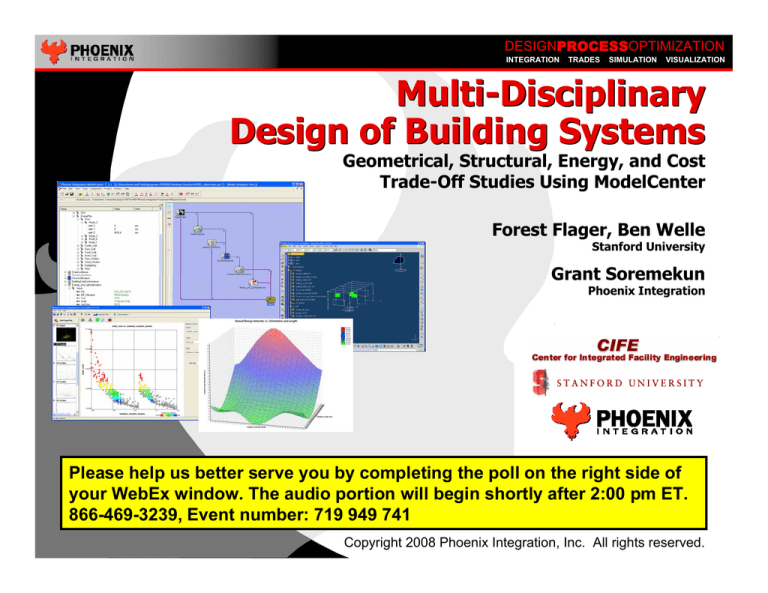

DESIGNPROCESSOPTIMIZATION

INTEGRATION

TRADES

SIMULATION

VISUALIZATION

Multi-Disciplinary

Design of Building Systems

Geometrical, Structural, Energy, and Cost

Trade-Off Studies Using ModelCenter

Forest Flager, Ben Welle

Stanford University

Grant Soremekun

Phoenix Integration

Please help us better serve you by completing the poll on the right side of

your WebEx window. The audio portion will begin shortly after 2:00 pm ET.

www.phoenix-int.com

866-469-3239, Event number: 719 949 741

Copyright 2008 Phoenix Integration, Inc. All rights reserved.

DESIGNPROCESSOPTIMIZATION

INTEGRATION

40 Minute Presentation

• Phoenix Overview

• Stanford/CIFE

TRADES

SIMULATION

VISUALIZATION

Agenda

A copy of this presentation

will be available for download

from the Phoenix website

shortly after the presentation.

Overview

Multi-Disciplinary Design of Buildings

• Case Study: Classroom Design Study

CAD, FEA, Building Code Conformance, and Energy/Lighting Tool

Integration

Cost/Performance Trades

• Future Work / Q&A

Submit questions using the Chat feature

© Copyright 2008 Phoenix Integration, Inc. All Rights Reserved

www.phoenix-int.com

DESIGNPROCESSOPTIMIZATION

INTEGRATION

TRADES

SIMULATION

VISUALIZATION

Background: Phoenix Integration

• 13 year history

• Provide engineering software and

services to customers in aerospace,

defense, and related industries

• Evolved out of a research program at

Virginia Tech

• Office locations

Philadelphia, PA (Corporate)

Blacksburg, VA (R&D)

California (Sales)

North East (Sales)

• World-wide sales in North America,

Europe, and Asia

© Copyright 2008 Phoenix Integration, Inc. All Rights Reserved

www.phoenix-int.com

DESIGNPROCESSOPTIMIZATION

INTEGRATION

TRADES

SIMULATION

VISUALIZATION

Phoenix Value Proposition

1. Improve your decision making

capability

Automate runs of existing tools to

quickly gather information

Apply intelligent algorithms to identify

the best solutions

2. Manage your analysis capability

Knowledge Capture, Search and Reuse

Collaboration and Synchronization

Data Pedigree/Traceability

© Copyright 2008 Phoenix Integration, Inc. All Rights Reserved

www.phoenix-int.com

DESIGNPROCESSOPTIMIZATION

INTEGRATION

TRADES

SIMULATION

VISUALIZATION

Software Automation

• Product Design

• Matlab

• Mathcad

• Excel

• In-house

• CAD

• FEA

• CFD

• Price

• Energy Plus

• ACEIT

• Given design parameters, predicts

performance characteristics:

• Modeling and Simulation

• Flames

• STK

• OpNet

• ProModel

• Arena

• Simulink

• Extend

• Vensim

• Given performance characteristics,

predicts how a system will react to

various stimulus over time

© Copyright 2008 Phoenix Integration, Inc. All Rights Reserved

ModelCenter

www.phoenix-int.com

DESIGNPROCESSOPTIMIZATION

INTEGRATION

TRADES

SIMULATION

VISUALIZATION

Multi-Disciplinary Analysis

ModelCenter - Integrated

Applications Available

Over the Network

Network

ModelCenter

© Copyright 2008 Phoenix Integration, Inc. All Rights Reserved

www.phoenix-int.com

DESIGNPROCESSOPTIMIZATION

INTEGRATION

TRADES

SIMULATION

VISUALIZATION

Multi-Disciplinary Trade Studies

Run

Matrix

Parameter Sweeps, DOE, Monte Carlo,

Optimization, Add your own…

Process

Results

ModelCenter

AoA: Analysis of Alternatives

CAIV: Cost As an Independent Variable

SoS: Systems of Systems

DFSS: Design for Six Sigma

MDO: Multi-Disciplinary Optimization

© Copyright 2008 Phoenix Integration, Inc. All Rights Reserved

www.phoenix-int.com

Introduction to the

Center for Integrated Facility Engineering (CIFE)

An academic research center within the Civil and Environmental

Engineering department at Stanford University:

y

Research focus is on the Virtual Design and Construction (VDC) of Architecture – Engineering – Construction (AEC) projects in collaboration with our industry partners

Overview of CIFE Research Projects

Master Planning

Integrated Concurrent Engineering

Collective Decision Assistance

4D Construction Planning

Design-Fabrication-Integration

Automated Field Instructions

Building Performance Monitoring

Process Integration and Design Optimization (PIDO) in Support of Multidisciplinary Building Design

Research Team:

Forest Flager, Structural Engineer

Benjamin Welle, Mechanical Engineer

Prasun Bansal, Aerospace Engineer

Kranthi Kode, Structural Engineer

Victor Gane, Architect

Industry Collaborators:

Phoenix Integration

Gehry Tehnologies

Supervised By:

Professor John Haymaker

Project Objectives

Overview

The time required for model-based structural

and energy performance analysis feedback means

few (if any) alternatives are evaluated before a decision

is made.

Objective

Develop a platform to integrate CAD and analysis

tools for design exploration and optimization that:

¾ Does not require specialist skills

¾ Provides a robust, flexible and extensible environment

Intuition

Providing designers with this platform will allow them

to explore the design space more efficiently, resulting

in higher performance and cost-effective design solutions.

Proof of Concept Case Study: Classroom

Variables

¾ Building orientation (0)

¾ Building length (L)

¾ Window / wall ratio (W)

¾ Structural steel sections

L

Constraints

¾ Fixed floor area

¾ Structural safety

¾ Thermal comfort

¾ Energy performance

¾ Daylighting performance

Objective

¾ Minimize first cost for structural steel

¾ Minimize annual operating costs for

energy

O

beam

steel frame

girder

column

Multidisciplinary Process Overview Structural Steel Section Optimization Process 2

3

2

3

4

Pin

4

5

Enc

0.16

5000000

4500000

0.14

4000000

0.12

3500000

0.1

3000000

0.08

2500000

2000000

0.06

1500000

0.04

1000000

0.02

500000

0

0

0

5

10

15

20

25

30

Iteration Number

Model Mass

Percentage Over Utilised

35

40

% o f e le m e n ts o v e r u tilis e d

1

M ass

1

Multi‐Disciplinary Analysis Model

ModelCenter

Impact of Steel Section Sizes on Structure Cost

Values for section

types / building

length that yield

best designs

Each line

represents a

single design

Beam Section Type

Cost

Max

DC Ratio

Building

Length

Girder

Sections

Column

Sections

Beam

Sections

Total Cost

Each point

represents a

single design

Impact of Steel Section Sizes on Structure Cost

Optimization Data For Beams, Columns, Girders

~2000 simulations

Hover

Hover over

over any

any design

design

point

to

view

point to view associated

associated

values

values and

and geometry.

geometry.

Beams and Column Size vs. Total Cost

W12x

HSS 4x

W14x

HSS 6x

HSS 8x

Impact of Building Geometry on Structure Cost

Plot Variable: response (Model.class_cost_2.total_cost)

Steel Cost vs. Building Length and Number of Columns

730872

691764

652655

613547

574438

535330

496221

457113

418004

378896

$720,000

$710,000

$700,000

$690,000

$680,000

$670,000

$660,000

$640,000

$630,000

$620,000

$610,000

$600,000

$590,000

$580,000

$570,000

total_cost

total cost of steel structure

$650,000

$560,000

$550,000

$540,000

$530,000

$520,000

$510,000

$500,000

$490,000

$480,000

$470,000

$460,000

$450,000

$440,000

$430,000

$420,000

$410,000

$400,000

$390,000

$380,000

$370,000

20

20.5

21

21.5

22

22.5

23

23.5

24

24.5

25

25.5

26

26.5

27

27.5

28

28.5

29

29.5

30

30.5

31

31.5

32

32.5

33

33.5

34

34.5

3535.5

36

36.5

37

37.5

38

38.5

39

39.5

40

40.5

41

41.542

42.5

43

43.5

44

44.545

45.5

46

46.547

47.5

48

48.549

49.5

5050.5

51

51.552

52.553

53.554

2.8 3

54.5

5555.5

5656.5

5757.5

5858.5

5959.560

bldg_length

building length (L)

3.2 3.4 3.6 3.8 4

9.6

8.6 8.8 9 9.2 9.4

7.6 7.88 8.2 8.4

6.4 6.6 6.8 7 7.2 7.4

5.4 5.6 5.8 6 6.2 num_columns_along_length

4.2 4.4 4.6 4.8 5 5.2

number of columns

along length

Energy and Daylighting Analysis

4 Primary Stages of Data Execution

Step 1: Geometric data is extracted from DP

Step 2: Through a series of steps, an

Energy Plus input file is created

Step3: EP runs energy simulation

Step 4: Output from EP is processed by

Phoenix to determine next geometric

design option based on constraints on

energy consumption, geometry,

daylighting performance, and cost

Impact of Design Variables on Energy Performance

Annual Energy Intensity (MJ/m2)

Annual Energy Intensity vs. Orientation and Length

Least Efficient

¾ Reducing west facing windows

to minimize energy consumption

is a common rule-of-thumb.

¾Our building displayed

seemingly incorrect results.

Length (mm)

Orientation (deg)

Most Efficient

Annual Solar Heat Gain vs. Orientation and Length

¾Visualizations enabled

transparency in the impact

between solar and lighting load

impacts on energy consumption.

Annual Solar Heat Gain

(MJ/m2)

¾ Result: Larger west facing

windows resulted in lower energy

consumption!

Length (mm)

Length (mm)

Orientation (deg)

Orientation (deg)

Optimization vs. DOE Results for

Energy and Daylighting Performance

¾ The correlation between the optimum designs using DOE and the optimizer was extremely

high. Simulation time to achieve optimum designs was reduced by almost 75%.

Total Annual Cost

($/ft2)

Total Annual Cost vs. Orientation and Length

Optimum areas of

design space

Length (mm)

Orientation (deg)

DOE- 416 simulations

Optimization-110 simulations

Next Steps / Future Work

Structural:

¾

Consider alternative structural materials

Mechanical / Energy:

¾

¾

¾

Consider different materials and HVAC equipment

Integrate the lighting engine Radiance for daylighting performance

Integrate a Computational Fluid Dynamics (CFD) simulation engine to optimize space temperature stratification, air speed, and mean radiant temperature

General: ¾

¾

¾

¾

¾

Tradeoffs btw Structural, Energy, and Cost Performance

Make software wrappers more robust / flexible

More complex building types

Integrate architectural analyses

Parallel computing to reduce trade study run times

DESIGNPROCESSOPTIMIZATION

INTEGRATION

TRADES

SIMULATION

VISUALIZATION

Questions and Answers

To submit a question, use the chat feature of WebEx. If we do not

answer a question online, we will be sure to follow up with an e-mail.

Upcoming Schedule:

y May: Automation, Integration, Trade Studies

Forest Flager

forest@stanford.edu

Ben Welle

bwelle@stanford.edu

Grant Soremekun

grant@phoenix-int.com

y June: Fidelity Forward Design: NX/Nastran

Previous Topics*:

y A Fully Integrated Risk and Cost Model for

Complex Aerospace Systems

y Analysis of Alternatives

y Intelligent Decision Making within Large Scale

Simulations

y System of Systems Optimization

webcast@phoenix-int.com

800-500-1936

© Copyright 2008 Phoenix Integration, Inc. All Rights Reserved

* Available for download from:

www.phoenix-int.com