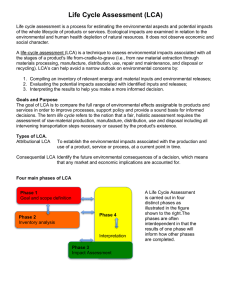

AWARENESS ON THE IMPLEMENTATION OF LIFE CYCLE ASSESSMENT IN LIGHT INDUSTRIES .

advertisement