CLIENT NAME: CLIENT I.D. #: LOCATION(S):

advertisement

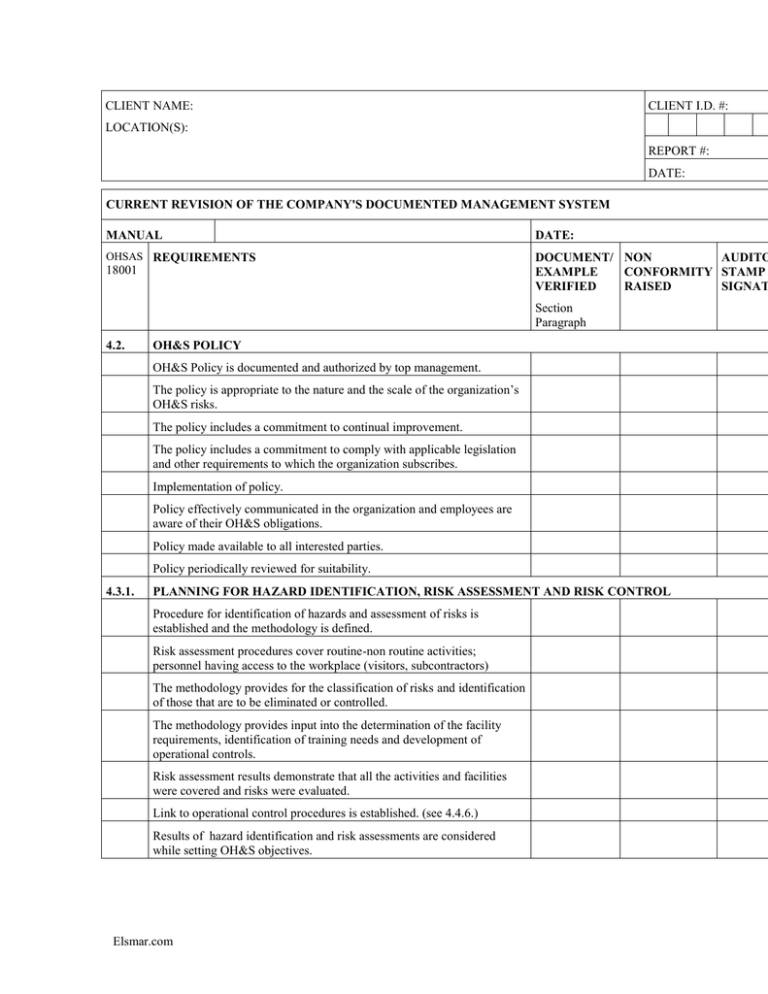

CLIENT NAME: CLIENT I.D. #: LOCATION(S): REPORT #: DATE: CURRENT REVISION OF THE COMPANY'S DOCUMENTED MANAGEMENT SYSTEM MANUAL DATE: OHSAS REQUIREMENTS DOCUMENT/ NON AUDITO EXAMPLE CONFORMITY STAMP VERIFIED RAISED SIGNAT 18001 Section Paragraph 4.2. OH&S POLICY OH&S Policy is documented and authorized by top management. The policy is appropriate to the nature and the scale of the organization’s OH&S risks. The policy includes a commitment to continual improvement. The policy includes a commitment to comply with applicable legislation and other requirements to which the organization subscribes. Implementation of policy. Policy effectively communicated in the organization and employees are aware of their OH&S obligations. Policy made available to all interested parties. Policy periodically reviewed for suitability. 4.3.1. PLANNING FOR HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK CONTROL Procedure for identification of hazards and assessment of risks is established and the methodology is defined. Risk assessment procedures cover routine-non routine activities; personnel having access to the workplace (visitors, subcontractors) The methodology provides for the classification of risks and identification of those that are to be eliminated or controlled. The methodology provides input into the determination of the facility requirements, identification of training needs and development of operational controls. Risk assessment results demonstrate that all the activities and facilities were covered and risks were evaluated. Link to operational control procedures is established. (see 4.4.6.) Results of hazard identification and risk assessments are considered while setting OH&S objectives. Elsmar.com REQUIREMENTS DOCUMENT/ NON EXAMPLE CONFORMITY VERIFIED RAISED Section Paragraph 4.3.2. LEGAL AND OTHER REQUIREMENTS A procedure is established for identifying and accessing legal requirements. Requirements other than legal were identified. The information of applicable legislation and other requirements is up-todate. Relevant information on legal and other requirements is communicated to employees and other interested parties. License/permit requirements are in place, legal requirements implemented. (also see 4.5.1.) 4.3.3. OBJECTIVES Documented OH&S objectives established for each relevant function. Results of hazard identification and risk assessments are considered while setting OH&S objectives. (see 4.3.1.) Objectives are established consistent with the commitment to continual improvement 4.3.4. OH&S MANAGEMENT PROGRAMMES Programmes for achieving OH&S objectives are established. Responsibilities, means and timeframe for achieving objectives are documented. OH&S management programmes are reviewed at regular and planned intervals. The OH&S management programmes are amended to address changing circumstances. 4.4.1. STRUCTURE AND RESPONSIBILITY Roles, responsibilities and authorities are defined and documented. A member of top management appointed to ensure that OH&S system properly implemented. OH&S performance reports are presented to the top management for review and as a basis of improvement of the OH&S management system. All those with management responsibility demonstrate their commitment to continual improvement of OH&S performance. 4.4.2. TRAINING, AWARENESS AND COMPETENCE Competence requirements are defined. Employees are aware of the importance of the requirements of the OH&S Elsmar.com AUDIT STAMP SIGNA management system. Elsmar.com REQUIREMENTS DOCUMENT/ NON AUDITO EXAMPLE CONFORMITY STAMP VERIFIED RAISED SIGNAT Section Paragraph Employees are aware of the OH&S consequences of their work activities, benefits of improved personal performance, and consequences of departing from procedures. Employees are aware of their roles and responsibilities in achieving conformance to the OH&S management system. Training procedures take into account differing levels of responsibility, ability, literacy and risk. Training needs are identified and trainings are provided to satisfy competence needs. Training records are maintained. 4.4.3. CONSULTATION AND COMMUNICATION Procedures to ensure that OH&S information is communicated to and from employees and other interested parties. Employee involvement to the development & review of policies and procedures to manage risks is documented. Employees are consulted for changes that affect OH&S-documented. Employees are represented on OH&S matters, and informed as to who is their employee OH&S representative(s) and management appointee. 4.4.4. DOCUMENTATION Core elements of the OH&S management system are documented. Provides direction to the related documentation. 4.4.5. DOCUMENT AND DATA CONTROL Procedures for document control are established. Documents are periodically reviewed, revised as necessary and approved by authorized personnel. Current versions available at all relevant locations. Obsolete docs protected against unintended use; retained ones identified. 4.4.6. OPERATIONAL CONTROL Operations and activities associated with risks where control measures need to be applied are identified. (Also see clause 4.3.1.) Operational control requirements cover all activities and facilities. (See guidance to operational control) Documented procedures exist where their absence could lead to deviations from the policy and the objectives. Operating criteria stipulated in the procedures. Elsmar.com REQUIREMENTS DOCUMENT / EXAMPLE VERIFIED NON CONFORMIT Y RAISED AUDITO STAMP SIGNAT Section Paragraph 4.4.7. EMERGENCY PREPAREDNESS AND RESPONSE Potential emergency situations and incidents are identified. Response plans for emergency situations and incidents are established and effective for the case. Plans are reviewed after incidents and emergency situations. Emergency procedures tested where practicable. See results of emergency tests and whether plans are reviewed according to the output. Emergency response teams properly trained. 4.5.1. PERFORMANCE MEASUREMENT AND MONITORING Procedures to monitor and measure OH&S performance on regular basis are established. Monitoring of qualitative and quantitative measures as appropriate to the needs of organization. Monitoring of OH&S objectives. Monitoring of compliance with operational criteria and legislation. Monitoring of accidents, ill health and incidents including near misses. Calibration and maintenance of monitoring equipment. 4.5.2. ACCIDENTS, INCIDENTS, NON CONFORMANCES AND CORRECTIVE AND PREVENTIVE ACTIONS Responsibility and authority for handling and investigation of accidents, incidents, non-conformances; taking action to mitigate their consequences; initiation of corrective and preventive actions is established. Causes of non-conformances are investigated and results documented. Appropriate corrective actions developed to eliminate the causes of nonconformances. Proposed corrective and preventive actions are reviewed through risk assessment. Corrective and preventive actions are followed up for effective implementation. 4.5.3. RECORDS AND RECORD MANAGEMENT OH&S records are identified. Records show effective operation of the OH&S system and conformance to requirements. Elsmar.com OH&S records are readily retrievable and retention times recorded. REQUIREMENTS DOCUMENT/ EXAMPLE VERIFIED NON CONFORMITY RAISED AUDITOR STAMP O SIGNATU Section Paragraph 4.5.4. AUDIT Audit Programmes and procedures for periodic system audits are established Internal audits determine whether or not the OH&S system conforms to planned arrangements including the requirements of OHSAS 18001 Internal audits determine whether or not the OH&S system is properly implemented, maintained and effective in meeting the organization policy and objectives. Audit programme is based on the results of risk assessment and previous audits. Audit procedures cover the scope, frequency, methodologies, competencies and responsibilities and requirements for conducting audits. Competence, experience, training and independence of internal auditors. Effectiveness of audit findings including reports and records. Management of audit follow-up, timeliness and effectiveness of the corrective actions. Internal audits provide information to management. 4.6. MANAGEMENT REVIEW Periodic review of OH&S SYSTEM BY top management to ensure its suitability, adequacy and effectiveness supported by appropriate records The management review addresses the need for changes in the policy, objectives and other elements of the system in the light of internal audit results, changing circumstances, and commitment to continual improvement. The results of the management review are documented. NUMBER OF NONCONFORMITIES RAISED: Elsmar.com MAJOR: MINOR:___________ OBS:_________ COMMENTS: SIGNATURE: Elsmar.com STAMP: