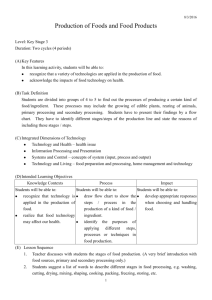

Good manufacturing practices for Active ingredient manufacturers

advertisement