B037 DEVELOPMENT AND APPLICATION OF A HYDRAULIC FRACTURE RESERVOIR SIMULATION TOOL

advertisement

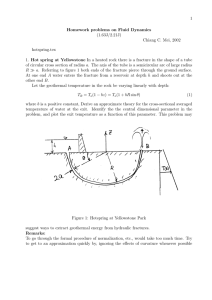

B037 DEVELOPMENT AND APPLICATION OF A HYDRAULIC FRACTURE RESERVOIR SIMULATION TOOL Torsten Friedel and Frieder Häfner Institute of Drilling Engineering and Fluid Mining, Freiberg University of Mining and Technology, Agricolastraße 22, D-09596 Freiberg (Germany) Abstract A single component, three-phase reservoir simulator is presented for detailed investigations of hydraulically fractured wells. The tool features a gas and loadwater phase, capturing inertial non-Darcy flow, and a special gel phase to represent the highly viscous fracturing fluid. Its nonNewtonian fluid characteristics is modelled by means of the Herschel-Bulkley fluid model with yield stress. Using state of the art numerical techniques, the tool is built around a fully unstructured discretisation framework, providing an accurate capture of the flow around fractures and wells and the opportunity for sophisticated wellbore flow modelling. The fracture Voronoi grids allow for simulation with well-test accuracy. The simulator is validated against analytical and numerical solutions. Introduction The benefits of a precise analysis of the transient flow in the fracture vicinity, with the aim of improving well performance, have been well recognized. Furthermore, the enormous development costs in, e.g., tight-gas reservoirs using multiple fractured horizontal wells, make accurate and reliable production forecasts a necessity. Fig.1 presents specific processes at fractured wells. A realistic cleanup scenario may imply: (i) the simultaneous flow of three phases, (ii) the formation of a load water invasion zone accompanied by hydraulic and mechanical damage in the fracture vicinity, (iii) filtercake buildup and erosion, (iv) gel residue damaging the proppant pack, incorporating complex non-Newtonian rheology, and (v) viscous fingering through the proppant pack. During the subsequent production, inertial non-Darcy flow and geomechanical effects, e.g., stress dependency of reservoir permeability and fracture closure, impact the behaviour of the fractured well. Furthermore, the fracture-reservoir system is characterised by highly discriminative magnitudes in space, with fracture width in the range of millimeters and by distinct time scales of cleanup and post-fracture production periods. A hydraulic fracture reservoir simulation tool has been developed to allow for detailed cleanup investigations as well as post-fracture evaluation within one unified workflow model. The tool aims to consider physical and technological aspects as accurately as possible. Primary objectives of the tool development and its application are: (i) to obtain a considerable increase in the quality of predictions from tight-gas reservoirs with fractured wells, by taking into account the specific conditions with the corresponding petro-physical functions, (ii) improving the insight into complex and highly nonlinear multi-phase flow phenomena, and (iii) contribute to a more realistic simulation technology for such reservoirs. 9th European Conference on the Mathematics of Oil Recovery - Cannes, France, 30 August - 2 September 2004 Gel residues unbroken polymers with non-Newtonian rheology Undamaged reservoir (< 1 km) Stress dependent reservoir permeability Cleanup processes Multi-phase flow effects Inertial (non-Darcy) flow =f(p) Leakoff-zone (invaded loadwater) (< 1m) Capillary endeffects Fractureclosure Fracture (width < 10 mm) Well (diameter < 0.10 m) Proppant Mechanical damage zone Filter cake Figure 1: Specific processes at hydraulically fractured wells Physical and Mathematical Model The starting point for the mathematical formulation is the integration of the mass balance equation for Np phases, over a finite control volume, ∆V , in its simplified form: − Np Np ∂ (φρp Sp ) dV − (ρpup ) n dA = qp , ∂t p=1 p=1 p=1 Np ∆A (1) ∆V where the volume integral of the advection term is already revised in a surface integral ∆A of the total surface ∆A by means of the Gaussian Theorem. For practical purposes, the gas, water and gel phases can be considered immiscible. The fluid system present is characterised by a highly discriminative rheology with different flow regimes. The classical method of using a single motion equation is hence insufficient. Rather, different kinds of motion equations needs to be implemented and switched in the simulator dependent on the fluid type. Traditionally, Darcy’s law has been used in petroleum reservoir engineering to account for viscous forces while neglecting inertial forces. These, however, are crucial for gas reservoirs, even in a low rate tight-gas environment, and are captured with the well known Forchheimer-equation. The inertial pressure drops are primarily caused by the continuous de- and acceleration of fluid molecules travelling along a tortuous flow path through the interconnected pores and also in the proppant pack. In vector form, it can be written as: µ (2) + βt ρ|u| u . −grad Φ = k Since a value βt = 0 marks the transition to Darcy’s law, Eq.(2) is the default motion equation for the gas and the water phase. The velocity of both phases is then: up,ND = −δp kkr,p grad Φp , µp δp = 1 , βt ρp kkr,p 1+ |up,ND | µp (3) already inhering the common multi-phase flow concepts. Permeability is assumed horizontally isotropic. Permeability and non-Darcy flow coefficients can realistically be defined as a function of the effective stress according, e.g., to the proppant type. Setting the fracture conductivity dependent on the effective stress also allows for consideration of fracture closure. A variety of important fluids exhibit non-Newtonian behaviour, i.e., the shear rate depends nonlinearly on the shear stress. Such fluids are primarily based on polymers and are often utilised for drilling or fracturing. The present approach facilitates a special gel phase to represent the fracturing fluid. This differs from the common concept to model polymers as a component of the water phase, affecting its viscosity. The equation used to calculate the viscosity of the gel phase is derived from the Herschel-Bulkley fluid model: τ = τ0 + K γ̇ n . Its derivation is based on one dimensional flow through a single capillary, using the Blake-Kozeny equation for laminar flow of Newtonian fluids in packed beds.1 In the rheology model, τ0 is the yield stress, K is the fluid consistency index and n constitutes the fluid behaviour index. The velocity of a Herschel-Bulkley fluid can be written analogously to the non-Darcy velocity in a generalised form: ⎧ 1/n ⎪ kk φC 1 ⎪ r,gel ⎨ − , |grad Φ| ≥ φC τ ; τ0 grad Φ 1− 2k 0 µeff 2k |grad Φ| , (4) up,HB = ⎪ ⎪ ⎩ 0, φC |grad Φ| < τ . 2k 0 where C is a tortuosity constant. Gravity effects are neglected. An effective viscosity coefficient µeff for multi-phase flow of such fluids is defined as follows1–3: n 1−n K 3 (150Cφ(Sgel − Sgel,irr )kkr,gel ) 2 . (5) 9+ µeff = 12 n In order to adapt the numerical framework to accommodate the non-Newtonian fluid behaviour, Eq.(4), a gel viscosity µgel is introduced. This viscosity reflects the equivalent viscosity of a nonNewtonian fluid moving at the same velocity as its Newtonian fluid counterpart1 and is derived by equating the Darcian velocity (δp = 1), Eq.(3), with the Herschel-Bulkley velocity, Eq.(4), i.e., |up,HB | = |up,ND |. Thus, the viscosity becomes a function of the pressure gradient in the gel phase, with a certain threshold pressure. Numerical Model and Software Design The physical model forms a set of residual equations which are solved fully implicitly using Newton’s method. Derivatives in the Jacobian matrix are derived numerically by finite-difference approximations. Derivation of underlying dependencies in the model are considered by either conventional table lookups or, preferably, in parametric form, such as the common Brooks-Corey multi-phase flow correlations. The framework facilitates the usage of Voronoi grids, generated either by an in-house pre-processor or by third party gridding applications. A Voronoi block is defined as the region of space that is closer to its grid point than to any other, and a Voronoi grid is made of such blocks.4 Mathematically, the major property of the Voronoi grid is its local orthogonality, i.e., the area open to flow between adjacent grid blocks is always orthogonal to the stream line between the corresponding grid points. Consequentially, the common two point flow stencil is applicable. The treatment of the non-Darcy flow requires some special treatment since Eq.(2) is nonlinear. 9th European Conference on the Mathematics of Oil Recovery - Cannes, France, 30 August - 2 September 2004 Previously, fully implicit schemes have been introduced.5 The current code utilises an implicit iterative scheme. In order to calculate the new solution, a control parameter δpk+1 is introduced to begin with, where δpk from the preceding iteration is used to calculate the velocity u∗p . δpk+1 1 = , k k k βt ρp kkr,p ∗ 1+ |up | µkp u∗p = −δpk k kkr,p grad Φkp . k µp (6) Subsequently, the velocity for the new iteration k + 1 can be computed while simultaneously damping the control parameter to avoid oscillations: uk+1 p = −δpk+1 kkr,p grad Φp µp k+1 , δpk+1 = δpk + (δpk+1 − δpk ) ∗ RP , (7) where RP denotes a relaxation parameter. Best results could be achieved with RP = 0.4...0.6. The total number of Newton iterations required for non-Darcy flow are slightly increased when compared with Darcy flow (δp = 1). For common three-phase problems, 2-4 iterations are taken until the solution converges. Contrary to the fully implicit treatment, where non-Darcy effects are not supposed to be large, the present approach facilitates even the consideration of extremely "turbulent" flow with control parameters 0 < δp 1. The code is realised by means of a MATLAB -FORTRAN coupling. Formulation of the set of equations is accomplished within a highly efficient Fortran-environment and linked with MATLAB6, where pre- and postprocessing as well as simulator control are performed. Both direct and iterative solvers are implemented for the solution of the system of linear algebraic equations. However, most promising is the use of a new algebraic multigrid solver7, which is currently under evaluation. Discretisation of Hydraulic Fracture The fracture is an object with specific properties and particular pre-history that should be considered in the evaluation of hydraulic fracture stimulation. In terms of numerical simulation of postfracture well performance, the problem can be addressed by (i) an adequate representation of the fracture in a reservoir simulator and (ii) a reasonably accurate picture of the invaded zone which formed by the leakoff process during fracturing. Both have been addressed in detail in one of our previous papers.8 Besides, the unstructured discretisation framework facilitates a sophisticated geometrical representation of both single and multiple fractured wells depending on the specific fracture properties, the well characteristics and the refinement parameters for the grids. Two examples of 2.5 dimensional fracture grids are presented in Fig.2. Additionally, structured fracture grids can be used based on the investigations of B ENNETT et al.9 Application Examples The simulator and the gridding scheme has been verified and validated against a series of synthetic examples. The checks include the comparison of results obtained, where available, from analytical solutions and a commercial reservoir simulator. The input properties for the cases are summarised in Tables 1 and 2. (a) Voronoi-type grid for a vertical fractured well with hexagonal background grid (b) Voronoi-type grid for a horizontal fractured well with 5 transverse fractures Figure 2: Examples of unstructured fractured well discretisations Case 1: Validation of Single-Phase Darcy Flow. Structured B ENNETT-type fracture grids are used for the verification of the real gas single-phase option. Both finite and infinite conductivity fractures are considered. As shown in the type-curves, Fig.3.a, the numerical solution is de facto identical to the corresponding dimensionless analytical solution of G RINGARTEN et al. for infinite conductivity fractures10 and C INCO -L EY et al. for finite conductivity fractures11. The unstructured Voronoi fracture grids, Fig.2.a., are validated for a slightly compressible fluid against the analytical solution for infinite conductivity fractures and the results of a commercial simulator in Fig.3.b. The dimensionless fracture conductivity is 2400 with a wellbore radius of 0.1 m and a reservoir permeability of 10 mD. The reservoir is rectangular and bounded (unit slope in the derivative plot). In contrast, the analytical solution takes only the infinite acting period into account. Case 2: Verification of Single-Phase Non-Darcy Flow. Simulator results are compared against the type-curves of G UPPY et al.12 for non-Darcy flow with real gas and constant pressure boundary conditions in dimensionless form in Fig.3.c. Both solutions exhibit very close agreement. Case 3: Validation of Three-Phase Flow Model. The three-phase model is validated against results of a commercial simulator5. A fractured vertical well is initially filled with a gel phase of constant viscosity. The fracture is surrounded by a water saturated zone (approx.0.5 m) at critical gas saturation (0.1). The rest of the reservoir is gas filled with water at residual saturation (0.5). During cleanup, the well produces with constant bottom hole pressure. Multi-phase flow functions in the formation are based on a Brookes-Corey model, with endpoint permeabilities 0.12 (gas) and 0.11 (water) and linear functions in the fracture. Capillary pressure at residual water saturation is 330 bars. There is no capillary pressure in the fracture. Results are shown in Figs.3.d and 3.e. The first presents the temporal development of phase saturations in the well block. The rates are shown in Fig.3.e. Both are in good agreement with the results of the commercial simulator. Case 4: Validation of Non-Newtonian Fluid Flow Model. The implementation of non-Newtonian fluids is verified by means of the analytical solution of I KOKU and R AMEY for transient ra9th European Conference on the Mathematics of Oil Recovery - Cannes, France, 30 August - 2 September 2004 dial flow of non-Newtonian power law fluid in its corrected form13. The power law model accounts for pseudo-plastic fluid behaviour without a yield stress. The effective viscosity is calculated with Eq.5. Results, shown in Fig.3.f, exhibit very good agreement to the analytical results. Validation of non-Newtonian fluid with yield stress is impossible thus far, since analytical solutions or appropriate fluid models in commercial simulators are not available. The simulation tool has been successfully used for investigations on the performance of hydraulically fractured wells in tight-gas reservoirs with detailed analyses, e.g., of loadwater and gel cleanup processes.14 Summary This papers presents a novel reservoir simulation tool for fractured vertical and horizontal wells. It features the specific physics such as non-Darcy flow and non-Newtonian fluids which are typical for fractured wells. Unstructured fracture grids are presented, providing well testing accuracy and very flexible handling of the fractures within a conventional full field model. The discretisation scheme and the physics of the simulator have been validated against a variety of cases revealing very good accuracy and reliability of the code. Nomenclature A ct C k K n n Np p qp Q rw RP S t tDxf u V z area, m2 total compressibility, 1/Pa tortuosity constant permeability, m2 iteration counter fluid consistency index, Pa.sn normal vector fluid behaviour index, index of time number of phases pressure, Pa mass source/sink, kg/(m3 .s) (well) flow rate, m3 /s well radius, m relaxation parameter saturation time, s dimensionless fracture time velocity, m/s volume, m3 depth, m βt γ̇ δ µ µeff ρ τ τ0 φ Φ non-Darcy flow coefficient, 1/m share rate, 1/s control parameter dynamic viscosity, Pa.s effective viscosity, Pa.sn .m1−n density, kg/m3 shear stress, Pa yield stress, Pa porosity z potential, Pa (with Φ = p + g 0 ρ(η) dη) D DNN gel HB irr ND r p dimensionless with non-Newtonian fluid gel Herschel-Bulkley irreducible (saturation) with non-Darcy flow relative phase References /1/ May E.A.; Britt L.K.; Nolte K.G. The Effect of Yield Stress on Fracture Fluid Cleanup. (SPE-Paper 38619), 1997. presented at the SPE Annual Technical Conference and Exhibition held in San Antonio, Texas. /2/ Ikoku C.U.; Ramey H.J.Jr. Transient Flow of Non-Newtonian Power-Law Fluids in Porous Media. Society of Petroleum Engineers Journal, (SPE-Paper 7139):164–174, June 1979. presented at 48th. Annual California Regional Meeting held in San Francisco, California. /3/ Al-Fariss T.; Pinder K.L. Flow of a Shear-Thinning Liquid With Yield Stress Through Porous Media. (SPE-Paper 13840), 1985. /4/ Palagi C. Generation and Application of Voronoi Grid to Model Flow in Heterogeneous Reservoirs. PhD thesis, Department of Petroleum Engineering, Stanford University, Stanford, California, 1992. /5/ Schlumberger GeoQuest. Eclipse 100 Technical Description 2003a, 2003. /6/ The MathWorks Inc. MATLAB 6.5: The Language of Technical Computing, 2002. Part: Using MATLAB, Version 6. /7/ Stüben K.; Clees T. SAMG User’s Manual Release 21c. Fraunhofer Institute SCAI, Schloss Birlinghoven D53754 St. Augustin, Germany, Aug. 2003. /8/ Behr A.; Mtshedlishvili G.; Friedel T.; Häfner F. Initialization of Reservoir Model with Hydraulically Fractured Well for Simulation of Post-Fracture Performance. (SPE-Paper 82298), 2003. presented at the European Formation Damage Conference held in The Hague, Netherlands. /9/ Bennett C.O.; Reynolds A.C.; Raghavan R.; Elbel J.L. Performance of Finite-Conductivity, Vertically Fractured Wells in Single-Layer Reservoirs. (SPE-Paper 11029), 1986. /10/ Gringarten A.C.; Ramey H.G.; Raghavan R. Unsteady-State Pressure Distributions Created by a Well With a Single Infinite-Conductivity Vertical Fracture. Society of Petroleum Engineers Journal, (SPE-Paper 4014): 347–360, Aug. 1974. /11/ Cinco-Ley H.; Samaniego-V.F.; Dominguez N.A. Transient Pressure Behavior for a Well With a FiniteConductivity Vertical Fracture. Society of Petroleum Engineers Journal, (SPE-Paper 6014):253–264, Aug. 1978. /12/ Guppy K.H.; Cinco-Ley H.; Ramey Jr. H.J. Effect of Non-Darcy Flow on the Constant Pressure Production of Fractured Wells. Society of Petroleum Engineers Journal, (June 1981):390–400, 1981. /13/ Ikoku C.U.; Ramey H.J.Jr. Numerical Solution of the Nonlinear Non-Newtonian Partial Differential Equation. (SPE-Paper 7661), 1978. /14/ Friedel T. Numerical Simulation of Production from Tight-Gas Reservoirs by Advanced Stimulation Technologies. PhD thesis, Fakultät für Geowissenschaften, Geotechnik und Bergbau der TU Bergakademie Freiberg, Freiberg, Germany, 2004. Appendix Table 1: Input parameters Cases 1, 2 & 4 Well rate (m3 /s) 1.00E-03 10 Permeability (mD) 10 Thickness (m) 0.2 Porosity 1E-03 Viscosity (Pa.s) 5E-10 Total compressibility (1/Pa) 3 Density (kg/m ) 1000 0.1 Well radius (m) Non-Darcy flow coeff. βt (1/m) 5.00E+11 Table 2: Input parameters Case 3 Permeability (mD) Thickness (m) Porosity Fracture half length (m) Dimensionless fracture conductivity Gel viscosity (mPa.s) Gel compressibility (1/Pa) Gel formation volume factor Gel density (kg/m3 ) Water viscosity (Pa.s) Water compressibility (1/Pa) Water formation volume factor Water density (kg/m3 ) Rock compressibility (1/Pa) Initial field pressure (Pa) Producer well pressure (Pa) 0.05 10 0.1 250 10 1.0 5.5E-10 1.05 800 0.25E-03 5.5E-10 1.05 1000 7.5E-10 600E+05 150E+05 9th European Conference on the Mathematics of Oil Recovery - Cannes, France, 30 August - 2 September 2004 (a) Case 1 - Real gas constant rate production of infinite and finite conductivity fracture (structured grid) (b) Case 1 - Water constant rate production with infinite conductivity fracture (unstructured grid) 1.0 G as saturation:Sim ulator W atersaturation:Sim ulator G elsaturation:Sim ulator 5 G as saturation:R eference 5 W atersaturation:R eference 5 G elsaturation:R eference 0.9 W ellblock Saturation 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0.0 0.0 0.2 0.4 0.6 0.8 1.0 Tim e (days) 40 70000 35 60000 (d) Case 3: Three phase flow (well block saturation) 30 50000 G as rate:Sim ulator 5 G as rate:R eference W aterrate:Sim ulator 40000 5 W aterrate:R eference G elrate:Sim ulator 30000 5 G elrate:R eference 25 20 15 20000 G as rate (m ‡/day) W aterand gelproduction rate (m ‡/day) (c) Case 2: Single-phase non-Darcy flow in fractured vertical wells 10 10000 5 0 0.01 0 0.1 1 Tim e (days) (e) Case 3: Three phase flow (production rates) (f) Case 4: Single-phase non-Newtonian (power law) fluid flow Figure 3: Application Examples