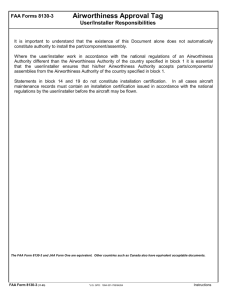

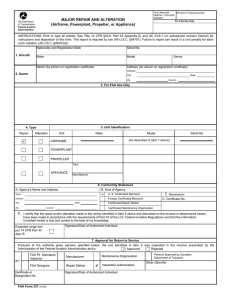

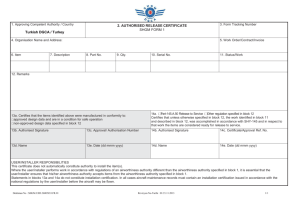

ORDER 8130.21F

advertisement