it does not fit aboard our ships. So whatever equipment or renewable sources we use to improve energy efficiency have to be worth that prioritization. So what are we trying to do? To meet these requirements, we want to do a couple of different things. We want to reduce our energy consumption for the equipment we already have across the board (vehicles, aircraft, radios, generators, computers, mobile command posts, night vision devices, etc.). It is always a challenge to re-buy or reset, and it is not particularly unusual to have a pilot or a truck or tank driver who is younger than the equipment he is using. In some cases, his father may have used the same equipment before him. We want our gear to last for a long time. Given Chapter 9 Adapting Expeditionary Capabilities 315 our resources, we have to be able to make it last for a long time. Unfortunately in many cases, when the original program manager made his design trades, gas was less than $1 a gallon. Fuel efficiency was not that important. Now it is. We seek to supply energy more efficiently and to supply it in part from renewable sources. One of the first things we need is the expertise found in this room and in other rooms like it to make improvements in the gear we have. In some cases, the production lines are long closed. So, how do we insert new technology? How do we do it gracefully, smartly, inexpensively, and without taking everything we have down? We will still need to be able to use the equipment, or at least some portion of it, while we refit. We are looking at all our equipment from top to bottom and from left to right as you can see in Figure 1. Figure 1. Recently Deployed Power and Energy Systems We have seen dramatic proof of the increase in the number of batteries used by a rifle company. We need to make a difference not only at company level but at squad level and for the individual Marine. If we can make that company 10% more efficient, they can go that much longer without resupply, that much farther, or operate that much more efficiently. At the same time, we have to 316 Climate and Energy Proceedings 2011 get a good return on our investment, so we have to take both capability and cost into account. We also have to change behavior. It is not just training; it is mindset. Something that makes us more efficient is not any good if we do not actually use it. We seek to combine efficient behavior and equipment. How are we going to do this? Well, Marines get it. Our young Marines clearly understand power consumption if only from the necessity of recharging their personal electronics. They do not always know what it costs, so we have to continue to meter up and show them the energy costs for the equipment that they are using. The Commandant has clearly said that we need to go faster. So we are getting very good acceptance. But that acceptance is based on the belief that what they get will work every time and it will make them better in combat. So far, what we have delivered in admittedly small amounts has met those requirements. Now, how do we transition that across the Marine Corps? We certainly look for your help in making reliable deliverables of the appropriate material solutions. So far, some things seem to be doing particularly well. I will not necessarily say that solar is better than any other renewable, but for the environments in which we expect to operate, and certainly in Afghanistan and Iraq, solar is pretty reliable. We can make it reasonably rugged, and it has a fairly good return. Geothermal and hydro are not quite as dependable in all the geographical locations that Marines can expect to visit. Moreover, solar is a technology that is fairly well understood at least in some installations. So, the question is how do we take that and have the high efficiencies and low weight that a small Marine unit can use? As a simple example, almost every Marine has a flashlight. If we just made a difference in flashlights between weight and power it would be a significant difference. Getting to the right kind of rechargeable batteries and getting to a more unified approach just on flashlights will make a big difference. There are lots of opportunities for improving technology across all our equipment, and solar has been a big help. Chapter 9 Adapting Expeditionary Capabilities 317 While industry is doing a good job making our IT equipment more energy efficient, there are some things that do not work as well. Tactical units—infantry, armor, and artillery—have to be able to pick up and move their gear on short notice, and they have to be able to operate as part of a Marine Air-Ground Task Force and more likely than not in some remote location. They may be able to connect their equipment, say a radar, to the power grid, or they may have to connect it to its own power supply. When you have to move often, and on short notice, renewable energy sources do not always enable rapid movement or provide the high energy densities that they need. Thus, in the short term, although we want to get out of the generator business, it is a technology we understand. We want to have energy sources, preferably as dense as possible, that can come and go with our units and plug into the commercial power grid when it is available. We need to be both efficient and effective. In the case of some of our tactical units, it is a real challenge to fit energy efficiency into their environment. We want our tanks to be as lethal as possible and to be able to move their 70-ton weight as rapidly as possible. Energy efficiency was not important when we first partnered with the Army on the M-1 tank. We have since put an auxiliary power unit (APU) on it so we do not have to run the tank main engine quite as much. The weight penalty was small, and we do save some fuel, so this modification has had a good outcome. That has not been true for everything. So, we are still looking for technologies that will provide energy efficiencies for the equipment used by our tactical units. Now let us look at what we are focused on for this coming year and what are we looking for in the long term. As Colonel Charette indicated, this is the year of the vehicle. A lot of our battlefield fuel is used by our vehicle fleet. As we have added vehicles and as they have gotten heavier in response to the improvised explosive device threat, our fuel use has increased further. My sons are 23 and 25. They are starting to learn exactly what it costs them to fill their car at the pump and that driving efficiently with a lighter foot on the pedal is a good thing. We want to put more effort into training our young Marine drivers to do the same thing. We want to provide 318 Climate and Energy Proceedings 2011 feedback within our tactical vehicles that shows the driver how the way they are driving is affecting the vehicle’s efficiency. To some extent, industry has led the way in efficiency improvements. However, we are not always able to use some of the advances they have made. Consider, for example, something as simple as low-rolling-resistance tires. Michelin sells them for commercial vehicles, but they are not made for the types of tires that we use on our large trucks. So, we are partnering with Michelin to see what can be done. In other cases, industry is not yet looking at the technology that we want to use. What is called on-board power generation is an example. Today’s military truck has enhanced vision devices for the driver, radios, and a host of other electronics to include, in some cases, cameras and jammers. We are looking at providing a more efficient bus inside that vehicle so it can use its electricity better and can in fact produce more of it. We have actually just about reached the physical size limit of alternators to generate power on board a vehicle. So, we are asking what can we do to make our vehicles more energy efficient? We are very interested in what is called concentrated solar. How can we obtain greater energy density? We also want to establish relationships and partnerships with the other organizations that are working on energy efficiency. We want to know what they are doing and, where possible, whether there is some sort of leveraging or trade-off that can occur. We think such collaborative efforts will help us move from the short term where we have seen success to the long term. We are interested in meeting with anyone who may have a path to success. By all means, please let us know. 319 Mr. Cody Reese First off, you might notice that unlike my panel colleagues, I am not a Marine colonel nor do I expect to be one anytime soon. But I definitely appreciate the work they are doing. The first commanding Mr. Cody Reese graduated from the University of California, Berkeley with a B.S. in mechanical engineering in 2002. Upon graduation, he served at the Naval Facilities Expeditionary Logistics Center under the Professional Development Center intern program. Following the receipt of his California Professional Engineer license in 2005, Mr. Reese took a position in the Amphibious and Expeditionary Systems Department at the Naval Facilities Engineering Service Center (NAVFAC ESC). At the Engineering Service Center, he has worked on projects ranging from autonomous crane systems for cargo transfer in high sea states to expedient airfield damage repair equipment. In 2009, Mr. Reese accepted his current position at NAVFAC ESC as Technical Direction Agent (TDA) for the Office of Naval Research (ONR) Code 30 Logistics Thrust. As TDA, Mr. Reese assists the ONR Logistics Thrust Program Manager with the development and execution of the logistics science and technology (S&T) program. Mr. Reese leads a team of subjectmatter experts who have a broad range of knowledge and experience in diverse expeditionary logistics disciplines including the following: expeditionary energy and power, autonomic logistics, water purification and distribution, logistics sustainment support for small-unit distributed operations, and sea-based logistics. The end users of the technologies include the Marine Corps and the Naval Expeditionary Forces. Mr. Reese is highly involved in concomitant duties in support of the command and the engineering profession. For the past 6 years he has served as senior staff for the Society of American Military Engineers, Seabee Engineering and Construction Camp. He has served for the past 4 years as the command’s Combined Federal Campaign chair and as a member of the command’s lauded recreation committee. He was recently inducted as a cadre member into the NAVFAC 2011 Leadership Development Program. 320 Climate and Energy Proceedings 2011 officer I served under at the Naval Facilities Engineering Command (NAVFAC) Engineering Service Center was Navy Captain Mark Samuels. He was an excellent public speaker; at the beginning of a presentation he would always tell a poor joke that would enhance his presentation. So, I am going to try that technique today and see how it works. I will tell one related to energy and climate change. What do you call a fish with no eyes? A fsh. See? Lame. As Colonel Ted Smyth said, I work for the NAVFAC Engineering Service Center. While the Center is doing fantastic things for Naval facilities engineering across the board, I have been assigned full time to support the Office of Naval Research (ONR). Basically, I get to go all kinds of good places. I have the coolest job in the room, and I think you will agree with me at the end of this. I am basically a science and technology scout for ONR Code 30 Logistics Thrust. ONR 30 is the Expeditionary Maneuver Warfare and Combating Terrorism Science and Technology Department, and as such it is focused on the expeditionary Navy and Marine Corps, the guys with boots on the ground. Within that, there are different technology thrusts: maneuver, fires, C4ISR (Command, Control, Communications, Computers, Intelligence, Surveillance and Reconnaissance). I support logistics, which is everything else to include energy, water purification, asset transport, and infrastructure. This year, in the logistics thrust area we are managing over 25 efforts focused on improving expeditionary logistics. In the remainder of my talk, I am going to delve into some of the cool technologies that we are looking at. As my panel colleagues have said, there are several different ways to reduce energy demand. To start with, there are behavioral initiatives, which I am not going to go into. The Marine Corps ethos is driving that pretty hard, and I think that is going to have a huge impact. Then there are technological options. There are specific device improvements that have a direct energy benefit, and there are those where the effect is indirect. A lot has been said about vehicles and convoys. I am not going to talk about specific vehicle improvements, although rest assured, ONR’s maneuver thrust has that covered. They are working heavily on Medium Tactical Vehicle Replacement (MTVR) fuel efficiency and hybrid vehicles. Chapter 9 Adapting Expeditionary Capabilities 321 The bottom line is that nearly every research and development effort in the logistics thrust reduces Marine Corps energy demand in one way or another. That being said, I get to basically present whatever I want out of the logistics portfolio, so naturally I will choose my favorites. I am going to start with power and then move on to water and cargo delivery. I am going to focus mainly on technologies at the applied level. We definitely support the basic research that supports these applied-level things, but it is not quite as easy to see the actual benefit that a carbon nanofoam is going to have on MTVR energy reduction. So, I will focus on those that have obvious applications. Let us start with a hybrid power source with a high energy density (Figure 1). This is basically the union of an alter-capacitor and a lithium-ion battery in one box. It has the same form factor as a BA-5590. It has the potential to double the specific energy of that battery. So basically you have a battery that has twice the power of the one that you now have. The indirect energy benefit is that you now have to bring fewer batteries to the fight. Batteries are heavy, and hauling them around the theater takes a lot of fuel. In addition, with fewer batteries we can reduce battery manufacturing and disposal. Although the manufacturing is not quite a Marine direct cost, disposal certainly is. Figure 1. Hybrid Power Source with High Energy Density 322 Climate and Energy Proceedings 2011 Now let us look at power management for military radios. We are basically adapting a power management integrated circuit that is found in a lot of commercial laptops, cell phones, and those types of things. It functions through selective power control to individual circuits in the radio with no adverse performance effects. Basically it just shuts down subsystems that are idle and consuming power within a specific device. It has the potential to reduce the power consumption of that device by 30%. With that, a radio squad can reduce its battery requirements for a 4-day mission by 12 pounds, which again leads to fewer batteries transported around theater and reduced manufacturing and disposal. Figure 2. Harvesting Electric Power from Walking My next concept is a device that harvests electric power from walking (Figure 2). This has been tried a couple of different ways before; our approach uses a backpack that effectively oscillates up and down as you walk. Depending on the load you are carrying and the speed at which you are moving, you can generate anywhere between 8 and 45 watts—a significant electrical output. As a secondary benefit, the backpack reduces load-related forces that cause musculoskeletal injury. I have run around with one of these on my back; it is actually pretty amazing. So obviously the direct energy benefit is that the Marine self-supplies his electrical needs. The indirect energy benefits are the same as reported previously. Chapter 9 Adapting Expeditionary Capabilities 323 Fewer batteries need to be transported to and around the theater, and manufacturing and disposal costs are reduced. Since you need fewer batteries, your pack is lighter than it would be otherwise. Although the pack weighs a little more, it pays off since you need fewer batteries. If you couple that with batteries that are twice as powerful and with radios that need 30% less power, this can definitely provide the guys on the ground with their own source of self-sustaining power even for the cases where other renewable energies might not be appropriate. Now let us turn from power to water purification, which is something I really like working on. This next one is a platformenabling technology that has applications across the different scales and levels of water purification systems used by the Navy and Marine Corps. It is effectively a pretreatment and uses a continuous-flow clarification process that operates on the sheer forces within a fluid with a very low-pressure drop (around 3 psi). It is not a centrifuge; it is basically just a curved rectangular channel with one input and two outputs. Figure 3. Small-Scale Fluid Particle Separator As you can see in Figure 3, it is pretty small. Figure 3 shows a tank of water that has been spiked with carbon particles measuring from 5 to 30 microns. The water initially goes in dirty, but by three quarters of the way around, the sheer forces cause the 324 Climate and Energy Proceedings 2011 carbon particles to band together in one particular region of flow. The water containing the particles can be diverted out one of the output ports, while the “clean” water goes out the other port. This is the closest thing to magic I have ever seen; it is amazing to watch. Its orientation does not matter; you can shake it while it is running. We are looking at using this on everything from small water purifiers all the way up to replacing the prefiltration systems on shipboard-level systems. The Navy has discovered that when they operate in remote regions, prefilter fouling for their reverse osmosis systems can go through the roof. They need six times as much prefiltration than they currently have. If we could use this instead, we could save a lot of room on the ship. In the expeditionary environment, we could save a lot of resupply of small filters for these water purification systems. Advanced energy recovery is another of our water-related concepts. It takes a lot of power to actually pump water through a plastic membrane to get freshwater out the other side. Typically, energy recovery systems are optimized for large-scale plants such as industrial water purification systems that process millions of gallons per day. Currently, none are really adapted to small expeditionary systems where you may be operating on fresh- or saltwater in any climate or place. So the reverse osmosis systems with energy recovery that we are looking at are scalable for the small range (40 gallons per hour). They allow for variable recovery ratio depending on the specific operating conditions. They have been shown to improve the efficiency of an actual system by as much as 60%. If we couple that with some of the less-resource-intense prefiltration, we can have a huge impact. An indirect energy benefit is that it reduces fuel transport requirements. This next concept is sort of a baby step in the direction of autonomous resupply. This is an upgrade to the existing CQ-10 Alpha SnowGoose unmanned aerial vehicle, which is a parafoil-based system (Figure 4). The parafoil is launched by towing it behind a Humvee on a trailer. We are upgrading it by adding a three- or four-blade autogyro that will prespin the rotors at zero pitch and then go full collective and launch up in the air. The system autogyros from that point on. It is a very simple autonomous system, and Chapter 9 Adapting Expeditionary Capabilities 325 it is extremely easy to operate. It can deliver up to 2400 pounds and can cover a 93-mile radius in 24 hours. How does this save fuel? Instead of using the parafoil, the alternative would be to send an MTVR with an armed escort that might have to drive 200 or 300 miles round-trip though the mountains to cover the same 93-mile radius. Thus, it offers an energy-efficient way to provide direct resupply for small expeditionary units. As a secondary benefit, it reduces maintenance needs for your vehicle fleet. Figure 4. CQ-10 “Bravo” Cargo Unmanned Air Vehicle System My next concept is a local favorite. It was originally developed right here at JHU/APL: it is a self-healing galvanic protection additive called polyfibroblast (Figure 5). It is basically uncured paint in a zinc microcapsule, and it is compatible with existing MIL-SPEC paints. It can be mixed in with current paints and applied without retraining or refitting the equipment. Essentially, when a scratch is made through the paint surface, it ruptures the zinc microspheres and the paint resin flows out and fills the cracks. In addition, the zinc provides a galvanic protection for the actual surface. You can also add fluorescent dyes to indicate damage so you can tell where the stuff has been used and where your vehicle has been damaged. While it has no primary energy benefit, it definitely reduces vehicle maintenance. The cost of corrosion for the Marine Corps 326 Climate and Energy Proceedings 2011 in 2007 was something like $600 million; a lot of that is due to the cost of rotating vehicles through maintenance cycles. Anything you can do to reduce that is going to save energy and dollars. Figure 5. Polyfibroblast: A Self-Healing, Galvanic Protection Additive The last technology effort I am going to cover is the modular composite bridge (Figure 6). The Marines and Army currently deploy 10 to 15 different types of bridging for theater aspects for different scenarios. Each bridge has its own deployment issues, maintenance, and training. The whole process is very energy intensive. What we are looking at is a system of basically giant carbonfiber Legos. This is the bridge that every 5-year-old dreams about. The kit has five or six basic components: a pier section, a ramp section, a beam, a bank seat, and a deck. You can combine these in multiple different ways to make short bridges, long bridges, pier bridges, or line-of-communication bridges. You can put railings on the bridges. The actual energy benefit of this is somewhat sneaky. Instead of shipping 15 different bridges to the theater, you can ship two full bridge kits and save a tremendous amount of logistics transport. Space is at a premium on our amphibious ships and on our ground transport vehicles. Shipping the equivalent of a medium girder bridge will take seven ISO containers instead of the 20 ISO containers that would be required to ship the existing medium girder bridge. Even though these modular bridges will Chapter 9 Adapting Expeditionary Capabilities 327 be slightly more expensive to procure, the energy savings and the overall life cycle cost savings are significant. Figure 6. Modular Composite Bridging Rest assured that we are also investing in the fundamental materials science that lies behind all this stuff. We are conducting research on nanocarbons. We are looking at composites for large structures and nanocomposite electrodes for solid oxide fuel cells. We are investigating self-lubricating coatings and alloys to enable maintenance reduction. We are looking at solar energy, including stretchable photovoltaic materials. These materials can stretch and crumple. They can get shot through, get damaged, and still function pretty well. In addition, we are looking at ways to optimize the logistics supply chain. How do we do packaging? Are containers the right thing? Austere cargo handling is a big issue. Is there a more efficient way to move a 55-gallon drum full of water than to find enough Marines to lift it? There are opportunities for automation in the packaging process. We are also working on the micro-grid concepts that you heard about earlier to include energy storage buffers and load-source management technologies. The things we really look for are platform-enabling technologies that can be scaled across many different systems and become game changers through their secondary or tertiary logistics effects. 328 Climate and Energy Proceedings 2011 Q& A Session with THE PANELISTS Robert Charette, Jr., mentioned that the Marines Q: Colonel would be working closely with the Army during the upcoming ExFOB 2011. Could you highlight some of the collaborative efforts with the other services and with the joint community? Colonel Robert Charette, Jr.: To answer that, let me say that we would not have come so far so quickly if it were not for OSD’s Power Surety Task Force and the work they are doing with the Army as part of the Net Zero Joint Capability Technology Demonstration at Fort Irwin. One of the first things we did when we stood up the E2O was go out to Fort Irwin and see what they were doing. As it turns out, the Army’s got a lot of things going on. We are partnered with them on our next ExFOB. We are also working with the Air Force, especially on the aviation side. Mr. Cody Reese: I want to mention that the DoD water purification community is one of the most integrated areas of any in which I have worked. Personnel from the Army, the Navy, and DARPA attend the meetings. Anytime I get a new idea from a white paper and abstract, I send it out to the joint team for their input and review. We have all learned a lot from the Army testing at Aberdeen and from the really basic research that DARPA is doing.