EVALUATION ON PROPERTIES OF TENDER MIXES ZANARIAH BT ABD RAHMAN

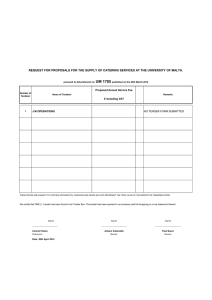

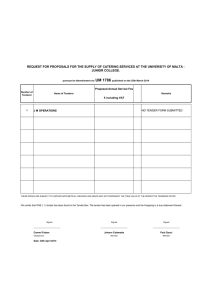

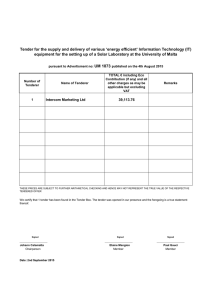

advertisement