Patient-based Quality Assurance for IMRT Conformal Radiation Therapy Outline

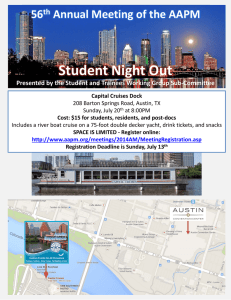

advertisement

Patient-based Quality Assurance for IMRT CE-IMRT4 Dirk Verellen et al. Verellen - AAPM 2004AZ-VUB Department of Radiotherapy, Conformal Radiation Therapy Verellen - AAPM 2004 Creation of conformal dose distributions & Target oriented positioning ! Outline Î Customize Î Target z z Assess interplay between IGRT and IMRT SM & IM assessment Î Dose z z your QA and Treatment Verification localization - IGRT: delivery - IMRT: Tools: Dosimeters & Phantoms Procedures Î Hazard Î Beware & Discrepancy Analysis of what has NOT been verified Verellen - AAPM 2004 Customize QA procedure Î Target localization and IMRT: Don’t miss the target z Most IMRT deliveries are temporal z z Real-time knowledge of the target localization becomes an integral part of patient-related QA for IMRT! Î Hazard analysis ⇒ customize procedure Verellen - AAPM 2004 Customize QA procedure Î How to get comfortable? Î Create an efficient QA-procedure “Don’t drown in film measurements” z Efficient processing required z Separate “machine specific” from “patient specific” QA z Verellen - AAPM 2004 Target Localization & dose delivery Î Conformal Dose distribution z High dose volume is shaped to the volume occupied by the target. z Don’t miss the target! ∴PTV and PRV should reflect set-up accuracy!!! Î Temporal Intensity Modulation z Optimization based on snap-shot. z Target displacement/movement influences dose distribution. ∴Real-time knowledge of anatomy required!!! Verellen - AAPM 2004 Target Delineation Verellen - AAPM 2004 Don’t miss the target: SM & IM Physical patient Î Î Î Î Î Î Î Î Î CT room coords Lasers Skin markers Images Bone Tumor Delineation Margin Planned beam Î Î Î Î Î Î Î Î Treatment room coords Lasers Skin markers Bone Tumor Beam Linac Treatment room 17 possibilities for geometrical errors Verellen - AAPM 2004 Van Herk et al. Virtual patient Don’t miss the target: SM & IM “perfect alignment” + room lasers + + + + + + + skin markers bone references Verellen - AAPM 2004 Anatomy tracking Don’t miss the target: SM & IM Verellen - AAPM 2004 Reduction of SM & IM: Patient immobilization Verellen - AAPM 2004 Reduction of SM & IM: Target localization Target localization≠immobilization Verellen - AAPM 2004 Reduction of SM & IM: Electronic Portal Imaging Verellen - AAPM 2004 As a positioning tool: only 2D information Reduction of SM & IM: Ultrasound Guidance Verellen - AAPM 2004 Reduction of SM & IM: Cone beam CT Verellen - AAPM 2004 Jaffray et al. Reduction of SM & IM: Stereoscopic X-ray Imaging Verellen - AAPM 2004 Reduction of SM & IM: Stereoscopic X-ray Imaging Implanted marker matching Automated DRR fusion Verellen - AAPM 2004 Reduction of IM Individualized IM Verellen - AAPM 2004 Gating Temporal intensity modulation Field 2 2 1 2 1 OAR 1 2 PTV 2 Field 1 Field 3 Verellen - AAPM 2004 Temporal intensity modulation Field 2 2 1 2 1 4 3 4 1 2 6 5 6 2 Field 1 Field 3 Verellen - AAPM 2004 Temporal intensity modulation Field 2 2 Field displacement 1 2 overdosage Field 1 1 Field displacement 2 3 4 5 2 3 4 3 4 5 6 4 5 3 6 4 underdosage Verellen - AAPM 2004 1 2 Field 3 Field displacement Temporal intensity modulation Film moving, non-gated delivery Film moving, gated delivery Verellen - AAPM 2004 Coping with motion: gating NOVALIS BODY II & III Verellen - AAPM 2004 Verellen et al, Radiother. Oncol. 2003 Coping with motion: gating Verellen - AAPM 2004 Coping with motion: gating Verellen - AAPM 2004 Coping with motion: tracking Verellen - AAPM 2004 Dose delivery Î Create an efficient QA-procedure “Don’t drown in film measurements” z Efficient processing required z Î Separate “machine specific” from “patient specific” QA Verellen - AAPM 2004 QA for IMRT: 4 levels Î Pre-clinical verification of IMRT treatment (Patient related) Î Verification of fluence maps, individual IMRT fields on water phantom Î IMRT delivery specific QA Î Basic QA (linac, MLC) 4 3 2 1 Verellen - AAPM 2004 Level 1: Basic linac QA Î Tests for Validation and after every accelerator check z z z z z MLC calibration and alignment Speed Stability Beam on/off stability Gravity test MLC reliability test Î Weekly test to find out if your MLC performs within specs z e.g. Garden fence test Verellen - AAPM 2004 Level 1: weekly QA pattern Test Pattern with Leaf Error Test Pattern after leaf replacement and MLC calibration Verellen - AAPM 2004 Solberg et al. Level 2: IMRT delivery specific QA Î Acceptance Î Commissioning z z e.g. alignment in tomotherapy e.g. MLC specifications and influence on OF Î Small field dosimetry amounts of MU Î Leaf control properties Î Small Verellen - AAPM 2004 Level 2: Chair Leaf transmission only Absolute dose Leaf transmission & Leaf separation A. Van Esch et al. Verellen - AAPM 2004 Level 3: Verification of IMRT delivery Î Geometric fluence profile test profile Î Making use of EPIDs Î Irregular Verellen - AAPM 2004 Level 3: Test pattern Verellen - AAPM 2004 Level 3: Test pattern Test Pattern with 2 mm Leaf Error and 10% Dose Error Test Pattern correctly delivered Verellen - AAPM 2004 Solberg et al. Level 4: Different philosophies Î Every z day ↔ Every patient ↔ Class solutions QA procedure largely dependent on approach Î Top-down ↔ Bottom-up zDetailed zAnalysis zTime straightforward consuming zComprehensive zDiscrepancy analysisVerellen complicated - AAPM 2004 Level 4: Comprehensive Verification ➨ Verification of treatment in toto: ● absolute dose verification: thermoluminescent and alanine detectors ● Evaluation of dose distribution: film dosimetry Original IMRT Plan simulated for phantom Verellen - AAPM 2004 verification Level 4: 2 legs to stand on Î The ability to create conformal dose distributions How to make sure it performs adequately each time? (machine related!) z How to make sure this particular treatment plan can be realized? (patient related!) z Î Target z oriented positioning How to make sure not to miss the target each time, and cope with motion during IMRT Verellen - AAPM 2004 delivery? QA in IMRT: an example Î Non-patient related (Is the system performing within specs?) z Comprehensive test for IMRT delivery capability Fluence map created by TPS, sequencing from TPS, transferred and delivered “Test Pattern” z e.g. every week Regular detailed QA of linac and MLC (basic verification) e.g. every month Verellen - AAPM 2004 QA in IMRT: an example Î Patient related (Can the system deliver this particular case?) z Comprehensive test for class solution (preclinical verification) Commercial “IMRT” phantom Anthropomorphic phantom Gel … z Pre-treatment verification for each patient Independent MU calculation Absolute dose check Verellen - AAPM 2004 Verification of fluence patterns Tools Î Dosimetry Î Phantoms Verellen - AAPM 2004 Dosimeters Î Integrating z z z z z z z Î TLD chips Alanine chips MOSFET Radiographic film (X-OMAT V, EDR-2) Radiochromic film EPID Gel Non-integrating z z z z Ionization chamber (conventional, micro, pin-point) diodes diamond Linear array detectors Verellen - AAPM 2004 Dosimetric verification Î Down scaling of Monitor units Losing small segments z Underestimation of scatter and leakage dose z Î Small field dosimetry dose delivery: Î Temporal z z integrating dosimeters (TLD, alanine, film, gel) non-integrating (ionization chamber, …) Verellen - AAPM 2004 Dosimeters Î0 z z z Film EPID Array of TLD chips z Conventional Micro z Î3 Diodes MOSFET Diamond TLD, alanine z dimensional z Ionization chamber Î1 Î2 dimensional z dimensional z z z Gel Stack of film 3D-array of TLD chips dimensional z z Stack of TLD chips Verellen - AAPM 2004 Linear array detectors Phantoms Î Generally z z Internal heterogeneities are anatomically relevant Multiple dosimeter comparison difficult Geometric alignment cumbersome Geometrically regular z 3 types Anthropomorphic Internal construction precise Multiple dosimeters possible Alignment straightforward Geometrically irregular Create fluence map to obtain a homogeneous dose distribution Easy for analysis Verellen - AAPM 2004 Phantoms Î 0D: z Ionization Chamber ABSOLUTE Î 2D: z Film Dosimetry RELATIVE Verellen - AAPM 2004 Phantoms Î 0D: z z Ionization Chamber ABSOLUTE TLD, alanine ABSOLUTE-RELATIVE Î 1D: z Stack of TLD Î 21/2D: z Film Dosimetry RELATIVE Verellen - AAPM 2004 Phantoms Î 0D: z TLD, alanine, MOSFET ABSOLUTE-RELATIVE Î 2D: z z Verellen - AAPM 2004 Film Dosimetry RELATIVE Stack of TLD Phantoms Î 3D: z z RELATIVE ABSOLUTE? De Wagter et al. Verellen - AAPM 2004 Phantoms Î 2D z Create fluence map to generate a homogeneous dose distribution Williams et al. Verellen - AAPM 2004 A. Van Esch et al. Phantom Verification Î Necessary z z tools: Dose Export of a defined area or plane into file or clipboard (ASCI) Independent registration of measurement and calculation needed Verellen - AAPM 2004 Procedures: level 4 Î Fluence profiles Measurement and analysis z Using measured fluence profiles to recalculate the dose distribution z Î Combining Î Absolute z z phantoms and dosimeters dose verification Measurement Calculation Î 3D Verification of dose distribution Verellen - AAPM 2004 Fluence profiles: Film Dosimetry rel. OD Film Response 4.5 4 3.5 3 2.5 2 1.5 1 0.5 0 EDR2 X-Omat V 0 2 4 6 8 Dose (Gy) Verellen - AAPM 2004 Fluence profiles: Film Dosimetry DD < 3%, DTA < 2mm Verellen - AAPM 2004 Ahlswede et al. Fluence profiles: EPID reference image measured image acceptance criteria: ∆ Dmax (e.g. 1 %) DTA (e.g. 1 mm) Verellen - AAPM 2004 A. Van Esch et al. Fluence profiles: the other way around Î Using measured fluence profiles imported back into the planning system to calculate what has been delivered! Verellen - AAPM 2004 Combining phantoms and dosimeters Î Transferring the patient’s treatment parameters to a phantom and recalculate the resulting dose distribution: “Mapping” Verification with the actual treatment parameters - Dose distribution may not be relevant Î Simulating the patient’s treatment on a phantom: “Simulation” Verification of specific treatment requirements - Actual treatment is not verified Verellen - AAPM 2004 Absolute dose and MU validation Î MU z validation requires either Direct measurement of dose using TPS MUs and fluences Time-intensive z Temporal High dose gradients Small field dosimetry Currently most thorough method of validation Independent computation of dose Most efforts still single point Ideally, recompute entire 3D dose Verellen - AAPM 2004 Absolute dose measurement Verellen - AAPM 2004 Alanine dosimetry Calculated (Gy) SD (Gy) Measured (Gy) SD (Gy) meas/calc case (a) case (b) case (c) 20.09 20.04 19.99 0.14 0. 09 0.05 20.01 19.79 19.77 0.20 0.12 0.19 1.00 0.99 0.99 Det. 1 Det. 2 Det. 3 10.73 10.85 4.32 0.14 0.12 0.07 10.74 10.77 4.31 0.13 0.11 0.04 1.00 0.99 1.00 Solitary target: Target surrounding OAR: Verellen - AAPM 2004 Ionization chamber* H&N IMRT Calc. SD Meas. SD (cGy) (cGy) (cGy) (cGy) 166.6 4.5 165.0 0.78 201.3 3.4 200.1 0.56 5 field Evenly distributed 5 field Avoiding air cavities *NAC 007 micro ionization chamber,Verellen Wellhöfer - AAPM 2004 Independent computation of dose Î Single ÎA z point approach simple method, spread sheet – based: Imported from TPS: z MU per beam Segment shapes and weights Not used from TPS: Original TMR data, OF, OAR Determination of segments that cover measuring point Verellen - AAPM 2004 Independent computation of dose unit normal deviate -10 -8 -6 -4 -2 0 2 4 6 8 10 45 0.21 40 frequency 35 0.18 normal distribution counts 30 0.15 25 0.12 20 0.09 15 0.06 10 0.03 5 0 0 -10 -9 -8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 difference (cGy) Mean: -0.2cGy SD: 2.0cGy Verellen - AAPM 2004 6 7 8 9 10 Dose distribution: mapping Original IMRT Plan Original Plan mapped onto Phantom Verellen - AAPM 2004 Dose distribution: simulation Original IMRT simulated for phantom Verellenplan - AAPM 2004 verification Film Dosimetry : mapping Gamma:Verellen 4% -DD 4mm DTA AAPM /2004 Film Dosimetry : mapping Verellen - AAPM 2004 Film Dosimetry: simulation Verellen - AAPM 2004 Film Dosimetry: simulation Verellen - AAPM 2004 Film Dosimetry: simulation Gamma: 4% DD / 4mm DTA Verellen - AAPM 2004 Phantom verification: gel measurement Relaxation rate image with contours along the pixels with 90% of the maximal dose Transversal CT- slice with PTV and calculated 90%-, 50%-, 20%- and 10%-isodose lines MRT-slice with contour along pixels with 90% of the maximal dose Ahlswede et al. Verellen - AAPM 2004 Phantom verification: gel-film GEL FILM - GEL FILM PLANNING - GEL PLANNING De Wagter et al. PLANNING - FILM Verellen - AAPM 2004 Hazard analysis ÎIntuition/experience from conventional RT is lost ÎFind weak links ÎDefine control points Verellen - AAPM 2004 Hazard analysis: some examples Î Leaf calibration e.g. OF can change with 7% for 0.1 cm difference in small field sizes for an Elekta linear accelerator. z Leaf sequence important z Î Tertiary collimator Alignment, abutting slices z Clearance z Verellen - AAPM 2004 Leaf Sequencing : DMLC ↔ SMLC 100 90 80 70 60 100 90 50 40 30 20 80 70 60 10 0 0 5 10 15 20 25 50 40 30 20 10 0 0 Verellen - AAPM 2004 5 10 15 20 25 Leaf Sequencing “Close-in” Technique “Sweep“ or “Sliding Window” Technique Desired IM - Profile 4 Trajectory Sequence 4 3 2 3 2 1 1 Ahlswede et al. Verellen - AAPM 2004 Sequential tomotherapy: alignment 0° 270° 90° Verellen - AAPM 2004 Sequential tomotherapy: alignment Verellen - AAPM 2004 Sequential tomotherapy: indexing Hardware + Software Verellen - AAPM 2004 Sequential tomotherapy: alignment 120 115 Dose (%) 110 alanine TLD film planning 105 100 95 Second rotation First rotation 90 0 1 2 3 4 5 6 7 8 9 10 11 Underdosage 12 13 14 Overdosage 15 postition (mm) Verellen - AAPM 2004 Direction of table movement Sequential tomotherapy: alignment 115 110 Dose (%) 105 alanine film planning 100 95 90 First rotation 85 0 1 2 Index +1mm 3 4 5 6 7 8 9 10 11 12 13 14 15 Underdosage 16 17 Second rotation 18 Overdosage position (mm) Verellen - AAPM 2004 Direction of table movement Sequential tomotherapy: alignment 120 115 Dose (%) 110 105 alanine film planning 100 95 90 First rotation 85 0 1 2 Index -1mm 3 4 5 6 7 8 9 10 11 12 13 14 15 Underdosage 16 17 Second rotation 18 Overdosage position (mm) Verellen - AAPM 2004 Direction of table movement Clearance and choice of origin Verellen - AAPM 2004 Clearance and choice of origin Verellen - AAPM 2004 Clearance and choice of origin Verellen - AAPM 2004 Discrepancy analysis Î TPS: z z z z z Basic beam data (PDD, OF, leaf offsets, penumbra) Linac model Dose calculation algorithm Leaf sequencing algorithm … Î Experiment: z z z z TLD calibration MLC data transfer Experimental set-up (many things can go wrong: MU, positioning, gantry, … typically after-hours) … Verellen - AAPM 2004 Discrepancy analysis (cont’d) Î Delivery z z z MLC calibration Linac operation … Î Analysis z Incorrect registration (measurement ↔ calculation) Down-scaling of MU z … z Losing small segments Underestimating leakage/transmission dose Verellen - AAPM 2004 Discrepancy analysis R2 = 1/T2 Planning minus gel Planning minus gel < -5% Verellen - AAPM 2004 De Wagter et al. > +5% Discrepancy analysis 0.8 cm 1.4 cm 2 x 15o 2 x 16o Verellen - AAPM 2004 De Wagter et al. Discrepancy analysis The relationship between measured versus calculated dose in function of increased constraints to the OAR while maintaining the prescribed target dose at 1.00 Gy Case 1 Case 2 Case 3 Case 4 Prescribed Calculated T (Gy) OAR (Gy) T (Gy) OAR (Gy) T (Gy) Measured OAR (Gy) T OAR (Gy) (Gy) 1.00 1.00 1.00 1.00 0.25 0.10 0.06 0.03 1.08 1.07 1.17 1.15 0.32 0.19 0.05 0.03 1.08 1.09 1.09 0.94 0.34 0.19 0.09 0.08 1.00 1.02 0.94 0.82 Verellen - AAPM 2004 Meas/Calc 1.04 0.98 1.83 2.92 MU/º 0.79 0.81 1.30 1.40 Inefficient use of the beam Dose (OAR) ↓ & Dose (Target) remains constant ⇓ The number of available ports ↓ ⇓ The number of MU/° or MU/segment ↑ ⇓ The contribution of leakage & scatter dose ↑ Verellen - AAPM 2004 Discrepancy analysis: Influence of leakage dose Î Î Ionization chamber measurements showed a transmission of 0.5% through the vanes of the MIMiC. This enables to calculate an estimated leakage dose based on the total amount of MU delivered during tomotherapy Total Leakage Calculated C + L Measured MU (cGy) (cGy) (cGy) (cGy) Case 1 Case 3 458 755 2.29 3.78 32.4 4.67 34.7 8.45 33.6 8.56 M/C M/(C+L) 1.04 1.83 0.97 1.01 Verellen - AAPM 2004 Discrepancy analysis ∆D = 1% DTA = 3mm day 1 vs day 6 day 1 vs day 2 day 1 vs day 4 Verellen - AAPM 2004 A. Van Esch et al. Discrepancy analysis ≠ Rectal filling day 1 day 4 day 1 versus day 4 Verellen - AAPM 2004 A. Van Esch et al. Discrepancy analysis Wrong energy ABSOLUTE RELATIVE ∆D=3.3% and DTA=3mm ∆D=3.3% and DTA=3mm MLC failure ∆D=5.5% and DTA=3mm Verellen - AAPM 2004 A. Van Esch et al. Beware of what has not been verified Î Threshold for skin contouring in TPS dose Î Heterogeneity correction Î Choice of phantom Î Target localization Î… Î Extra-target Verellen - AAPM 2004 Extra-target dose Gonick & Huffman Verellen - AAPM 2004 WBED for a prostate case Î Assuming identical scatter conditions: Hp(10) = 1.55 x 10-2 mSv/MU Hp(70 Gy) = Hp(10) x #MU x #fractions serial tomother. (654 MU, 5 arcs): IMRT 1 (490 MU, 6 fields): z IMRT 2 (128 MU, 6 fields): z Dynamic arc (292 MU, 1 arc): z z Verellen - AAPM 2004 Heterogeneity correction Cranial measurement Caudal measurement air cavity : target volume : Verellen - AAPM 2004 1774 mSv 1595 mSv 417 mSv 158 mSv Heterogeneity correction CC Algorithm Clarkson Algorithm PB Algorithm Verellen - AAPM 2004 Target volume Heterogeneity correction Verellen - AAPM 2004 Heterogeneity correction BrainSCAN PB Pinnacle CCC calc/meas calc/meas Balthazar I 1.05 ± 0.03 1.02 ± 0.03 1.06 ± 0.02 1.00 ± 0.02 1.04 ± 0.01 1.02 ± 0.01 (radius 2.1cm) Balthazar II (radius 1.4cm) Melchior (side: 5.9cm) Verellen - AAPM 2004 Heterogeneity correction 80 30 60 50 40 80 95 90 100 100 5 30 50 80 80 5 30 30 60 40 20 50 80 95 95 90 80 90 50 20 5 Film – Brainscan PB 20 40 60 Film - Pinnacle CCC 80 20 40 60 80 (100% ⇔ 2Gy) Verellen - AAPM 2004 Heterogeneity correction # pixels / total #pixels 1 0.8 0.6 0.4 PB film sphere+margin CCC 0.2 sphere only 50 100 150 200 Dose (cGy) Verellen - AAPM 2004 Choice of phantom Gamma: 4% DD / 4mm DTA Verellen - AAPM 2004 IMRT: Patient related QA Analysis? Integration? Efficiency? Verellen - AAPM 2004 Conclusions Î Analyze the chain of events in your IMRT treatment procedure Hazard analysis: define control points Customize QA/QC procedure z Get comfortable with each step z Beware of what has not been verified! z z Î Complementary dosimetry procedure should be efficient Î Training of personnel! Î QA Verellen - AAPM 2004 Acknowledgements Special thanks to: Ann Van Esch (University Hospital Leuven) Carlos De Wagter (Ghent University Hospital) Julia Ahlswede (Charité, Berlin) Tim Solberg Verellen - AAPM 2004 (UCLA)