Team 10: The Calvin Bolt

advertisement

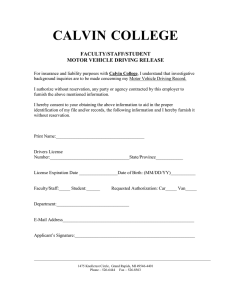

Team 10: The Calvin Bolt Project Proposal and Feasibility Study Laura Boluyt Daniel DeVries Christine De Zeeuw Vincent Rovedatti Engineering 339 Senior Design Project 11 December 2015 2015 © Team 10 and Calvin College Executive Summary Calvin College’s Engineering Program culminates in a year-long senior design project, integrating a Christian faith into the engineering design process. Christian perspectives factor into the decision making process of design as well as traditional engineering design norms. Team 10 is the senior engineering design team responsible for the Calvin Bolt, and the team consists of two mechanical and two electrical engineers. The Calvin Bolt will be designed as a four person electric vehicle that will be used for transportation across Calvin’s campus. The Calvin Bolt contains several elements, including the brakes, steering, electric motor, electronic dashboard, and the overall aesthetic design. Each of these elements has been researched by the team and declared feasible for the implementation of a working prototype. Team 10 will continue the design process to build a fully functional prototype in the spring of 2016. Table of Contents Table of Contents ........................................................................................................................................... i Table of Figures ........................................................................................................................................... iv Table of Tables ............................................................................................................................................. v 1 Introduction ................................................................................................................................................ 1 1.1 Calvin College Engineering ....................................................................................................... 1 1.1.1 Senior Design ............................................................................................................. 1 1.2 The Team ................................................................................................................................... 1 1.2.1 Laura Boluyt .............................................................................................................. 2 1.2.2 Vincent Rovedatti ...................................................................................................... 2 1.2.3 Christine De Zeeuw ................................................................................................... 2 1.2.4 Daniel DeVries .......................................................................................................... 2 1.3 Project Definition ....................................................................................................................... 3 1.3.1 Safety ......................................................................................................................... 3 1.3.2 Ease of Use ................................................................................................................ 3 1.3.3 Quality ....................................................................................................................... 3 1.3.4 Maintenance ............................................................................................................... 3 1.3.5 Aesthetics ................................................................................................................... 3 1.3.6 Seasonal Outdoor Usage ............................................................................................ 4 1.4 Motivation .................................................................................................................................. 4 1.5 Customer .................................................................................................................................... 4 1.6 Design Norms ............................................................................................................................ 4 2 Requirements ............................................................................................................................................. 6 2.1 Functionality .............................................................................................................................. 6 2.2 Capacity ..................................................................................................................................... 6 2.3 Speed.......................................................................................................................................... 6 2.4 Safety ......................................................................................................................................... 6 2.5 Time feasibility .......................................................................................................................... 6 2.6 Budget ........................................................................................................................................ 6 2.7 Project Deliverables ................................................................................................................... 6 3 Project Management .................................................................................................................................. 7 3.1 Project Breakdown .................................................................................................................... 7 3.1.1 Electronic Dashboard ................................................................................................ 7 i 3.1.2 Braking System .......................................................................................................... 7 3.1.3 Steering ...................................................................................................................... 7 3.1.4 Motor ......................................................................................................................... 7 3.1.5 Frame Design ............................................................................................................. 7 3.2 Schedule ..................................................................................................................................... 8 3.2.1 Team Meetings .......................................................................................................... 8 3.3 Budget ....................................................................................................................................... 8 3.4 Team Roles ................................................................................................................................ 8 4 Design Process ......................................................................................................................................... 10 4.1 Beginning of Year Testing ....................................................................................................... 10 4.2 Dashboard Hardware ............................................................................................................... 10 4.2.1 Research ................................................................................................................... 10 4.2.2 Alternatives .............................................................................................................. 11 4.2.3 Decisions.................................................................................................................. 12 4.2.4 Testing ..................................................................................................................... 13 4.3 Dashboard Features .................................................................................................................. 13 4.3.1 Research ................................................................................................................... 13 4.3.2 Alternatives .............................................................................................................. 14 4.3.3 Decisions.................................................................................................................. 15 4.3.4 Testing ..................................................................................................................... 15 4.4 Brakes ...................................................................................................................................... 15 4.4.1 Research ................................................................................................................... 15 4.4.2 Alternatives .............................................................................................................. 15 4.4.3 Decisions.................................................................................................................. 16 4.4.4 Testing ..................................................................................................................... 17 4.5 Steering .................................................................................................................................... 17 4.5.1 Research ................................................................................................................... 17 4.5.2 Alternatives .............................................................................................................. 17 4.5.3 Decisions.................................................................................................................. 18 4.5.4 Testing ..................................................................................................................... 19 4.6 Motor ....................................................................................................................................... 19 4.6.1 Research ................................................................................................................... 19 4.6.2 Decisions.................................................................................................................. 19 4.6.3 Testing ..................................................................................................................... 20 ii 4.7 Frame Design ........................................................................................................................... 21 4.7.1 Research ................................................................................................................... 21 4.7.2 Alternatives .............................................................................................................. 21 4.7.3 Decisions.................................................................................................................. 22 4.7.4 Design ...................................................................................................................... 23 4.7.5 Testing ..................................................................................................................... 25 5 Business Plan ........................................................................................................................................... 26 5.1 Market Competition ................................................................................................................. 26 5.2 Break-even Analysis ................................................................................................................ 27 6 Conclusion ............................................................................................................................................... 28 6.1 Final Results ............................................................................................................................ 28 6.2 Future Works ........................................................................................................................... 28 7 Acknowledgements .................................................................................................................................. 29 8 Works Cited ............................................................................................................................................. 30 9 References ................................................................................................................................................ 31 10 Appendices............................................................................................................................................. 32 iii Table of Figures Figure 1: The Team....................................................................................................................................... 1 Figure 2: Original Vehicle (Volts-Wagon) ................................................................................................. 10 Figure 3: The Honda Micro Commuter Digital Dashboard Tablet ............................................................. 11 Figure 4: Drum Brake Diagram .................................................................................................................. 15 Figure 5: Disc Brake Diagram .................................................................................................................... 15 Figure 6: Rack and Pinion System .............................................................................................................. 17 Figure 7: Recirculating Ball Steering.......................................................................................................... 17 Figure 8: Preliminary Electrical Circuit for the Motor and Lighting Elements .......................................... 19 Figure 9: Modern Style of a Sedan ............................................................................................................. 20 Figure 10: Modern Style of Small Truck .................................................................................................... 21 Figure 11: Modern Style of Hatchbacks ..................................................................................................... 21 Figure 12: Calvin Bolt Frame Design ......................................................................................................... 22 Figure 13: Isometric View of Calvin Bolt Frame with Panels .................................................................... 23 Figure 14: Side View of Calvin Bolt Frame with Panels ............................................................................ 23 Figure 15: Design Color Scheme for the Calvin Bolt ................................................................................. 24 iv Table of Tables Table 1: Comparison of Dashboard Layout Alternatives ........................................................................... 12 Table 2: General Frame Dimensions .......................................................................................................... 22 Table 3: Competitor Prices for Electric Golf Carts ..................................................................................... 25 Table 4: Estimated Fixed and Variable Costs for Production ..................................................................... 26 Table 5: Production Costs Estimates .......................................................................................................... 38 Table 6: Budget Tracking and Parts Cost ................................................................................................... 39 v 1 Introduction 1.1 Calvin College Engineering Calvin College’s Engineering Program is a four-year program that culminates in a senior design project. Calvin’s Engineering program is designed to have students take engineering courses from all four concentrations (electrical/computer, mechanical, chemical, and civil/environmental) for the first two years. The last two years of the program are spent in the student’s chosen concentration with concentration-specific courses. 1.1.1 Senior Design Course The Senior Design project is split between the ENGR 339 and ENGR 340 courses, taken in the fall and spring semesters respectively. The Senior Design project is 6 credit hours in total and serves as the senior capstone class for Calvin College engineering students. The Senior Design capstone class focuses on team and project development as well as various topics on professional development. The first half of the project, ENGR 339, focuses more on developing the project and completing a feasibility study and the second half of the project, ENGR 340, focuses more on how to complete the final design and analysis of the project. At Calvin College, Christian perspectives and faith are the foundation of each class, and the senior design capstone class is no different. The senior design course aims to not only teach students about the skills and techniques for completing a senior design project, but also integrates a Christian faith into each design element and strategy. 1.2 The Team Team 10 consists of Laura Boluyt, Vincent Rovedatti, Christine De Zeeuw, and Daniel DeVries. The team consists of two electrical engineers, Boluyt and De Zeeuw, and two mechanical engineers, DeVries and Rovedatti. The dynamic range of experiences for the team makes them well suited for the project. Figure 1: The Team 1 1.2.1 Laura Boluyt Laura is an electrical and computer concentration engineering student from Grand Rapids, Michigan. She has industry experience in control systems and project engineering at Consumers Energy. Laura also has managerial background through her work experience at Calvin College. Her interest and experience with control systems and design of automation solutions will be beneficial to this project. In her free time, Laura enjoys dancing, playing the guitar, traveling, and serving in the high school youth group at her church. 1.2.2 Vincent Rovedatti Vincent is a mechanical concentration engineering student with a math minor, and is from Ripon, California. Vincent hopes to pursue graduate studies in automotive systems, but would not mind working for automotive or aeronautical companies. Vincent’s knowledge in automotive work (primarily restoration of old cars), general knowledge of how cars work and run, and simulating programs will aid in the aerodynamics and construction of the vehicle. As a research assistant at Calvin College, Vincent provides experience with CFD (Computation Fluid Dynamics), as well as being very knowledgeable about the metal and wood shop. In his free time (or lack thereof), Vincent enjoys watching movies, working out, and making latte art for the customers of the Fish House. 1.2.3 Christine De Zeeuw Christine is an engineering student with an electrical/computer concentration from Dexter, Michigan. She is an active member of the Calvin College Wind Ensemble, and is Secretary for the IEEE Student Chapter at Calvin College. Christine has gained research experience through an internship at the University of Michigan, and industry experience working as an intern for SeaLandAire Technologies. Her experience and interest in data collection and analysis will be valuable for the dashboard design and interface. In her free time, Christine enjoys teaching herself piano, playing tennis, cross stitching, and watching movies. 1.2.4 Daniel DeVries Daniel is pursuing a Bachelors of Science in Engineering with a Mechanical Concentration at Calvin College. He is from Grand Rapids, MI. He has gained experience in mechanical engineering through several summer internships. In his free time Daniel enjoys cycling, rock climbing and disc golf, and is involved with music at Calvin. After graduation in May 2016 he plans to either pursue a graduate level degree in medical based mechanical engineering or seek a full time position working in mechanical design and manufacturing. 2 1.3 The Project Definition The objective of Team 10’s project is to design and build a 4-person electric vehicle. The design of this vehicle will use a previous senior design team’s final product (Volts-Wagon) as a starting point, improving the functionality and design of this vehicle. The vehicle will be a cross between a golf cart and a standard car, combining design aspects from both types of vehicles. The primary elements of this vehicle include the brakes, steering, electric motor, electronic dashboard, and overall aesthetic design. The specific goals that pertain to this project are as follows. 1.3.1 Safety Passengers will be contained within the vehicle during standard travel and sharp or moderate turns. Road obstacles such as bumps and holes will not compromise the integrity of the vehicle or the safety of the passengers. 1.3.2 Ease of Use Driving forwards and backwards, turning, braking, accelerating, and using vehicle lights should not be more difficult than operating a golf cart or other vehicle. The dashboard elements will be user-friendly, and the vehicle controls easy to navigate and operate. The vehicle aims to fill a need for those who have mobility challenges (i.e. elderly community members or those with a temporary or permanent disability) and difficulties climbing in and out of a golf cart. 1.3.3 Quality The vehicle will be fully functional and will be a quality-engineered final product. No element of the vehicle should be partially functional, and care to produce quality parts shall impact every design decision. 1.3.4 Maintenance The vehicle will be easy to maintain and repair so that it will be fit for continued use in the future. Any necessary documentation for the vehicle will be provided by Team 10. 1.3.5 Aesthetics The vehicle will be visually appealing and present Team 10’s project in an effective way to Calvin College’s campus. The vehicle should effectively represent the Calvin Engineering Department through a vehicle that is aesthetically pleasing. 3 1.3.6 Seasonal Outdoor Usage Taking Michigan’s weather into account, the vehicle will have the capabilities of driving in the winter months. A front windshield will protect the driver from precipitation and wind that may obstruct the driver’s view while driving. 1.4 Motivation Team 10 found this project appealing because there were many aspects of the original design that the team felt could be improved and modified. This project is a great learning experience because it allows the team to learn from the strengths and weaknesses of the Volts-Wagon design, incorporating that into Team 10’s project. This experience will be very relatable to industry and will provide valuable experience for future jobs and design experiences. Members of the team have personal experience using a golf cart to provide transportation across campus for those who have mobility challenges. Members of the team have also become aware of the inability for the parents of fellow Calvin peers to accompany their child on a campus tour due to their low mobility and the lack of a vehicle designated for this purpose. Team 10 saw this as an opportunity to improve the accessibility of Calvin’s campus. 1.5 Customer The Calvin Bolt will be designed and built for Calvin College. The original design, completed by last year’s senior design team, was made for the Calvin Admissions Department, but the Admissions Department has indicated that they no longer desire an admissions vehicle. Despite this, the team is still designing the vehicle with the Admissions Department in mind in case they should want the vehicle after the completion of the project. Should the Admission Department not want the vehicle, it could be used to promote the Engineering department and provide a service for those who have trouble walking long distances across campus instead. Indirect customers for this project are those who have mobility challenges or those who have trouble walking long distances across campus. The vehicle is being designed to accommodate that group of people, but not for one particular person. 1.6 Design Norms Design norms provide a way for Calvin Engineering students to integrate relationships with God and those around them into the engineering design process. These guidelines challenge the engineer to consider outside relationships and consequences. One design norm that characterizes Team 10’s project is trust. One of the top priorities for this project is safety, and the passenger should trust the design and know that it is dependable and reliable. The 4 passenger puts their safety into the team’s hands, and it is the team’s job to make sure that the customer can trust the design. Another design norm that fits into the project is integrity. Team 10’s design strives to be pleasing and intuitive to use, demonstrating a complete harmony between form and function. The design also strives to make Calvin’s campus accessible to all, especially those with mobility challenges or limitations, promoting human relationships and interaction through this vehicle. A third design norm that fits into the project is stewardship. The electric motor provides an excellent way to minimize the degradation of the environment. Other design elements strive to be an efficient use of resources such as materials and money. 5 2 Requirements To achieve the project goals listed above in accordance with Calvin College’s policies, there exists a certain set of requirements. 2.1 Functionality The vehicle must be fully functional and able to withstand minor and possibly major road disturbances and weather conditions. The vehicle must be in a stable state at all times, and the brakes must be fully operational and effective. The frame must be able to withstand the load of up to four passengers and provide some protection in the event of a crash. 2.2 Capacity The vehicle must be able to hold 4 passengers safely, and provide the electrical power to transport them across Calvin’s campus. The vehicle must also be able to fit on Calvin’s sidewalks. 2.3 Speed The vehicle must operate within the maximum 25MPH speed limit set on Calvin’s campus grounds. 2.4 Safety The vehicle must include safety features for the driver and passenger such as doors, a parking brake, turn signals, headlights, and brake lights. 2.5 Time Feasibility The vehicle must be designed, constructed, tested, and fully functional before May 7, 2016. 2.6 Budget The team has a $500 budget set by the Calvin College Engineering Department. Additional funds can be acquired upon an approved request, but the team should honor the $500 budget as much as possible. 2.7 Project Deliverables By the end of the project, the team will have completed a Project Proposal and Feasibility Study (PPFS) and a Final Report. The team will also provide all drawings, relevant calculations, team notebooks, and a team website in addition to the final vehicle prototype. 6 3 Project Management 3.1 Project Breakdown 3.1.1 Electronic Dashboard The Calvin Bolt will feature an electronic dashboard system to display various instruments and readings, including, but not limited to: the current speed, power usage, battery life, blinker system, time of day, outside temperature, and distance traveled. To achieve this, a touch screen display will connect via a programmable device to serve as a straightforward user-interface for the driver. 3.1.2 Braking System Similar to most modern day ground transportation vehicles, the Calvin Bolt will implement disc brakes for stopping. Unlike traditional vehicles, however, the Calvin Bolt will have brakes on just the front wheels rather than all four. The braking system needs to be able to bring the vehicle to a complete stop in a distance similar to that of a traditional automobile. 3.1.3 Steering The Calvin Bolt will implement a rack and pinion steering system. This system is proven to be reliable with little to no maintenance needed and is very easy to install. The steering system must to be able to maneuver corners with ease for the driver as well as remain stable when going over a bump in the road. 3.1.4 Motor The Calvin Bolt will be powered by an electric motor and a 48V battery pack, following the zeroemissions trend for golf carts and other related vehicles. The Calvin Bolt will be using an electric motor and controller obtained from the 2014-2015 senior design Team 04, which has the required capacity to properly propel the vehicle. The motor needs to have enough power to allow the vehicle to travel at least 5 miles or 30 minutes on a single battery charge. 3.1.5 Frame Design The Calvin Bolt will be made of aluminum pipe rather than steel in order to decrease the weight and increase the power to weight ratio. The Calvin Bolt will be created with a design that imitates a modern hatchback, but still has the soul characteristics of an electric golf cart. The design for the Calvin Bolt needs to look aesthetically pleasing while keeping its passengers safe and comfortable. 7 3.2 Schedule Each team member maintains a Google Calendar, which is shared amongst the whole team; this allows the team to remain organized and updated on any potential schedule conflicts. For the first semester of the senior design course and project, Team 10 mainly focused on research and design for the various aspects of the Calvin Bolt: business planning, ordering parts and preliminary coding and testing of specific components. During interim and the second semester, Team 10 will focus on building the vehicle, coding, testing and making any necessary adjustments and retesting in preparation for a final presentation on May 7th, 2016. The complete Gantt chart utilized for the Calvin Bolt is included in Appendix F. 3.2.1 Team Meetings Weekly meetings are conducted to collectively set short and long-term goals and weekly tasks for each member, as well as share ideas, research and results. At these meetings, the team may modify the Gantt chart, but each team member also maintains a personal checklist for specific tasks. Regular meetings with the project advisor, Ned Nielsen, are also completed to discuss progress and any potential questions. 3.3 Budget For the entirety of the project, Daniel DeVries maintains the budget for The Calvin Bolt. This includes keeping records of all costs associated with the purchase of components and materials, including shipping costs. While the team collectively acknowledges the necessity of any changes in the design process that might affect budget, DeVries is responsible to ensure that the budget and bookkeeping are accurately reflected. An Excel Spreadsheet to organize material costs for the project may be useful. In efforts to build a cost-effective prototype, The Calvin Bolt will employ as many salvageable parts from the original vehicle as possible. The team is also fortunate enough to have some parts donated or made available free of charge. A contingency in budget will be kept to allow for unforeseen costs to be covered. The detailed breakdown of the budget is presented in Appendix E. 3.4 Team Roles Each member of Team 10 is responsible for one aspect of the design project. While one member is in charge of a particular design aspect, each member will report their progress to the team for design verification and assistance. In particular, the members in the same engineering concentration will check the other’s work to ensure safety and quality of design. 8 Laura Boluyt is taking the lead on the time, temperature, Calvin map, speedometer, and light adjustment features on the electronic dashboard. She is also the team webmaster, responsible for designing and maintaining the team’s website. Daniel DeVries is the head of the braking system, and is working on the design process of the frame and other body elements. He is also the budget manager for the team. Christine De Zeeuw is the head of the electric motor system, and is taking the lead on the battery life, power drawn, charging capabilities, and turn signal system on the electronic dashboard. Vincent Rovedatti is the head of the steering system, and is working on the design of the frame and other body elements. 9 4 Design Process 4.1 Beginning of the Year Testing In September of 2015, Team 10 was able to test drive the 2014-2015 Volts-Wagon, pictured in Figure 2. From this drive, our team identified multiple areas in which the vehicle could be improved. Figure 2: Original Vehicle (Volts-Wagon) [1] Firstly, the original steering mechanism was created from a bicycle gear and chain. The system was constructed in a way that produced a large amount of slack in the chain and led to difficulties in steering control to the point where safety concerns arose. Next, the throttle and brake system for the vehicle were manipulated by a lever placed on the floor between the front seat driver and passenger. To accelerate or decelerate, the lever was pushed forwards or backwards, respectively, which caused inconvenience on the driver, especially when paired with the steering difficulties. Third, Team 10 noticed a significant lack of braking power when taking the Volts-Wagon for a test drive. The braking system was deemed unsafe, making it a key system to be optimized on the Calvin Bolt. Finally, the floor of the vehicle was raised roughly 15 inches above the ground, with the seats only resting 4 inches from the floor, which not only restricted low-mobility passengers from sitting in the vehicle, but also created problems for anyone wearing articles of clothing such as skirts or dresses. In general, the ride was uncomfortable and a lack of vehicle safety was made apparent. 4.2 Dashboard Hardware 4.2.1 Research Electronic interactive dashboards have become a more common feature in automobiles in the past 20 years, displaying vehicle metrics such as gas mileage, tank life, and other features such as GPS. The Calvin Bolt’s electronic dashboard application aimed to have a mountable tablet or screen to display 10 metrics to the user, combining the traditional dashboard elements of a car with additional features found on other interfaces. The Honda Micro Commuter Prototype released in Japan in 2012 included a design for a tablet-based dashboard that mounted directly in front of the steering wheel. As seen in Figure 3, this electronic dashboard had many of the same design elements of the Calvin Bolt’s dashboard: this tablet dashboard encompasses all traditional automobile dashboard elements into one location with the speedometer being a primary feature. The touch screen nature of the tablet allows the user to select different options and view different data if necessary. Honda used a Samsung Galaxy Tablet for their dashboard display. Figure 3: The Honda Micro Commuter Digital Dashboard Tablet [2] The Honda Micro Commuter Prototype’s digital dashboard design provided one layout design for the various dashboard elements, and allowed the team to get a better sense of how to design the interface and think about the pros and cons of different dashboard displays. 4.2.2 Alternatives Three main alternatives were considered for the layout and corresponding hardware: a tablet device alone, a traditional car dashboard display (gauges and meters), and a combination of a tablet device and traditional car dashboard displays. Table 1 outlines the pros and cons of each alternative. After considering the various advantages and disadvantages of each alternative, the team determined that a singular device was the most important criteria for two main reasons: the time and financial resources of the team are limited and spreading the information out among multiple devices would require complicated intercommunication, and the use of an electric motor eliminates common traditional dashboard displays or gauges such as fuel or gas mileage. Therefore, the team decided to pursue a singular tablet device to contain all of the elements of the electronic dashboard. 11 Table 1: Comparison of Dashboard Layout Alternatives Tablet Device Only Traditional Dashboard Display Tablet and Traditional Dashboard Display Centrally located(all information in one place) Most natural for the user Ability to show blinker lights with traditional LEDS Pros Have traditional display in front of the steering wheel One device to control Cons Smaller area to place all the information Need multiple screens or gauges Spreads information out in car interior Driver may need to operate/touch to get certain information (safety concern) Not all of our metrics can be displayed with traditional gauges Multiple screens/devices to display information Needs to be mounted where driver can see it Takes up more space (multiple components) Both a Raspberry Pi and Arduino microprocessor were considered as a platform for the electronic dashboard system. For the Raspberry Pi, noticeable advantages for the Calvin Bolt included: cost, the graphical user interface (GUI) and embedded display cooperation, and programming in Python. On the other hand, an Arduino also offered some appealing advantages as well: convenience of sensor collaboration, donation accessible to team, and programming in C/C++. 4.2.3 Decisions Based off of the research findings between the two platforms, it was determined that the best option for The Calvin Bolt was to incorporate both the Raspberry Pi and Arduino. The team plans to optimize on the ease of user interface development with the Raspberry Pi and the effectiveness of the Arduino’s sensor readings and data computation. Moving forward, Team 10 plans to begin programming on both platforms to produce a user-friendly interface for the Calvin Bolt. Various sensors and other devices will be utilized to record data, which an Arduino will read and compute, sending the results to a Raspberry Pi. The Raspberry Pi will then connect the collected data to a variety of displays in a full screen graphical user interface. 12 4.2.4 Testing An Arduino was donated by Andrew De Zeeuw, a member 2012/2013 Team 13, which will allow the team to begin testing the device before the end of the fall semester and begin writing preliminary code for the sensors and system. Complete testing of the compound system will involve collecting sensor data and determining the accuracy and efficiency of the translation to the display. To ensure the tablet system is suitable and transparent to the user, subjects not involved in the programming will also test the system. 4.3 Dashboard Features 4.3.1 Research One of the key features Team 10 hopes to integrate into the electronic dashboard is a battery life display: this feature will let the user know how much charge their previous trip has drawn and how much charge remains in the batteries before the batteries will die. Traditional voltmeter and ammeter measuring techniques were researched to determine if they could properly find the voltage and current drawn from the batteries. Portable handheld voltmeters and ammeters cannot handle the surge of current given by the motor while it is running. Typical handheld voltmeters and ammeters have a 20A limit since they are commonly used for small circuits and batteries when the motor is not running. The electric motor used by Calvin Bolt runs at 100A continuously or at 300A for one minute, exceeding the capacity of a standard voltmeter or ammeter. Research into the Alltrax SPM48400 controller revealed that it has measurement capabilities of various motor metrics, including battery voltage, battery current, motor voltage, and motor current. Power, which can be converted into horsepower, can be calculated from current and voltage, providing a viable option for satisfying the battery life display feature. The speedometer will be one of the main components to the electronic dashboard display. A vehicle speed sensor is one of the fundamental components to determining the current speed. The vehicle speed sensor outputs a 5 vdc square sine wave revealing the number of times a part of the drive train rotates per mile. Once the number of pulses in the sine wave is counter per second, a simple calculation can be conducted to determine the number of pulses per mile and ultimately the miles per hour travelling speed. Team 10 also desires the current time and outside temperature to be included as features for the dashboard. By using a simple sensor and connecting it directly to an analog pin in the Arduino, simple code can be performed to convert the readings to a temperature that can then be sent to the Raspberry Pi and display. With the idea that the Calvin Bolt will be a campus vehicle, the team hopes to incorporate a campus map in the display, allowing the passengers the ability to track where they are located on campus. A GPS module to store current position data can then be sent to the Arduino to be calculated. 13 Prioritized as a secondary feature to the Calvin Bolt, a lighting system is also being considered. The original vehicle incorporated an under glow lighting affect, which is something the Calvin Bolt team would like to expand on as time allows. This feature is being considered because of the desire for the Calvin Bolt to be a college campus vehicle that will be aesthetically pleasing and inspire interest in Calvin College and more specifically, Calvin Engineering. The Phillips Hue is a personal wireless LED lighting system that has a variety of applications. Further research into this product revealed that in order to connect the controller to the lights, a bridge transmits a basic web server using a modified open source linux firmware. This is something that could be achieved through the Arduino, therefore cutting down on costs compared to purchasing the product. 4.3.2 Alternatives Two alternatives were considered for the battery life feature. The first alternative was the Alltrax controller for the electric motor. The controller software has the option to save trip data to a file, storing data points for the battery and motor voltage/current either continuously or discretely. The controller requires the use of a computer-type device that can both run Windows 7 and download a software package approximately 5,000 MB in size. The controller can be connected to the computer through a USB A Male to USB B Female cord. After learning that the Alltrax controller requires the computational power and software in Windows 7 and may not feasible for the Calvin Bolt, investigations into another alternative was required. This second alternative consists of a combination of sensors to gather speed and distance information to calculate the approximate power drawn by the motor during a trip. The calculations completed in Appendix B determined the average energy draw per trip from the battery pack using the average velocity, distance travelled, and average power calculated using force and velocity. A velocity sensor and a GPS device could provide the velocity and distance parameters required to calculate the power drawn from the battery for that particular trip. Team 10 has considered a range of methods for allowing the users of the Calvin Bolt to best navigate campus. One option is to allow the system to continuously update the current location to the display device. Another option is to pre-store a list of coordinates in relation to a grid on the campus map so that the current location data could be compared to these coordinates, thus updating the display with the vehicle location at the closest pre-set location point. A few alternatives for the lighting of the Calvin Bolt include: reinstalling the original red LED strip, creating an Arduino-controlled system for the Philips Hue or other LED lights, installing the Hue or a comparable lighting system and phone app. Team 10 will continue research and testing on the best alternative for vehicle speed sensors and temperature sensors to be used for the Calvin Bolt. Main considerations for these decisions will include: price, effectiveness, and durability to various temperature and weather conditions. For the Calvin Bolt’s lighting system design, the Arduino will be used as a controller, paired with the LED lights and the GUI user-interface. 14 4.3.3 Decisions The team decided that the second alternative would be the most feasible option for the team. Since the Alltrax controller has strict limitations on what software and hardware it requires, the team felt that time would be better spent on the second alternative rather than the first. In the spring semester, the team will try to determine a relationship between the variables of velocity, distance, and possibly forces that will produce the same results as the controller. The Alltrax controller will stay play a crucial role for this alternative as it will be used as a verification of the results gathered through other sensors. Calculations of the power drawn done by the selected alternative can be compared to the values generated by the controller, allowing the selected alternative to have a solid verification system. 4.3.4 Testing Calvin Bolt will begin testing various sensors during Interim term, working through various calculation methods to determine the power drawn from the battery. Complete testing of this feature will involve driving the vehicle with the controller taking data at the same time as the sensor package, comparing the two metrics and making adjustments when necessary. Regarding the campus map feature of the Calvin Bolt, Team 10 plans to conduct further research into the feasibility of a continuously updated location to the display. The accuracy of a GPS module with buildings in such close proximity throughout campus will be a large factor in design. 4.4 Brakes 4.4.1 Research One of the most frequently used and most important systems in any vehicle is the braking system. The braking system needs to stop the vehicle effectively and reliably every time the operator engages the system. A failure to do so can result in serious injury and destruction of property. In order to avoid this, Team 10 researched various methods of braking to determine which type of braking system would be best for implementation in the Calvin Bolt. The alternatives were evaluated for effectiveness as well as how well they met the design norms Team 10 designed around. 4.4.2 Alternatives Two categories of alternatives were considered within the scope of the Calvin Bolt braking system. The first set of alternatives was the type of brake mechanism and the second set was the method of brake actuation (the method by which the vehicle’s operator engages the brakes). Two types of mechanisms employed in commonly used brake systems are drum brakes and disc brakes. Drum brakes have spring-loaded shoes which expand within the drum and bring the outer cylinder to a stop, as shown in Figure 4. 15 Figure 4: Drum Brake Diagram [3] Disc brakes on the other hand have a disc, or rotor, attached to the vehicle’s wheels or axle. Upon actuation, brake pads are engaged on the outside of the rotor to bring the vehicle to a stop as shown in Figure 5. Drum brakes tend to be less expensive while disc brakes generally provide superior braking force. Figure 5: Disc Brake Diagram [4] Two common methods of actuation were considered; cable and hydraulic. Pneumatic actuation also exists but generally only for large, heavy vehicles. Cable actuated brakes cost less but suffer from cable stretch which makes the brakes less effective over time. Hydraulic systems cost more and have more working parts, but provide stronger, more reliable braking. 4.4.3 Decisions Team 10 decided to employ hydraulic disc brakes on the Calvin Bolt. Although hydraulic disc brake systems cost more than other systems, this braking system was selected because it provides the maximum 16 braking abilities and thus the safest vehicle possible (from the perspective of braking). The hydraulic disc system will be a major upgrade from the cable actuated drum brake system used on last year’s VoltsWagon. The Volts-Wagon suffered from a severe lack of braking power, which made the vehicle hazardous to operate. Implementing hydraulic disc brakes on the Calvin Bolt will meet this need and fulfill the standards of trust and integrity Team 10 seeks to integrate into the Calvin Bolt. Due to the somewhat expensive nature of hydraulic disc brake systems, Team 10 will determine the feasibility of acquiring mostly used parts for use on the Calvin Bolt. The major components for a hydraulic disc brake system are the fluid master cylinder, discs, calipers, brake pads and fluid lines. Team 10 believes that all of these components, except the brakes pads and fluid lines, can be salvaged from used systems. The Calvin Bolt system will employ as many of these components used as possible. 4.4.4 Testing The braking system will need to be tested once the initial prototype has been fully constructed. In order to verify that the braking system meets the stopping requirement presented earlier the vehicle will be brought to top speed and then brought back to a complete stop in a variety of manners. The vehicle will need to be able to achieve a complete stop under both slow controlled conditions (similar to normal braking conditions) and quick response conditions (such as encountering an unexpected obstacle in the road). Depending on the vehicle’s performance through these tests the braking system will either be established as a working system or will be updated to better achieve the goals of the Calvin Bolt. 4.5 Steering 4.5.1 Research A very important system in any vehicle is the steering system. The steering system needs to turn the vehicle effectively and reliably every time the operator uses the system. To satisfy this requirement, Team 10 researched various methods of steering to determine which type of steering system would be best for implementation in the Calvin Bolt. The alternatives were evaluated for effectiveness as well as how well they met the design norms Team 10 designed around. 4.5.2 Alternatives Two alternatives were considered for the steering mechanism for the Calvin Bolt; rack and pinion, and recirculating ball steering. These are two purely mechanical steering systems both used in cars and trucks today. Rack and pinion systems are the most common style found in cars and trucks today due to their reliability and ease of implementation. 17 Figure 6: Rack and Pinion System [5] Recirculating ball steering is also used in cars and trucks, but is generally meant for heavier vehicles that are harder to steer and require a lot of moving parts to work. Recirculating ball steering provides ease of steering above the level provided by a rack and pinion steering system. Figure 7: Recirculating Ball Steering [6] 4.5.3 Decisions The team decided that the rack and pinion system’s reliability trumped the recirculating ball steering. The rack and pinion system best met Team 10’s goal to provide the customer with a product they can trust and be confident in. Since recirculating ball steering is also for heavier vehicles, the team didn't think it was necessary and thought it would ramp up the price too much to be effective in the small 4 person electric vehicle market. Team 10 strives to be clear and honest with our customer in order to make the Calvin Bolt design as trustworthy as possible. The team is also trying to be stewards by not over designing a car that uses more material to do the same work. Due to the expensive nature of modern rack and pinion systems on the market, the team decided to reuse parts from a previous senior design team “Maneuverable Mobile”. The “Maneuverable Mobile” has the same rack and pinion system that the team desires for the Calvin Bolt. The team is not expecting to use all the same parts because the design has a different set of dimensions and specs, but will modify or replicate most of the parts using the Calvin Metal Shop. 18 4.5.4 Testing The rack and pinion steering system will be tested before being put into the Calvin Bolt by making sure the rack and pinion has the correct gear ratio that provides optimal steering. After the rack and pinion system is implemented, we will test the steering again to make sure the system is stable and easy to use while driving. 4.6 Motor 4.6.1 Research The motor to be used for the Calvin Bolt is a Mars Electric Model ME0708 motor, controlled by an Alltrax SPM48400 controller. Both the motor and its controller came from the 2014-2015 senior design Team 04, the Volts-Wagon. The data sheet and performance curve for the motor can be found in Appendix A. This motor was used to propel a similar vehicle that weighed approximately 750 lbs unloaded, and approximately 1500 lbs of load weight. Since the Calvin Bolt will be made of aluminum, the vehicle weight will be approximately the same since the frame will be larger than that of the VoltsWagon. 4.6.2 Decisions The calculations found in Appendix B factored in the overall weight and forces to determine if the motor was capable of propelling the vehicle and fulfilling the design requirements of the Calvin Bolt. Another set of calculations determined if the batteries obtained by Team 10 would provide the necessary charge for the Calvin Bolt to travel 5 miles on a single charge. The formulas in these calculations were reused with permission from the 2014-2015 Team 04. The calculations show that the batteries have enough charge to complete 2.7 trips, where a trip was defined as traveling 5 miles in 30 minutes. Therefore, the vehicle can travel 13.5 miles for about 85 minutes without stopping. Trust is evident in this part of the design as there is a 5 HP buffer between the motor’s peak HP rating and the maximum HP draw required of the motor. Since the motor and controller were used for a different project last year, the motor configurations need to be investigated to determine if a redesign is necessary. Appendix C contains screenshots of the controller software package, illustrating the current settings of the controller. Further investigations over the next few weeks will determine if the values for the under/over voltages and throttle/speed curves need to be altered to better integrate into the Calvin Bolt’s design requirements. Figure 8 shows the overall schematic of the motor system, including the headlights and brake lights. A DC-DC converter powers the vehicle lighting to ensure that the lights do not draw too much power from the battery pack: the DC-DC converter pulls equal charge from each of the 4 batteries to generate a 12V output voltage to power the lighting system. The DC-DC converter also separates the lighting system from the motor circuit so that the motor will continue to operate even if the lighting system fails. This adds an additional layer of safety in the event that the lights draw too much current. 19 Figure 8: Preliminary Electrical Circuit for the Motor and Lighting Elements. Additional features that will be added to the schematic are the electronic dashboard and a turn signal system. The electronic dashboard will be utilizing a Raspberry pi as the primary component, which only needs 5 V to operate. A turn signal system will add 4 more lights, a switch, and a small flasher unit to the system and will draw upon the same DC-DC converter as the other lights in the system. As the power parameters for each circuit are solidified during the next semester, a more accurate picture of the total power usage for each device will form. However, current estimates of the power required show that the batteries will be able to supply enough power, or that additional battery power required by the circuit is minimal. The batteries will be charged by a SCH SE-1072 Series Charger Schumacher Electric Golf Lead Acid Battery Charger, which was the same charger used by 2014-2015 Team 04. The charger has the capability to charge all four batteries simultaneously through a standard 120V wall outlet. 4.6.3 Testing The motor was tested at the beginning of the year during the test ride in 2014-2015 Team 04’s prototype. The motor was fully functional at that time and has not been used since the prototype was disassembled. The motor will be tested during the build phase in the spring semester to ensure that the motor is still 20 working properly and no parts were damaged during the transfer and installation of the parts. The additional circuits will be tested as they are constructed to determine if they are functioning properly before integrating them into the overall electrical system. 4.7 Frame Design 4.7.1 Research A very important system in any vehicle is the frame system. The frame system needs to be strong under design specifications and reliable every time the operator uses the Calvin Bolt. To satisfy these requirements, Team 10 researched various methods of frame design to determine which would be best for implementation in the Calvin Bolt. The alternatives were evaluated for effectiveness as well as how well they met the design norms Team 10 designed around. 4.7.2 Alternatives Two categories of alternatives were considered within the scope of the Calvin Bolt frame design. The first set of alternatives was the style of modern car the team wanted to imitate and the second set was the material used. There were several styles of modern cars that were considered when designing the Calvin Bolt frame. The styles of modern cars included sedans, small pickup trucks, and hatchbacks. The sedan is a 4-door car with a trunk in the back to allow space for personal item storage. The team was interested in this style because it is the most common style of cars and is usually the bestselling on the market. Figure 9: Modern Style of a Sedan [7] The small pickup truck is a 2-door truck with a short bed. The small pickup design was appealing because a second row of seating could be folded into the bed of the truck allowing the Calvin Bolt to operate as both a 4-person transportation vehicle and a 2-person utility vehicle. 21 Figure 10: Moderns Style of Small Truck [8] The hatchback is a 4-door car with a “hatch” in the back to maximize room and space for its passengers. The hatchback allows for the car to be smaller than the sedan, which makes it more nimble and uses less material to make the car lighter. Figure 11: Modern Style of Hatchbacks [9] The team looked at steel and aluminum to make the Calvin Bolt. Steel is cheaper and was used to make cars back in the early 1900’s, but steel is heavier and is prone to rust out if not treated. Aluminum is lighter than steel, does not rust and is now being used to make car frames. Aluminum is more expensive, and is prone to cracking. 4.7.3 Decisions Team 10 decided to design the Calvin Bolt to imitate a modern style hatchback frame and to make the frame out of aluminum. A sedan style frame would be hard to design, use up too much material to get the same amount of people space as the hatchback style; therefore, the team decided that a small truck style frame would be unsafe for the people in the bed of the truck. 22 4.7.4 Design The frame was designed using SolidWorks as seen in Figure 12. The frame’s general dimensions are given in Table 2. The design incorporates straight-tubed aluminum piping welded together using TIG (Tungsten Inert Gas) welding. Figures 13 and 14 show the frame with body panels added. The body panel materials has not yet been chosen but will be determined in the spring of 2016 depending on the leftover budget. A mockup of the desired color scheme for the Calvin Bolt can be seen in Figure 15. The rendering was done using Forza Motorsport 5. Figure 12: Calvin Bolt Frame Design Table 2: General Frame Dimensions Length 13.5 [ft] Width 5.2 [ft] Height 4.7 [ft] 23 Figure 13: Isometric View of Calvin Bolt Frame with Panels Figure 14: Side View of Calvin Bolt Frame with Panels 24 Figure 15: Design Color Scheme for the Calvin Bolt 4.7.5 Testing Testing of the frame will be conducted by loading it with people and weights to ensure it can hold the required weight. The team is also planning on testing where the center of gravity is in the car to ensure proper weight distribution. 25 5 Business Plan 5.1 Market Competition The small electric vehicle market is well established due to the increased demand for golf-cart like vehicles in sports venues, university campuses, and senior living communities in addition to the traditional gold course. The three main competitors for the Calvin Bolt are Club Car, E-Z-GO, and Yamaha. Club Car manufactures golf, utility, and transportation vehicles that can fulfill a variety of needs. Club Car currently has about 40 base models in their stock, and is continuing to grow with an increased demand for these types of vehicles. Accessories and other parts can be added to any Club Car to make it customizable to the customer’s application. E-Z-GO manufactures primarily golf carts with a line of personal vehicles that still maintain the golf cart style and layout. E-Z-GO’s vehicles are primarily designed to carry people, lacking the hauling capabilities of certain Club Car models. E-Z-GO offers additional parts and accessories as well, ranging from audio systems to seating. Yamaha is a manufacturer of a wide range of transportation vehicles, including speedboats, snowmobiles, motorcycles, ATVs, and golf carts. Yamaha boasts a 6.7 horsepower A.C. motor in their electric golf cart models, surpassing both E-Z-GO and Club Car, who have horsepower ratings of 4.4 and 3.3 respectively. Just like Club Car and E-Z-GO, Yamaha offers a variety of additional parts and accessories to customize the vehicle. For its electric golf cart line, only two person vehicles are available; a gas motor powers all four-person vehicles. The marketing strategy for Calvin Bolt is to create a vehicle that is a cross between a golf cart and a car, making the vehicle more comfortable and accessible. In the case of mass production, the Calvin Bolt would be marketed as a product that promotes accessibility for those who have mobility challenges while maintaining a high aesthetic standard; the product would also be a cheap option for businesses looking to have a larger capacity vehicle with a larger passenger seating space than a traditional golf cart. Table 3 lists the price points of the Calvin Bolt’s major competitors based on price research for a brand new cart. Table 3: Competitor Prices for Electric Golf Carts Competitor Base Price Club Car (4 seater) $6,700 E-Z-GO (4 seater) $7,500 Yamaha (2 seater) $5,500 26 5.2 Breakeven Analysis The costs for the materials and labor to construct the Calvin Bolt was researched and can be found in Appendix D. The team estimated that mass production of the Calvin Bolt would produce 250 units per year. The annual fixed and variable costs as well as the per-unit variable costs can be found in Table 4. The break-even analysis found that 127 units must be sold for the company to start generating a profit. Table 4: Estimated Fixed and Variable Costs for Production Cost Per Unit Annual Parts/raw materials (+10%) $2,997.50 $749,375 Labor and Burden $720 $180,000 Overhead $500 $125,000 Factory $150 $37,500 Total Variable Costs $4,368 $1,091,875 Building Rent Building Utilities Building Operating Costs Insurance Engineering Staff (with benefits) Welding Staff (with benefits) Linemen Staff (with benefits) Administration Staff (with benefits) Marketing Staff (with benefits) Finance Staff (with benefits) Total Fixed Costs Total Costs Profit Company Contingency Selling Price Profit ----------------------- $55,938.75 $34,309.1 $117,993.30 $100,000 $351,000 $236,250 $506,250 $94,500 $67,500 $67,500 $1,631,241.15 --35% margin 40% margin 20% margin $17,288 --- $2,723,116.15 ------$4,322,000 $1,598,884 27 6 Conclusion 6.1 Final Results Team 10 has found that the Calvin Bolt senior design project is feasible. The frame was successfully constructed virtually using SolidWorks software, and meets the design specifications. The electronic dashboard can be completed with technology available on the market to perform the required functionality. Additional design work will be completed by the team to ensure that feasibility is maintained during prototype construction. 6.2 Future Work The next step for Team 10 is to construct a fully functional prototype. This construction will begin with the assembly of the vehicle’s frame. All of the vehicle’s major systems (dashboard, brakes, steering, drivetrain) will be included in the prototype. The prototype is scheduled to be completed by the beginning of April, 2016 so that testing and modifications can be made before the prototype’s due date in May, 2016. Currently the team plans to do all of the construction and assembly themselves; however, the prototype’s body panels and paint job might be sourced to an outside company or individual with such expertise to reduce the time spent and increase the quality of the finish. A final decision regarding these choices will be made mid-spring 2016 based on the progress made and remaining budget. 28 7 Acknowledgements Team 10 would like to acknowledge the following people for their support, advice, and overall assistance with the Calvin Bolt. Thank you for all of your help to make this project a success! 2012-2013 Senior Design Team 17: Matt Wever, Preston Phillips, David Exoo, and Mike Vriezema – Donation of Disc Brakes 2014-2015 Senior Design Team 04: Thomas Brown, Garrick Hershberger, Jee Myung Kim, and Andrew White Ned Nielsen – Team Advisor Professor Yoon Kim – Electrical advice and wisdom Andrew De Zeeuw – Electrical advice and wisdom – Donation of Arduino Unit Phil Jasperse – Metal shop supervisor Megan Schroder – Photographer for Team Picture Gino Berlin – Assistance with exterior aesthetic design Team 10 would also like to thank all of our friends and family for their constant support and interest in the project’s success. 29 8 Works Cited [1] < http://www.calvin.edu/academic/engineering/2014-15-team04/progress.html> [2] Lim, Anthony. "Honda unveils Micro Commuter Prototype EV." paultan.org. Ed. Paul Tan. Driven Communications Sdn Bhd, 14 Nov. 2012. Web. 15 Oct. 2015. <http://indianautosblog.com/2012/11/honda-micro-commuter-ev-prototype>. [3] "What is Brake Hardware." Quality Brake Hardware Matters. N.p., 2015. Web. 20 Oct. 2015. <http://www.completebrakejob.com/what-is-brake-hardware> [4] Sclar, Deanna. "How to Check Disc Brakes for Dummies." Auto Repair for Dummies. for Dummies, 2015. Web. 27 Oct. 2015. <http://www.dummies.com/how-to/content/how-to-check-discbrakes.html> [5] Wright, Lance. "Rack and Pinion Steering." Auto Repair Help. N.p., 2015. Web. 18 Oct. 2015. <http://www.auto-repair-help.com/automotive_maintenance/rack_pinion.php> [6] Nice, Karim. "How Car Steering Works." How Stuff Works. N.p., 2015. Web. 22 Oct. 2015. <http://auto.howstuffworks.com/steering3.htm> [7] Padgett, Marty. "2008 Toyota Corolla Review." The Car Connection. N.p., 29 May 2008. Web. 29 Oct. 2015. <http://www.thecarconnection.com/overview/toyota_corolla_2008> [8] "Photos and Videos: 2014 Toyota Tacoma Regular Cab Pickup Colors." Kelley Blue Book. N.p., 2008. Kelley Blue Book. Web. 3 Nov. 2015. <http://www.kbb.com/car-colors/2014-toyota-tacomaregular-cab-pickup-colors/> [9] Ford Fiesta ST. Sandicliffe, 2015. Web. 26 Oct. 2015. <http://www.sandicliffe.co.uk/ford/st/fiesta-st> [10] "ME0708 Brush-Type DC Motor." Motenergy. N.p., n.d. Web. <http://www.motenergy.com/me0708.html>. [11] "SPM Series & Perm Magnet Motor Controller." Alltrax. N.p., n.d. Web. <http://www.alltraxinc.com/Products_SPM.html>. 30 9 References "Building a Digital Speedometer." Sparkfun. N.p., 9 Mar. 2009. Web. 15 Oct. 2015. <https://www.sparkfun.com/tutorials/123> McMillan, Matthew. "Arduino - Digital Speedometer." matthewmcmillian.blogspot.com. N.p., 3 Feb. 2014. Web. 15 Oct. 2015. < http://matthewcmcmillan.blogspot.com/2014/02/arduino-digitalspeedometer.html> Bruce, James. "How to Control Philips Hue Lights from an Arduino (and Add a Motion Sensor)." makeuseof. N.p., 10 Apr. 2015. Web. 25 Oct. 2015. <http://www.makeuseof.com/tag/controlphilips-hue-lights-arduino-and-motion-sensor/> meethue.com. Philips, n.d. Web. 25 Oct. 2015. <http://www2.meethue.com/en-us/about-hue/what-huedoes/> adafruit. Philips, n.d. Web. 29 July 2012. <https://learn.adafruit.com/tmp36-temperature-sensor/using-atemp-sensor> "Connecting a Parallax GPS module to the Arduino." Arduino Playground. N.p., n.d. Web. 18 Oct. 2015. <https://playground.arduino.cc/Tutorials/GPS> Cooper, Tyler. "DS1307 Real Time Clock Breakout Board Kit." adafruit. N.p., 29 Jan. 2013. Web. 28 Oct. 2015. <https://learn.adafruit.com/ds1307-real-time-clock-breakout-board-kit/overview> Croft, Brock. "How to Display the Time for your Arduino Clock Project." Arduino Projects for Dummies. for Dummies, n.d. Web. 29 Oct. 2015. <http://www.dummies.com/how-to/content/how-todisplay-the-time-for-your-arduino-clock-pro.html> Borque, Brad. "Arduino vs. Raspberry Pi: Mortal Enemies or Best Friends?." Digital Trends. N.p., 8 Mar. 2015. Web. 12 Oct. 2015. <http://www.digitaltrends.com/computing/arduino-vs-raspberry-pi/> Hollingworth, Gordon. "The Eagerly Awaited Raspberry Pi Display." Raspberry Pi. N.p., 8 Sept. 2015. Web. 15 Oct. 2015. <https://www.raspberrypi.org/blog/the-eagerly-awaited-raspberry-pidisplay/> "Raspberry Pi 7" Touchscreen LCD Display." MCM Electronics. N.p., 2015. Web. 15 Oct. 2015. <http://www.mcmelectronics.com/product/83-16872?scode=GS401&utm_medium=cse&u> Wright, Lance. "How to Add Turn Signals and Wire Them Up." Auto Repair Help. SBI, 2015. Web. 18 Oct. 2015. <http://www.auto-repair-help.com/automotive_maintenance/rack_pinion.php> "Formulas for Quick Calculation of Horsepower and Power." iProcesSmart. N.p., 2008. Web. 1 Nov. 2015. < http://www.iprocessmart.com/techsmart/formulas.htm> Club Car. Ingersoll Rand, 2015. Web. 26 Oct. 2015. <http://www.clubcar.com/us/en/home.html> E-Z-GO. N.p., 2015. Web. 18 Oct. 2015. <http://www.ezgo.com/> Yamaha Golf Cars. Yamaha, 2015. Web. 18 Oct. 2015. <https://www.yamahagolfcar.com/ 31 10 Appendices Table of Contents Table of Contents ........................................................................................................................................ 31 A. Electric Motor and Controller Documentation..................................................................................... 32 a. Motor Drawing .................................................................................................................................. 32 b. Controller Wiring Diagram ............................................................................................................... 33 B. Calculations .......................................................................................................................................... 34 a. Speed, Force, and Power Calculations .............................................................................................. 34 b. Battery Charge/Energy Calculations ................................................................................................. 35 C. Current Alltrax SPM48400 Controller Settings ................................................................................... 36 D. Production Costs .................................................................................................................................. 38 E. Budget Tracking ................................................................................................................................... 39 F. Gantt Chart............................................................................................................................................ 41 32 A. Electrical Motor and Controller Documentation a. Motor Schematic 33 b. Controller Wiring Diagram 34 B. Calculations a. Speed. Force, and Power Calculations 35 b. Battery Charge/Energy Calculations 36 C. Current Alltrax SPM48400 Controller Settingss 37 38 D. Production Costs Table 5: Production Cost Estimates Item Cost Building Rent $3.75/sq. ft. for 14,917 sq. ft. Building Utilities $2.30/sq. ft. for 14,917 sq. ft. Building Operating Costs $7.91/sq. ft. for 14,917 sq. ft. Insurance $100,000 per year Engineering Staff 3-5 engineers @ $65,000/yr each Administration Staff 1 @ $70,000/yr Marketing Staff 1 @ $60,000/yr Labor and Burden 12.50/hr per worker – 8-10 workers Annual Units sold 1000 39 E. Budget Tracking Table 6: Budget Tracking and Parts Costs Item Cost -- Painting Equipment or Contractor $100 -- Floor Material $15 -- Grill / Front Styling $35 -- Front Wheel mounts $35 -- Door System $25 -- Wheels $150 -- Metal or polymer? for panels $10-50 -- Headlamps $45 -- Aluminum for frame $55 -- Rack and Pinion Steering Assembly $150 Brake System -- Calipers / pads /rotors $150 -- Hydraulic lines $30 -- Hydraulic fluid $10 -- Master Cylinder & Pedal $100 Lights -- Switch $10 -- Flasher Unit $15 -- Wiring $ FREE -- Turn signal lamps $ 10-20 -- Lamps $ FREE Dashboard -- Screen $60 -- Processor $45 -- Sensors $100 -- Wiring $ FREE Suspension -- Interior Components $20 -- Steering wheel $20 -- Seats $100 40 Drive Train -- Pedal system $40 -- Batteries $180 -- Axle w/ transfer case $300 -- Motor $450 -- Controls $350 $2,817 Total 41 F. Gantt Chart 42 43 44