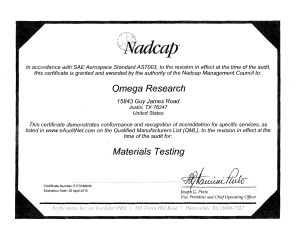

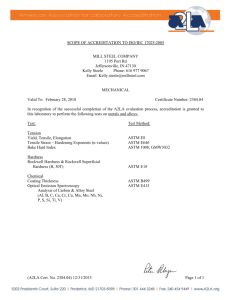

General Requirements for Accreditation

advertisement