Document 14671350

advertisement

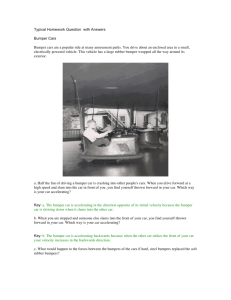

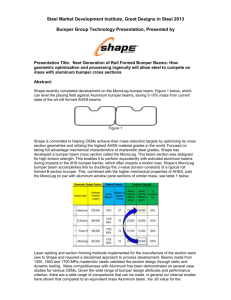

International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 34 DESIGN AND ASSESMENT OF A FIBRE GLASS LEAF-SPRING REINFORCEMENT ON CARBON FIBER POLY-ETHER-IMIDE (PEI) BUMPER’S IMPACT PERFORMANCE 1 ASHA SATURDAY,2 EJEHSON PHILIP SULE,3 EZEONWUMELU OGECHUKWU, 4SAMUEL WADZANI GADZAMA, 5OKOYE C. BENJAMINE, 1 ashiga4oxide@yahoo.com,2ejehsonadole@yahoo.com,3oscargulfecho@yahoo.com.,4swadzani @yahoo.com 1,2,3,4,&5 Scientific Equipment Development Institute SEDI,P. O .BOX 3205,Enugu ,Enugu State,Nigeria ABSTRACT The automotive industry has been very competitive as far as its design and material usage are concerned. The automotive industries face greater market pressure on how to develop high quality products at lower cost, reduced weight in order to improve fuel efficiency and cost, this aesthetics consideration had led the automotive engineers not to focus on car’s delicate component and engine besides the users. Good bumper design like Car body shell stiffness can help to protect the occupants of a car. Thus , this work aims to design and analyzed impact performance on absorption of impact energy during a low and high speed collision, stress distribution ,stiffness and rate of deflection a carbon fibre PEI- Poly-Ether-Imide fibre glass leaf spring reinforced bumper to protect delicate car component ,occupants and pedestrian. The bumper performance is enhanced by the leaf spring fibre glass reinforcement in PEI bumper which lowered the deflection or deformation on impact. IJOART KEY WORDS: fibre glass Leaf spring reinforcement, PEI bumper ,impact performance, collision. INTRODUCTION These numbers call for the necessity to Car accidents are happening every day, nor improve the safety of automobiles during of these had favoured neither the car delicate accidents. As a result, most present-day systems nor the users. Most drivers are automobiles have at least safety belts with convinced retractors and airbags besides the bumpers that they can avoid such instantaneous situations by jumping out or that swerving the car. Nevertheless, many of collision. An automobile's bumper is the thousand of front-most or rear-most part, ostensibly thousands to million wounded every year. designed to allow the car to sustain an are dead and Copyright © 2016 SciResPub. hundreds received this sudden impact on IJOART International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 35 without damage to the vehicle's The bumper like the entire body of safety systems. They are not capable of a car is made of plated steel as it reducing injury to vehicle occupants in was used, high-speed well, as it was very strong in a crash, impact impacts, but are increasingly being designed to mitigate injury This material worked to but it was very heavy and dented But this is performance as it does not return to against the opinions and minds of users its normal position after impact. As ,common men and women including the car engine design has improved, steel engineers who wished bumpers should have bumpers the ability to protect the vehicle occupants disappeared and delicate parts like the convector classic cars. Reducing the weight of (radiator),and engine as a system. Bumper the car for fuel economy makes the systems usually include a reinforcement use of steel bumper not in vogue. pedestrians struck by cars.[1] have pretty much for anything except IJOART bar plus energy-absorbing material, such as polypropylene foam. The more a bumper extends from a car body, when other factors remain equal to the more it absorbs crash energy and reduces damage. The majority of modern plastic car bumper system fascia’s are made of thermoplastic olefins (TPOs), II. Plastic bumper polycarbonates, polyesters, polypropylene, Most modern cars use a reinforced polyurethanes, polyamides, or blends of thermoplastic bumper, as they are these with, for instance, glass fibers, for cheap to manufacture, easy to fit strength and structural rigidity. The level of and impact is a function of speed of the vehicle. crash. Hence the momentum of cars is dependent on speed at that particular time. III. absorb more energy during a Body kit bumper Modified cars often now have a full body kit rather than just a front TYPES OF BUMPERS I. Steel bumper Copyright © 2016 SciResPub. and rear bumper. These kits act as a skirt around the entire body of the IJOART International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 IV. 36 car and improve performance by thermoplastic reducing the amount of air flowing polycarbonates, polyesters, polypropylene, underneath so polyurethanes, polyamides, or blends of reducing drag. Hence, the bumper these with, for instance, glass fibers, for forms an integral part of this body strength and structural rigidity. The use kit. of plastic in auto bumpers and fascias gives Carbon fiber bumper designers a tremendous amount of freedom Carbon fiber body work is normally when it comes to styling a prototype the thing of super-cars, but many car vehicle, or improving an existing model. companies, specialist Plastic bumpers contain reinforcements that modifiers, are starting to use it for allow them to be as impact-resistant as replacement body part on everyday metals while being cars. replace than their the car and and (TPOs), less expensive metal to equivalents. IJOART However the cost of repair of damaged plastic or composite bumper is high, even if it is amended it lost its beauty, because the technology is not available in this part of country-Nigeria. olefins This is one of the Plastic car bumpers generally expand at the same rate as metal bumpers under normal driving temperatures and do not usually require special fixtures to keep them in place. numerous disadvantages of the modern cars The replacement of metal in bumper to imported into the country reduce the weight of the vehicle, reduce Replacing one involves a lot of searching for scrap cars or having one specially made. foam. Better bumpers often have hydraulic shock absorbers instead of, or in addition to, the foam. Today's plastic auto bumpers and aesthetically fascia pleasing, systems are while offering advantages to both designers and drivers. The majority bumper system of modern plastic fascias Copyright © 2016 SciResPub. are made car of cost and improve petrol consumption has follow several stages mostly directed at the bumper fascia and polypropylene, improving polyurethane, thermoplastics, elastomers, PC/ABS and PC/PBT blends. Bumpers fascias are hardly 3 mm thick and the key physical properties are for Today, flexibility and shock resistance. the mostlyused polypropylenes, due to materials are compromise between cost and mechanical properties. IJOART International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 37 Other thermoplastics used for fascias have the mainly particles by developing an alloy at the been alloys-based PBT polycarbonate, which have and been used polypropylene surface. This and was elastomers obtained by mainly in Europe by top car models of optimization of the molecular structure of BMWand Mercedes. Polyurethane is also both components Basically, used in bumpers where flexibility has the important mechanical properties of a car advantage of avoiding deformation. For bumper are strength and toughness as example, a bumper which is made of well. Toughness is a mechanical term polyurethane will roll back into its initial that is used in several contexts. Loosely shape after small shock or collision where speaking, it is a measure of the ability of the speed is usually less than 5 km/h. It is materials to absorb energy before it tends very convenient and avoids costly repair. to fracture. Fracturetoughness is a property For Nissan, they developed an integrated indicative of a material’s resistance to the most IJOART lightweight bumper system for their vehicle fracture when a crackis present. For a using higher modulus polypropylene. The material to be tough, it must display both usage of this material precluded the need high strength and ductility. for the steel reinforcement that up until then was necessary for the polypropylene STATEMENT OF THE PROBLEM bumper. In order to obtain the required Luxury cars, very expensive not only to material properties which is high in purchase but also to repair. Bumper designs strength, an of Modern front-end styling that can either advanced compounding technology was slide under the bumpers or vehicles they applied to improve the existing mineral strike or that simply do not have enough filled polypropylene bumper material. The room to absorb the energy of speed crash. higher by The bars underneath bumper covers often advanced in compounding technologies are not up to absorbing the energy. The bars which minimized the filler function and may not be big enough to provide much achieved in higher dispersion level for protection from damage or they may be higher loading for fine particulate filler. too flimsy to absorb much energy. Hence Impact design modulus and modulus strength impact was was achieved increased by of a glass fibre leaf spring improving the interfacial strength between Copyright © 2016 SciResPub. IJOART International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 38 reinforcement PEI bumper is design and on the glass fibre leaf spring reinforced PEI analysed. bumper due to the collision .To mitigate the AIMS AND OBJECTIVES degree of damage to passengers caused by automobile collisions, a PEI leaf spring This work is to determine energy absorption damper reinforced bumper was desiged its structure that will . In order to achieve effectiveness in impact energy attenuation the main objective, the analysis of stress and impact performance. distribution ,stiffness and rate of deflection COMMON BUMPER SYSTEMS The bumper systems are are detailed 2. Plastic fascia, reinforcing beam and energy absorption system diagrammatically as follows; IJOART 1. Plastic fascia and reinforcing beam system C a. d. b. Copyright © 2016 SciResPub. IJOART International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 39 e. METHODOLOGY Properties of these materials using solid The 3D model of bumper reinforcement is made in SOLID WORKS 2014 After this works material data BASE MATERIAL –PEI the same model is imported in to ANSYS workbench for impact analysis and total deformation is observed. We applied high IJOART Velocity condition for impact ,90,100,110,120,130,140,150 at 80 km/hr and assumed car weight of mass 1000 kg. In 100% frontal impact force component is perpendicular to the bumper. by using Newtons second law, we calculated force F SOURCE:Solid Works 2013c value. This point force applied centrally on FOR PEI (30% CARBON FIBRE) Bumper beam ANALYSIS The analysis is done with models designed with SOLID Works 2014c with controlled test using PEI material only. And the fibre glass leaf spring reinforced PEI Bumper. MATERIALS COMPOSITION 1. PEI Culled from GRANTA 2011(Copyright © 2011, Granta Design, Cambridge, UK) 2. Fibre glass Copyright © 2016 SciResPub. IJOART International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 40 The kinetic Energy of a moving Car is equal REINFORCED MATERIAL –S –GRADE to the energy to cause deformation. 𝐾𝐸 = 1�2 𝑚𝑉 2 FIBRE GLASS [1] Where 𝐾𝐸 is kinetic energy possessed by the car, 𝑚 is the mass of the car, and V is the speed of the car. Work Done on deformation of the bumper 𝑊𝐾 = 𝐹𝑑 [2] 𝐾𝐸 = 𝑊𝐾 [3] Hence ,the conservation of energy , SOURCE:Solid Works 2013c IJOART For S –grade Fibre Glass properties 1� 𝑚𝑉 2 = 𝐹𝑑 2 [4] The speed is in kilometers per hour ,hence speed in meter per second becomes 𝑉 (𝑚⁄𝑠𝑒𝑐) = 𝑉(𝐾𝑚 ⁄ℎ𝑟 )∗1000 3600 [5] The force required for the deformation is analytically equal to the impact force as well as the centripetal force. Hence, Hooke’s law; Culled from GRANTA 2011(Copyright © 2011, Granta Design, Cambridge, UK) 𝐹 = 𝐾𝑒 [6] For elastic body like the bumper that is From the law of conservation of energy ,energy possessed by the a car during motion must be equal to energy to stop it from subject to deformation on collision Where, e is extension and K,Elastic constant or stiffness of the reinforced bumper body. moving . Hence ,from Newton’s third law of motion ,’ To every action, there is equall and This could be written as equation opposite reaction’. Copyright © 2016 SciResPub. IJOART International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 𝐹𝐼𝑀𝑃 = 𝑆𝛿 = 𝐾𝛿 41 Fig,1.3 D model [7] Where 𝑒=𝛿 = extension as elastic deformation(deflection)(m) 𝐾 = 𝑆=Stiffness of the bumper (N/m) MODELING ASSUMPTIONS In the analysis certain assumptions were made and are as stated as follows: i. The leaf spring is assumed to be fixed at the eyes. ii. The material composition was selected to be AISI316 Annealed stainless steel bar(SS). iii. Displacement x (m) is taking considering first impact load and not rebounce. iv. There is no friction between the bod under test and the applied load . v. PEI material and leaf spring material are isentropic on their individual basis. vi. weight is contant at all speed. a. IJOART b. fig 2, a and b 3 D Mesh model MODELS Fig 3. PEI deflection @ a particular speed Copyright © 2016 SciResPub. IJOART International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 42 Fig 6. PEI von mises stress @ a mean speed Fig 4. PEI Von Mises stress @ a REINFORCEMENT particular speed An average speed of 115𝐾𝑚ℎ𝑟 −1 (31.94m𝑠𝑒𝑐 −1 ) will give a IJOART maximum deformation of 63.1045 mm Fig 7.3 D model of fibre glass leaf spring reinforcement Fig 5. PEI deflection @ a mean speed Fig 8.3 D model of fibre glass leaf spring reinforcement mesh Copyright © 2016 SciResPub. IJOART International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 Fig 9.3 D model of fibre glass leaf spring reinforcement von misses stress @ a 43 Fig 11.3 D model of fibre glass leaf spring reinforcement deflection @ mean speed speed IJOART Fig 12.3 D model of fibre glass leaf spring reinforcement von misses stress @ mean Fig10.3 D model of fibre glass leaf spring speed reinforcement deflection @ a speed MEAN VALUES MESH DETAILS Table 1. MESH PROPERTIES Total Nodes Copyright © 2016 SciResPub. Aspect Jacobian Ratio Points 16537 10.822 4 Points Total Mesh Type Element Size IJOART International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 Elements 7728 44 Solid Mesh 25.8514 mm TABLE 2.VALUES FROMTHE SIMULATION The average weight of the car assumed, M =300kg Distant travelled on the said speed, d=100m s/n Car Speed, Impact V(𝐾𝑚ℎ−1 ) Max 𝛿,(mm) 4 110 5 120 6 130 7 140 8 150 Mean,(𝑥̅ ) 115 30.56 REINFORCED BUMPER Copyright © 2016 SciResPub. 29.3723 0 18.598 37.1942 0 26.4406 45.8944 0 32.6254 55.532 0 39.4765 66.088 0 46.9805 77.5615 0 55.1368 89.953 0 63.9456 103.262 0 73.407 63.1045 0 44.8596 937.50 100 27.78 (Mpa) 740.74 90 25.00 3 Node: 130 stress 8544 V(𝑚𝑆 −1 ) 22.22 2 𝛿,(m) IJOART 80 Von Force,F(N) Deflection, Deflection, Mises Node: 1 Min 1157.41 1400.46 33.33 1666.67 36.11 1956.02 38.89 2268.52 41.67 2604.17 31.94 1591.43 MODEL PROPERTIES IJOART International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 Mass: 18.4541 kg Total Nodes Volume: 0.0145308 m^3 Density: 1270 kg/m^3 Weight: 180.85 N 45 Aspect Jacobian Ratio Points 18406 14.042 4 Points Total Mesh Type Element Size Solid Mesh 29.7989 mm Elements MESH DETAILS 8661 TABLE 3. MESH PROPERTIES TABLE 4.VALUES FROMTHE SIMULATION The average weight of the car assumed, M =300kg Distant travelled on the said speed, d=100m s/n IJOART Car Speed, Impact V(𝐾𝑚ℎ−1 ) Max Force,F(N) Deflection, 𝛿,(mm) Node: 1 80 2 90 25.00 3 100 4 110 5 120 6 130 7 140 Deflection, Mises 𝛿,(m) Node: 121 stress (Mpa) 3.53059 0 3.32523 4.46841 0 4.2085 5.51656 0 5.19569 6.67501 0 6.28676 7.94385 0 7.48179 0 8.7807 0 10.1835 740.74 937.50 27.78 1157.41 30.56 1400.46 33.33 1666.67 9.32298 36.11 1956.02 38.89 2268.52 Copyright © 2016 SciResPub. Von 14715 V(𝑚𝑆 −1 ) 22.22 Min 10.8125 IJOART International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 8 150 Mean,(𝑥̅ ) 115 41.67 2604.17 31.94 1591.43 46 12.4123 0 11.6903 7.58524 0 7.14403 IJOART GRAPH Effect of impact Force compare results at a glance effect of the fibre glass leaf spring reinforcement on the PEI bumper a. WITHOUT REINFORCEMENT Maximum Deflection of bumper ,mm The graphs are detailed to show and 120 100 80 60 40 20 0 y = 0.0396x + 0.0094 R² = 1 0 1000 2000 3000 Impact Force ,N Copyright © 2016 SciResPub. IJOART International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 Fig 13. Effect of impact force on bumper Effect of Impact Force Maximum Deflection,mm Deflection without reinforcement Von Mises stress (Mpa Stress built up as a result of impact 80 y = 0.0288x - 1.3089 R² = 0.9987 60 40 47 15 y = 0.0048x - 3E-05 R² = 1 10 5 0 0 1000 2000 3000 Impact Force,N 20 0 0 1000 2000 3000 Impact Force,N Fig 16. Effect of impact force on bumper Deflection with reinforcement Stress built up on bumper Fig14. Effect of impact force on bumper Von Mises stress without reinforcement Von Mises Stress,Mpa IJOART ximum Deflection ,mm Effect of car speed on bumper 150 y = 1.0555x - 58.27 R² = 0.9925 100 50 50 100 y = 0.0045x + 5E-06 R² = 1 10 5 0 0 1000 2000 3000 Impact Force ,N 0 0 15 150 Car Speed Km/hr 20 Fig 17 Effect of impact force on bumper Von Mises Stress with reinforcement Fig 15. Effect of Car speed on bumper Deflection without reinforcement REINFORCED BUMPER Copyright © 2016 SciResPub. IJOART International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 48 Maximum deflection,mm Effect of car speed 15 y = 0.1269x - 7.0061 R² = 0.9925 10 5 0 0 50 100 150 200 Car Speed km/hr Fig 18. Effect of Car speed on bumper Fig20. Rate of Deflection with time of Deflection with reinforcement collision Car Speed,km/hr Effect of car Speed 200 on the bumper without reinforcement IJOART y = 0.0373x + 55.666 R² = 0.9925 150 100 50 0 0 1000 2000 3000 Impact Force,N Fig 19. Effect of Car speed on impact force on the bumper with reinforcement Fig 21. Rate of Deflection with time of collision on the bumper reinforcement DISCUSSION Bumper deformation becomes necessary to consider on collision with a pedestrian, or an obstacle. Hence ,damage caused to the bumper ,car’s delicate parts are greatly considered besides weight reduction and impact on pedestrians that do not make us Copyright © 2016 SciResPub. use steel leaf spring reinforcement. The models results on tables ( 2) , and (4) IJOART International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 49 revealed that reinforcing the PEI bumper The bumper dynamic simulation on impact with a material with high yield strength will analysis for a fibre glass leaf spring help to reducing the deformation of the reinforced PEI bumper performance could bumper. Using be fibre glass and PEI used on further bumper design. composite matrix may not give the results as Simulation results reveal good performance performed by the ingenuity of incorporating as low deformation was achieved with shock absorbing ability of leaf spring, hence reinforcement compared with the with large a fibre glass leaf spring was conceptualized deformation without reinforcement. it can be in the design. Graphical representation from concluded that the bumper is an important the results in the tables ( 2) , and (4) show member of an automobile from the safety at a glance the effect of the fibre glass leaf point spring components. Thus analysis of bumper reinforcement on the impact performance of the reinforced PEI bumper. The spread will of help view of the car’s delicate to increase IJOART or propagation of the considered to replace the the safety existing deformation with the collision simulation materials like steels and general fiber. The time in fig. (20) and (21)was shown to x-ray project data can be used for best bumper collision that will involve drag before designs stoppage. However, other conditions that material,weight reduction ,and performace could improve the bumper reinforcement point of view. Impact loading parameters could also be investigated-thickness of the were bumper, and geometric parameters of the kinectic energy possessed at a distant of fibre glass leaf spring. A correlation work on 100m. parametric analysis of the effect of geometrical parameters on the performance of modern vehicles from evaluated for varying speeds and FUTURE WORK of a master leaf spring was done by Haruna The experimental impact test at various M S, Enebe O ., Asha .S 2015 el ta energy on this model should be done for an revealed that thickness, radius of curvature, onward assurance of the performance and span ,and width of leaf spring affects its acceptability by the automotive industries. performance . Fatigue test could be done as well as a CONCLUSION Copyright © 2016 SciResPub. comparative work should be done on this IJOART International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 50 model with static and dynamic impact Automobile Engineering, vol. 227, analysis. no. 6, (2013) June, pp. 905-913. 4. R. S. Ali Sidhu Aidy and M. R. REFFERENCE Hassan, 1. S. N. Ch. Dattu. V., N. Surya Kiran , 2011, “Experimental determination of fatigue life of B. Atcha Rao., 2014. Fea Analysis automotive jounce (Dynamic) on a Engineering Passenger Car bumper Key Materials”, Fracture Bumper Body Material . Journal of and Strength of Solids VII, vol. Basic 462-463, (2011), pp. 634-638. and Research Applied Engineering Print ISSN: 2350-0077; 5. F.-K. Chen and S.-W. Liu,2013, Online ISSN: 2350-0255; Volume 1, “Die Number 2; October, 2014 pp. 33-37 stamping a high strength automotive © bumper inner”, Advanced Materials Krishi Sanskriti Publications compensation design for IJOART http://www.krishisanskriti.org/jbaer. Research, html Manufacturing 2. Haruna M .S ,Enebe O,Asha .S. 2015.Correlation Analysis Of The Advances in Science and Engineering, vol. 712-715, (2013), pp. 796-799. Effect Of The Geometry Of An 6. S. Wu, H. Liu and H. Wu,2013, Automobile Master Leave Spring On “Haitao Analysis of effectof process Its International parameters Journal of Arts and Combined automobile Sciences Vol.. 4, No. 1, March/April, molded parts”, Advanced Materials 2015 ISSN: 2315-8085 Research, Advances in Materials Performance- 3. J. Huang, Y. Xia, B. Nie and Q. Zhou, 2013,“A bumper model with dynamic bumper Materials of a injection Processing, vol. 652-654, (2013), pp. 2062-2066. 7. M. M. Rimy and A. A. Faieza, simulations of pedestrian legform 2010, “Simulation of car bumper impacts”, material Engineers, stiffness war page for Institution contact and on Proceedings of Part D: of the using finite element Mechanical analysis”, Journal Engineering, vol. 4, no. 3, (2010), of Journal of Software pp. 257-264 Copyright © 2016 SciResPub. IJOART International Journal of Advancements in Research & Technology, Volume 5, Issue 4, April-2016 ISSN 2278-7763 51 IJOART Copyright © 2016 SciResPub. IJOART