Introduction Digital Mammography QA: Comparing the

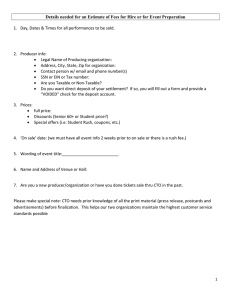

advertisement

Slide 1 Slide 2 Introduction Digital Mammography QA: Comparing the Manufacturers Recommendations What is QC and why is it important? Review & compare QC tests Key take home points Eric A. Berns, Ph.D. Northwestern University Medical School Lynn Sage Comprehensive Breast Center Chicago, IL Slide 3 Slide 4 Introduction ScreenScreen-Film MQSA – Mammography Quality Standards Act ACR – American College of Radiology Slide 5 Slide 6 ScreenScreen-Film Slide 7 ScreenScreen-Film Slide 8 ScreenScreen-Film ScreenScreen-Film Slide 9 Slide 10 ScreenScreen-Film FFDM In FFDM, the manufacturer designs and mandates their own QC program In FFDM, you must the manufacturers’ manufacturers’ QC program Slide 11 Slide 12 Quality Control: Why? Reduce exposure to patients and personnel Consistent image quality RWS Detect and correct for potential problems, before they impact image quality Slide 13 Slide 14 Before You Begin QC What is Quality Control? Determination of what is “Normal” Normal” Golden Rules for Medical Physicist & Tech QC Detection of what is “Abnormal” Abnormal” – Must use manufacturer’ manufacturer’s QC procedures Understanding of how to return to “Normal” Normal” from “Abnormal” Abnormal” – Manufacturers’ Manufacturers’ QC may refer to Monitor Manufacturers’ Manufacturers’ QC In particular, in FFDM, how do you know what you are – Multimodality Workstations have own separate QC seeing is what it is supposed to be? Slide 15 – Printers may have their own QC Slide 16 Before You Begin ACR Accreditation - www.acr.org – Physics forms • http://acr.org/accreditation/mammography/mammo_qc_forms.aspx • GE Senographe 2000D, DS, and Essential – – – – Fischer Senoscan Lorad Selenia Siemens Novation Fuji FCRm • Note: Note: if using unit for both screenscreen-film & CR, you must accredit for both FDA Accreditation – www.fda.gov/cdrh/mammography/ – Other vendors when approved Before You Begin Slide 17 Slide 18 Before You Begin Slide 19 Before You Begin Slide 20 Before You Begin Before You Begin Slide 21 Slide 22 Before You Begin Note: – For new unit: unit: Must use most current version Vs. – For renewal unit: unit: Can use older version (version used when tested previously) Slide 23 Slide 24 Mammo Unit Evaluation ScreenScreen-Film Mammo – Ensure locks, detents, angulation indicators, and mechanical support devices operate properly Collimation ScreenScreen-Film Mammo – Assure XX-ray field aligns with the light field – Collimator allows full coverage of receptor – Chest wall edge of compression paddle aligns with chest wall of receptor FFDM – Same FFDM – Same – Multiple targe/filters and/or multiple paddle positions – Chest Wall Missed Tissue – Compression Plate Overlap on the Chest Wall Side Slide 25 Slide 26 Collimation Fuji FCRm Fuji FCRm GE 2000D, DS, Essential Fischer Senoscan Lorad Selenia Siemens Novation Same as ScreenScreen-Film X X X X X Multiple target/filter combo’ combo’s X X Multiple paddle positions Collimation – Test for routinely used X • Collimator, bucky, X Chest Wall & Missed Tissue Compression Plate Overlap on Chest Wall Slide 27 X X X compression paddle combo’ combo’s X • target materials X Slide 28 GE Collimation – Mo/Mo – Rh/Rh – Different paddle positions Fischer Senoscan Collimation Slide 29 Slide 30 Fischer Senoscan Lorad Selenia Collimation Collimation Assessment – Use coin techniques as described in ACR Manual – 24 x 30 cm – 18 x 24 cm (left, center, right – paddle shifts) Slide 31 Slide 32 Siemens Novation DR Siemens Novation DR Chest Wall and Compression Plate Overlap Missed Tissue on Chest Wall – Place coin tangent to – Mount paddle chest wall edge of – Measure overlapping distance bucky – Add the missed tissue value – Measure coin and for total subtract from full – Must be < 6.5 mm diameter – Must evaluate for ALL – Missed tissue must be < 5 mm compression paddles including mag Slide 33 Slide 34 Limiting Spatial Resolution Spatial Resolution ScreenScreen-Film Mammo Fuji FCRm – LineLine-pair test tool GE 2000D, DS, Essential Fischer Senoscan Lorad Selenia Siemens Novation X X • Focal spot FFDM – LineLine-pair test tool • Focal spot • Detector & imaging chain Slide 35 Same as ScreenScreen-Film (Focal Spot Eval) Measure using LP phantom on top of acrylic MTF X X X X Slide 36 Fuji FCRm System Resolution – Up to 10 lp/mm Test Pattern – 4 cm acrylic – Parallel & Perpendicular to tube with 33-5 degree angle The system limiting spatial resolution must be: > 8 lp/mm + 2 lp/mm (6 to 10 lp/mm) Fischer Senoscan Evaluation of System Resolution – 3.153.15-16.6 lp/mm Test Pattern – Modulation in Normal mode @ 7 lp/mm must be > 10% – Modulation in Hi Res mode at 11.1 lp/mm must be > 5% Slide 37 Slide 38 GE 2000D, DS, & Essential GE 2000D MTF Measurement – Monthly – Raw Image Focal Spot Evaluation •Mo/Mo •Rh/Rh •Large & Small Spots (1.5 mag) MTF (%) = (Std. Dev.) x 222 / (Mean Dark ROI – Mean Light ROI) MTF (%) @ 2 lp/mm > 58% Slide 39 MTF (%) @ 4 lp/mm > 25% Slide 40 GE 2000D 2000D Addendum: SubSub-system MTF – Optional replacement for MTF & Focal spot – No need for film • Use specific bar pattern & 4.5 cm acrylic block GE DS & Essential MTF and CNR Measurement - Weekly – Test consistency of CNR and ensure contrast is adequate • IQST Test tool • Use ROI tools to calculate subsub-system MTF • Repeat at 1.8 mag Action Limit: – MTF @ 2 lp/mm > 58%, MTF @ 4 lp/mm > 25% – Change in CNR must not exceed 0.2 Slide 41 Slide 42 Lorad & Siemens AEC Performance ScreenScreen-Film Mammo Evaluation of System Resolution – 5-15 lp/mm Test Pattern – Measure optical densities The system limiting spatial resolution must be: • Different thicknesses using clinical modes > 7 lp/mm • Different density settings ((-2, -1, 0, +1, +2, etc.) FFDM – Measure resultant techniques – Measure signal, exposure, & SNR values Slide 43 Slide 44 AEC Fuji FCRm Fuji FCRm GE 2000D, DS, Essential Fischer Senoscan Lorad Selenia Siemens Novation X X Density Control Function Same as ScreenScreen-Film – 4 cm acrylic, ACR phantom technique Density Control Function X ACR Reproducibility X Image Mode Tracking X CNR X SNR – Repeat at -2, -1, 0, +1, +2 etc. density X X X X X X – Record mAs – mAs change should be 5 to 15% per step Slide 45 Slide 46 Fuji FCRm Fuji FCRm Reproducibility & Image Mode Tracking – 4 cm acrylic with clinical technique CNR Per Object Thickness – Position ion chamber in beam – Record mAs and X – Repeat 3 times – CNR using clinical technique for 2 cm – Repeat in each mode (small, large, mag, no grid) – Action Limits: Limits: – Repeat for 4 and 6 cm – Action Limits: Limits: • Coefficient of variation for Exposure or mAs must not exceed 0.05 • CNR of 2 cm relative to 4 cm must be > 100% • No significant difference in exposure between small and large bucky when using similar grids • CNR of 6 cm relative to 4 cm must be > 75% Slide 47 Slide 48 GE 2000D GE DS & Essential DS specific QC tests AOP Mode and SNR Check – Variable thicknesses of acrylic – Std, Auto – Evaluate: • Correct techniques? • Adequate SNR? Acrylic Thickness 2.5 cm TargetFilter Mo-Mo Selected kVp 27 kVp Selected mAs 20-60 4.0 cm Mo-Rh 28 kVp 35-90 6.0 cm Rh-Rh 32 kVp 35-90 – AOP Mode and SNR Check • Use builtbuilt-in software for image acquisition 2.5 cm Acrylic • AOP: STD/Auto Exposure Parameters For AOP STD mode oly Acrylic Thickness (mm) 4.0 cm Acrylic Each “raw” raw” image must have a measured SNR of at least 50 6.0 cm Acrylic Track/Filter mAs 25 Mo/Mo 2020-60 26 50 Rh/Rh 4040-90 29 60 Rh/Rh 4545-95 31 SNR must be > 50 kV Slide 49 Slide 50 Lorad Selenia Siemens Novation Automatic Exposure Control AEC Image Stability and Reproducibility and SNR – AUTOAUTO-FILTER – 2, 4, 6, 8 cm – ACR Phantom – 4 cm ((-5 thru +5) – Mo/Mo, 28 kV, “H”, sensor 1 – Use ROI to measure mean pixel value – Record mAs, SNR, Mean, Entrance Exposure (5 times) inside virtual AEC detector Action Limits: Performance Criteria – Coef. of Var for mAS and X < 5% – Pixel value should not vary by more – SNR and Mean shall not vary by + 15% of Mean than 10% of mean – Exposure compensation steps shall meet requirements in pixel value table Slide 51 Slide 52 Siemens Novation DR Uniformity of Screen Speed & Detector Performance AEC Thickness Tracking – 2, 4, and 6 cm – “H” mode – Max deviation = (Max difference / mean value ) * 100 ScreenScreen-Film Mammo – Measure if OD’ OD’s are consistent – Check for artifacts FFDM – FlatFlat-field uniformity – Detector calibration – Pixel correction test – CR Reader Scanner Performance Slide 53 Slide 54 Detector Performance GE Fuji FCRm 2000D, DS, Essential Fischer Senoscan Lorad Selenia Fuji FCRm Siemens Novation Dynamic Range Same as ScreenScreen-Film (Screen Uniformity) FlatFlat-Field Uniformity X Detector Calibration – To confirm the dynamic range of reader and plate X X X – Use 2 & 4 cm acrylic X CR Reader Scanner Performance X – Technique for 6 cm – View image to determine if 3 regions are visible Dynamic Range X Primary Erasure X InterInter-Plate Consistency X Geometric Distortion and discernable X Pixel Correction Ghosting X X X Slide 55 Slide 56 Fuji FCRm CR Reader Scanner Performance – Establish that IP reader & optics do not exhibit scan or print jitter – NonNon-grid exposure Fuji FCRm Primary Erasure (Additive & Multiplicative) – To assess the erasure performance of reader and plates – Additive: Shoot phantom, process, wait 1 minute, – Position rulers in “T” formation reprocess, change S value to 10X original, – Expose & process inspect for visibility of phantom image – Action Limit: Image must have smooth borders free from jagged edges or defects – Multiplicative: Shoot & process phantom, shoot 4 cm acrylic on same cassette, process and inspect for visibility of phantom image Slide 57 Slide 58 Fuji FCRm GE 2000D, DS, & Essential FlatFlat-field uniformity – Test to ensure detector performance acceptable InterInter-Plate Consistency • Measures detector uniformity (signal & noise) – To confirm xx-ray absorption & SNR consistency • Measures bad pixels – Expose plates using clinical technique with 4cm – System automatically calculates pass/fail acrylic – Record mAS (must be within +10%) – Calculate SNR (must be within +15%) QAP Slide 59 Slide 60 Fischer Fischer Senoscan Flat Field and Detector Calibration – Run daily calibration using software Use 4 cm Geometric Distortion acrylic – Exposure resulting in 1000 ADU’ ADU’s – No Artifacts at WW > 800 – Compute deviation between corner and center means –Use a 40 mesh Cu screen –Acquire image at low technique – Must be within + 20% of center ROI –Visually inspect for distortions or blurring Slide 61 Slide 62 Lorad Selenia Detector Calibration – Every two weeks Lorad Selenia Detector Ghosting – Assure ghosting does not interfere with image quality – 4 cm acrylic block – no paddle – 4 cm acrylic covering half of detector – Built in Calibration software – Set AEC clinically – Follow onon-screen instructions – 4 cm acrylic covering entire detector – Make exposure – • Review image for artifacts possible (~ 1 minute after first) • Repeat until you have 8 images • End calibration Calculate Ghost Image Factor = (MeanR3 – MeanR2 / MeanR1 – MeanR2) • Calibration is performed automatically Slide 63 Place 0.1 mm AL on top – Make 2nd exposure (AEC) as soon as – Must be within + 0.3 Slide 64 Siemens Novation DR Detector Uniformity – Make exposure: 28 kV, 50 mAS, Mo/Mo – Select ROI 128 x 128 pixels – Record measurements in corners and center – Pixel value inside each of 5 ROI’ ROI’s Siemens Novation Detector Calibration Test – Objective: to determine if system was correctly gain calibrated – Must be done weekly (technologist) – Follow onon-screen instructions – Acquire 8 images shall not differ by more than 10% – Images should be free of artifacts of mean Slide 65 Slide 66 Siemens Novation DR Siemens Novation DR Pixel Correction Test Ghost Image Evaluation – Calibration mode – Setup with 2mm steel bar – Create new pixel map – Exp 1: 1: Mo/Mo, 23 kV, 2 mAs – record mean – Follow onon-screen instructions – Exp 2: 2: Mo/Mo, 28 kV, 200 mAs - remove steel – Acquire image – Wait 180 seconds, place 4 cm Acrylic on top – Evaluate image is free from collimator or debris artifacts – Exp 3: 3: Mo/Mo, 28 kV, 14 mAs – System compiles new pixel – Calculate % Ghosting = (PV1 – PV2) / PV1 map +PV2 – System display results – must Action Limit: Limit: % Ghosting < 3% Slide 67 meet requirements Slide 68 Artifacts Artifacts ScreenScreen-Film Mammo Fuji FCRm GE 2000D, DS, Essential Fischer Senoscan Lorad Selenia Siemens Novation X X X X X – Evaluate cassettes Same as ScreenScreen-Film FFDM – Evaluate detector – CR: Imaging Plates Expose Using Acrylic Slide 69 Slide 70 Artifacts Artifacts Artifact evaluation Mo/Mo Slide 71 Artifacts Slide 72 Artifacts Mo/Rh Rh/Rh Slide 73 Slide 74 Artifacts Artifacts Possible cause: Possible Cause: Cause: condensation on Detector dropout or detector mismis-registration Slide 75 Slide 76 Artifacts Image Quality Processing Steps for Digital Images ScreenScreen-Film Mammo – ACR Phantom Scores Image Detection Calibration File Image Correction Raw Image Processing Processed Image Display – Optical Density & Contrast FFDM – ACR Phantom Scores • Pass/fail requirements differ by vendor – SignalSignal-toto-Noise Ratio (SNR) – ContrastContrast-toto-Noise Ratio (CNR) Slide 77 Slide 78 Image Quality Fuji FCRm Image Quality GE 2000D, DS, Essential Fischer Senoscan X X Lorad Selenia ACR Phantom Imaging Siemens Novation GE & Fischer & Fuji Lorad & Siemens Fibers 4 5 Specks 3 4 Masses 3 4 Same as ScreenScreen-Film Manual Techniques Clinical Technique X CNR X X Slide 79 X X Partial X X Slide 80 GE 2000D ACR Phantom Imaging – Manual technique (Mo/Mo, 26 kVp, 125 mAS) – Score the processed image GE 2000D ContrastContrast-toto-Noise Test (CNR) – To examine consistency of CNR ratio measured over time – Use the raw image – + 20% of baseline – Acquisition workstation – Each monitor of the RWS Background ROI Mass ROI – Laser imager CNR = (Meanbackground - Meanmass)/SDbackground Slide 81 Slide 82 GE DS Fischer Senoscan Phantom Image Acquisition Test and Image Quality DS specific QC tests – Select Techniques to give 1000 ADU – Phantom Image Quality – Compare background mean, StdDev, and ADU level difference to baseline values • Manual technique: Rh/Rh, 29 kVp, 56 mAs – Score : 4 fibers, 3 speck groups, and 3 masses – MTF and CNR Measurement • Use IQST test tool • Use builtbuilt-in software for image acquisition • Manual technique: Rh/Rh 30 kVp, 56 mAs • Results are automatically displayed (pass/fail) • Same action limits as 2000D Slide 83 Slide 84 Lorad Selenia Siemens Novation DR Phantom Image Quality – Select clinical exposure mode (i.e. AUTOAUTO-FILTER) – Print film – Measure background OD and density difference – Plot on tech worksheets • Background must be > 1.20 OD + 0.20 • DD must be > 0.40 + 0.05 Phantom Image Quality – Position phantom 1 cm over chest wall edge – Select: 28 kV, AECAEC-Auto, Mo/Mo – Score on RWS or Film – Score on each Soft Copy Workstation • 5 fibers – Fiber > 5 • 4 speck groups – Specks > 4 • 4 masses – Masses > 4 Slide 85 Slide 86 Lorad & Siemens Fuji FCRm ContrastContrast-toto-Noise Test (CNR) – To examine consistency of CNR ratio measured over time – Use 4 cm acrylic & 0.2 mm Al SNR and CNR Measurements – Manual technique (Mo/Mo, 26 kVp, 125 mAs) – Calculate CNR using software – SNR at least > 40 – + 20% of baseline – CNR should stay within ±15% of baseline • Obtained during acceptance testing Slide 87 Slide 88 kVp ScreenScreen-Film Mammo – Assure that actual kVp is • Accurate (+ (+ 5% of indicated) • Reproducible (Coeff. Var. < 2%) FFDM – Same HVL ScreenScreen-Film Mammo – Assure HVL is adequate to minimize patient dose – HVL shall meet FDA’ FDA’s Performance Standards FFDM – Same Note the lead sheet Slide 89 Slide 90 Dose Radiation Output ScreenScreen-Film Mammo ScreenScreen-Film Mammo – Dose for single CC view of ACR phantom shall – System shall be capable of producing a not exceed 3.0 mGy per exposure minimum output of 7.0 mGy/sec @ 28 kVp Mo/Mo over 3.0 second period FFDM FFDM – Same – Same – S value confirmation – Exposure Linearity Slide 91 Slide 92 Radiation Output Fuji FCRm Same as ScreenScreen-Film X S Value Confirmation X Exposure Linearity GE 2000D, DS, Essential Fischer Senoscan X Fuji FCRm Lorad Selenia Siemens Novation X X S Value Confirmation – Make exposure at 25 kV Mo/Mo to give X > 20 mR – Exposure cassette at this technique X (wait 10 min. & process) – Record S value – Calculate “Corrected S value” value” – Action Limit: Limit: Corrected S value should not exceed the range of 120 + 20% (96 < S < 144) Slide 93 Slide 94 Viewing & Viewing Conditions Fischer Senoscan Exposure Linearity and Reproducibility ScreenScreen-Film Mammo – Procedure: – Luminance (> (> 3000 cd/m2) • Measure exposure at specified techniques – Room illuminance (< (< 50 lux) • Calculate: Output = Average exposure reading/mA – Viewbox cleaning Linearity = (A(A-B)/(A+B) < 0.08 FFDM Reproducibility = StdDev/Avg < 0.035 for each technique – Same Slide 95 Slide 96 Assessing Tech QC ScreenScreen-Film Mammo Film Processing ScreenScreen-Film Mammo – Measure optical densities – Assess site’ site’s QC program – Check that QC tests are properly performed – Independent checks of tech QC tests • Density difference, midmid-density, base+fog • Measures consistency FFDM – Manufacturers’ Manufacturers’ recommendations FFDM – Same – Some refer to printer manufacturers’ manufacturers’ recommendations – Typically identical to ACR SFM Manual Slide 97 Slide 98 Film Processor QC Follow Printer Manufacturers QC If Not, Use Theirs Fuji FCRm GE 2000D, DS, Essential Fischer Senoscan X X X X X X Film Processing Lorad Selenia Base + Fog Siemens Novation Wet Processing Follow FFDMs’ FFDMs’ QC X Laser Printer Northwestern Memorial Hospital - Processor ID: Kodak 8900 - Oct 2006 Base + Fog Northwestern Memorial Hospital - Processor ID: 2 - MAR 2006 Base + Fog X 0.35 0.40 0.30 0.35 0.30 0.25 0.25 0.20 0.20 0.15 0.15 Base + Fog Action Limit = 0.22 Base + Fog Action Limit = 0.23 0.10 Base + Fog Daily Value 0.10 Base + Fog Daily Value Base + Fog - Operating Level = 0.19 Base + Fog - Operating Level = 0.2 0.05 0.05 0.00 O ct ob er 2, O 20 ct ob 06 er 3, O c to 200 be 6 r 4, O ct 20 ob 06 er 5, O 20 ct ob 06 er 6, O c to 200 ber 6 O 9, cto 20 ber 06 10 O ct ,2 ob 00 er 6 1 1, O cto 200 ber 6 12 O cto , 20 be 06 r 13 O ct ,2 ob 00 er 6 1 6, O ct 200 ob er 6 17 O cto , 20 be 06 r 18 O ct ,2 ob 00 er 6 1 9, O cto 20 ber 06 20 O cto ,2 0 06 be r2 O 3, ct 200 ob er 6 2 4, O cto 20 ber 06 25 O cto , 20 be 06 r2 O 6, ct 200 ob er 6 2 7, O cto 20 ber 06 30 ,2 0 06 06 06 a r- a r- 6 06 a r06 -M ar -0 6 M ar -0 6 14M ar s er -0 6 vic e 3/ 15- 14 M a r06 16 -M a r06 17 -M a r06 20 -M a r06 21 -M ar -0 6 22M ar -0 6 23M ar -0 6 24M ar -0 6 27M a r28- 06 M a r06 29 -M a r06 30 -M a r06 31 -M a r06 9 -M 8 -M 13- 10 a r- a r- a r- ar -0 06 7 -M 6 -M 3M 2M 1M 06 0.00 Date Slide 99 Date Slide 100 Film Processing Film Processing MidMid-Density Density Difference Wet Processing Laser Printer Northwestern Memorial Hospital - Processor ID: 2 - MAR 2006 Mid-Density Northwestern Memorial Hospital - Processor ID: Kodak 8900 - Oct 2006 Mid-Density Wet Processing Laser Printer Northwestern Memorial Hospital - Processor ID: 2 - MAR 2006 Density Difference Northwestern Memorial Hospital - Processor ID: Kodak 8900 - Oct 2006 Density Difference 2.60 2.30 1.70 2.50 1.60 2.40 1.50 2.30 1.40 2.20 1.90 1.30 2.10 1.80 1.20 1.70 1.10 HD Step=13 2.00 LD Step=10 MD Step=12 2.20 1.90 2.10 1.80 2.00 1.70 1.60 1.50 2.00 Mid-Density Upper Control Limit = 1.48 1.40 1.90 Mid-Density Daily Value 1.00 Mid-Density Daily Value Operating Level = 1.33 Mid-Density Daily Value 1.70 Mid-Density Lower Control Limit = 1.76 Density Difference Daily Value 1.20 Density Difference Daily Value 1.60 1.10 Density Difference Lower Control Limit = 1.95 Date 06 , 20 6, cto be r O O ct 200 ob 6 er O 9, cto 20 be 06 r1 O 0, cto 20 be 06 r1 O 1, cto 20 be 06 r1 O 2, cto 20 be 06 r 13 O , 20 ct ob 06 er 16, O cto 200 ber 6 17, O cto 200 be 6 r1 O 8, cto 20 be 06 r1 O 9, cto 20 be 06 r2 O 0, cto 20 be 06 r 23 O , 20 ct ob 06 er 24, O cto 200 ber 6 25, O cto 200 ber 6 26, O cto 20 be 06 r2 O 7, cto 20 be 06 r3 0, 20 06 06 20 20 , 20 3, 2, be r5 be r4 ber cto cto ct ob er cto O O 6 6 6 06 Date O 1-M ar -0 6 2M ar0 3-M 6 ar -0 6 6M ar06 7-M ar -0 6 8M ar0 9-M 6 ar06 10 -M ar06 13 -M ar06 14 -M arse 06 rv ic e 3/ 14 15 -M ar -0 166 M ar06 17 -M ar -0 206 M ar06 21 -M ar -0 226 M ar06 23 -M ar -0 246 M ar06 27 -M ar06 28 -M ar06 29 -M ar06 30 -M ar06 31 -M ar06 ob O ct ob 6 20 06 er 11, 20 ob 06 er 12, O ct 20 ob 06 er 13, O ct 20 ob 06 er 16, O ct 20 ob 06 er 17, O ct 20 ob 06 er 18, O ct 20 ob 06 er 19, O ct 20 ob 06 er 20, O ct 20 ob 06 er 23, O ct 20 ob 06 er 24, O ct 20 ob 06 er 25, O ct 20 ob 06 er 26, O c to 20 ber 06 27 O c to ,2 00 ber 6 30 ,2 00 6 2 00 er 10, O ct 6 6 2 00 2 00 2 00 9, er ob ct O ct O 2 00 2 00 6, ob er 5, 3, 2, 4, er er er er ob ob ob ob ct O ct ct ct ct O O O O 9M ar 1 0 -0 6 -M ar06 13 -M ar -0 14 6 -M ar06 rv ic e 3 1 5- /1 4 M ar -0 16 6 -M ar1 7- 06 M ar -0 20 6 -M ar06 21 -M ar -0 22 6 -M ar06 23 -M ar2 4- 06 M ar -0 27 6 -M ar2 8- 06 M ar -0 29 6 -M ar06 30 -M ar3 1- 06 M ar -0 6 se 6 6 06 6 ar- 8 -M 06 ar -0 ar0 ar -0 ar- ar- M 7- M M 6 -M 3- 2- 1 -M 06 Date 1.50 06 1.00 0.70 1.30 Density Difference Daily Value Operating Level = 1.62 Density Difference Lower Control Limit = 1.47 Density Difference Daily Value Operating Level = 2.1 0.80 1.40 Density Difference Upper Control Limit = 1.77 1.30 Density Difference Upper Control Limit = 2.25 Mid-Density Lower Control Limit = 1.18 0.90 Mid-Density Daily Value Operating Level = 1.91 1.50 1.80 O Mid-Density Upper Control Limit = 2.06 1.60 Date Slide 101 Slide 102 Film Processing Lorad Dmax Laser Printer QC - Daily Laser Printer Northwestern Memorial Hospital - Processor ID: Kodak 8900 - Oct Dmax 2006 40% • SMPTE pattern from AWS • Measure OD 4.00 3.90 3.80 3.70 3.60 3.50 • 10%, 40% and 90% • Plot midmid-density (40%), density difference (40(40-10%), lower density (90%) • + 15 from baseline 3.40 3.30 3.20 3.10 3.00 Dmax Daily Value 2.90 2.80 90% 10% Dmax - Operating Level = 3.44 Dmax Action Limit = 3.19 2.70 cto cto O O O cto be r2 ,2 00 be 6 r3 ,2 00 be 6 r4 O ,2 cto 00 be 6 r5 O ,2 cto 00 be 6 r6 O ,2 cto 00 be 6 r O 9, cto 20 be 06 r1 O 0, cto 20 be 06 r O 11 cto ,2 00 be 6 r1 O 2, cto 20 be 06 r O 13 cto ,2 00 be 6 r1 O 6, cto 20 be 06 r O 17 cto ,2 00 be 6 r1 O 8, cto 20 be 06 r 19 O cto ,2 00 be 6 r2 O 0, cto 2 be 00 6 r2 O 3, cto 20 be 06 r2 O 4, cto 20 be 06 r2 O 5, cto 20 be 06 r2 O 6, cto 20 be 06 r2 O 7, cto 20 be 06 r3 O 0, cto 20 be 06 r3 1, 20 06 2.60 Date Slide 103 Slide 104 RWS QC Follow monitor manufacturers QC If Not, Use FFDM’ FFDM’s Multimodality Workstations Fuji FCRm GE 2000D, DS, Essential X X X X X X Fischer Senoscan Lorad Selenia Siemens Novation FDA Approved Multimodality Workstations – AGFA IMPAX MA3000 – Sectra IDS5/mx – Kodak DirectView PACS System 5 – McKesson’ McKesson’s PACS Mammo Station – iCad Second Look 500M Use FFDM manufacturers’ manufacturers’s QC X X – Cedera II-ReadMammo – Fuji Synapse – GE Seno Advantage & Centricity – Fischer Senoview Plus (Cedera) – Hologic SecureView DX – Siemens MammoReportPlus Slide 105 Slide 106 AGFA IMPAX MA3000 – – – – – – – Barco Clean monitor surface Measure display white & black Measure quality level Measure uniformity Calibrate displays View SMPTE pattern Viewing conditions – – – – Eizo GE Seno Advantage – – – – I-Guard Check Quality Level Display White Calibration Settings Check – – – – Viewing conditions check and setting Monitor calibration Image quality – SMPTE pattern Analysis of screen uniformity Pattern Check Luminance Check Grayscale Check Uniformity Check Siemens MammoReport Plus – – – – – – – Geometric distortion Reflection Luminance Response Luminance Uniformity Resolution Noise Overall Evaluation Slide 107 Planar – – – – – Monitor Cleaning Viewing Conditions Check Monitor Calibration Check Image Quality – SMPTE Visual Inspection for Display Defects Slide 108 Suggestions Troubleshooting QC Keep a good file system for naming & numbering the different QC tests Archive all digital QC images on a CD Keep QC test tools in a safe place Repeat test – Clean plexiglass & move slightly Questions to ask yourself: Perform flatflat-field imaging before phantom imaging tests – Are you using the correct image? Raw vs. Processed? Perform testing in the morning – Are the ROI’ ROI’s in the correct location? Have a system for monitoring the “Auto Print/Auto Push” Push” functions ReRe-boot system Call service – ReRe-calibration solves most image quality problems Slide 109 Slide 110 Key Take Home Points Key Take Home Points Obtain proper handshands-on training Review workstation monitors – look at the clinical Must perform manufacturer specific QC tests images! Artifacts – most problems can be seen here – Do they match? ReRe-booting and/or rere-calibrating fixes most – Appropriate dark and light levels problems Be aware of separate QC for review workstations Laser Printer – Dmax at least 3.5 OD Know, and be involved with, your site QC program – MidMid-density about 1.5 OD Slide 111 Slide 112 Thank You SAM Questions Digital Mammography Quality Assurance: Comparing the Manufacturers Recommendations Slide 113 4% 16% 62% 0% 18% Slide 114 In digital mammography, who mandates the pass/fail criteria for site QC? 1. The American College of Radiology 2. The FDA 3. The FFDM unit manufacturer 4. NEMA 5. MQSA Slide 115 Answer: 3 - The FFDM unit manufacturer References MQSA Regulations 900.12(e)(6) http://www.fda.gov/CDRH/MAMMOGRA PHY/frmamcom2.html#s90012 Slide 116 How do you accredit a Fuji CR Mammography system which uses both CR and screenscreen-film on the same x-ray system? Answer 3: The FFDM unit manufacturer Explanation “the quality assurance program shall be substantially the same as the quality assurance program recommended by the image receptor manufacturer, except that the minimum allowable dose for screenscreenfilm systems in this section” section” As 1 mammography unit? As 2 mammography units? 3. You cannot use CR and film on the same unit. 4. CR is exempt from accreditation 4% 1. 92% 2. 4% 0% Slide 117 Slide 118 Answer: 2 – As 2 mammography units References http://www.acr.org/accreditation/mammography/ mammo_faq/mammo_faq_mamac.aspx#8.0.1 Slide 119 Answer: 2 - As 2 mammography units Explanation As of November 15, 2006 facilities using both screenscreen-film and CR on the same mammography units must accredit these 2 systems as 2 separate units. Slide 120 What are the minimum passing ACR phantom scores for the Lorad Selenia for weekly QC? 4% 1. 11% 2. 80% 3. 0% 4. 4% 5. 5 Fibers, 4 Speck Groups, 3 Masses 4 Fibers, 3 Speck Groups, 3 Masses 5 Fibers, 4 Speck Groups, 4 Masses 4 Fibers, 4 Speck Groups, 3 Masses 4 Fibers, 4 Speck Groups, 4 Masses Answer 3: 5 Fibers, 4 Speck Groups, 4 Masses References Hologic. Lorad Selenia Quality Control Manual MANMAN-00093, Revision 003, Bedford (MA): Hologic, 2005 Slide 121 Answer 3: 5 Fibers, 4 Speck Groups, 4 Masses Explanation The Lorad Selenia QC manual states that the ACR Phantom minimum passing scores are as follows: 5 Fibers 4 Speck Groups 4 Masses