Laser-based Non-destructive Evaluation John S. Popovics Learn the basis and application

advertisement

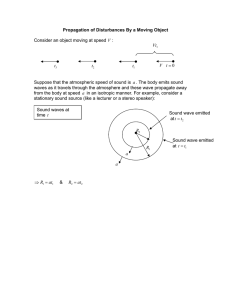

Laser-based Non-destructive Evaluation John S. Popovics Objective: Learn the basis and application of laser-based NDE techniques Topic significance Lasers are important in many engineering applications Remote or embedded sensing* Manufacturing process monitoring* Medical procedures Communication systems The application of lasers to engineering tasks will become more widespread in the future Laser-based NDE Lecture outline Basic concepts • waves • optics • lasers • optical fibers Techniques • wave generation • wave detection • fiber sensing Applications • smart structures • laser-based ultrasound Laser-based NDE What are waves? Propagation of a disturbance through a medium (mass is not transported in propagation direction) Excitation Direction of Travel Direction of Particle Disturbance of Wave Front Laser-based NDE Types of waves Mechanical waves - motion or pressure sound, ultrasound, vibration, etc. (can propagate in solids and fluids, but not vacuum) Electromagnetic waves – electric or magnetic field light, radio waves, RADAR, microwaves, etc. (can propagate in all media – very fast) Laser-based NDE Harmonic wave propagation 1.5 T D is place me nt 1 0.5 0 -0.5 m -1 phase delay -1.5 0 20 40 60 80 T ime 100 position of mass on a spring • Many phenomena arise from harmonic motion • Propagating waves cause harmonic motion at a sensed spot. Laser-based NDE What is wave frequency? The period (T) is the time required for wave motion to complete a round trip (measured in seconds) The frequency () is the inverse of T (measured in 1/seconds or “Hertz”) In audible sound, frequency is interpreted as the pitch In visible light, frequency is interpreted as the color. Laser-based NDE Harmonic wave behavior All waves obey fundamental principles Frequency-wavelength relation V= A the frequency () of a propagating wave is related to its wavelength () by the propagation velocity (V) Sound waves in air: V = 330 m/s For = 440 Hz (middle “A” on a piano), then = 0.75 m Laser-based NDE Wave interference + + = (T/2 phase delay) Constructive Interference Laser-based NDE = Destructive Interference Combine waves Combine waves If two harmonic waves are combined together, the amplitude of the resulting combined wave depends on the alignment (phase delay) of the two individual waves. Reflection & refraction When a propagating wave traveling in a medium impinges on an interface with another medium, wave reflection and refraction occurs. A portion of the incident wave energy will propagate back into the original medium (reflection) while the remaining wave energy will propagate through into the second medium (refraction). Laser-based NDE Wave reflection & refraction Reflected angle equals the incident angle Note: t > i Laser-based NDE Transmitted angle depends on the incident angle and the properties of the two media Total internal reflection incident reflected wave wave i r M edium 1 Incident angle is greater than the “critical” angle: no refraction, all reflection M edium 2 Note: t > 90o Laser-based NDE Refracted angle must be greater than incident Optical spectrum Ultra-violet Infra-red Wave length (in air) 700 nm 550 nm 400 nm 5.45x1014 Hz 7.50x1014 Hz Frequency 4.28x1014 Hz Laser-based NDE Quantum behavior of light Light behaves both as a wave and also as a collection of discrete packets (photons) of energy. Light can absorb or emit a finite amount of energy – a “quantum”. The amount of energy is related to the frequency of the light () Through Planck’s constant (h): E = h where h = 14.4 eV s Laser-based NDE Lasers Lasers are devices that amplify and direct a light beam. Flash light Laser low intensity, broad range of frequencies, large beam divergence. high intensity, narrow range of frequencies (single frequency), small beam divergence. Laser-based NDE Lasers Rapid decay Excited states Light amplification E2 (at a single meta-stable E1 frequency) achieved Lasing Pumping by “pumping” and L = (E1-E0)/h P = (E2-E0)/h “lasing” atoms in a E0 special medium. A stimulated emission Ground state transition between two energy states is Pumping frequency p is associated with greater than lasing absorption or frequency L emission of light at a certain frequency Laser-based NDE Lasers Incident photon Output photons Laser material Pump energy Pumping: laser medium illuminated with an intense light source with P or an electrical discharge is passed through a gaseous medium. Stimulated emission: a photon of light passes through an excited later medium and induces an excited atom to reduce back to the ground state. Thus we generate a second identical photon, and the initial light is amplified. Light amplification by stimulated emission of radiation Laser-based NDE Lasers Beam “collimation” (tight directivity) achieved by a light “resonator”. Collimated laser beam Stimulated laser light Fully-reflecting mirror 1 to 4 mm wide Partially-reflecting mirror Laser-based NDE Laser systems Laser, Mode m m) Type Wavelength ( He - Ne, CW gas 0.633 interferometry CO , pulsed gas 10.6 wave generation 2 Application YAG, CW solid state 1.06 interferometry YAG, pulsed solid state 1.06 wave generation Ruby, pulsed solid state 0.694 wave generation semi -conductor 0.815 Ga - As, CW fiber optics Properties of the light controlled by the laser generating system: gas, solid state or semi-conductor Lasers can generate either a continuous beam (CW) or repeated short bursts (pulsed) of light Laser-based NDE Thin (0.1 mm) optical fibers Light can travel great distances within a transparent fiber if total internal reflection is achieved: incident light within acceptance angle and ncladding < ncore i > crit t > i leakage fiber cladding fiber core light critical angle acceptance angle total internal reflection Laser-based NDE Lasers are a good light source for optical fiber What is NDE? Non-destructive evaluation Detect defects, dimensions, etc. without damaging the material • Ultrasonic sound waves • X-ray / CAT scans • Magnetic techniques • RADAR scanning • Thermal imaging X-ray radiograph Laser-based NDE Ultrasonic NDE Flaw detection: wave echoes from airfilled defects such as cracks and voids wave path Signal amplitude Back surface echoes wave source Time Signal amplitude crack crack echoes Time Laser-based NDE Laser wave generation thermoelastic source plasma source laser beam heated area vaporized plasma resulting forces Lasers can generate mechanical waves in solids without contact Laser-based NDE Wave sensing with Lasers reference mirror beam splitter laser source moving surface photodetector output Michelson interferometer Laser-based NDE Very small surface motion (on the order of the optical wavelength) can be detected. Two split Beams are recombined. The light intensity of the combined beam varies because of phase interference as the path length changes owing to surface displacement. Max intensity = in phase Min intensity = out of phase Wave sensing with Lasers incident light surface motion higher frequency incident light surface motion lower frequency Heterodyne interferometer or “vibrometer” Laser-based NDE Larger surface motion (vibration) can be detected. Frequency shifts in reflected laser light are monitored. Shifts are related to relative surface velocity resulting from Doppler shift phenomenon. Optical fiber sensors Optical fibers act as internal condition sensors when they are attached to a structure or material. Minute changes in stretching, pressure and temperature induce changes in the intensity, phase, polarization and wavelength of the light traveling in the fiber. By monitoring changes in the light, changes in internal condition can be inferred. Optical fiber Light in Light out Laser-based NDE stretching “Smart” structures “Smart” or “adaptive” materials contain embedded fiber optic sensors combined with distributed actuator systems. Capable of sensing the state of the material and then modifying accordingly “smart” Hmmm.. Laser-based NDE Application: smart structures * Image from AMS lab at MIT Material checks and corrects unwanted vibration or deviations from pre-assigned shape in aircraft and helicopter structures Laser-based NDE Application: embedded sensors Embedded optical fiber serve as rugged strain sensors in concrete. Here fiber optic sensors provide data during a test, which agree with conventional sensors at the surface Laser-based NDE Application: vibration monitoring Surface motion map for van provided by scanning laser vibrometer Full-field displacement monitoring can rapidly provide information about dynamic motion of a structure. Here areas of large surface motion (vibration) are indicated by “+”. Laser-based NDE Application: metals processing Ultrasonic signal Back-wall echoes Lasers can perform non-contact ultrasonic inspection. Here a laser ultrasonic system monitors the thickness of hot-rolled (1000oC) steel tubes during processing from a safe distance (up to 5 m away) Laser-based NDE Application: train rail inspection (Center Nondestructive Evaluation at The Johns Hopkins University) Power Supply M1 IR Pulse Laser Oscilloscope Charge Amplifier M2 Capacitive Air-Coupled Transducer Testing set up Laser-based NDE A hybrid Laser scanning system allows rapid non-contact inspection of rail in place. Small fatigue cracks in the rail head should be located Analysis approach Images from CNDE at The Johns Hopkins University Crack No Crack Laser-based NDE Summary • Lasers are devices that create a high intensity, directed light beam. • Lasers can be used to generate waves and detect stretching or motion in a solid material without direct contact with the material. • Lasers are useful in many important engineering applications, including NDE: laser ultrasonics, “smart” structures and vibration sensing. • The use of lasers will become more common in the future. Laser-based NDE