Team 14: Expedition Camper Project Proposal and Feasibility Study

advertisement

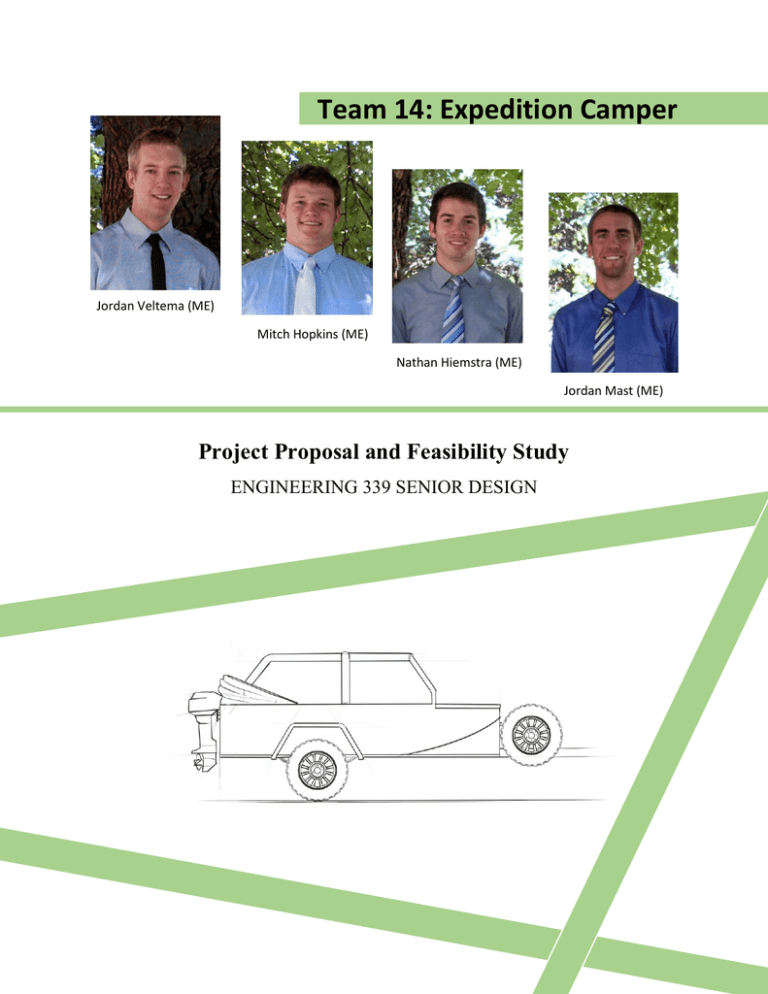

Team 14: Expedition Camper

Jordan Veltema (ME)

Mitch Hopkins (ME)

Nathan Hiemstra (ME)

Jordan Mast (ME)

Project Proposal and Feasibility Study

ENGINEERING 339 SENIOR DESIGN

2

Executive Summary

This report details the research and design of an expedition camper. The team designed this camper to be

taken off-road over very rugged terrain. The most unique aspect of this project is that the camper is designed

to also function as a boat. The camper’s complex design and robust construction allows it to be pulled over

large obstacles encountered on off-road trails, as well as to be removed from the trailer and placed into a

pond or lake so that it can traverse across water. Team Expedition Camper, otherwise known as Team 14,

has chosen this project for their senior capstone project. After completing the feasibility study, it has been

determined that the creation of this camper is indeed feasible.

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

3

Contents

Executive Summary ...................................................................................................................................... 2

Table of Tables ............................................................................................................................................. 6

Table of Figures ............................................................................................................................................ 7

1

Introduction ........................................................................................................................................... 8

1.1

The Project .................................................................................................................................... 8

1.2

Design Norms ............................................................................................................................... 8

1.2.1

Transparency ......................................................................................................................... 8

1.2.2

Integrity: ................................................................................................................................ 8

1.2.3

Trust: ..................................................................................................................................... 8

1.3

The Team ...................................................................................................................................... 8

1.3.1

1.4

2

The Class....................................................................................................................................... 9

Project Management ........................................................................................................................... 10

2.1

Project Breakdown ...................................................................................................................... 10

2.1.1

Frame Assembly ................................................................................................................. 10

2.1.2

Boat and Camper Design .................................................................................................... 10

2.1.3

Suspension .......................................................................................................................... 10

2.1.4

Hitch Design ....................................................................................................................... 10

2.1.5

Launch Mechanism ............................................................................................................. 10

2.2

Schedule ...................................................................................................................................... 11

2.2.1

Task List.............................................................................................................................. 11

2.2.2

Gantt chart ........................................................................................................................... 11

2.3

3

Team Roles ........................................................................................................................... 9

Budget ......................................................................................................................................... 12

Method of Approach ........................................................................................................................... 13

3.1

Research ...................................................................................................................................... 13

3.1.1

Hitch Research .................................................................................................................... 13

3.1.2

Trailer Research .................................................................................................................. 13

3.1.3

Boat Research ..................................................................................................................... 13

3.1.3

Camper Research ................................................................................................................ 13

3.1.4

Motor Research ................................................................................................................... 13

4 Requirements ......................................................................................................................................... 14

4.1

Safety .......................................................................................................................................... 14

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

4

4.2

Operating Conditions .................................................................................................................. 14

4.3

Functionality ............................................................................................................................... 14

4.4

Regulations ................................................................................................................................. 14

5 Project Specifications............................................................................................................................. 15

5.1

5.1.1

Size ...................................................................................................................................... 15

5.1.2

Weight ................................................................................................................................. 15

5.1.3

Durability ............................................................................................................................ 16

5.1.4

Aesthetics ............................................................................................................................ 17

5.1.5

Usability .............................................................................................................................. 17

5.2

6.

Camper ........................................................................................................................................ 15

Boat ............................................................................................................................................. 17

5.2.1

Materials ............................................................................................................................. 17

5.2.2

Shape ................................................................................................................................... 19

5.2.3

Stability ............................................................................................................................... 19

5.2.4

Launch Parameters .............................................................................................................. 24

Design Process .................................................................................................................................... 26

6.1

Tub Design................................................................................................................................... 26

6.2

Boat Hull...................................................................................................................................... 27

6.3

Top .............................................................................................................................................. 28

6.4

Windshield and Hatch ................................................................................................................. 30

6.5

Trailer .......................................................................................................................................... 30

6.5.1

Suspension Analysis ............................................................................................................ 30

6.5.2

Trailer Jacks ......................................................................................................................... 32

6.6

Strap Sizing .................................................................................................................................. 32

6.7

Manufacturing ............................................................................................................................ 33

6.8

Design Calculations ..................................................................................................................... 33

6.8.1

Hitch .................................................................................................................................... 33

6.8.2

FEA Models ......................................................................................................................... 36

6.8.3

Motor .................................................................................................................................. 39

7. Testing................................................................................................................................................... 40

7.1

Safety .......................................................................................................................................... 40

7.2

Launch Capabilities .................................................................................................................... 40

7.3

Strength ....................................................................................................................................... 40

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

5

8 User Friendly ......................................................................................................................................... 41

8.1

Detachability ............................................................................................................................... 41

8.2

Mobility....................................................................................................................................... 41

9 Business Plan ......................................................................................................................................... 41

9.1

Market Competition .................................................................................................................... 41

9.2

Break-even Analysis ................................................................................................................... 42

10 Conclusion ........................................................................................................................................... 43

11

Acknowledgements ......................................................................................................................... 43

12

Bibliography ................................................................................................................................... 44

Apendix A: EES Calculations .................................................................................................................... 45

Appendix B: Design Drawings .................................................................................................................. 47

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

6

Table of Tables

Table 1: Anticipated tasks for design and build of the Expedition Camper. .............................................. 11

Table 2: Cost Estimate ................................................................................................................................ 12

Table 3: Market Research of Expedition Camper ....................................................................................... 16

Table 4: Two capacities of typical off-road vehicles .................................................................................. 16

Table 5: Properties of common hull materials ........................................................................................... 18

Table 6: Component Weights ..................................................................................................................... 20

Table 7: Weight Calculations ...................................................................................................................... 23

Table 8: Off-road campers and their base purchase prices. ........................................................................ 42

Table 9: Cost per camper and annual fixed costs. ....................................................................................... 42

Table 10: Break Even Analysis for Expedition Camper ............................................................................. 43

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

7

Table of Figures

Figure 1: The Gantt chart above gives a visual for the anticipated schedule for our team. ........................ 12

Figure 2: Angle of list as a function of the width of the boat. .................................................................... 21

Figure 3: Distance boat lists into the water as a function of width of the boat. .......................................... 22

Figure 4: Distance Camper will sink into water based on weight ............................................................... 24

Figure 5: Camper height dimensions for launch parameter reference. ...................................................... 25

Figure 6: Dimensions and calculations to find height difference between points A and B ........................ 26

Figure 7: Approximate dimensions for Jeep-styled tub portion of camper................................................. 27

Figure 8: Approximate boat hull dimensions. ............................................................................................. 28

Figure 9: Approximate top dimensions. ...................................................................................................... 29

Figure 10: Approximate roll bar dimensions. ............................................................................................. 29

Figure 11: Leaf spring suspension system .................................................................................................. 31

Figure 12: Air bag suspension system ........................................................................................................ 31

Figure 13: Stacker jacks and scissors jacks ................................................................................................ 32

Figure 14: 501 with a 510 off-road trailer hitch by Lock N’ Roll .............................................................. 34

Figure 15: Solid works model of three axis hitch ....................................................................................... 35

Figure 16: Trailer Strength FEA ................................................................................................................. 37

Figure 17: Trailer Displacement Figure ...................................................................................................... 37

Figure 18: Boat Stress FEA ........................................................................................................................ 38

Figure 19: Boat Deflection FEA ................................................................................................................. 39

Figure 20: Preliminary design drawing. ...................................................................................................... 47

Figure 21: Side view, top down. ................................................................................................................. 48

Figure 22: Side view, top up ....................................................................................................................... 48

Figure 23: Front View ................................................................................................................................. 49

Figure 24: Top View ................................................................................................................................... 49

Figure 25: Boat removed from trailer. ........................................................................................................ 50

Figure 26: Colored side view, top down. .................................................................................................... 51

Figure 27: Colored side view, top up. ......................................................................................................... 51

Figure 28: Colored perspective view showing entrance. ............................................................................ 52

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

8

1

Introduction

1.1

The Project

Team 14, Expedition Camper, is designing and building a multipurpose recreational unit. The design allows

the trailer to have a detachable section which can be loaded into the water and driven away as a boat. The

product is aimed at outdoor, wilderness enthusiasts who enjoy the beaten trail rather than the paved road.

The unit is lightweight and durable allowing it to travel on rugged terrain. The unit is sleek, aesthetically

pleasing, as well as aerodynamic. The watercraft portion is easily detachable from the trailer and has the

ability to move through water. Optimization calculations are used to determine the best combination of all

engineering aspects.

1.2

Design Norms

As Calvin engineers in training, our team strives to uphold Christian values in the design of the unit. In

order to uphold these Christian values, the following design norms are being implemented.

1.2.1 Transparency

In order for the Expedition Camper to appeal to the greatest number of people, it is designed so that the

customer can learn to use it rather easily. The team is ensuring that the design of the Expedition Camper is

not only user friendly, but also that it holds in high regard the safety and well-being of the end user.

1.2.2 Integrity:

In order for the Expedition Camper to fulfill the design norm of integrity, it is designed to be intuitive and

easy to operate. The design is simple enough for the common user to understand how it works.

1.2.3 Trust:

The Expedition Camper itself is a good concept, but in order to meet the design norm of trust, it also has to

endure sustained use. The Expedition Camper is strong and reliable. The user will feel completely safe

when using the product.

1.3

The Team

The team consists of Nathan Hiemstra, Mitchell Hopkins, Jordan Mast, and Jordan Veltema. Each member

is studying in the mechanical concentration of engineering at Calvin College. Jordan Veltema has some

background in manufacturing, as well as experience with automotive body repair. Both Jordan Mast and

Nathan Hiemstra have worked at Innotec for the past two years and have gained experience with

manufacturing equipment. Mitchell Hopkins has grown strong in the use of design software as he has been

working with Progressive Surfaces for the past two years.

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

9

1.3.1 Team Roles

Nathan Hiemstra – Design and Manufacturing

Nathan has a large amount of knowledge with regard to manufacturing, as well as skills in sheet metal

work, welding, and fabrication of various metal products. He is in charge of managing the construction of

the prototype and is working closely with Mitchell to develop a proper prototype design that allows for ease

of manufacturing. This also includes allocating people and resources to fabricate all of the necessary parts,

welding, and subassemblies to build the prototype.

Jordan Mast – Website Design/ Team Management

Jordan has the most knowledge with respect to website design and team management, as well as a strong

knowledge of metal fabrication. He is in charge of creating and keeping the website up to date, as well as

being heavily involved with the manufacturing of the prototype. Furthermore, Jordan is tasked with

managing the team ensuring that they stay on schedule and within budget.

Jordan Veltema – Documentation

Jordan has excellent editing and documentation skills, as well as an expansive knowledge about cars and

other vehicles. He is in charge of making the final edits on all written documents done collectively by the

team, and he also is assisting in the design and building of the prototype.

Mitchell Hopkins – Design and Analysis

Mitchell has a vast knowledge of computer software design. His extensive experience with the Solidworks

software package allows him to construct a detailed 3D model of the prototype. He is in charge of creating

a complete model of the project as well as performing Finite Element Analysis of various parts or

subassemblies. He is primarily working with Nathan and Jordan Mast in order to ensure that manufacturing

of all of the non-purchased parts goes smoothly.

1.4

The Class

This project will span the entire two semesters of the team’s senior year in Calvin College’s engineering

program. The senior capstone project class challenges the students in the program to use all the knowledge

they have gained to tackle a real-world project. With the knowledge and experience our team has gained

over the past few years, the team is creating something unique and fun. Using gained knowledge, the team

is performing detailed studies and calculations to determine the best way to design and build our product.

By the end of the class, the team will have a product that will be presented on senior design night. The

team’s ability to solve complex problems will be represented by our end product.

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

10

2 Project Management

2.1

Project Breakdown

The project is broken down into five main categories, each of which have a significant role in the final

outcome of the design. The five sub-sections of the project include frame assembly, boat and camper design,

suspension, hitch design, and launch mechanisms. Each member of the team has assumed responsibility of

certain tasks, but as a whole the team is working together to make sure each is done well.

2.1.1 Frame Assembly

The frame assembly is the structural backbone of the entire unit. In order to ensure that the design is strong,

the frame needs to be built carefully. Without a rugged frame the integrity of the entire unit may be

compromised.

2.1.2 Boat and Camper Design

The boat and camper is one combined piece so that it is structurally sound. This is key for when it is being

pulled on rough terrain. It needs to be rugged in order to prevent damage or failure from constant abuse on

unpaved trails. It also is aerodynamic and aesthetically pleasing.

2.1.3 Suspension

Rugged terrain means rugged conditions. The team is analyzing different suspension systems to be used on

the trailer to reduce the impact forces on the unit itself. For structural stability, adding suspension is a big

help. In the final design the team is using either a typical leaf spring suspension system or an airbag

suspension system.

2.1.4 Hitch Design

Typical hitches do not allow for multiple axes of movement. Taking a trailer off-road brings with it the

obstacles of uneven pathways. A typical hitch only moves from side to side. For this project the team wants

a hitch that can move on multiple axes. The hitch must be able to move multi-axially. This will allow the

trailer to move more freely from the vehicle as it is being pulled over different obstacles.

2.1.5 Launch Mechanism

Having a unit that can be taken to remote areas makes conventional methods of transferring a boat between

a trailer and water hard to do. With this in mind typical boat launches will not be available for use. The

trailer needs to be specially designed for use in a non-typical boat launch scenario. The team is considering

a launch mechanism that will make transferring the boat to and from the water easier in situations where a

normal boat launch is not accessible.

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

11

2.2 Schedule

2.2.1 Task List

The following table shows the task list for the year of what needs to be completed for our project. In order

to finish the project, every item on the task chart will be addressed in some way or manor. Many of these

tasks are addressed in more detail in later sections of the report.

Table 1: Anticipated tasks for design and build of the Expedition Camper.

TASK NAME

DESCRIPTION

PROJECT MANAGEMENT

Determine our goals and estimate time for each task.

GANTT CHART

Plan for the year which will roughly be followed

RESEARCH

Research necessary for all aspects of our design.

BUDGETING

Budgeting to determine the rough cost of our project.

BUDGET PROPOSAL

Finalize total budget.

CONCEPTUAL DRAWINGS

Preliminary drawings of end product

DESIGN

Designing each component to meet engineering requirements.

FEA ANALYSIS

Perform computer simulations to test component strengths

CAMPER

Must be able to handle constant abuse from rugged terrain.

BOAT

Must be safe on water having maximum buoyancy and stability.

PPFS REPORT

Mid-Year report stating the feasibility of the project

MANUFACTURING

Final stages consist of the construction of our project.

TESTING

Final testing will be done on the product

FINAL REPORT

A final report will be issued on the website

2.2.2 Gantt chart

At the beginning of the year the team put together a list of anticipated tasks that would need to be completed.

The task list is shown previously and a Gantt chart is shown below indicating an approximation of how

each task fits within the schedule of the year.

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

12

Figure 1: The Gantt chart above gives a visual for the anticipated schedule for our team.

2.3

Budget

The following spreadsheet provides an estimation of project expenses required for building a prototype

Expedition Camper (Table 2).

Table 2: Cost Estimate

STARTING BALANCE

$ 2,255.00

COMPONENTS

Cost

Remaining Balance

TRAILER & BOAT

$ 800.00

$ 1,455.00

TROLLING MOTOR

$ 250.00

$ 1,205.00

WOOD

$ 100.00

$ 1,105.00

ALUMINUM

$ 425.00

$ 680.00

STEEL

$ 200.00

$ 480.00

ELECTRICAL

$ 75.00

$ 405.00

AIR BAG SUSPENSION

$ 100.00

$ 305.00

MISC

$ 100.00

$ 205.00

CONTINGENCY

10%

RAW MATERIALS

ADDITIONAL

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

13

3 Method of Approach

3.1

Research

3.1.1 Hitch Research

As a team, one of our first steps was to research hitch designs for our project. The goals of our project

require the design to be able to navigate over rough terrain. Typical trailer hitch designs only have one axis

of movement. Our design requires a hitch that can move in three directions, so we needed to find a way to

allow that to happen. To do this we found a design that incorporates three axes of rotation.

3.1.2 Trailer Research

The trailer did not require extensive research. A rugged camper design means that the piece carrying the

camper must be robust as well. Looking into the trailer, we determined that typical trailers, with some

modification, would be more than capable of handling rough terrain. The major strength issues come with

respect to the boat and camper, rather than the trailer.

3.1.3 Boat Research

In order to ensure that the camper can function effectively as a boat on water, research was done on the

shape, weight, and size of the boat. Initial calculations, which are also addressed later, were made to

determine how to design the boat. The team decided that a flat bottom boat, made of aluminum, would be

ideal, but finding a boat with our specific requirements may be difficult.

3.1.3 Camper Research

The camper portion of the project did not require much research. As a group, we know that the frame of the

camper must be strong and durable. Most campers are designed based on the fact that they are pulled on

paved roads, while ours will mostly be pulled off-road. This meant that the team only needed to determine

which materials would be adequate for the design.

3.1.4 Motor Research

Because the unit is able to float on water and in order to make sure the unit does not drift away with the

current; it needs a source of thrust to move through the water. In order to determine the motor that would

be required, research was done to determine what types of motors would fit the specifications of our unit.

Based on weight, size, and water displaced, a motor was chosen.

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

14

4 Requirements

4.1

Safety

The Expedition Camper is designed for one or two people. When it is being used on land as a camper, it is

properly attached to the trailer to ensure safety of the user while moving in and out of the camper. The

transfer of the Expedition Camper on and off of the trailer is simple enough for one person to do it on their

own. The procedure is straightforward and there are no steps involved that would put the operator at risk of

injury.

The Expedition Camper also is able to operate safely as a watercraft. The motor is properly mounted to the

back of the camper, like a typical out-board motor. Proper installations have been made to allow the user

to operate the motor free from any possible safety risks. When the camper is out on the water, it is stable

enough for a person to move about the camper without struggling to stay balanced.

4.2

Operating Conditions

The camper is able to be towed across all types of terrain that a Jeep or truck can travel across. The

Expedition Camper is also able to withstand weathering and impact from rocks and other rough terrain. The

operator can maneuver the Expedition Camper across the water with ease. Operating the throttle and

steering of the motor is comfortable and straightforward. The Expedition Camper also requires minimal

maintenance.

4.3

Functionality

As a multipurpose unit, the Expedition Camper functions as a camper on land and a boat in the water. The

exterior of the camper has an elegant look to it with the interior of the camper having approximately 12 ft3

of storage space for typical camping supplies. The camper also provides proper sleeping accommodations

for various types of weather. One feature of the camper is that it is able to be used on the water for

recreational activities such as fishing and duck hunting. Adding and removing the sides of the camper is

simple enough to do while out on the water. The camper is able to take on small waves while maintaining

stability.

4.4

Regulations

In order for the project to be a legal boat, there are certain equipment requirements given by the United

States Coast Guard that specify what the boat requires. In the state of Michigan there are four equipment

items that are required; personal flotation devices, a bell or whistle, visual distress signals, and a fire

extinguisher. All four of these items are incorporated into the design of the boat so that it is considered a

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

15

legal vessel in the state of Michigan. In order for the project to also be a legal camper, it must have working

tail lights.

5 Project Specifications

In designing an Expedition Camper, there are numerous factors that must be taken into account. Because

the Expedition Camper has the ability to function as both a camper and a boat, discussion of the

multifunctional aspects of the Expedition Camper was divided into two sections: those associated with the

camper portion and those associated with the boat portion. Due to the fact that they are one piece in the

actual design, these discussions somewhat intertwine and overlap.

5.1

Camper

For the camper portion of the design, defined to be the bottom tub and the top, important design factors

include size, weight, durability, aesthetics, and usability.

5.1.1 Size

The first factor researched was size. There are many different dimensions that are important in the design

of an Expedition Camper. The first group of dimensions that were determined describe the usable space

inside the camper. In order to determine acceptable interior camper dimensions, research was performed

with regard to different off-road campers currently on the market. Table 3 summarizes these interior

dimensions for three of the major off-road campers. From these benchmark examples, it was determined

that the interior of the camper should have a width of approximately 5 ft, a length of approximately 8 ft,

and a height of approximately 4 ft. Given these rough dimensions, several other factors were used to

determine more exact interior dimensions.

5.1.2 Weight

Another important factor evaluated was the dry weight of the camper. The dry weight is defined to be the

weight of the camper without the weight that would be added from additional items such as water jugs,

gasoline cans, furnishings, baggage, tools, equipment, and so on. Research of the dry weights of other offroad campers currently on the market was again used in the determination of an acceptable dry weight for

the Expedition Camper being designed. These dry weights are included in Table 3 for the same three offroad campers used for dimension criteria. From these weights it was concluded that the camper should

have a dry weight of 1500 lb., which is on the higher end of the examples provided. This is because it is

assumed that the additional boat functionality, not present in the benchmark examples, adds some extra

weight to the camper.

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

16

Table 3: Market Research of Expedition Camper

TRAILER

LENGTH

WIDTH

HEIGHT

DRY WEIGHT

[IN]

[IN]

[IN]

[LB]

80

54 or 60

45

1500

109.5

53

44.5

1250

107

54

45

1283

MOBY1 XTR1

SO-CAL TEARDROPS

THE KRAWLER

2

ADVENTURE TRAILERS

TEARDROP3

Furthermore, the dry weight and overall weight of the camper become important aspects when evaluated

according to the measure of the tow capacity of the typical off-road vehicle. Table 4 contains research with

regard to the tow capacity of several typical off-road vehicles. This research confirms the maximum dry

weight decision of 1500 lbs and also sets a requirement that the weight of the camper not exceed 2000 lbs

when fully loaded with all accessories.

Table 4: Two capacities of typical off-road vehicles

VEHICLE

TOW CAPACITY [LBS]

JEEP WRANGLER (2 DOOR, 4 DOOR)4

TOYOTA FJ CRUISER

NISSAN FRONTIER

6

5

2000, 3500

4700

6500

5.1.3 Durability

A third factor that was important to the design of the camper is durability. The camper and top are able to

withstand impact forces and heavy vibrations that it encounters given that the camper’s intended use is the

harshest of off-road environments. In order to achieve a design featuring a high level of durability, material

properties in addition to overall structural design are extremely important. Given that the boat portion of

the Expedition Camper is in the most susceptible position to be affected by the harsh environments

1

http://moby1trailers.com/moby1-xtr/

http://www.socalteardrops.com/page.php?p=22

3

http://www.adventuretrailers.com/teardrop.html

4

http://www.jeep.com/en/2013/wrangler/capability/towing/

5 http://www.toyota.com/fjcruiser/features.html#!/exterior/4702/4703/4704

6 http://www.nissanusa.com/trucks/frontier

2

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

17

experienced in an off-road setting, material considerations are discussed in the following boat section of

the report.

5.1.4 Aesthetics

The overall look and feel of the camper also play an influential role in the design. In order for the Expedition

Camper to be a competitive option for outdoor enthusiasts, the design must be aesthetically pleasing. One

of the largest groups of people for whom the Expedition Camper would appeal, would be Jeep owners due

to the Jeep’s extreme level of popularity in the off-road realm. Because of this fact, it was decided that the

Expedition Camper would do well to incorporate Jeep styling. Furthermore, with regard to marketability,

there is no Jeep-styled multipurpose off-road camper currently on the market. The absence of similar

products on the market provide a good opportunity for the Expedition Camper.

5.1.5 Usability

Another critical factor of the project, specifically with respect to the camper portion, is the ease of use. This

is especially true in its application with regard to the top of the camper. This is a crucial requirement

especially when the Expedition Camper is used in its boat function. The sides and roof of the top are easily

removable so they will not obscure the view of users when used in its boat function. To achieve this

transformable functionality, the sides and top of the camper are constructed from a vinyl/cloth material so

that they can be easily zipped out, rolled up, or folded down. This also allows users to stand up inside when

the Expedition Camper is being used as a boat.

5.2

Boat

Designing a camper with additional functionality as a boat presents several other design factors that must

be taken into account. These factors include materials, shape, and stability.

5.2.1 Materials

Correct material selection is pivotally important due to the fact that the Expedition Camper is subjected to

some of the harshest environmental conditions when put to use. Research revealed four potential candidates

for material selection: wood, fiberglass, aluminum, and steel.

In order for the end product to comply with the other design requirements, wood can quickly be eliminated.

This is because the boat portion of the camper must be capable of withstanding harsh conditions of the offroad environment, such as impact loads, abrasive contact, and constant vibrations. Not only would a

wooden hull be impractical for withstanding impacts and abrasion, it also would be susceptible to rattle

apart and therefore would most certainly develop leaks over time. Furthermore, development of a wood

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

18

hull that can withstand the conditions seen in an off-road environment would undoubtedly lead to a design

that does not fit within the weight constraints of the project.

An evaluation of the three remaining materials, fiberglass, aluminum, and steel, reveals that aluminum is

the optimal construction material for the hull of the camper. That an aluminum hull best fits the

requirements of the project is shown from several different aspects. These include strength, weight,

abrasive resistance, and cost.

From a strength point of view, low carbon steel has the highest tensile strength, as shown in Table 5.

However, because a design criterion of the project is that it must be relatively lightweight, building the

camper hull from an extremely dense material, such as steel, most assuredly will lead to an Expedition

Camper that surpasses weight constraints. On the opposite end of the spectrum fiberglass has a relatively

weak tensile strength. While a fiberglass hull could provide enough strength, the amount of fiberglass

needed to build this hull would result in an Expedition Camper that is heavier than desired. The main

interest from a design standpoint is the strength-to-weight ratio of the material. Because 40-45 aluminum

stands between fiberglass and steel with both tensile strength and density, it boasts the highest strength-toweight ratio. Therefore, aluminum is the best candidate for construction material from both a strength and

weight point of view.

Table 5: Properties of common hull materials 7

MATERIAL

TENSILE STRENGTH

DENSITY [LB/FT3]

STRENGTH/WEIGHT

[PSI]

RATIO

FIBERGLASS

18000

95-100

180-189

LOW CARBON STEEL

58000-68000

470

123-145

40-45 ALUMINUM

45000

168

230

Not only does aluminum score high in the strength and weight categories, it also has several other favorable

properties with regard to abrasive resistance and weather-ability. Aluminum is extremely robust. Unlike

fiberglass, it does not gouge or scratch easily. These material properties are extremely desirable for the

expedition camper, given that it will undoubtedly see the occasional brush of a tree branch or impact of a

stone. Additionally, aluminum ranks high in the category of weather-ability. Both steel and fiberglass are

highly susceptible to deteriorate over time. Steel corrodes quickly with the elements, while fiberglass

blisters and delaminates. On the other hand, the only concerns with aluminum are that it can develop cracks

7

http://www.trekkeryachts.com/construction.php

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

19

if cyclically loaded and not reinforced properly and that it can develop corrosion when in contact with

dissimilar metals. However, both of these are easily remedied with care. Furthermore, aluminum is fire

resistant, a valuable aspect given that the camper will be used in campfire settings.

It is true that fiberglass boats are less expensive to produce in a long-run production environment. Once

the molds have been built for the boat, an easy, repeatable process can be used to mold multiple boat hulls.

However, the capital investment costs required for good, production quality molds are staggering. With

aluminum, there are no hefty up-front costs like this required.

5.2.2 Shape

Another important factor to the boat portion of the camper is the shape of the hull. While there are a variety

of boat hall shapes that could be used, such as pontoons, v-hull, or tri-hull, it is clear that a flat bottom shape

best suites the functionality of the Expedition Camper. Unlike other boat bottom shapes, the flat-bottom

provides the lowest profile. This is important for ground clearance when traversing over rough, rocky, and

uneven terrains. It is also important from an aesthetics point of view because it is desired that the Expedition

Camper be disguised as more of a camper than as a boat. Furthermore, a flat-bottom shape allows for the

Expedition Camper boat portion to be launched in more shallow waters than any other hull shape would

offer. This is an important aspect, which will be described more in later sections given that the camper will

need to have the ability to launch without access to a ramp made specifically for launching a boat.

5.2.3 Stability

One of the biggest hurdles in the design of the boat portion of the Expedition Camper is stability on water.

Typically, small aluminum boats are known for being quite unstable on water. For example, small

aluminum boat users are often forced to stay close to the centerline of their boats due to the fact that

movement to the outer edge of the boat causes larges angles of list, or tipping into the water. In fact, these

boats can become so unstable on water that movement of large masses, such as humans, to the outer edges

of the boat can cause the boat to capsize or tip over. Therefore, one of the big areas requiring extensive

research and calculation is stability.

As previously discussed, research showed that a flat bottom boat is not only the best option from an offroad ground clearance and ease of launch-ability point of view, but also from an increased stability on water

point of view. However, there are several other factors that play a significant role in determining the

stability of a flat bottom aluminum boat. The most significant factors include the location of the center of

gravity of the boat, as well the width or breadth of the bottom of the boat.

After performing detailed research with regard to other off-road campers currently on the market, it was

determined that the width of the camper should be approximately 5 ft. Therefore, it is assumed that the

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

20

bottom of the boat hull portion of the camper should have a width that is slightly less, between 4ft and 5 ft.

In order to determine the relationship between boat stability and width, engineering relationships used in

naval architecture are required. Detailed study and research of boat stability relationships used in naval

architecture revealed that the models utilized are quite complex. Therefore, although a complex model for

stability is difficult to implement, by extensively simplifying the model, basic stability information can be

derived.

Specifically, what is of interest is the angle and distance that the boat tips, or in naval architecture

terminology, lists to one side once a person on the boat shifts to the outer side of the boat. Therefore, to

further simplify the calculation, the boat was modeled as a transverse 2D plane of the cross-section of the

boat.

Several parameters are required for calculation of boat stability; the angle or distance that the boat lists.

The first parameter is the center of gravity. In order to determine the center of gravity of the boat, the

weights of major boat components need to be taken into account as well as the weight of a person. The

weights that are assumed for each of the major components, as well as for the person, are shown in Table

6. Note that the center of gravity of the boat is the key component affecting the stability of a boat. In

essence, the lower the center of gravity of the boat, the more stable the boat is when floating and when

loads are shifted on the transverse plane within the boat. The second parameter is the center of buoyancy

of the boat that is found using relationships developed in “Ship Stability for Masters and Mates.” Using

naval architecture theory along with these two parameters and basic trigonometry, the angle of list and

distance that the boat tips when a person shifts from the centerline of the boat to the side of the boat can be

calculated.

Table 6: Component Weights

COMPONENT

WEIGHT [LBF]

BOAT SIDES

90

BOAT BOTTOM

250

MOTOR

60

FRONT, WINDSHIELD, HATCH

140

FLOOR

100

HUMAN

200

Assuming no external forces, such as waves or wind, and that the person is located at the centerline of the

boat, the boat sits transversally flat in the water with no list. In this scenario, the centers of gravity and

buoyancy of the boat are vertically aligned. However, when the person shifts to the outside of the boat, the

boat lists or tips in that direction. The boat lists in the direction that the person moves due to the fact that

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

21

the movement of the person causes the center of gravity of the boat to be shifted in that direction. The boat

has a listing moment until the center of buoyancy changes and aligns with the new, shifted center of gravity.

Under this methodology, Figures 2 and 3 were derived showing both the angle of list as a function of boat

bottom width and the distance that the side of the boat sinks into the water as a function of boat bottom

width.

20

18

Angle of List [deg]

16

14

12

10

8

6

4

2

0

30

35

40

45

50

55

60

65

Bottom Width [in]

Figure 2: Angle of list as a function of the width of the boat.

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

70

75

22

7

6

Tip Distance [in]

5

4

3

2

1

0

30

35

40

45

50

55

60

65

70

75

Bottom Width [in]

Figure 3: Distance boat lists into the water as a function of width of the boat.

From Figures 2 and 3, it was determined that a boat bottom width of somewhere between 4 ft and 5 ft should

not be an issue from a stability standpoint. Ideally, the boat would be designed with a bottom width closer

to 5 ft because of the added stability shown by Figures 2 and 3. With the boat designed as such, if a person

moved from the centerline of the boat to the outer edge of the boat, an angle of around 6 degrees would be

incurred, resulting in a 3 inch downward shift into the water. It is deemed by the team that this is an

acceptable displacement.

Finally, it is worthwhile noting that the calculations performed are an extensively simplified theoretical

approximation of the actual situation.

In the realm of modern naval architecture, advanced and

sophisticated computer modeling is used to model and evaluate the stability of boats in all planes and axes

of motion under an extremely large number of conditions. While the model used to derive Figures 2 and 3

is very basic, after correlating these calculations with information provided by boat owners with similar

size boats, the calculations appear to provide an acceptable approximation of the actual situation.

Because one of the major constraints for the Expedition Camper is that it must be lightweight, an

approximate analysis was done to determine the overall weight of both the camper and the trailer. The first

part of Table 7 shows the approximate weight of major components on the camper and boat portion of the

Expedition Camper. Note that this is a dry weight, meaning, it does not include accessories such as

furnishings and other equipment and supplies. The second part of Table 7 shows the approximate weight

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

23

of the trailer portion of the Expedition Camper. The importance of this analysis lies in the fact that it shows

that the project is feasible from a weight standpoint. As an estimate, the team saw that the weight of the

camper portion of the Expedition Camper is less than the max design constraint of 1500 lbs. Furthermore,

the total weight of the camper is less than the max tow capacity of 2000 lbs, from Table 4, of the typical

vehicle that would tow the Expedition Camper. Finally, note that these values are very conservative. In

actuality, they will likely be lower.

Table 7: Weight Calculations

Assembly

Component

Material

Weight [lb]

Hull

Aluminum

400

Base

Aluminum

150

Top

Steel/plastic/cloth

50

Steel/cloth

100

Floor

Wood

100

Hatch

Steel/glass

60

Wall/windshield

Steel/glass

80

Outboard motor

N/A

60

Battery

N/A

30

Fuel Tank

N/A

30

Boat/Camper

Rollbar

Sum

1060

Trailer

Trailer frame

Steel

400

Leaf springs

Steel

60

Shocks

Steel

10

Jacks

Steel

30

Steps

Steel

15

Hitch

Steel

10

Wheels/tires

N/A

125

Sum

650

Sum

1710

Total

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

24

5.2.4 Launch Parameters

An important aspect that was considered in the design of the Expedition Camper are factors affecting how

it is launched into the water. Typically, a boat launch or ramp is used to put a boat into the water. The

purpose of the boat launch is that it more quickly increases the depth of the water with respect to distance

from the edge of the body of water. In other words, a boat launch allows a boat to be easily removed from

its trailer. However, the Expedition Camper has capability of functioning on bodies of water, way out in

the wilderness, where no boat launches are present. The Expedition Camper, therefore, is designed to

launch without a boat launch.

One factor that aids the launch process of the Expedition Camper is the flat-bottom profile of the hull. This

profile allows the camper to be launched in relatively shallow bodies of water. Basic buoyancy calculations

reveal that that the camper requires a depth of approximately four inches to float. Figure 4 shows the

relationship between the distances that the camper sinks into the water and the weight of the camper. Note

that this calculation assumes a bottom area of the camper of approximately five feet wide by 10 feet long.

The Expedition Camper sits relatively high off the ground for traversing rough terrain, but it was also

required that the camper needs to be low to the ground for ease of launching it into the water. A proposed

solution to these height differences is installing an adjustable airbag suspension in place of a leaf-spring

suspension. Not only would this type of suspension provide the adjustability necessary, it would also

provide a smoother ride for traversing rough terrain. Note that these suspension options will be discussed

more in a later section of the paper.

2500

Depth [in]

2000

1500

1000

500

0

0

1

2

3

4

5

Camper Weight [lbs]

Figure 4: Distance Camper will sink into water based on weight

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

6

25

Since the launch sites that will be used are not going to be typical boat launches, certain launch parameters

needed to be met in order to perform a successful launch. Due to the large off-road tires being used, the

Expedition Camper sits high on the trailer, approximately two feet above ground. Assuming a scenario

where the trailer enters the water with the bottom of the lake being flat, the Expedition Camper requires a

minimum water depth of 28” for a successful launch. Below is a schematic of the camper showing the

dimensions of the camper launch requirements. The water level after launch is the water line that the camper

floats at when in the water.

Figure 5: Camper height dimensions for launch parameter reference.

As previously mentioned, the worst case scenario is a flat lake bed, requiring a 28” depth of water at the

tires to launch. This scenario is very unlikely, as most lake bottoms have a grade to some extent. The

distance from the hitch of the trailer to the wheel axle is 10’, and the distance from the wheel axle to the

back of the camper is 4’. Based on these dimensions, a one degree incline of the lake bottom results in the

back of the camper being approximately 2.93” below the hitch height. Furthermore, each additional degree

of incline drops the back of the boat another 2.93”. In regards to the degree of incline, the back of the

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

26

camper drops 0.84”/degree below the camper height in line with the trailer axle. Figure 6 shows the

dimensions used and calculations performed in obtaining these values.

B

A

Y

X

120”

θ

48”

For θ=1 degree:

Y = 120” x sin (1) = 2.09”

X = (120” + 48”) x sin (1) = 2.93”

X – Y = 0.84” therefore for every degree incline, the change in height between locations A and B is 0.84”

Figure 6: Dimensions and calculations to find height difference between points A and B

For example, if the lake bottom has a ten degree incline, the back of the camper is 8.4” below the front in

line with the tires. Due to this, any incline greatly increases the ease of launching the camper. The back of

the camper sits lower compared to the rest, and therefore enters the water first and reduces the upward force

that the camper is experiencing from the trailer bunks.

Design of the expedition camper focuses on compiling the different design decisions that have been made

through both research and engineering analysis. While all components of the design fit together as one

unit, to simplify the design process, the camper will be split into several major components. The major

components of the expedition camper include the boat hull, the tub, the top, and the trailer. Each of these

components is detailed in the following sections.

6.

Design Process

6.1

Tub Design

The tub design of the camper is one of the most crucial components. This is due to the fact that it stands at

the core of the Expedition Camper. Not only does the tub portion form what would be thought of as the

camper portion, the place where the living space is found, it also is the general aesthetic makeup of the unit

making it look more like a camper than a boat. The tub has a width of 59 in and a length of 100 in. Note

also that these tub dimensions are the same as those found on a Jeep Wrangler (years 1997 through 2006),

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

27

thereby fulfilling the criteria that the camper is aesthetically pleasing. Furthermore, a camper tub shaped

and dimensioned after the Jeep Wrangler gives opportunity for other Jeep-based accessories to be applied

to the camper, such as tops. Figure 7 below shows the overall styling as well as approximate dimensions

for the tub portion of the camper.

Figure 7: Approximate dimensions for Jeep-styled tub portion of camper.8

6.2

Boat Hull

As previously determined, a flat bottom shaped hull provides the best options from a variety of different

perspectives, including ground clearance, ease of launch, and increased stability on water. Furthermore, a

flat bottom boat lends itself to easier manufacturing due to the fact that it does not require the formation of

complex shapes. An additional advantage of a flat bottom hull shape is that the shape and form allows for

easier adaptation of a camper, due to the simple rectangular shape of the top rails that a flat bottom boat

hull provides. The boat hull of the camper is designed around the dimensions of the tub portion of the

camper, detailed in the previous section. Figure 8 shows approximate dimensions chosen for the boat hull,

which coincide closely with the dimensions desired for the tub portion of the camper.

http://s213.photobucket.com/user/jscherb/media/Camper/DinootWide1_zpsf2cd9bcf.jpg.html?sort=3&o

=145

8

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

28

Figure 8: Approximate boat hull dimensions.9

6.3

Top

Another key component in the design of the Expedition Camper is the top. The top of the camper must be

easily removable to allow for standing of occupants when the camper is used in its boat configuration.

However, not only does the top need to be easily removable, it also must be lightweight in order to satisfy

the weight constraints of the design. Under these criteria, it was determined that a top made of waterproof

cloth would be the best option, both from a lightweight and a simplicity point of view. Since the team

desires to incorporate Jeep-styling into the design, a Jeep soft top is the logical solution because it satisfies

all design constraints. While some modifications to the top are required to fit the exact application, the

Jeep soft top is the perfect candidate. A 2004-2006 Jeep Wrangler LJ soft-top fits with the current design

dimensions and would only require modification of the side windows. Furthermore, the soft top involves

a framework that allows it to be easily removed by folding down. On a Jeep Wrangler, this framework is

connected to the roll bar. While a new framework and mounting system could be constructed to eliminate

the need for a roll bar in the camper, adding a roll bar to the camper serves as an extra measure of safety,

should the camper tip over when being used on extreme terrains. Therefore, the team decided that a roll

bar would be a good option for the camper. Figures 9 and 10 show approximate soft-top and roll bar

dimensions.

9

http://chicago.craigslist.org/nwi/boa/4225400901.html

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

29

Figure 9: Approximate top dimensions.10

Figure 10: Approximate roll bar dimensions.11

10

11

http://www.netcarshow.com/jeep/2004-wrangler_unlimited/800x600/wallpaper_04.htm

http://www.netcarshow.com/jeep/2004-wrangler_unlimited/800x600/wallpaper_08.htm

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

30

6.4

Windshield and Hatch

A front entrance point is desired on the camper. This is due to the fact that locating the hatch or door for

entering anywhere else on the camper leads to issues of developing a door that can seal when partially

submerged under water. Furthermore, positioning the entrance in the front of the camper allows for the

camper to remain aesthetically pleasing by not hindering the Jeep-styling incorporated into the tub. While

the entrance could be in the rear of the camper, the camper’s motor is mounted in this location. Therefore

this is not a viable option. In addition to a front hatch allowing entrance into the camper, solid walls are

positioned alongside the hatch with windows. This front area acts as a windshield when used in a boat

configuration.

6.5

Trailer

The final major component from a design standpoint is the trailer. While the trailer and its associated

components requires an amount of engineering analysis, the trailer also must fit the camper and boat hull

well. In order to maintain the desired aesthetics, the boat is positioned such that the seam between the

camper tub and the boat hull is in line with the top of the rail of the trailer. This is necessary in order to

ensure the camper look while being pulled on land. Other major design characteristics possessed by the

trailer include fenders, a toolbox, and steps. The fenders are attached to the trailer such that the boat slides

in between them. A toolbox is integrated into the front of the trailer to help conceal the boat hull, as well

as serve as a storage space for the outboard motor when the camper is being used. Finally, steps are

incorporated into the front of the trailer to allow users to easily enter.

6.5.1 Suspension Analysis

Another critical aspect that allows the camper to go off-road is the suspension system of the trailer. Typical

boat trailers have a leaf spring suspension system that absorbs various loadings and vibrations, resulting in

a smoother, less stress intensive ride. For the application of this camper, the team looked at two different

suspension styles; leaf springs and air bags.

As previously mentioned, leaf springs are very typical on most boat trailers and are readily available in

most shops. However, they do not allow for any vertical adjustment of the trailer, which could be an issue

when trying to launch a boat in a location where there is not a standard boat launch. Figure 11 shows what

a typical leaf spring suspension system would look like on a trailer.

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

31

Figure 11: Leaf spring suspension system12

Alternatively, an air bag suspension system does allow for vertical adjustment of the trailer. As seen in

Figure 12, an air bag suspension system attaches to the axle via a few mounting plates and bars.

Figure 12: Air bag suspension system13

The picture shows the axle being cut into two sections for additional flexibility when driving over rugged

terrain. However, the air bags can also be connected to a single axle without being cut. While driving, the

air bags are filled with compressed air to the rated pressure allowing fluid movement while driving. One

unique aspect about the air bags is that they can also be depressed by releasing the air from the bags to

lower the whole trailer by a few inches.

For this project the added adjustability included with the air bag suspension would be very beneficial,

allowing the camper to be launched in remote areas. Unfortunately, budget and time constraints have forced

12

13

http://www.personalwatercraft.com/products/what-to-look-for-in-a-pwc-trailer-1159.html

http://www.naxja.org/forum/showthread.php?t=1002676

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

32

us to use the basic leaf spring design for the suspension system. This is because it does not require any

additional modifications or costs to the type of trailer that we will use.

6.5.2 Trailer Jacks

When the Expedition Camper is being used on land for camping purposes, it will require support for when

a person is inside of it. Four jacks will be included with the camper to place at each corner in order to

stabilize it, similar to typical campers used today. Because off-road tires will be used for the camper trailer,

the camper will be sitting fairly high off the ground. The axle of the trailer will be 16” above the ground,

and the base of the trailer around 8”-10” above the axle, making the required height for the jacks to be a

minimum of 26” extended.

Two different types of jacks were considered for the expedition camper: stacker jacks and scissors jacks.

Images of each are shown below in Figure 1314,15.

Figure 13: Stacker jacks and scissors jacks

Stacker jacks are fairly cheap, but no sizes have been found to be adjustable to more than 17”. Scissor jacks

on the other hand are more expensive, but do have a larger variety of ranges, some of which being able to

extend to more than the 26” required. One consideration was having blocks to be placed under the stacker

jacks, giving them the extra 10” needed. This option was decided against because it would not be as stable

and would take up more storage space. After discussing the available options, it was decided that the best

option is to use 30” scissors jacks, costing around $100 for the pack. These were the best option because,

although they cost more, they provide a safer and more secure foundation for the camper, adhering to the

design norm of trust.

6.6

Strap Sizing

In order to ensure that the boat does not bounce off the trailer, a set of ratchet straps are installed to hold it

in place. These straps have to be strong enough to hold the boat in place while being pulled over rough

terrain. This means that a lot of force will be acting on the straps and proper size must be considered. The

14

15

http://www.etrailer.com/Trailer-Jack/Stromberg-Carlson/JSC-30.html

http://www.etrailer.com/Trailer-Jack/Ultra-Fab-Products/UF48-979003.html

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

33

team determined that if the boat were to bounce excessively a strap would feel the entire weight of the boat,

which was determined to be a maximum of 1500 lbs. By using this information the team decided to use

four straps that are rated for the weight of the boat. This will give us a large safety margin and ensure that

our boat will not bounce off the trailer.

6.7

Manufacturing

After obtaining the proper funds, the team will begin manufacturing by purchasing both an aluminum flat

bottom boat and trailer as well as designing and fabricating an aluminum Jeep tub. The team will then

modify the boat so that it will allow the Jeep tub to be connected to it via a watertight weld. Once this is

completed, the team will fabricate the camper floor and side panels as well as install an easily removable

top. If given time and funding beyond this, the team will design and install interior furnishings and

additional storage compartments.

6.8

Design Calculations

In order to determine if the design would be feasible, basic calculations and conceptual drawings were done.

The size of the trailer and boat determines the overall dimensions of several other pieces in the design. The

team is setting a baseline parameter for the trailer of having the ability to withstand a one-foot drop, such

as might be encountered when running over a rock, and remain structurally intact. We also performed

stability and buoyancy calculations to determine how the camper would perform on water. Under the

assumption of impact forces, FEA analysis was used to evaluate the structural integrity of the design.

6.8.1 Hitch

Since the goal of designing the camper is to make it as rugged as possible, the trailer hitch must match this

goal as well. It was determined that a regular, conventional trailer hitch will not suffice for this project

because of its lack of mobility. A regular trailer hitch has only one degree of freedom that allows it to rotate

around the ball it is connected to. In order for the hitch to be able to fully function as needed in an off-road

situation, it was determined that the hitch needed to have three degrees of freedom. Two options evolved

from this issue; build one or buy one. After doing some research, an appropriate hitch was found that we

could buy. Lock N’ Roll16 designs and manufactures many types of off-road hitches for trailers. Figure 14

shows an example of one of their particular hitches.

16

www.locknroll.com

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

34

Figure 14: 501 with a 510 off-road trailer hitch by Lock N’ Roll17

Unfortunately, the price of this hitch is just over $200 which is too large of an expense given the projects

budget. Further research showed that $150-$300 is a fairly common price range for these style hitches, and

building one is much cheaper than buying one. Due to the large differences in prices, the team decided to

manufacture a hitch to decrease expenses. A search of multiple trailer forums proved effective in finding a

design for the necessary hitch. Using, Solidworks a model for the hitch was then created, and is shown in

Figure 15.

17

https://locknroll.com/gallery/gallery-category/

This document is the property of Team 14: Expedition Camper (Calvin College).

Duplication of any portion of this document may only be done with team consent.

35

Figure 15: Solid works model of three axis hitch

This hitch was designed by Jeff Scherb and has been used with his consent. The team plans to build this

hitch and perform multiple stress tests to confirm its safety. This hitch has the ability to rotate around the

three axes of a standard three-dimensional coordinate system.

6.8.1.1 Hitch Analysis

The hitch is a critical aspect to allow the camper to go off-road, therefore the team determined that an

analysis of the hitch was warranted. Rather than perform an extensive finite element analysis of the entire

hitch assembly, the analysis was simplified down to determining the strength of the pins and bolts in the

hitch. Since the diameters of the pins are smaller than the diameters of the bolts and are made from the