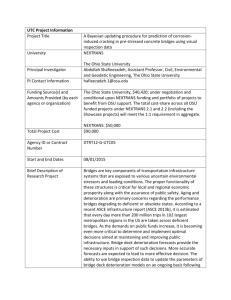

STANADARD SPECIFICATION FOR CONCRETE STRUCTURES –2001 “MAINTENANCE”

advertisement