Team 15: SolarCycle Project Proposal and Feasibility Study

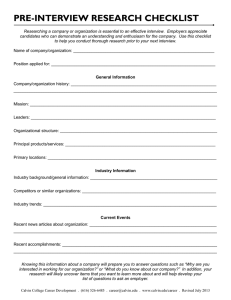

advertisement

DECEMBER 9, 2013 Team 15: SolarCycle Project Proposal and Feasibility Study Jack Amick, Matt DeYoung, Mike Houtman, Tae Lim Engineering 339: Senior Design Project Calvin College SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 2/37 12/09/2013 © 2013, Team 15 and Calvin College This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 3/37 12/09/2013 Executive Summary The United States currently faces the problem of high priced transportation fuel, as well as the destructive consequences of carbon dioxide emissions. This project proposes to resolve this problem by means of an electric powered motorcycle with solar charging opportunities. In this way the design will hold the option for both wall outlet charging in addition to a longer solar charging. This will therefore provide the option for either low cost wall charging or charging by electricity generated from solar panels. This solar charging option also frees the consumer from contributing to carbon dioxide emissions related to electricityproducing coal power plants. The team consists of four students pursuing a Bachelor of Science in Engineering with a concentration in Mechanical Engineering at Calvin College. The fall semester was spent on research and component selection while the spring semester will be put towards assembling and testing the proposed design. For this project, the design proposes a motorcycle to travel at least 25 miles at a steady speed of 25mph, sufficient for a commuter in a city such as Grand Rapids, as well as the criteria to reach a maximum speed over 30mph, in order to qualify for a state of Michigan road motorcycle licensing. Similarly, the solar charging equipment requires 80% battery charge within an 8hr time period, or a complete work day. To achieve these requirements, the motor must supply a minimum steady power supply of 5hp. The batteries must supply a total voltage of 48V, in order to comply with the controller selected, and must supply a total 40Ah to the system. The solar panel assembly must supply a total of 200W to the battery charging. For times of bad weather or little sunlight, the bike will also support charging from a standard 120V wall outlet. In order to fulfill these constraints, the motor selected is a Briggs and Stratton, 6hp continuous brushed, permanent magnet, DC motor. The batteries chosen will consist of four 12V 40Ah batteries connected in series to supply a total 48V supply power. The solar panel assembly will consist of 2 panels of 100W on the sides of the bike. This leads to a total budget request of $850 to faithfully fulfill the preceding design. This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 4/37 12/09/2013 Contents Executive Summary....................................................................................................................................... 3 1. Introduction .......................................................................................................................................... 6 a. Problem Definition ............................................................................................................................. 6 b. Design Norms ..................................................................................................................................... 6 2. Project Management ............................................................................................................................ 7 a. Team Organization ............................................................................................................................. 7 i. Jack Amick .......................................................................................................................................... 7 ii. Matthew De Young ............................................................................................................................ 7 iii. Michael Houtman .............................................................................................................................. 8 iv. Tae-Hyung Lim ................................................................................................................................... 8 3. Requirements ........................................................................................................................................ 9 a. Functional .......................................................................................................................................... 9 b. Performance ...................................................................................................................................... 9 4. Research .............................................................................................................................................. 10 5. Main Component Selection ................................................................................................................ 11 a. Motorcycle Frame ............................................................................................................................ 11 b. Electric Motor and Controller .......................................................................................................... 11 c. Battery Pack ..................................................................................................................................... 11 d. Solar Panels ...................................................................................................................................... 12 6. Task Specifications and Schedule........................................................................................................ 13 7. Design.................................................................................................................................................. 14 a. Criteria ............................................................................................................................................. 14 b. Alternatives ...................................................................................................................................... 14 c. Decisions .......................................................................................................................................... 14 8. Calculations ......................................................................................................................................... 16 9. Cost Analysis ....................................................................................................................................... 20 a. Operational Budget.......................................................................................................................... 20 b. Production Cost Estimate ................................................................................................................ 20 This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study c. Team: Document: Issue: Page No: Date: 15 PPFS Final 5/37 12/09/2013 Cost Drivers and Tradeoffs............................................................................................................... 23 d. Alternatives Available ...................................................................................................................... 24 10. Business Plan....................................................................................................................................... 25 11. Conclusion ........................................................................................................................................... 26 12. Acknowledgements............................................................................................................................. 27 13. Appendix ............................................................................................................................................. 28 a. Bibliography ..................................................................................................................................... 28 b. Calculations ...................................................................................................................................... 29 c. Solar Resources ................................................................................................................................ 32 d. Parts Documentation ....................................................................................................................... 33 This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 6/37 12/09/2013 1. Introduction a. Problem Definition With the price of oil steadily increasing, the global supply decreasing, and the impact of CO2 emissions becoming more certain, consumers are seeking vehicles with a lower fuel consumption. Currently, there are few alternatives to driving fossil fuel powered vehicles and these few alternatives are very expensive. SolarCycle's project focuses on the conversion of a gasoline motorcycle to an electric motor that runs on electricity generated from solar cells. This project aims to design an inexpensive form of transportation with zero emissions resulting from both operations and charging. The goal of the project is to design a small vehicle to be used for a short commute to and from work or school. The major appeal to this design is the low fuel cost and carbon neutrality of the operations. The primary market for this product will consist of small distance city commuters. This can be implemented for college students, high school students, businessmen, and many others for low cost, emission free transportation. The product is much more marketable in the Southern United States, providing a higher solar charging capacity as well as a longer season for comfortable motorcycle travel. b. Design Norms The team focused on three different norms when designing the product; stewardship, caring, and trust. The team considered stewardship as one of the design norms because it is important for the team to ensure proper care of the environmental by emitting no emission. Caring for the customers is important for the team because the team wanted to ensure customers’ happiness through designing quality products and personal care. Lastly, trust was another factor in the team’s design norms because ensuring safety of operators is one of the major concerns when designing a vehicle that is made to be driven on public roads. This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 7/37 12/09/2013 2. Project Management a. Team Organization SolarCycle consists of four Calvin College Seniors: Jack Amick, Matthew De Young, Michael Houtman, and Tae-Hyung Lim. All four students anticipate graduating with a Bachelor of Science in Engineering with a Mechanical Concentration. The team members are shown in Figure 2-1, below. Figure 2-1. Team Photo - Michael Houtman, Tae-Hyung Lim, Matthew De Young, Jack Amick (L-R) i. Jack Amick Jack is pursuing a Bachelor of Science in Engineering with an International Mechanical Engineering Concentration at Calvin College. He is from Lanesborough, Massachusetts. Jack is also an amateur photographer and enjoys cycling in his free time. After graduation, he plans on searching for a job in mechanical design. ii. Matthew De Young Matthew is from Dyer, Indiana, a small suburb about 45 minutes from Chicago. In his junior year at high school he decided to pursue engineering because of his skill in math and science. Matthew is currently in his fourth year of studying German and mechanical engineering. He especially enjoys thermodynamics and product design. After graduation, Matthew hopes to pursue a career in designing HVAC (Heating, Ventilation, and Air Conditioning) systems or designing alternative energy systems. This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 8/37 12/09/2013 iii. Michael Houtman Michael is a senior engineering student at Calvin College, pursuing a Bachelor of Science in Engineering with an International Mechanical Engineering Concentration. Michael is from Escondido, California in San Diego County. Michael enjoys hiking, camping, and fishing in his free time. He is anticipating searching for a position in the aeronautic industry post-graduation. iv. Tae-Hyung Lim Tae-Hyung Lim is a senior student at Calvin pursuing a Bachelor of Science in Engineering with Mechanical Concentration and a minor in mathematics. He was born in South Korea and came to the U.S. to study when he was 16 years old. He enjoys music, playing soccer, and traveling. Tae hopes to pursue a career in the automotive industry or as an engineering consultant after graduation. This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 9/37 12/09/2013 3. Requirements a. Functional The SolarCycle will be powered by an electrical motor with capability of using solar panels for battery charging. A connection for the standard 120 Voltage (V) wall outlet will also be offered to provide an alternative charging method in instances of bad weather conditions or any technical failure relating solar charging system. Solar panels will be installed with foldable brackets, to be conveniently positioned as needed. The SolarCycle will be user friendly and easy to control, since no clutch or gear shifting is necessary. The traffic lightings, including brake light, head light, and direction turn lights, will be installed to meet street legal requirements as well as to insure passenger safety. The SolarCycle will offer enough space and power for two passengers. b. Performance Travel distance of 25 miles at average speed of 25mph will be ensured for daily usage. A maximum charging time of 8 hours is designated for charging using solar panels. This corresponds to the time of a traditional, American working day. This charging is then constrained to the solar energy on an average day during motorcycle season. The safety and performance of the SolarCycle will be analyzed and tested by mathematic calculations, FEA modeling, and eventually experimental tests. Because Michigan defines a motorcycle as a two wheeled vehicle that can attain speeds greater than 30mph, and because the motorcycle will be able to achieve speed greater than 30mph, the motorcycle will be required to meet Michigan motorcycle requirements in order to operate legally on a public road. This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 10/37 12/09/2013 4. Research In the research to this design, it was discovered that many projects have previously been done to convert personal motorcycles to run on electricity. These projects were further researched to get an idea of what problems may occur in the design, what other people have done, and how to improve upon current designs. In addition, previous Calvin College senior design projects have focused on designing electric vehicles. The team will use these reports to learn more about the motor and controller now dedicated to this design. The team discovered that many projects used chain-driven motorcycles to make the conversion process simpler. Since the team acquired a shaft driven motorcycle, a linkage and driveshaft mechanism will be designed and tested. This is necessary as a reliable mechanism to connect the electric motor to the existing drive shaft. Brief research was done to determine availability of each component of SolarCycle, with required specifications for batteries and solar panels. The team was able to find and contact venders for batteries and solar panels, and are awaiting accurate price quotes. A large amount of time was devoted to the research and contact of battery suppliers. It was decided that the pursuit of lithium ion batteries should no longer be considered due to both price and safety concerns brought up by Professor VanderLeest. Instead, deep cycle marine batteries are the prime candidate to fulfill the design specifications. In addition to battery specifications, the solar assembly was researched and a solar map was found for the month of June, to be representative of the motorcycle riding season. After further research, it was determined that the power rating given to solar panels corresponds to the DC output under standard test conditions. Therefore, this design will require more efficient solar cells, in order to achieve high power rating in a smaller area. It is essential to get this power rating in a PTC rating form, or under real world conditions. In order to supplement the disassembly of the Honda 1984 Nighthawk, the service manual for this design was found available online. This document was invaluable in the removal of the motorcycle gas tank, carburetors, exhaust, and engine. In addition to the chassis documentation, the motor and controller documentation have been found available in Appendix E. The motor specifications have been found from the Etek database and the controller diagram was found from the 2002 Knight Riders Calvin College senior design final report. This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 11/37 12/09/2013 5. Main Component Selection a. Motorcycle Frame The motorcycle acquired is a 1984 Honda CB700S. This is a shaft driven motorcycle which will add some complexity to the project, but the team is confident that they will be able to design an efficient drivetrain to connect the motor to the shaft. The motorcycle is in good condition, and the frame should easily be able to support the additional electrical components. b. Electric Motor and Controller The motor and controller were acquired from the Calvin College Engineering department. These were used on a previous electric car project in 2002, The Knight Riders, and can easily be repurposed for this project. The motor is a 48V 6-horsepower (hp) continuous Briggs and Stratton Etek electrical motor with a 15hp maximum. Calculations confirming that this motor will be sufficient to power the design may be found in section 8. The controller is a custom controller designed by Briggs and Stratton to be paired with this motor. According to the report from The Knight Riders, this controller also includes automatic regenerative braking that reverses the electric poles on the motor and allows the motor to act as a generator when braking. This offers the ability to regenerate some of the power lost. The specifications on this motor and controller can be found in more detail in Appendix E, Parts Documentation. c. Battery Pack Because the motor is restricted to a voltage range of 12V-48V, the battery pack should supply this to the motor. However, after researching the controller, it was found that the controller is restricted to a 48V system. Therefore a steady supply of 48V must be used in this design. To keep the project simple, four 12V batteries will be selected and connected in series to increase the overall voltage to 48V. To achieve the requirement that the vehicle will run at 25mph for 25 miles, the batteries must supply 40 Amp-Hours (Ah) at a minimum. This is further discussed in section 8 where the calculations may be found to confirm this result. The team is currently searching for batteries to fulfill both the budget and space constraints. The final obstacle addressed is in the power supply to the instruments and lights of the vehicle. These run of a 12V system and cannot be connected directly to our 48V driving system. The team intends to remedy this through either a separate 12V battery to power this system or through the use of a DC/DC inverter to lower the voltage level before sent to the lights and instrumentation. The team favors this latter system, This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 12/37 12/09/2013 as it allows for a lumped charging system, while the separate battery system would require separate charging. d. Solar Panels As estimated in section 8, when charging four 12V batteries that are rated at 40Ah within an 8 hour period, the solar panels must supply a minimum of 210 Watts (W). This is assuming that the batteries are completely empty, and that the sun is shining directly on the solar panels throughout the entirety of the 8 hours. Therefore the calculations may be lowered to account for the unrealistic scenario, discussed further in section 8. Solar panels that will provide this much power can be found to fulfill both the constraints of the design specifications. However, these panels are very costly and therefore the power may be lowered to account for this budgetary issue. This issue has being researched further and panels with a rating of 100W will be sufficient to the designs of this project. This amounts to a combined power supply of 200W. This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 13/37 12/09/2013 6. Task Specifications and Schedule The team detailed the schedule in their Work Breakdown Schedule. Throughout the fall semester the team will focus on research, design, and component selection. At this time the team has already found a motorcycle to use as their base and an electric motor and controller to power the motorcycle. During the spring semester the team will focus on building, testing, and optimizing the motorcycle. The next stage in the design is the selection of batteries and solar panels of appropriate size and capacity to meet the project requirements. The team is currently in the process of contacting battery suppliers in an attempt to get a discount or possibly a donation of materials. Once these specifications have been selected, the team will construct a cost estimation for the project. This will be an estimation of all costs related to purchasing the components and building the motorcycle. The team also intends to analyze the mechanical components of the motorcycle using finite element analysis. This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 14/37 12/09/2013 7. Design a. Criteria The team decided on a list of criteria that the motorcycle should meet when it is completed. The first is that the motorcycle must travel a minimum of 25 miles at 25mph on a single charge. The motorcycle must also support two methods of charging, through solar panels mounted on the sides of the motorcycle and through a standard 120V wall outlet. The motorcycle must be street legal, as the desired speed of the motorcycle is too high to allow for legal travel on sidewalks. b. Alternatives The team considered a number of alternative designs to meet the criteria. One of the first design alternatives considered was whether the power from the motor will be delivered via a shaft or chain. The team also had to consider the option to use a brushless or brushed motor when designing for the motor. In addition to regular charging, the team also considered designing a system so that batteries could be easily swapped for charged ones. A hybrid system was also considered in place of a pure electric drive system. c. Decisions After discussing the alternatives, the team decided that the motor should be brushed, that power should be transmitted by a shaft, and that the easy swap battery system and hybrid concepts are not feasible. The team chose the brushed motor for budgetary and availability constraints. A permanent magnet brush electric motor was found available within the Calvin College Engineering Building for no cost. A shaftdriven power system was chosen because the motorcycle that was purchased for a base frame is shaft driven, and the conversion to a chain-driven system would require additional time for very little payout. The team decided against the easy swap battery system for the time being because the batteries have not been chosen and it is unclear if the motorcycle frame is compatible to a requirement. However this idea has not been abandoned and may be implemented after a further research of battery availability. The team also decided to discard the hybrid concept because a hybrid vehicle would not fulfill the requirement of 100% emission free drive. In addition, the motorcycle frame does not allow for both a functioning gasoline motor and a functioning electric motor with required battery bank, given the space provided. A confirmation of the space available for both the batteries and motor can be seen in Figure 7-1, below. This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 15/37 12/09/2013 Figure 7- 1: A CAD drawing of the 1984 Honda CB700s frame and motor assembly, confirming the space available This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 16/37 12/09/2013 8. Calculations The primary calculations for this design focused on the motor and battery selection process. The motor was selected based upon preliminary research of the Coefficient of Drag (CD) for a motorcycle and the Rolling Friction Coefficient (r) of the tires on pavement. Research yielded a CD ranging from 0.6 - 1.2 depending on the riding position. Similarly r was found to range from 0.005 - 0.025 for motorcycle tires on paved asphalt. In addition to these coefficients, the total weight of the vehicle (W), maximum velocity (vmax), average velocity (vavg), incline climbing velocity (vclimb), and frontal area (Ax) were used for calculating the forces applied to the motorcycle, in equations 8-1 and 8-2, resulting from air drag (Fair) and road-tire friction (Frolling). 𝐹𝑟𝑜𝑙𝑙𝑖𝑛𝑔 = 𝑊𝑟 1 𝐹𝑎𝑖𝑟 = 2 [𝐶𝐷 𝜌𝑎𝑖𝑟 𝐴𝑥 (𝑣𝑚𝑎𝑥 )2 ] [Eq. 8 − 1] [Eq. 8 − 2] Using these forces, the power required may then be calculated. This was achieved using equations 8-3, 84, 8-5, and 8-6. These calculate the power required for a steady speed under maximum velocity (Psteady), power required to overcome hills and inclines given a maximum road grade (β) of 5% (P climb), power required to accelerate to maximum velocity (Paccel), and a steady power of the motor under average velocity (Pavg). 𝑃𝑠𝑡𝑒𝑎𝑑𝑦 = (𝐹𝑟𝑜𝑙𝑙𝑖𝑛𝑔 + 𝐹𝑎𝑖𝑟 )𝑣𝑚𝑎𝑥 𝑃𝑐𝑙𝑖𝑚𝑏 = 𝑊𝑣𝑐𝑙𝑖𝑚𝑏 𝛽 + (𝐹𝑟𝑜𝑙𝑙𝑖𝑛𝑔 + 𝐹𝑎𝑖𝑟 )𝑣𝑐𝑙𝑖𝑚𝑏 𝑃𝑎𝑐𝑐𝑒𝑙 1𝑊 [2 𝑔 (𝑣𝑚𝑎𝑥 2 )] = 𝑡𝑎𝑐𝑐𝑒𝑙 𝑃𝑎𝑣𝑔 = (𝐹𝑟𝑜𝑙𝑙𝑖𝑛𝑔 + 𝐹𝑎𝑖𝑟 )𝑣𝑎𝑣𝑔 [Eq. 8 − 3] [Eq. 8 − 4] [Eq. 8 − 5] [Eq. 8 − 6] Using the inputs in the Table 8-1, the calculations confirmed the choice of a Briggs and Stratton ETEK 6hp continuous, 15hp maximum electric motor. These calculations may be found in the MathCAD document, Appendix C. This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 17/37 12/09/2013 Table 8-1: Power Equation Variable Inputs and Justification Input Variable CD Assigned Value 0.80 A conservative estimate to the range found in research r 0.02 A conservative estimate to the range found in research β 5% Maximum grade allowable for a city road or highway Ax 10.8 ft2 Preliminary measurement of frontal area for both rider and bike taccel 10 sec Iterated in order to achieve a realistic motor size Justification Calculated combined weight of frame (230 lbf), motor (30 lbf), W 630 lbf ρair 1.187 𝑚3 Density of air at standard environmental conditions (25°C, 1 atm) Vmax 55 mph Minimum speed required for highway use Vclimb 35 mph Minimum speed required for licensing of a street motorcycle Vavg 25 mph Minimum speed required for road use 𝑘𝑔 batteries (170 lbf), and passenger (200 lbf). The frontal area was calculated through a rectangular estimation of the cross section containing both the rider and motorcycle. Similarly, the weight of the motorcycle frame was measured after the removal of the engine and internal combustion components. This is seen in Figure 8-1, shown below. This rectangular estimation resulted in a frontal area of 10.8ft2 and the frame is measured at 228lbf. This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 18/37 12/09/2013 Figure 8- 1: Frontal Area Estimation of Operator and Vehicle (left) and Weight Measurements of Frame (right) In addition to the calculations for the motor selection, calculations were also performed in regards to battery selection. The battery selection calculations are dependent on the voltage and amp hour rating of the battery (Ah). Because the Briggs and Stratton ETEK motor and controller combination is a 48V system, the battery layout must provide a 48 input voltage. This will be achieved through four 12V batteries connected in series for a combined voltage of 48V. In order to obtain specifications for the desired battery Ah to be purchased (Bah), equation 8-7 was employed. This uses the inputs of system voltage (Bv), minimum required Power (Pavg), and the range of the motorcycle of 25 miles (d). The total calculations and iterated solutions to the battery sizing may be found in the MathCAD document, Appendix C. This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study 𝑃𝑎𝑣𝑔 = 𝐵𝑎ℎ 𝐵𝑣 𝑣𝑎𝑣𝑔 𝑑 Team: Document: Issue: Page No: Date: 15 PPFS Final 19/37 12/09/2013 [Eq. 8 − 7] When solving for the battery amp hours needed (Bah), equation 8-7 will provide the total necessary Ah needed for the 48V system. Because the 12V batteries must be connected in series to provide the necessary 48V input, Bah represents the minimum Ah needed for each battery to be purchased. This is primarily due to the condition of circuit current remaining constant when connected in series. Therefore if it were to become necessary to integrate batteries of a lower Ah than Bah, it would require connecting of both 12V in series and parallel wirings to achieve a higher current rating. This is not only a more complex wiring addition, but also it is not feasible to add more batteries due to space constraints on the frame. Calculations for the solar panels required to fully charge the battery system implement equation 8-8, in which the power required from the panels (Psolar) is found from the power of the batteries and the objective charging time of 8 hours (tcharging). 𝑃𝑠𝑜𝑙𝑎𝑟 = 𝐵𝑎ℎ 𝐵𝑣 𝑡𝑐ℎ𝑎𝑟𝑔𝑖𝑛𝑔 [Eq. 8 − 8] Equation 8-8 represents the necessary power rating of the solar panels in order to fully charge the system from emptied cells. This, however, is very unrealistic and it must be remembered that the system will almost never be expected to charge from completely emptied battery cells. Therefore a correction factor (Cbattery) may be added to account for this. This correction factor, Cbattery, may be assigned a value of 0.80 or 80% battery level. In addition to this over calculation, this preliminary calculation also neglects the sun coverage and view factors associated with solar charging. This represents a severe under calculation and the equation may be modified to account for the view factor relating to solar movement and availability within Michigan (Fsolar). For this factor, a solar map was implemented and can be found in Appendix D. This modification results in corrections that may be found in equation 8-9. 𝑃𝑟𝑒𝑎𝑙,𝑠𝑜𝑙𝑎𝑟 = 𝐶𝑏𝑎𝑡𝑡𝑒𝑟𝑦 𝐹𝑠𝑜𝑙𝑎𝑟 𝑃𝑠𝑜𝑙𝑎𝑟 [Eq. 8 − 9] This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 20/37 12/09/2013 9. Cost Analysis a. Operational Budget Team 15 requests $850 as its total operational budget for the academic year. This allocation corresponds to the purchase of a motorcycle chassis, batteries, battery charger, solar panels, and additional assorted electrical and mechanical components. The motor and controller were acquired free of charge from the Calvin College Engineering Department, and the motorcycle has already been purchased from a local, Craig’s List, dealer. A breakdown of the budget can be seen in Table 6-1 below. Table 6-1. Operational Budget Project Budget Description Motorcycle Motor Controller Batteries Solar Panels Other Electronics Other Parts TOTAL Budget $100.00 $0.00 $0.00 $350.00 $250.00 $75.00 $75.00 $850.00 Currently, a large part of the budget is allocated towards the purchase of deep cycle marine batteries. However, the team is also searching for alternative ways to acquire these batteries, including through a donation or educational discount. The solar panels are the other main cost associated with this budget and have been researched to provide adequate funding for two panels of the necessary power requirements. b. Production Cost Estimate If the product were to be put into large scale production and assembly, additional costs are necessary. Table 6-2, below, outlines the cost estimation for product design, components, materials, and production. Additionally, Table 6-3 includes the annual production cost, assuming 5000 bikes are made per year, and the total yearly profit assuming all bikes are sold. This includes the estimated marketing and shipping costs This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 21/37 12/09/2013 of the product. A break-even analysis was performed and it was found that approximately 200 bikes need to be sold to break-even, with a retail price of $6000. This is a ground-breaking selling price because it is similar to the price of other motorcycles, but includes the additional benefit of free solar charging. We hope that we can keep this price-point low, but understand that it may change as the future design also changes. The government also sponsors a federal tax credit 10% of the purchase cost, up to $2,500, for an electric motorcycle. This may be very appealing to any potential customers who are concerned with an expensive selling price. This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 22/37 12/09/2013 Table 6-2. Production Cost Estimation Task Frame Drivetrain Battery Mount Solar Mount Design Hours 50 50 25 25 Total Price $ 5,000 $ 5,000 $ 2,500 $ 2,500 $ 15,000 Components Component Motor Solar Panels Batteries Wheels and Steering Lights & Electrics Controller Suspension Brakes Total/Bike Price/Part $ 750 $ 350 $ 400 $ 400 $ 200 $ 300 $ 250 $ 150 $ 2,800 Materials Material Amount/Bike Cost/Bike Aluminum (lbs) 200 $ 160 Production Task Hours Price/Bike Frame (Form/Weld) 3 $ 300 Solar Mount Assembly 2 $ 200 Battery Mount Assembly 2 $ 200 Drivetrain Assembly 3 $ 300 Electrical Wiring 2 $ 200 Final Bike Assembly 2 $ 200 Paint/Detail 2 $ 200 Total/Bike $ 1,600.00 This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 23/37 12/09/2013 Table 6-3. Annual Production Cost and Profit Annual Production Cost (Assuming 5000 bikes/yr) Design $ 15,000 Components $ 14,000,000 Materials $ 800,000 Production $ 8,000,000 Shipping $ 500,000 Marketing $ 250,000 Total Cost $ 23,565,000 Cost/Bike $ 4,713 Selling Price $ 6,000 Profit per year $ 6,435,000 c. Cost Drivers and Tradeoffs Currently the project anticipates operating on a preliminary budget of $850. This has been a primary driving constraint for many of the designs we hope to implement. The most apparent of this budgetary dilemma is through the battery selection. Ideally and if put to market, the design would be best suited with a lithium-ion battery system in order to reduce weight and space required and subsequently obtain a further range with the bike. However, due to the large costs associated with lithium ion batteries the decision has been made to implement deep cycle marine batteries for the power system. This will achieve the desired energy levels for the design for a significantly lower cost of a similar lithium ion system. The tradeoff comes in the form of larger mass and more space taken up by this design. In addition to the battery tradeoff, there also exists a tradeoff in motor and controller selection. Obviously more money amounts to a larger motor and more speed. This also means an alternative cooling method, with the current system as an air-cooled motor. For this tradeoff, the design salvaged a 6hp continuous motor and 48V controller from the Calvin College Engineering Department, a $750 value. This allowed for more flexibility in the budget. The final budgetary tradeoff was mentioned previously in section 5 regarding solar panel selection. The design calls for an estimated total solar power of 200W, however this conflicts with the low budgetary constraint also placed on the design. Therefore, in order to more accurately fulfill this monetary issue, the This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 24/37 12/09/2013 design may be lowered to increase the charging time or decrease total charging capacity. This will not pose a significant alteration to the design and does not affect the feasibility of the project. d. Alternatives Available The alternatives available for this design include a reduction of the solar panel size or the addition of saddle bags to account for the battery size. However these will not be necessary, as the budget and space constraints allow for the full design to be implemented. This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study 10. Team: Document: Issue: Page No: Date: 15 PPFS Final 25/37 12/09/2013 Business Plan The complete marketing and business plan for the SolarCycle may be found on SolarCycle’s website: http://www.calvin.edu/academic/engineering/2013-14-team15/ This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study 11. Team: Document: Issue: Page No: Date: 15 PPFS Final 26/37 12/09/2013 Conclusion Thus far, the team was able to set up a detailed project design and has been successful in meeting specified deadlines. Through discussions, the team has decided to build the model with a shaft-driven brushed motor due to budget limitations and conventionality. Most of the main components have been acquired at minimal cost, and required performance calculations were conducted based on the research and specifications of the individual components. Based on the performance calculation, a total of 6.2 Mega Joules (MJ) of energy was found necessary to run the SolarCycle at average speed (25mph), which affected the group’s choice of batteries. The design was focused to ensure the operator’s safety as well as user friendliness. Therefore, the design has been deemed viable and feasible to the constraints of the Calvin College Engineering 339 senior design course requirements. Some of the tasks necessary after current scheduling include: purchasing batteries, installing electrical components, and assessing safety and performance of the prototyped model. Current schedule entails a complete breakdown of the design planning. Following a completion of the design, testing and safety measurements will be necessary to ensure a reliable product. This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study 12. Team: Document: Issue: Page No: Date: 15 PPFS Final 27/37 12/09/2013 Acknowledgements The team would like to thank the following for their support and encouragement throughout the project: Calvin College Engineering Department The team advisor, Professor N. Nielsen The Calvin College mechanics shop manager, Mr. Phil Jasperse The Calvin College electronics shop manager, Mr. Chuck Holwerda The team members’ friends and family This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study 13. Team: Document: Issue: Page No: Date: 15 PPFS Final 28/37 12/09/2013 Appendix a. Bibliography eHonda Electric Motorcycle. <http://electricfinn.wordpress.com/> "Electric Motorcycle Conversion Notes." The Renewable You, 27 May 2008 <http://www.therenewableyou.com/BattCycle_adam@try.com_08_10_04.pdf>. Kolk, Jason, Craig Mulder, R.J. Pruitt, and Matthew Thelen. The Knight Riders: Calvin College, 2002. This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 29/37 12/09/2013 b. Calculations This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 30/37 12/09/2013 This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 31/37 12/09/2013 This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 32/37 12/09/2013 c. Solar Resources This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 33/37 12/09/2013 d. Parts Documentation This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 34/37 12/09/2013 This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 35/37 12/09/2013 This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 36/37 12/09/2013 This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons. SolarCycle Project Proposal and Feasibility Study Team: Document: Issue: Page No: Date: 15 PPFS Final 37/37 12/09/2013 This document is the property of Calvin College Engineering Department Team 15: SolarCycle. This document must not be, partially or totally, reproduced without the consent of the previously mentioned persons.