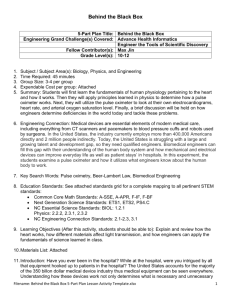

PULSE OXIMETER DISPLAY SYSTEM Final Report Taylor DeHaan, Scott Block, Nick McKee

advertisement