Application of PIV to characterise the Flow- Stationary Flow-Bench

advertisement

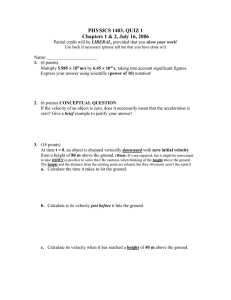

Application of PIV to characterise the FlowPhenomena of a Heavy-Duty Cylinder Head on a Stationary Flow-Bench E. Doosje1, R.J.M. Bastiaans, R.S.G. Baert Eindhoven University of Technology Abstract With modern heavy-duty diesel engines the design of the inlet ports in the cylinder head is such that some degree of swirling motion is induced in the engine cylinders during intake. This swirling motion is mostly characterized using a stationary flow bench. In such a flow bench, a dummy cylinder is used instead of the cylinder in the engine. In this situation there is no moving piston, the air can flow out of the open end of the dummy cylinder. To measure the intensity of the swirling motion a swirl-torquemeter is used. This swirl-torquemeter is a flow rectifier, which is placed in the dummy cylinder. The restraining torque on the flow rectifier is a measure of the momentum in the flow. Simulations of the flow in the cylinder indicate that the flow is influenced by the flow-rectifier in such a way that the measured values can be questioned. One of the objectives in this research is to find out if this influence exists. To do this, the velocity field in the cylinder is measured using Particle Image Velocimetry (PIV). From the velocity measurements, the swirl was calculated and compared to the swirl measured using a swirl-torquemeter. The validity of the assumptions made when using a swirl-torquemeter was evaluated from the velocity fields. Last, turbulence characteristics were determined and a spectrum was made. 1 Introduction In diesel engines, the motion of the charge is used to promote the mixing of fuel and air in the combustion chamber at the moment the fuel is injected ([3],[4]). In heavy-duty engines (e.g. truck applications or stationary power generation) a rotating air motion is used. This air motion is called swirl. The axis of rotation is parallel to the cylinder axis, but does not necessarily coincide with it. To measure the rotational speed of this air motion different methods are applied. In the industry so called swirl-torquemeters are commonly used. These measurements are performed on a flow-bench rather than in a running engine. On such a flow-bench the cylinder head to be measured is placed in normal or upside-down orientation; a 1 Corresponding author, email: e.doosje@tue.nl 302 Session 5 dummy cylinder is placed instead of the normal engine liner. There is no moving piston in this situation; the air can flow out of the open end of the cylinder. The swirl-torquemeter is then placed on the open end of the dummy cylinder. The swirl-torquemeter consists of a flow-rectifier, which straightens the rotating flow (Fig. 1). This flow straightening causes a reaction torque on the flow-rectifier. This torque is equal to the angular momentum-flux in the flow. The angular mo2π R mentum-flux I& can be calculated using I& = ∫ ∫ ρ ⋅ vax ⋅ vtan ⋅ r 2 drdϕ , in which 0 0 vax and vtan are the axial and tangential velocity components and r the radius. Fig. 1. Swirl-torquemeter principle of operation [7]. If one assumes a certain flow-profile and moment of inertia, the measured torque can be converted to an angular rotation speed. For swirl measurements, a so-called ‘solid-body’ rotation is assumed for this purpose. With this assumption the tangential velocity component vtan is proportional to the radius r , v tan = ω ⋅ r , in which ω is the angular velocity of the charge. The axial velocity component vax is assumed constant in the cylinder. Assuming also a constant density ρ , the rotational speed can be calculated from ω r = 2⋅M m& ⋅ Rcyl 2 . In this equa- tion, M is the measured torque, m& is the mass flow and Rcyl is the radius of the cylinder. Turbulence and PTV 303 In this research, PIV was applied to measure a 2D velocity-field at the location in the cylinder, where normally the swirl-torquemeter would be placed. The resulting velocity-field was used to calculate the reaction torque that a swirltorquemeter would measure. This calculated torque was then compared to the readings from a swirl-torquemeter, measured on a reference flow-bench using the same cylinder head. The objectives of this study can be summarized as follows: 1. 2. 3. 4. 5. To obtain insight on the flow-phenomena in a stationary flow bench application. To test the ‘solid-body’ assumption used in swirl measurement practice. To try and predict angular swirl momentum from PIV measurements and compare these with readings from a swirl-torquemeter. To check on influence of the swirl-torquemeter on the flow. To analyse the flow turbulence. 2 Experimental Set-up 2.1 Flow-bench In order to use the PIV technique, a dedicated stationary flow-bench was built in which the dummy cylinder was replaced by a glass cylinder. The dimensions were kept equal to the cylinder used in the reference flow-bench. The flow through the set-up was controlled in such a way, that the pressure drop over the inlet section is kept constant (Fig. 2). This pressure drop, measured between the inlet manifold and the dummy cylinder, was set to 10 kPa. A compressed air system was used for the air supply. The air, which was seeded for the PIV measurements, was extracted from the set-up and filtered before releasing it back into the atmosphere. The maximum airflow used was approx. 700 mn3/h. The cylinder head used is a modern, 4-valve type with two inlet and two exhaust valves. 2.2 Seeding To achieve the necessary seeding density for the PIV measurements, different devices have been tested. A simple nozzle-type device was found to perform best and was used in the measurements. Also, different seeding materials were tested. Titanium dioxide was found to perform best. The material used was commercially available TiO2, and had a mean diameter of around 1 µm. This material was mixed with approx. 10 mass percent of larger particles (i.e. TiO2 with a diameter of 60 µm) to prevent clogging of the material in the nozzle. The seeding supply was controlled by manually regulating the amount of seeding. Because the imaging diameter of the particles is diffraction limited, it is not possible to distinguish between the small and large particles at the time of evalua- 304 Session 5 tion. The number of larger particles, however, is small compared to the total number of particles. This means that the error due to the bad following behaviour of the large particles is small. Compressed air Air extraction Camera controlsignal measurementsignal Pressure relief 7.5 => 3 bar Seeding introduction MFM Buffer 2 m3 p=3 bar (constant) Optical access DPM Flow Measurement plane Cylinder Control valve rectifier 1.75*B Cylinder head valveactuator laboratory + Setpoint dp (preset) - PID delta p + Setpoint flow (fluctuates) - PID flow DPM : Differential Pressure Meter MFM : Mass Flow Meter Fig. 2. Flow set-up. 2.3 PIV-system A double-cavity ND-YAG laser (Continuum Surelite) with a pulse energy of 200 mJ was used. The maximum repetition frequency was 10 Hz, the pulse duration 9 ns. To form a light sheet, a single spherical positive lens and a single negative cylindrical lens were used. The sheet thickness was approx. 1.5 mm. The camera used was a Kodak ES 1.0 CCD camera, with a CCD of 1008x1018 pixels. A 532 nm filter was used to prevent ambient light from entering the camera. The images were recorded with a Dantec FlowMap processor, which calculated the raw vector maps by cross-correlation processing. The time between frames was set to 10 µs. Further validation and analysis was done using various routines written with Matlab. The recorded images were stored on disk to analyse these later using different interrogation methods. The data transfer speed of the PIV system at which the images are transmitted limits the measurement frequency to one velocity field every two seconds. This relatively large interval assures that the velocity fields are statistically independent, which is important for the present turbulence analysis. Because the seeding quantity was regulated manually, it was not possible to keep the seeding density sufficiently high. Therefore, an interrogation area size of 64x64 pixels was used. For selected images, it was possible to use an area of 32x32 pixels, however to obtain sufficient velocity fields for averaging, all image sets were initially processed using a 64 pixel interrogation area. Since 50% overlap was used, there are 30x30 vectors in the velocity field. Turbulence and PTV 305 3 Measurements The measurement section was located 1.75 times the cylinder-bore B downstream from the cylinder head. Measurements were performed in a plane perpendicular to the cylinder axis. The flow rate was set by adjusting the valve lift and keeping the pressure drop constant. For comparison of the calculated torque to the torque measured with an impulse swirl meter, the flow rate must be the same in both sets of experiments. To check this, the flow rate was compared to a reference measurement of the same cylinder head on a different flow bench and was found to be nearly equal. Measurements were performed for different valve lifts ranging from 20% to 95% of the full span. For each valve lift setting, PIV measurements were made until approximately 150 image sets were acquired. After manual rejection of the image-sets with a low seeding density, approximately 100 raw velocity fields were available for validation and analysis. At a later stage, the light sheet was rotated by 90 degrees, so the velocity field in the vertical plane through the cylinder centre could be measured. This measurement was performed for a free outflow (the same situation as the previous measurement). A flow-rectifier was then placed in the cylinder to simulate the presence of a swirl-torquemeter, and the measurement was repeated to see the effect on the velocity field. 4 Validation methods To validate the raw velocity fields and remove spurious vectors, various routines in Matlab were used. The total number of outliers was about 20-25%, depending on the flow conditions. Three criteria for validation were applied: 4.1 Absolute length of a velocity vector A normal distribution was assumed for the ensemble of the length of all vectors in the field. Vectors that have a length deviation of more than 3 times the standard deviation σ were rejected. After rejection of these vectors, a new mean and standard deviation were calculated. This process was repeated until all remaining vectors were within the mean plus or minus 3 times the standard deviation σ . Calculating this distribution for all vectors at a certain grid-location during a time interval would statistically be more correct, however the result is nearly the same since spurious vectors caused by correlation errors are found far from the mean. A distribution plot of all initial raw vectors confirms this. Using the same preset limit value for all fields is very difficult, since the mean velocities are not the same. 306 Session 5 4.2 Peakheight-ratio The ratio of the heights of the first and second peak was taken to be >1.05. This threshold value has been selected based on experience from earlier measurements. 4.3 Deviation of a velocity vector relative to the local median For each vector, a local median was determined using a number of ‘layers’ around the vector (e.g. a median for 3x3, or 5x5 vectors). Relative to this local median, a deviation in velocity magnitude and direction was calculated. A separate threshold was set for the deviation in magnitude and direction, and vectors were rejected according to this threshold. The use of the local median is preferred over the local mean; in areas with many spurious vectors (for instance due to a low seeding density) the local mean is not representative [8]. These validation methods were applied in the order described. When the order of the validation methods is altered, the first step always removes the most invalid vectors. Rejected vectors were replaced by an interpolation from neighbouring vectors. 5 Results 60 60 40 40 20 20 y [mm] y [mm] Two examples of single velocity fields can be seen in Fig. 3. Limitations of the PIV equipment limit the measurement frequency to one velocity field every two seconds. These velocity fields are clearly snapshots of the flow, since they are very different. It can be seen that the flow is very unstable. The circles in the figures indicate the position of the inlet valves, when viewed from the cylinder side and are printed there for orientation in comparisons with CFD calculations. 0 0 −20 −20 −40 −40 −60 10 m/s −60 −60 −40 −20 0 x [mm] 20 40 60 10 m/s −60 −40 −20 0 x [mm] 20 Fig. 3. Instantaneous velocity fields, valve lift 80%. 40 60 Turbulence and PTV 307 Since the swirl-torquemeter has certain size and mass, the torque it measures is due to some time average of the velocity fields it straightens. When the velocity fields for a valve lift of 80% are averaged in time, the field in Fig. 4 results. 60 40 40 20 20 y [mm] y [mm] Vectorveld (smoothed), lift: 12 mm 60 0 0 −20 −20 −40 −40 −60 10 m/s −60 −60 −40 −20 0 x [mm] 20 40 10 m/s −60 60 Fig. 4. Time averaged field, valve lift 80%. 0 x [mm] 20 40 60 60 40 40 20 y [mm] 20 y [mm] −20 Fig. 5. Time averaged field, valve lift 40%. 60 0 0 −20 −20 −40 −40 −60 −40 10 m/s −60 −60 −40 −20 0 20 40 Fig. 6. Time averaged field, valve lift 60%. 60 10 m/s −60 −40 −20 0 [ 20 40 60 ] Fig. 7. Time averaged field, valve lift 95%. In Figs. 5 to 7, three more time averaged velocity fields are shown; the valve lifts are 40, 60 and 95% respectively. It can be seen that for lower valve lifts and therefore lower mass flow rate the motion of the air is less like a solid body rotation. At lower valve lifts the centre of rotation is shifted from the cylinder centre and the tangential velocity component has changed direction in a part of the field. The arrows in the figures are scaled in the same way so the magnitude of the velocity can be compared easily. 308 Session 5 6 Torque Calculations and Comparison The integral equation for calculating the torque or angular momentum-flux I& , 2π R I& = ∫ ∫ ρ ⋅ vax ⋅ vtan ⋅ r 2 drdϕ can be approximated using the following summation 0 0 on the interrogation areas: 2π R ∫∫ ρ ⋅ v I& = ax ⋅ vtan ⋅ r 2 drdϕ ≅ ∑ϕ ρ ⋅ v ax ⋅ vtan ⋅ r 2 drdϕ = m& r, 0 0 ∑v tan ⋅ rdxdy = m& x, y ∑ (v ⋅ x − u ⋅ y)dxdy x, y This summation is calculated for all interrogation areas within the cylinder perimeter. Assuming a constant axial velocity and density, the local values do not need to be known. Measuring the total mass flow rate is sufficient. In Fig. 8, this torque calculation is shown for a measurement series of one valve lift setting (65% lift). The line in the figure is the running average of the calculated torque values, whereas the stars are the instantaneous torque values themselves. It can be seen that the torque values from individual velocity fields show a large fluctuation. The average however, does take a rather constant value after about 50 velocity fields. Due to its mass and dimensions, the swirl-torquemeter is believed to measure the average of the torque induced by the flow field. Distribution/convergence calculated torque (vax constant), lift: 65% 100 190 Reference swirl-torquemeter 80 PIV constant axial velocity PIV scaled axial velocity 140 40 torque [Nmm] Calculated torque [Nmm] 60 20 90 0 40 −20 −40 0 20 40 60 80 Velocity field nr. 100 120 140 -10 0 20 40 60 80 100 valve lift [%] Fig. 8. Torque calculation, valve lift 65%. Fig. 9. Torque comparison. In Fig. 9 the calculated torque is compared against the measured torque from a swirl-torquemeter. The calculated torque from PIV is substantially lower than the torque measured with the swirl-torquemeter. In the figure, 2 lines for the calculated torque are drawn. The lower line, labelled ‘PIV constant axial velocity’, is the torque calculated using the equation above. Here, the axial velocity is assumed constant in the cylinder (a so-called ‘plug-flow’ profile). The upper line, labelled Turbulence and PTV 309 ‘PIV scaled axial velocity’, is calculated using a scaling of the axial velocity with the velocity in the measurement plane. This scaling is done in such a way that the total flow is the same as in the previous method. When using this scaling, the velocity vectors would make the same angle with the measurement plane. As can be seen, the torque calculated using this scaling is closer to the reference torque. More important, it shows that measuring only 2 velocity components is insufficient for a good comparison between a swirl-torquemeter and the velocity measurements. One can calculate almost any torque by assuming some distribution of the axial velocity in the cylinder. The real flow is much more complicated than the solid-body profile assumption used in swirl measurement practice. 7 Tangential Velocity Profile To calculate a rotational speed from the measured torque when using a swirltorquemeter, a solid-body flow profile is assumed. In such a profile, the tangential velocity is proportional to the radius. In the time averaged velocity fields, the radial distribution of the tangential velocity is determined. The cylinder bore is divided in rings of equal width (Fig.10). After this, the tangential velocity is averaged within each ring. In Fig. 11 this distribution is plotted for a number of valve lifts. It is clear that the solid-body assumption is less valid at lower valve lifts (40% and 60% valve lift). An ideal solid-body profile would yield a straight line. The distribution at larger valve lifts is closer to this (80% valve lift in the figure). Tangential velocity 12 valve lift 40% valve lift 60% 10 valve lift 80% vtan [m/s] 8 6 4 2 0 0 -2 Fig. 10. Averaging tangential velocity. 20 40 60 80 100 % of radius Fig. 11. Tangential velocity profiles. 310 Session 5 8 Flow field statistics As mentioned earlier, the flow field is very unstable. In most velocity fields, a rotating structure (vortex) can be identified. For every velocity field the location of the most prominent vortex was calculated using the following equation for the normalised angular momentum ([1], [2]): 1 Γ1 ( Px , y ) = (2 N + 1) 2 x+ N y+ N ∑ ∑ i= x− N j = y − N r r r ri , j × ui , j 1 r r = 2 ri , j ⋅ ui , j (2 N + 1) ∑ sin ϕ , i, j r in which ri , j is the position vector, ui , j the velocity vector and ϕ is the angle between these. The normalized angular momentum Γ1 is calculated for each location Px , y . Γ1 Can take on values between –1 and 1. 60 60 40 40 20 20 y [mm] y [mm] This normalised angular momentum is derived from the velocity field topography and does not take the magnitude of the velocities in account. For N , the number of layers around the centre point P , a value of 2 was used. When a plot is made for the distribution of the minimum and maximum value of Γ1 and its location in the cylinder, one can see that for larger valve lift and therefore larger airflow there is less spread in the location of the maximum. In Fig. 12 and 13 a distribution for 2 different valve lifts is shown. In these plots, Γ1 values between –0.75 and 0.75 were rejected (the calculation of Γ1 always yields a value, even in a parallel flow). 0 0 −20 −20 −40 −40 −60 −60 −60 −40 −20 0 x [mm] 20 40 Fig. 12. Γ1 min(o)/max(*), valve lift 60%. 60 −60 −40 −20 0 x [mm] 20 40 60 Fig. 13. Γ1 min(o)/max(*), valve lift 80%. In Fig. 12, for 60% valve lift, it can be seen that there is a clear separation between left (o) and right (*) rotating vortices. At the right of the field, there is often a large vortex, at the left there is often a pair of smaller counter rotating vortices. Turbulence and PTV 311 In Fig. 13, for 80% valve lift, the increased mass flow creates a dominant left rotating vortex, which has its centre of rotation closer to the cylinder centre. 9 Turbulence Characteristics To examine the energy involved in flow structures of different size, a Fourier analysis was performed. At a certain radius, a circle consisting of points was drawn. When one follows this circle, it can be viewed as a domain without boundaries. Along this circle, a Fourier analysis was performed on the tangential component of the velocity vectors. Since the velocity vectors are spaced on a cartesian grid, interpolation is used to find the velocities in the points on the circle. The standard Matlab function ‘griddata’ was used to perform the interpolation. This interpolation has certain effects on the results of the following Fourier analysis. To compensate for these effects, a synthetic velocity field was created. This field consisted of the same Cartesian grid with on it a sinusoidal fluctuation in tangential velocity with known amplitude. The Fourier analysis was performed on this synthetic velocity field to see to which extent the energy can be found. It was found that for higher frequencies (wave numbers) the calculated energy from the Fourier analysis was lower than the known energy in the velocity field. The ratio of these two v 2 (k ) / P (k ) > 1 was used to correct the Fourier analysis of the actual velocity fields. Of course, there is a limit in the frequency/wave number that can be used, which is determined by the grid spacing. The energy spectrum found this way is plotted in Fig. 14. When this analysis is performed on the velocity field at different valve lifts, the results differ slightly. In Fig. 15 these results are plotted. 1.00E+06 1.00E+02 1.00E+01 1.00E+00 1.00E+05 E(k)/(ν5ε)1/4 80% lift Al2O3 seeding Power (corrected for interpolation) 80% lift TiO2 seeding 53% lift 60% lift 1.00E+04 70% lift 80% lift 90% lift 95% lift Ck=2 (-5/3 slope) 1.00E-01 1000 100 10 λ=2π/k Fig. 14. Energy spectrum, valve lift 80%. 1.00E+03 1.00E-04 1.00E-03 1.00E-02 kη Fig. 15. Scaled energy spectrum. 312 Session 5 The wave number axis is scaled with the Kolmogorov length η , the energy axis is scaled with the kinematic viscosity ν and dissipation rate ε . The dissipa- ε can be estimated from ε = U 3 , in which U is a mean velocity and L L a characteristic size of the domain (the cylinder bore). The Kolmogorov length tion rate η can be estimated from η = ν ε 3 1 4 , in which ν is the kinematic viscosity. As can be seen in Fig. 15, the energy spectrum has the − 5 slope, which is 3 2 −5 characteristic for an inertial sub range. From E (k ) = Ck ε 3 k 3 , an estimate for the Kolmogorov constant Ck can be made. A line based on Ck = 2 [6] is plotted in Fig. 15. 10 Conclusions 1. 2. 3. 4. 5. The flow in a stationary flow bench has been investigated using PIV. The measured velocity fields provide insight in the flow structures that occur. These velocity fields can be used to validate CFD calculations of the same flow. It was found that the ‘solid-body’ assumption that is used in swirl measurement practice to convert a measured torque to a rotational speed is only valid at larger valve lifts and mass flow rates. With lower mass flow rates, the centre of rotation does not coincide with the cylinder centre. Also the radial distribution of the tangential component of the velocity does not yield a straight line (i.e. is not proportional to the radius). The torque calculated from PIV measurements of the velocity distribution is significantly lower then the torque, measured using a swirl-torquemeter. The assumptions made on the distribution of the axial velocity in the cylinder have a determining effect on the calculated torque. To make a good comparison between calculated and measured torque, the local axial velocity needs to be known. Stereo-PIV could be used to measure this. By comparing the velocity measurements in a vertical plane through the cylinder axis (not shown in the paper), with and without a flow-rectifier, no significant influence of the swirl-torquemeter on the flow was found. It was found however, that the axial velocity profile is much more complicated than the constant axial velocity used for the ‘solid-body’ profile assumption. From a frequency analysis of the velocity field, it was found that the measured flow structures can be described by isotropic turbulence. The energy spectrum shows a characteristic ‘ − 5 3 ’ slope, indicating that the flow structures can be placed in the inertial sub range. Turbulence and PTV 313 References 1. Graftieaux, L., Michard, M. and Grosjean, N. (2001) Combining PIV, POD and vortex identification algorithms for the study of turbulent swirling flows, Measurement Science and Technology 12, p 1422-1429. 2. Grosjean, N., Graftieaux, L., Michard, M., Hübner, W.Tropea, C. and Volkert, J. (1997) Combining LDA and PIV for turbulence measurements in unsteady swirling flows, Measurement Science and Technology 8, p 1532-1539. 3. Heywood, J.B. (1988) Internal combustion engine fundamentals, McGraw Hill, New York. 4. Ladommatos, N., Balian, R.A. and Stone, R. (1992) Analysis of swirl and its effect on diesel combustion, SAE technical paper series 921643. 5. Liu, S., Meneveau, C. and Katz, J. (1994) On the properties of similarity subgrid scale models as deduced from measurements in a turbulent jet, Journal of Fluid Mechanics vol. 275 p 83-119, Cambridge University Press. 6. Lesieur, M (1997) Turbulence in fluids, Kluwer Academic, Dordrecht. 7. Tippelmann, G. (1977) A new method of investigation of swirl ports, SAE Technical Paper Series 770404. 8. Westerweel, J. (1997) Efficient detection of spurious vectors in particle image velocimetry data, Experiments in Fluids 16, p 236-247.