A028

advertisement

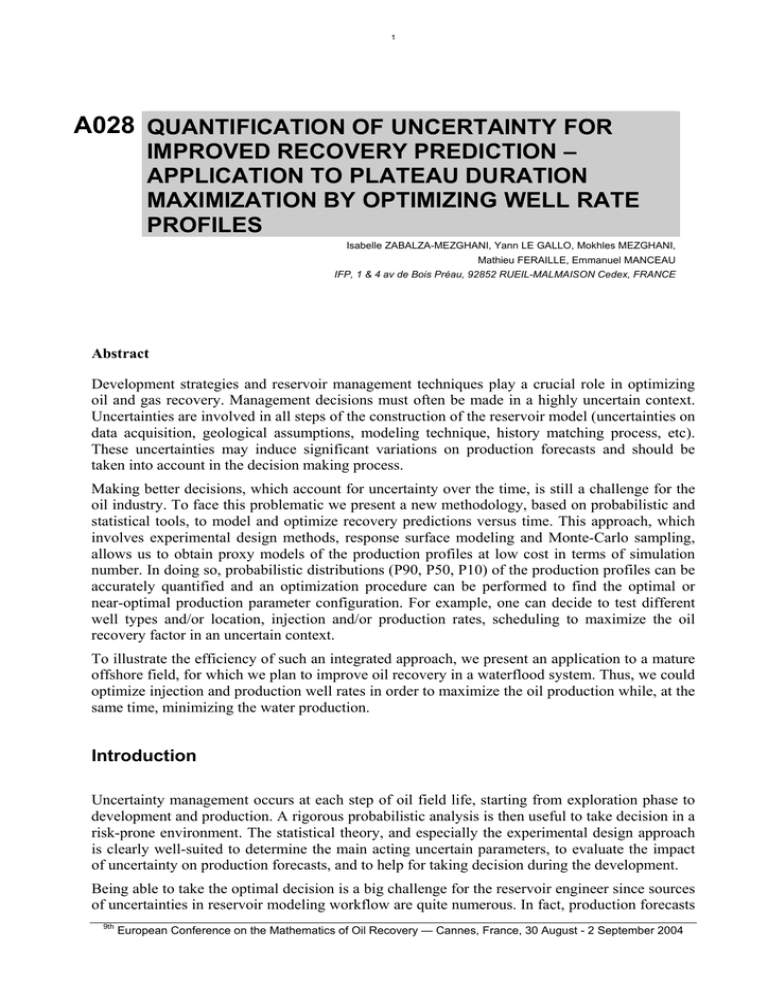

1 A028 QUANTIFICATION OF UNCERTAINTY FOR IMPROVED RECOVERY PREDICTION – APPLICATION TO PLATEAU DURATION MAXIMIZATION BY OPTIMIZING WELL RATE PROFILES Isabelle ZABALZA-MEZGHANI, Yann LE GALLO, Mokhles MEZGHANI, Mathieu FERAILLE, Emmanuel MANCEAU IFP, 1 & 4 av de Bois Préau, 92852 RUEIL-MALMAISON Cedex, FRANCE Abstract Development strategies and reservoir management techniques play a crucial role in optimizing oil and gas recovery. Management decisions must often be made in a highly uncertain context. Uncertainties are involved in all steps of the construction of the reservoir model (uncertainties on data acquisition, geological assumptions, modeling technique, history matching process, etc). These uncertainties may induce significant variations on production forecasts and should be taken into account in the decision making process. Making better decisions, which account for uncertainty over the time, is still a challenge for the oil industry. To face this problematic we present a new methodology, based on probabilistic and statistical tools, to model and optimize recovery predictions versus time. This approach, which involves experimental design methods, response surface modeling and Monte-Carlo sampling, allows us to obtain proxy models of the production profiles at low cost in terms of simulation number. In doing so, probabilistic distributions (P90, P50, P10) of the production profiles can be accurately quantified and an optimization procedure can be performed to find the optimal or near-optimal production parameter configuration. For example, one can decide to test different well types and/or location, injection and/or production rates, scheduling to maximize the oil recovery factor in an uncertain context. To illustrate the efficiency of such an integrated approach, we present an application to a mature offshore field, for which we plan to improve oil recovery in a waterflood system. Thus, we could optimize injection and production well rates in order to maximize the oil production while, at the same time, minimizing the water production. Introduction Uncertainty management occurs at each step of oil field life, starting from exploration phase to development and production. A rigorous probabilistic analysis is then useful to take decision in a risk-prone environment. The statistical theory, and especially the experimental design approach is clearly well-suited to determine the main acting uncertain parameters, to evaluate the impact of uncertainty on production forecasts, and to help for taking decision during the development. Being able to take the optimal decision is a big challenge for the reservoir engineer since sources of uncertainties in reservoir modeling workflow are quite numerous. In fact, production forecasts 9th European Conference on the Mathematics of Oil Recovery — Cannes, France, 30 August - 2 September 2004 2 can be affected by several sources of uncertainty coming either from the static model (petrophysical and fluid property distributions, structural representation of the reservoir,…), the upscaling phase, the fluid flow modeling (relative permeability curves from core analysis, the PVT modeling process, the well architecture and design, …). The final objective of a reservoir evaluation is to take decisions in term of field production scheme based on technical and/or economic criteria. This may include a decision regarding the optimization of the number of production wells, their location and architecture, injection schemes to maximize oil recovery and/or field net present value. To face such a problem, we propose a methodology for designing production scheme which is inspired both by experimental design approach and inversion techniques to match the desired production forecast [3] and thus to optimize the production recovery. Experimental Design based Methodology for Improved Recovery Prediction Uncertainty quantification for reservoir management Risk assessment in Geosciences is a difficult problem to face with. Indeed, the sources of uncertainties are very numerous, and the number of uncertainties involved along the modeling workflow can be so high that an exhaustive study of each case is practically non-realistic. Nowadays, the most well known methods used to handle uncertainties are Nested simulations, Decision tree analysis, Monte-Carlo sampling [1]. These approaches are rigorous, systematic and ensure reliable results in terms of uncertainty quantification. On the other hand, their common characteristic is the very large number of simulations required to efficiently handle all uncertainties. Since the simulation cost associated with these approaches is not quite significant for risk assessment in complex reservoir modeling simulation, a compromise has to be found between the reliability of the approaches and their related cost. To improve the feasibility of these sampling methods, one solution could be to reduce the modeling workflow simulation time. For instance, one could consider a material balance evaluation instead of a complex fluid flow simulation, streamline simulations or an efficient approximation of the classical modeling workflow. The two first approaches, which imply strong physical assumptions of the fluid flow behavior, may be useful to drive the interpretation of reservoir, but cannot ensure complete assessment for a real field case application. Thus, we will focus on providing an efficient approximation, through experimental designs, which consists in building a statistical model of the fluid flow behavior. Classical experimental design use Uncertainty assessment through experimental design has been validated for reservoir engineering [2][4]. This theory allows studying and quantifying the impact of uncertain parameters on a given production response. Let us consider a production response of interest, (typically the cumulative oil production, the recovery factor, the gas-oil ratio), denoted by prod, and some uncertain deterministic reservoir parameters which can be either "physical parameters" or "production parameters", denoted by x1, x2, …, xn . The primary goal of experimental designs is to provide the right set of simulations to perform to estimate the prod behavior as a function of x1, x2,… , xn. 3 More specifically, it allows to: − Identify the parameters that are actually influent on the production response prod. This step is crucial since it allows to eliminate parameters that have a negligible impact on the response and to focus on the influent ones. − Build an accurate proxy model (polynomial), which links the production response y to the influent uncertain parameters: prod ≈ β 0 + β 1 x 1 + β 2 x 2 + Κ + β 12 x 1 x 2 + Κ + β n x n2 (1) This simple analytical model can be used to by-pass the reservoir flow simulator for the uncertainty quantification, to finally provide fast evaluation of production forecasts in an uncertain environment. One of the most obvious uses of the proxy model is clearly the intensive computation, for instance for Monte-Carlo sampling. On the other hand, if the uncertain parameters are "controllable parameters", a simple optimization of the proxy model could provide the optimal condition to optimize the production. New Method for Improved Recovery Prediction One of the main objectives of a reservoir study is to determine the future production scheme to maximize the field value. This is an optimization: for instance, find the optimal location of a new well to maximize the net present value or the production of the field. The optimization can be done on an accurate proxy model of the field value. On the other hand, to design an improved recovery phase, the reservoir engineer would have to deal not only with a single characteristic value of the field (for instance the NPV or the cumulative oil production at a given time), but rather with whole production profiles. He would be able to determine the impact of controllable production parameters (well rates, well location, scenarios for injection scheme,…) on an entire production profile such as oil rate or plateau behavior. To solve such problem, we propose an approach, based both on experimental design method and inversion process, to approximate and optimize production profiles, with respect to different production scenarii. Methodology Overview The experimental design method will be useful to model the impact of changing production parameters on the production response at each time step of the profile. The inversion process will allow to determine the optimal value of these production parameters to match the desired recovery profile. This approach aims at taking the best of experimental design and inversion to take the right decision to manage the field production: − Experimental design approach is clearly well suited to such a workflow, since inversion process is fluid flow simulation consuming. Thus, in by-passing the fluid flow simulator by an accurate proxy model, the inversion of the desired recovery profile becomes instantaneous. − Inversion is here used not to constrain observed data, but "to match the most optimistic future" [3]. Thus, the reservoir engineer defines a synthetic profile for improved recovery. The inversion process aims at defining the value of the production parameters, which would allow satisfying this desired recovery profile. This approach, based on inversion and experimental designs, is illustrated through the workflow presented on Figure 1. 9th European Conference on the Mathematics of Oil Recovery — Cannes, France, 30 August - 2 September 2004 4 MAT CHING THE OPTIMISTIC RECOVERY PROFIL E IMPACT o f PRODUCTION SCENARIOS on ADDITIONAL RECOVERY E XP ERI ME NTAL DES I GN Inje c t io n Prof i le 250 200 150 Inje c t i on P ro f i le 250 100 200 In je c t i o n P ro f i l e 50 450 150 400 0 0 100 1000 2000 3000 4000 5000 350 6000 7000 8000 Ti me ( y e ar) 300 250 50 200 0 0 1000 2000 3000 4000 5000 6000 7000 8000 150 100 Ti me ( y e ar) 50 0 0 1000 2000 3000 4000 5000 6000 700 0 8000 Ti me ( y e a r) P RO XY M ODEL S FOR THE P RO FIL E T3 T1 Tn T2 Objective Function 350 Proxy Model s Prediction SCHEME IMPACT T.. . Rate (m3/d) 250 200 150 100 50 0 0 500 1000 1500 2000 Rate (m3/d) 250 200 150 100 50 0 0 500 1000 1500 2000 OP TI MIS TI C RECOV E RY PROFI LE 300 250 200 Optimization 150 300 100 250 50 200 OBTAI NE D RECOV E RY P RO FIL E 150 0 100 0 500 1000 1500 2000 50 0 0 500 1000 1500 2000 Figure 1: Method for improved recovery prediction Inverse problem formulation The inversion phase consists in minimizing an objective function, which model the mismatch between the desired synthetic profile for improved recovery and the current simulated profile, according to the values of the production parameters. The goal is to identify their respective optimal values with respect to the recovery profile of interest. The objective function F to minimize is of the following form: ⎛ nw EDpred ⎜ P ( x ) − P jOPT nT ∑ ij 1 ⎜ i =1 F (x ) = ∑ nT j = 1⎜ σj ⎜⎜ ⎝ ⎞ ⎟ ⎟ ⎟ ⎟⎟ ⎠ 2 (2) where: − x is the production parameters to be optimized. For instance, well locations, rates, etc., − nT is the number of time steps, n w is the number of production wells, − PijEDpred is the production response predicted by experimental design for the ith well and the jth time step, − P OPT is the optimal production response value that should be reached for the jth time step, j − σ j are weighting coefficients, which represent the tolerance to reach the ideal profile. In Equation 2, P OPT and σ j are chosen by the reservoir engineer to represent an optimistic j production profile to reach. The PijEDpred terms stand for the current simulated profile. 5 However, these values are not obtained directly through a fluid flow simulation, but using the proxy model provided by experimental designs. In fact, an experimental design approach is used to obtain, for each time step and for each well, a proxy model, which represents the behavior of the production as a function of the production parameters to optimize. This integrated approach, coupling experimental designs and inversion process, is powerful to help in taking the right decision to design production schemes in a risk prone environment. Note that the feasibility of different scenarii may be investigated to compare different production strategies or to test optimistic and pessimistic assumptions. Application to Plateau Duration Maximization In order to highlight the efficiency of this approach to help in decision taking in an uncertain framework, we present an application on a reservoir case. Reservoir Description The reservoir case is a 3D 3-phase Black-Oil synthetic reservoir model derived from real field. The horizontal grid is 31 in X-direction and 12 cells inY-direction respectively. Each cell is 250m by 250m. This reservoir is divided in 3 layers with equal thickness. There is no vertical communication between these layers. There is a strong bottom aquifer (layer 4). Concerning the horizontal displacement, the permeability distribution is slightly heterogeneous, as shown on Figure 2. The porosity is almost uniform at 27%. For the permeability, an uncertainty remains, which is modeled through a permeability multiplier in the interval [0.3; 1]. Figure 2: Horizontal Permeability Distributions - Layers 1, 2, 3. This reservoir is produced through 7 production wells located as shown on Figure 3. Each production well may produce with a water-oil rate up to 150m3/d. The maximum allowable water cut is 95%. All the wells are completed in the three reservoir layers. CLM- I101 CLM- P207 CLM- P107 CLM- I303 CLM- P101 CLM- P304 CLM- P204 CLM- I203 CLM- P103 CLM- P301 CLM- I305 CLM- I205 CLM- I306 CLM- I102 Figure 3: Injection and Production Wells Location The pressure maintenance will be led through a peripheral water injection scheme based on 7 injection wells. These wells are completed in the three layers. The injection starts at the beginning of the production to maintain pressure above bubble point pressure. 9th European Conference on the Mathematics of Oil Recovery — Cannes, France, 30 August - 2 September 2004 6 Objectives of Study The objective of this study is to determine the optimal injection strategy to produce the reservoir, that is to say the appropriate injection rates for each of the 7 injection wells to maximize the oil production, while taking into account the uncertainty that remains on the horizontal permeability. To do so, we propose to illustrate the methodology described above. In our case, the uncertain parameters, which will be involved, are the 7 injection rates and the horizontal permeability multiplier. The minimum injection rate has been fixed at 1m3/d to model a "no-injection" scenario, and the upper bound has been fixed to 300m3/d. We aim to maximize the oil production rate over the 15 years of production. Scheme Optimization In the proposed methodology described in Figure 1, the first step of this production scheme optimization, is to determine an experimental design to assess efficiently the impact of the uncertain parameters on the oil production rate. Since we are dealing with a total number of 8 uncertain parameters and aim at optimizing their respective values, we decide to consider a central composite design for 8 parameters, which implies 81 fluid flow simulations. The 81 simulation results (different combinations of the 7 injection rates and the permeability multiplier) are presented in Figure 4. Figure 4: Oil Production Profiles according to Experimental Design These production profiles are then used to fit as many response surfaces as time steps, that is to say 37 response surfaces. In doing so, we are able to reproduce and predict the oil production rate profile for any combination of the 8 considered parameters. Then, the response surfaces are used to build an objective function, as defined in Equation 2. To do so, a synthetic profile to be matched is defined according to the most optimistic expectation we can hope in terms of oil production. In order to determine optimistic but realistic oil production profile to be matched, a Monte-Carlo sampling, with uniform distributions for each of the 8 parameters, has been performed. Thus, 10000 possible oil production profiles have been considered to assess the range of uncertainty on oil production induced by the uncertainty on the 8 parameters. We would like to point out that these 10000 simulations have been made based upon the 81 response surfaces, which do not imply any additional fluid flow simulation. The target oil production profile to be matched is chosen as the maximum of the envelope (P0). This objective function is then minimized to find the optimal set of the uncertain parameters. Concerning this optimization phase, a special focus on the status of the horizontal permeability 7 should be done. In fact, it has no physical sense to aim at optimizing such unknown parameter, since we do not have any control on its value. That is why, in the whole optimization process, this parameter is still considered as uncertain, and was assigned a probabilistic uniform distribution. In doing so, our goal is to get an optimal probabilistic distribution for each controllable parameters, that is the 7 injection rates, which lead to fit as well as possible the required oil production profile while taking into account the uncertainty on the permeability. Results Figure 6 presents the obtained oil rate profiles after this scheme optimization. The red and green profiles represent respectively the maximum and minimum profiles that should be reached while taking into account the permeability uncertainty. The blue profile is the target profile assumed to be the most optimistic. R e q u ir e d P r o file M a x O b ta in e d M in O b ta in e d R e q u ir e d P r o file M in O b ta in e d M a x O b ta in e d Figure 6: Optimal Oil Rate Profiles versus Required Profile Figure 7: Optimal Injection Rates Distribution for the 7 wells 9th European Conference on the Mathematics of Oil Recovery — Cannes, France, 30 August - 2 September 2004 8 As illustrated on Figure 7, the optimal value for each injection rate is not a single value but a probabilistic distribution, since the permeability multiplier remains uncertain and has been modeled with a uniform distribution. We can observe that the optimal injection rate for well I102, is equal to 300m3/d, independently from the permeability value. For wells I203, I305 and I306, the optimal value is described with a probabilistic distribution, but the variance is quite low. A rate about 230m3/d, 90m3/d and 160m3/d respectively for these wells lead to an optimal injection scheme. On the other hand, the uncertainty on the permeability plays a major role for determining the optimal injection rates for wells I101, I205 and I303. This uncertainty on permeability implies a large spread of uncertainty for these optimal injection rates, varying for well I101 from 240m3/d to 300m3/d. This reservoir study highlight the interest of the proposed integrated approach for Improved Oil recovery, since the optimal injection scheme is clearly not to inject at a maximum rate for every well. In fact, the right balance has been found to improve oil recovery, while controlling preferential water displacement and avoiding water production. Conclusions The integration of statistical methods such as experimental design theory with inversion methods allows clearly to efficiently design production scheme for improved oil recovery while dealing with uncertainties. The experimental design technique helps in controlling and reducing the number of reservoir simulations to catch all influential parameter impact and finally to determine their value to optimize production. This approach was successfully applied to a reservoir case to determine the optimal injection rates to improve oil production and control water production. Acknowledgments The authors thank IFP for its permission to publish this work. Part of this work has been performed as part of the COUGAR II Joint Industry Project, sponsored by BHP-BILLITON CONOCO-PHILLIPS, GAZ DE FRANCE, PETROBRAS, REPSOL-YPF, SAUDI-ARAMCO. References [1] Box, G.E.P. & Draper, N.R.: ''Empirical Model Building and Response Surfaces'', Wiley Ed., 1987. [2] Damsleth E., Hage A. And Volden R.: "Maximum Information at Minimum Cost: A North Sea Field Development Study Using Experimental Design", paper SPE 23193 presented at the Offshore Europe Conference, Aberdeen, 3-6 September 1991. [3] Guérillot D., Roggero F.:"Matching the Future for the Evaluation of Extreme Reservoir Development Scenarios", 8th European Symposium on Improved Oil Recovery, Vienna, 15-17 May 1995. [4] Zabalza-Mezghani I., Manceau E., Feraille M., Jourdan A.:"Uncertainty Management From Geological Scenarios to Production Scheme Optimization", Journal of Petroleum Science and Engineering, to be published.