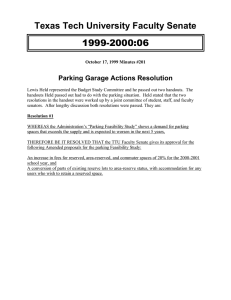

Project Proposal and Feasibility Study

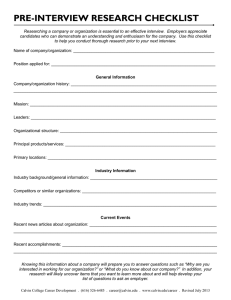

advertisement