IOLA, KANSAS RESIDENTIAL LEAD CONTAMINATION A Thesis by Andrew Lloyd Haner

advertisement

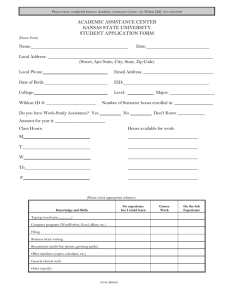

IOLA, KANSAS RESIDENTIAL LEAD CONTAMINATION A Thesis by Andrew Lloyd Haner Bachelor of Science, Wichita State University, 2004 Submitted to the Department of Geology and the faculty of the Graduate School of Wichita State University In partial fulfillment of the requirements for the degree of Master of Science December 2007 © Copyright 2007 by Andrew Lloyd Haner All Rights Reserved IOLA, KANSAS RESIDENTIAL LEAD CONTAMINATION The following faculty have examined the final copy of this thesis for form and content, and recommend that it be accepted in partial fulfillment of the requirement for the degree of Master of with a major in Geology ____________________________ John Gries, Committee Chair ________________________________ Collette Burke, Committee Member ________________________________ William Parcell, Committee Member ________________________________ Peer Moore-Jansen, Committee Member iii DEDICATION To my parents and my friends iv Lead found in the earth . . . affects our environmental future resulting in life changes. v ACKNOWLEDGMENTS I would like to thank John Gries for his guidance, friendship and allowing me to be myself. Thanks to the members of my committee: Collette Burke, William Parcell, Peer MooreJansen, I would like to express my gratitude for contributing to my success. Special thanks to Wan Yang, Salvatore Mazzullo, Hongsheng Cao, Kevin Smith and all the friends that I made in the Geology department. I am grateful to Seagull Environmental Technologies, Inc. for allowing me time off to pursue my degree. Sincere appreciation goes to my coworker Rick Claytor from whom I learned a great deal. Thanks also to Eddie Mcglasson of the Environmental Protection Agency for providing me permission to use the project for my thesis. vi ABSTRACT In the late 1800’s and early 1900’s lead and zinc mining became prominent in Kansas, Oklahoma, and Missouri. With no knowledge of the effects that would impact the future, the mining companies continued to strip the land. With the discovery of lead and zinc ores in southeast Kansas, southwest Missouri, northeast Oklahoma in the late 1800’s a way to process the ores in a cheap way was needed. Natural gas in locations like Iola Kansas helped led to cheap ore processing and smelting. After the cheap fuel for the processing began to diminish in the early 1900’s, the multitude of smelters began to decrease. With the creation of the Environmental Protection Agency in 1970, concerns for the environment became a more than ever important issue. In the 1990’s, the EPA began to collect environmental impact data from areas potentially affected by mining, to access the effects of lead mining on residential areas in southeast Kansas and southwest Missouri. Thus, the methods of residential lead sampling were created. In Iola, Kansas the Kansas Department of Health and Environment performed tests to measure the extent that environmental impact from the smelters had on human residents of the town. With this evidence, the EPA was asked to conduct more testing, and to perform a cleanup of residential sites to help protect the environment and human health. vii PREFACE As I child I grew up in the southeastern part of Kansas, where there were many mines, chat piles, lead and zinc everywhere. I was told that lots of people got sick working in the mines and that their lives changed because of what had happened in the area. I could see the devastation that occurred and how the land had been stripped. My own family members were affected with health problems. I knew that I had to find out more about this. My motivation to learn more and more about the earth and its many interesting facets began early in my educational life. As I strived to increase my knowledge and understanding in the earth sciences at Hutchinson Community College, I became intrigued with geology and the earth’s structure. I decided to continue my education at Wichita State University and pursue a degree in geology. This created an atmosphere of learning experiences. As a result of my educational experience I took a job with a company which aided the EPA in their investigations. In April of 2006, Seagull Environmental Technologies, Inc. (SETI) started in the project in Iola, Kansas. SETI began the long process of getting permission to test the soil, testing the soil, and determine what needed to be done. I was amazed by who and what the lead and zinc had affected. Rich and poor, young and old, private businesses and residential properties were involved. I decided to investigate how all this had started and what had caused so much change in these people’s lives. I began to research about lead and zinc, smelters, and the involvement in these by the Environmental Protection Agency. It was a goal to provide this information for future generations so that there was a record of the history of lead and zinc mining and associated environmental problems that have influenced their lives. viii TABLE OF CONTENTS Chapter Page 1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2. HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2.1 2.2 2.3 2.3.1 2.4 Mining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Iola, Kansas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Environmental Protection Agency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Iola Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Seagull Environmental Technologies, Inc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 3. METHODOLOGY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 4. RESULTS AND CONCLUSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 ix LIST OF FIGURES FIGURE Page 1. Possible explanation of origins, movement and deposition of ore bearing solutions. . . . . 1 2. Galena (lead sulfide) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 3. Sphalerite (zinc sulfide) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 4. The Tri-state lead and zinc mining district with blue areas showing mined areas . . . . . . 4 5. Miners from the Tri-state mining district . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 6. Ore bucket from the Baxter Kansas Museum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 7. Contaminated water flowing into a stream . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 8. Area Southeast Galena, Kansas 1980, before reclamation . . . . . . . . . . . . . . . . . . . . . . . 10 9. Area Southeast Galena, Kansas 1999, after reclamation . . . . . . . . . . . . . . . . . . . . . . . . 10 10. Early Iola, Kansas with smelter in background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 11. Excavation of lead-contaminated soil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 12. Example of field sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 x Chapter One INTRODUCTION The Iola Project was an investigation of the history of lead and zinc production, and the resulting soil contamination intensifying health hazards. The goal for the project was to find problem areas, clean the area up and provide information for the community and property owners. Lead and zinc ores were deposited at the top of Mississippian rocks during the Pennsylvanian Period. Resulting from a barrier, the Cherokee shales, the metals migrated laterally and to deposit galena, sphalerite and other minerals in the Mississippian lime stones (Fig. 1)(Brosius, 2001, p.2). Figure 1. Possible explanation of origins, movement and deposition of ore bearing solutions. (Brosius, 2001, p.2). 1 Galena, lead sulfide (PbS) and sphalerite, zinc sulfide (ZnS), mineral deposits were found in the Ozark Plateau which covers about 55 mi2 in southeast Kansas. Other minerals found in the area include pyrite, marcasite, dolomite, calcite, quartz and jasperoid. Lead sulfide has a dark steel blue color. Its structure is crystalline commonly forming cubes with solid angles with octahedron faces. Many are different in their dimensions. The cleavage of the mineral is in three directions at right angles to each other. If the ore was to be broken it would break along the cleavage lines causing the pieces to be right angles to each other (Figure 2) (Brosius, 2001, p.3). Figure 2. Galena (lead sulfide) Zinc sulfide is made up of metallic zinc and sulphur. Sphalerite is generally impure and the combination could not be separated by the process of smelting which caused a variety of colors to form. Pure zinc is never white but its impurities could cause it to be a slight yellow. It varies in color from amber, steel gray and black. A common name for this ore was blackjack. Other impurities in this ore, such as clay and flint rock make it more difficult to separate (Figure 3) (Brosius, 2001, p.3). 2 Figure 3. Sphalerite (zinc sulfide) 3 CHAPTER TWO HISTORY Mining Blackjack (zinc ore) was found in Galena, Kansas in 1870 which instituted years of lead and zinc mining. The area of southwest Missouri, southeast Kansas and northeastern Oklahoma encompassed the largest lead and zinc mines in the world (Figure 4) (Brosius, 2001, p.1). Approximately 11,000 miners worked in this area in addition to many others supporting the work. Figure 5 is a photograph at the Galena Mining museum of my great grandfather’s mining crew. Zinc was much more commonly mined, but lead proved easier to smelt in homemade furnaces. Figure 4. The Tri-state lead and zinc mining district with blue areas showing mined areas (Brosius, 2001, p.1). 4 Figure 5. Miners from the Tri-state mining district. Most mining was underground by shaping rooms and pillars. In some areas the ore was closer to the surface. Surface mining could be done easier by individuals who coined the phrase “the poor man’s mining”. In the beginning miners used very crude methods. A drill, dynamite, hoist, rope and bucket made from a barrel were items that the miners used to get the ore from the mines. Some miners used a sluce-box which was a wooden trough that was placed in a stream so that the water could run through it and wash the ore. A picture from the Baxter Historical museum (Figure 6) is of a bucket that was used to bring up water and rock from the mine. As 5 time went on newer methods were developed and a horse power whim was used to bring up the rock. Later, the operations were run by stationary steam engines. The ore was then ground and washed by steam power. Usually a large building was built over the shaft with a steam powered whim. A large shaft was drilled until the ore was found. Many drifts were then drilled laterally so that the majority of the ore could be taken out. Some of the chambers were fifty to seventy five feet in height. Figure 6. Ore bucket from the Baxter Kansas Museum taken in 2007. Often groundwater seeped into the mines causing the rooms to fill with water, thus pumping plants had to be installed to remove large amounts of water, sometimes 24 hours a day. Operating costs for running these mines became very high. In the early 1900 a gas field was discovered in Iola Kansas. Use of natural gas helped to reduce smelting costs. Gas fired smelters were built and coal fired smelters were closed. Lead and zinc mining gradually declined until 1970 when all mines were shut down due to environmental and physical concerns. Many health hazards resulted from improper mine 6 closings that affected people’s lives such as open mine shafts, collapsed shafts, and subsidence areas. These subsidence areas were located in areas of pillar robbing in which removal of the ore out of the pillars that supported the mine’s roof would cause the structure to collapse. The U.S. Bureau of Mines investigated the mine area and found 599 mine hazards in Galena Kansas. The area is known as Hell’s Half Acre. Lead smelting was considerably cheaper than zinc smelting. Metallic fumes from the smoke stack were saved by putting wool bags in the ceiling of a large chamber called a bag house. The bag ends were put over the area where the smoke escaped. This gas product flowed through these bags so that the solid products would come out. The vapor was changed into lead oxide and then into lead sulphate. This was separated into a pigment used in white paint. Zinc smelting was a complicated process. The ore was crushed and went through a furnace which removed the sulfur leaving the metal behind in the form of an oxide. Then it was mixed with carbon and placed in a clay chamber which was heated causing an action of the zinc to become a metallic state. The heat caused the liquid zinc to be deprived of oxygen which allowed it to flow into the clay receptacle. As the liquid zinc cooled it was able to be molded. The product could then be sold at this point. Iola, Kansas Drilling for coal and zinc began in Iola, Kansas during the late 1870’s; while drilling for the ores, a gas well was struck. At the same time they opened a vein that contained mineral water. They weren’t interested in the gas but decided to advertise the water for medicinal purposes. A hotel was built next to the well so that people could come and use the water for bathing. The gas from the well was used to heat the water. It was advertised that the water could cure rheumatism, dropsy, hemorrhoids, pimples, headaches and heart disease to name a few. The 57 actual mineral water was shipped all over the world. About 1890 the usefulness of the water played out. So it was decided to bring a zinc smelter process to Iola because of the cheap gas that could be used in the smelters. Iola quickly became one of the largest producers of zinc in the United States. By the early 1900’s the Iola gas field was the largest in the world. At one point there were 308 producing wells, but by 1910 all but three smelters had shut down due to failing gas pressures. ( Allen, 1983, p. 2) Years of mining also left serious environment problems. Once they stopped pumping the water out of the mines, they filled with water. The sulfur ions from the zinc and lead combined with iron in the water to form iron sulfide which was acidic and contaminated the water. Other dissolved metals were also found in the water. This contaminated water leaked into the ground water and springs. Water running through tailings containing lead, zinc and cadmium made it into streams and rivers (Figure 7 (KGS, 2005, p.3). Figure 7. Contaminated water flowing into a stream. 8 The US Environmental Protection Agency and many citizens helped fill in the mine collapsed areas and shafts. They brought in new soil to cover the area that had been mined and left over materials in the area (Figures 8 & 9) (Brosius, 2001, p.4). The funding for most of the work where no responsible parties exsisted was funded by CERCLA, the Comprehensive Environmental Response, Compensation, and Liability Act, commonly known as the superfund. It was created to help pay for remediation of sites. The money is received as a tax on petroleum and chemical industries. The EPA was formed in response to public concern about the conditions of water, air, and land. It was important to take steps to correct this problem and to keep it from happening again. Environmental Protection Agency The U.S. Environmental Protection Agency was created in 1970. President Richard Nixon reorganized the executive branch of government to form the new agency. “He took the air, solid waste, radiological health, water hygiene and pesticide tolerance functions from the department of health, education and welfare; water quality and pesticide label review from the interior department; radiation protection standards from the atomic energy commission; pesticide registration from the department of agriculture.”(Wisman, 2007, p.1) William Ruckelshaus stated in his first speech to the National Press Club,”An environmental ethic is needed.” “Each of us must begin to realize our own relationship to the environment. Each of us must begin to measure the impact of our own decisions and actions on the quality of air, water, and soil of this nation. ”This agency’s responsibilities are to protect air and water resources; drinking water supplies and manage the Superfund. They do this by conducting research, setting standards, monitoring and enforcement, providing information and 9 financial support to both local and state governments. In 1980 the National Environmental Policy Act was passed. Figure 8. Area Southeast of Galena, Kansas 1980, before reclamation. Figure 9. Area Southeast Galena, Kansas 1999, after reclamation. 10 Its purpose was: • “To declare a national policy which will encourage productive and enjoyable harmony between man and his environment.” • “To promote efforts which will prevent or eliminate damage to the environment and biosphere and stimulate the health and welfare of man.” • “To enrich our understanding of the ecological systems and natural resources important to the Nation.” (Lewis, 1985, p. 2) According to Jack Lewis in the November 1985 EPA Journal, the EPA has developed into the most competent agency in the federal government. Iola Project During 2006 the environmental protection agency began conducting evaluation of the Iola area where the former smelter was located between the intersection of Highway 169 and 54 in Allen County. (Young, 2007, p.1) The smelter affected many properties in the area. The smelting activities occurred more than a century ago (Figure 10) (Johnson, 2006b, p. 13). Figure 10. Early Iola, Kansas with smelter in background. 11 According to the Iola Register random sampling was begun by the Kansas Department of Health and Environment which concluded that there was reason to further investigate the soil. Soil around some schools and several homes were found to exceed acceptable limits of less than 400ppm (Figure 11) (Johnson, 2006c, p. 1). 12 Figure 11. Excavation of lead-contaminated soil. Soil samples were done first at the schools to determine if any danger was found for the children. In children, lead can lead to damage in the brain and body which may cause some neurological damage. They found that there wasn’t any pattern to the lead contamination because they felt the tailings had been used randomly. The presence of the lead was found to be more prominent at older homes in the area. (Johnson, 2006b, p. 13) 12 The purpose according to the fact sheet published by the Environmental Protection Agency in August 2006 was: • “to find the concentrations of lead in the soil that were greater than 800 parts per million • where high impact child areas had soil concentrations over 400 ppm • residences where children’s blood level were greater than 10 micrograms per deciliter and lead concentrations in soil over 400 ppm • Industrial properties with lead concentrations in the soil greater than 1000 ppm.” (Young, 2007, p. 1) Some of the residents indicated that material from the smelter had been used for fill around homes, sidewalks and driveways. The EPA said that the primary concern was with lead and lead compounds. Children playing in the contaminated areas were at highest risk of exposure. In order to reduce human health and environmental risks, these properties were a top priority. Every property that the owners gave permission to be tested was tested. The Iola Register stated in their article, “School cleanups just a start,” that the problem stemmed from the smelter that was located in the town many years ago. Ore from other counties in Kansas was transported to the area to be processed in the smelter; the waste material was used for fill material for sidewalks, driveways, foundations and elsewhere. According to Eddie McGlasson, environmental scientist with the Environmental Protection Agency, the clean up would cost about $2 million but it would be funded by the EPA superfund money and federal funds. 13 Seagull Environmental Technologies, Inc. To aid in the testing of the site at Iola, Seagull Environmental Technologies, Inc. was brought in to help. This group provides many services: • “Emergency responses to Hazardous substances • Superfund site assessments, targeted Brownfield’s assessments, and Phase I and Phase II environmental site assessments • Environmental remediation, lead and asbestos abatement, and removal oversights” (Seagull, 2007, p. 1) The company provides many assessments and tasks throughout the nation. Members of the company helped perform the assessments of the residential properties in Iola Kansas. 14 Chapter Three METHODOLOGY Before any screening could be done, every property owner was spoken with so that access to their land could be obtained. Once access was granted a two person crew began work. All information was kept in a log book. While one person began to sketch out the property, the other gathered GPS coordinates, wrote them in the log book and began to sample. A property was usually split into two to four sections called cells (Figure 12). Nine uniform samples were obtained using an ice cream scoop and deposited into a pie pan from each cell. Using a spoon, the soil was homogenized and then sieved. The sieved soil was then ready to be analyzed using an X-ray fluorescence (XRF) machine. Three readings in parts per million (ppm) were taken over twenty nominal seconds and then averaged for comparison purposes. A large database was created to track all information. Home owners received a copy of the field sheet for their records. Once the soil was determined to exceed EPA standards, the property was scheduled to be cleaned up. The clean up contractors excavated the contaminated cell by removing six inches of soil first. Then the XRF machine was used to determine if the sample was less than 400 ppm and if it was under 400 ppm, the clean soil was brought in and the ground was seeded. If the soil sample was over 400 ppm, another six inches of dirt was removed. If it was still over 1200 ppm, the soil was removed up to two feet. Clean soil replaced the soil that was removed and then the area was seeded. This left each property just like it was before the project began. Materials used during the project were computers, GPS, field sheets, field book, ice cream scoop, pie pan, zip lock bags and pen or pencil. Larger equipment was used for excavation of the soil and dump trucks for removal and replacement of the soil. All were essential in checking the samples and replacing the soil properly. Multiple groups of people helped in the 15 process. The Environmental Protection Agency, Seagull Technologies, Inc. and other contractors have contributed to the success of the Iola Project. Those areas that were granted access have been identified and cleaned up according to EPA standards. The community and property owners have been given information regarding their report. Congresswoman Boyden praised the work in the Iola area by forwarding a message to the EPA for all the efforts in making this project a success. 16 United Zinc # 1 Residential Property Screening Form EPA Site # ______ Name: _____________________________ Address: _____________________________ ____________________________________ Phone #______________________________ Owner Information on back:___ Date(s): ______________ XRF I.D. Screening Results: ___________ Post-Removal: ___________ Operator __________ __________ Latitude ________________________________________ Longitude ______________________________________ 07-01-2005 Residential Screening Form Figure 12. Example of field sheet. 17 Chapter Four RESULTS AND CONCLUSIONS The following results can only be partial due to their sensitive nature. The government only has released specific information that can be given to the general public at this time. The project is ongoing and has not been fully documented. In the future, further information may be given. Most of the results were obtained from the official web site of the environmental protection agency. During the project, approximately 1672 homes were tested. 1141 under 400 ppm and 531 above. There were 131 properties that were excavated and replaced with new soil. The project has not been finalized. Therefore, future screening, testing and excavation may be needed in the future. For those properties that were not considered an emergency response under this project, they will be cared for at a later date. Iola, Kansas was a very good example of what has happened in many places in the world where this type of lead and zinc deposits are found. You are able to see the effects that occurred in Iola, Kansas which may reveal an insight of what may have already developed or might one day. Perhaps we will be able to learn from what we have done and be able to use this information to help with further study. 18 REFERENCES 19 LIST OF REFERENCES Allen County Historical Society, 1966-1983, Tales of Early Allen County, p. 2. Johnson, B., 2006a, Excavations on Hold, The Iola Register, p. 1 & 4. Johnson, B., 2006b, Process began two years ago, The Iola Register, p. 1 & 13. Johnson, B., 2006c, School cleanups just a start, The Iola Register, August 17, p. 1 & 13. Brosius, L., and R. Sawin, 2001, Lead and zinc mining in Kansas, Kansas Geological Survey Public Information Circular 17, University of Kansas, p.1-4 Kansas Geological Survey, last updated 2005, Lead and zinc mining, Geokansas, www.kgs.kw.edu/Extension/ozark/mining.html. Lewis, J., last updated 2007, The Birth of the EPA, www.epa.gov/history/topics/era/15c/htm. Seagull Environmental Technologies, Inc., last updated 2007, www.seagullenvirotech.com. Wiseman, P., last updated 2007, EPA History (1970-1985), www.epa.gov/history/topics/era/15b.htm. Young, B., 2007, Time-Critical Removal and Disposal of Soils-United Zinc #1 Superfund Site, Iola, Kansas, www.epa.gov/region7/news_events/factsheets/fs_time-critical_disposalsoils_ united_ zinc1_sprfnd_iola_ks0806.htm. 20