vii TABLE OF CONTENTS CHAPTER

advertisement

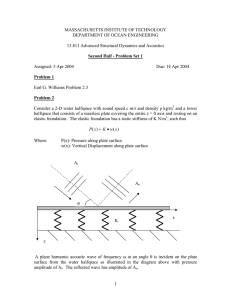

vii TABLE OF CONTENTS CHAPTER 1 TITLE PAGE DECLARATION ii DEDICATION iii ACKNOWLEDGEMENT iv ABSTRACT v ABSTRAK vi TABLE OF CONTENTS vii LIST OF TABLES xii LIST OF FIGURES xiv LIST OF ABBREVIATIONS xviii LIST OF APPENDICES xxiii INTRODUCTION 1 1.1 Background of Research 1 1.2 Problem Statement 2 1.3 Objective of Research 3 1.4 Scope of Research 3 1.5 Importance of Research 4 1.6 Visits to Kay Marine Sdn. Bhd. 5 1.7 General Outline Of The Thesis 7 viii 2 LITERATURE REVIEW 9 2.1 Overview 9 2.2 Catamaran 10 2.3 SWATH 10 2.4 Semi-SWATH 11 2.4.1 11 2.5 2.6 Semi-Swath Structure Design and Component 12 2.5.1 Longitudinal Frame 15 2.5.2 Transverse Bulkhead 16 2.5.3 Stiffeners 16 2.5.4 Plate 16 Loading In General 17 2.6.1 In-Plane and Lateral Load 19 2.6.2 Failure Mode 20 2.6.2.1 Plate Buckling 21 2.6.2.2 Column Buckling 23 2.6.2.3 Overall Collapse 25 2.7 Ultimate Strength of Ship 27 2.8 Seakeeping 33 2.8.1 Wave Characteristic 34 2.8.2 Wave Forms 34 2.9 3 Concept of Semi-Swath Summary of Study 36 RESEARCH METHODOLOGY 37 3.1 Research Design and Procedure 37 3.2 Development of Scale Down Model 39 3.2.1 DNV and Llyod’s Classification 44 3.2.2 Finite Element Analysis 45 3.3 Development of Data Acquisition System 46 3.4 Development of Principle Approach 46 ix 4 DEVELOPMENT OF FIRST PRINCIPLE APPROACH 53 4.1 First Principle Approach 53 4.1.1 Longitudinal Section 54 4.1.2 Transverse Section 57 4.2 Ultimate Strength of Ship 4.3 Computer Programming for First Principle Approach 4.4 59 Verification of First Principle Approach Programming 5 58 63 FINITE ELEMENT ANALYSIS AND COMPUTATIONAL ANALYSIS OF BEAM WAVE 64 5.1 Introduction 64 5.2 Limitation of Finite Element Method 65 5.2.1 Static Condition 65 Semi-SWATH Modeling 65 5.3 5.3.1 Hull Module of Semi-SWATH Structure 67 5.3.2 Material 68 5.3.3 Load 68 5.3.4 Boundary Conditions 70 5.4 Validation of FEM 71 5.5 Computational Analysis of Beam Wave 73 5.5.1 Parameters of Computational Analysis 73 x 6 DEVELOPMENT OF DATA ACQUISITION SYSTEM AND EXPERIMETAL SETUP 77 6.1 Data Acquisition Concept 77 6.2 Sensor Using Strain Gauge 78 6.2.1 Installation of Strain Gauges 81 DAS Hardware and Validating Signal 82 6.3.1 83 6.3 6.4 6.5 Excitation Voltages Application Software –LabVIEW 83 6.4.1 Concept of Hooke Law- Stress Strain 86 6.4.2 Poisson Ratio 87 Calibration of Measurement On Semi-SWATH Structure 6.6 Experimental At National Hydraulic Research Institute of Malaysia (NAHRIM) 7 88 90 RESULTS AND DISCUSSIONS 93 7.1 Background 94 7.1.1 Scale Effect 94 7.1.2 Static Load Analysis 94 7.2 Discussion on DAS System and Finite Element Results 96 7.3 Discussion on First Principle Approach 96 7.4 Result Comparison 97 7.4.1 Static 99 7.4.2 Dynamic – Wave 101 7.5 Application on Evaluation Initial Design of Steel and Composite Structure Strength 111 xi 8 CONCLUSION 113 8.1 Conclusion 113 8.2 Future Development 115 REFERENCES 117 Appendices A-D 127-219 xii LIST OF TABLES TABLE NO. 2.1 TITLE PAGE Summary of Previous Researcher on Strength of Structure 36 3.1 Dimensions Semi-SWATH Hull Design 41 3.2 Summary of Analysis/Method for Semi-SWATH 50 4.1 Development of First Principle Approach 53 4.2 First Principle Approach Results Comparison 63 5.1 Aluminum & Wood : A Material Properties For Yield and Tensile Strength 68 5.2 Boundary Condition for Semi-SWATH Structure 71 5.3 Main Parameter of Grillage 1a Smith (1975) 71 5.4 Main Parameter of Beam Sea Computational Analysis 74 6.5 Calibration Results on Semi-SWATH Structure 88 7.1 Results Data for Semi-SWATH Using Maxsurf Software 95 7.2 Overall General Comparison 98 7.3 Position Strain-Gauges Connected to DAS System By Experiment 7.4 98 Experiment T6- Major Result of the Maximum Stress Occur at Semi-SWATH Structure – Static Condition 107 7.5 Comparison of Form Moment Acting 109 xiii 7.6 Early Application by First Principle Approach 112 xiv LIST OF FIGURES FIGURE NO. TITLE PAGE 1.1 SWATH Ship 2 1.2 Catamaran Boat at Kay Marine Sdn. Bhd. 5 1.3 Catamaran Boat under Construction 6 1.4 Grillage Deck Structure 6 1.5 Bulkhead & Frame Structure 7 2.1 Semi-SWATH Design 12 2.2 Semi-SWATH Structure and Module 13 2.3 Grillage of Longitudinal Frame 15 2.4 Instability Failure Mode 20 2.5 Overall Collapse 26 2.6 Wave Characteristic 34 2.7 Hogging and Sagging Moment Relation to the Wave 35 3.1 Flow Chart of Methodology 38 3.2 Grillage 2a – Overall Collapse (Smith, 1975) 40 3.3 Grillage 2a (Smith, 1975) 40 3.4 The Original Design of Scale Down Semi-SWATH 3.5 Model 41 The Design of Scale Down Semi-SWATH Model 41 xv 3.6 The Scale-Down Semi-SWATH Model at Marine Technology Lab UiTM Shah Alam 4.1 42 Flow Chart of First Principle Approach Computer Programing 62 5.1 Wireframe of Semi-SWATH - CATIA 66 5.2 Finite Element Full Modelling 66 5.3 Displacement 67 5.4 Load Static on Semi-SWATH Hull – Hydrostatic Pressure – Half Breadth 69 5.5 Pressure Loading & Constrains 70 5.6 Boundary Condition for Grillage Models 1a – In-Plane Load Only 72 5.7 FEM Result of Grillage Models 1a 72 5.8 Element and Node of Semi-SWATH 74 5.9 SeaFEM Result on Beam Wave of Semi-SWATH 75 5.10 Beam Wave Analysis Result for Bottom Structure of Semi-SWATH at Wave 0.1 m. Heading 180o 75 6.1 Strain Gauges Attach to Structure – Top View 79 6.2 Strain Gauges Attach to Structure 79 6.3 SCXI-1600 and Terminal Block (SCXI-1314) 83 6.4 Data Acquisition Concept – Lab View 84 6.5 Block Diagram for Data Acquisition Software (Stress) 85 6.6 Block Diagram for Data Acquisition Software (Strain) 85 6.7 Front Panel for Stress 86 6.8 Graph Stress Vs Time at Front Panel 86 xvi 6.9 Calibration Equipment for Semi-SWATH Structure 89 6.10 Load Apply on Semi-SWATH Structure 89 6.11 Calibration Results Compared to Standard Data 90 6.12 Flume with Wave Generator at NAHRIM 91 6.13 Wave at 0.1m 92 6.14 Early Preparation in Flume 92 7.1 Static & Dynamics Wave Test at NAHRIM 94 7.2 Position Strain Gauge at Semi-SWATH 99 7.3 Stress Comparison at Static Condition for Joint Transverse and Longitudinal Stiffness (ST): ST5, ST10, ST13, ST14 7.4 Stress Comparison at Static Condition for Transverse Stiffness (ST): T2, T3, T4, T5, T6, T7 7.5 100 101 Stress Comparison at Static and Wave Condition for Joint Transverse and Longitudinal Stiffness ST14 102 7.6 Stress – Wave. Comparison between L16 & ST14 103 7.7 Stress Comparison at Static and Wave Condition for Longitudinal Stiffness L16, L17, L19 7.8 Stress Comparison at Static and Wave Condition for Longitudinal Stiffness L16 7.9 105 Stress Comparison at Wave Condition for Transverse Stiffness (ST): T2, T3, T4, T5, T6, T7. 7.10 104 106 Highest Stress On T6 and Comparison T8 (Forward Structure) - Wave – Experiment 108 xvii 7.11 Form Moment Acting : Sagging on Structure of Semi-SWATH 7.12 109 Form Moment Acting : Hogging on Structure of Semi-SWATH 110 xviii LIST OF ABBREVIATIONS a - spacing of transverse frame, plate length A - length of panel AA - cross-sectional area AB - area of the bottom including stiffeners AD - cross-section area of the deck including stiffeners Ae - effective cross section area As - effective shear (web) area ASR - area of one hull side including stiffeners AT - cross sectional area of longitudinal Av - volume of electrode metal melted off per unit length b - spacing between longitudinal stiffeners, plate width bwt - spacing between transverse stiffeners/frame, plate width B - width of panel C - spring stiffness of plate D - depth of the midship section Df - flexural rigidity Dx - longitudinal flexural rigidity Dy - transverse flexural rigidity E - modulus of elasticity - stress deck F - factor gage g - gravity = 9.81 m/s2 or 32.185 ft/s2 or 385.92 inch/s2 gS - distance from the center of the deck area to the plastic neutral axis G - modulus of elasticity fD xix h - wave height Ic - current I - moment of inertia Ia - moment of inertia (longitudinal) I et - effective second moment of areas panel section Ie - effective second moment of areas panel section I pc - polar moment of inertia I px - moment of inertia of the effective plate associated with the stiffeners extending in the x directions I py - moment of inertia of the effective plate associated with the stiffeners extending in the y directions Is - second moment of area of panel Ix - moment of inertia of stiffeners with effective plate extending in the x-direction Iy - moment of inertia of stiffeners with effective plate extending in the y-direction Iz - moment of inertia about vertical axis through CE k, K c - buckling coefficient K - St. Venant torsion constant Ki - constant coefficient – initial distortions L - length of wire l - length of stiffener LT - length of stiffeners between tripping brackets m - number of half-waves plate in x direction Mo - maximum bending moment Mp - Caldwell fully plastic moment M uc - Caldwell ultimate bending moment M uh - Hughes ultimate bending moment M uho - ultimate bending moment in hogging condition xx M usa - ultimate bending moment in sagging condition n - number of half-waves plate in y direction P - pressure Pcr - critical load R - resistance Rm - plate coefficient MIT r - radius of gyration re - effective radius of gyration s - spacing between stiffeners S - spacing of primary members Sx - spacing of stiffeners extending in the x direction Sy - spacing of stiffeners extending in the y direction t - thickness of plate t p , t pt - built thickness of plating (longitudinal) t tt - built thickness of plating (transverse) tw - thickness of stiffener web - possion ratio w - equivalent fillet ye - distance from the centroid axis to the transverse cross section yf - distance from the centroid axis to the mid-thickness of the Av 0 .6 stiffener flange yp - distance from midthickness of the plate to centroid axis effective cross section of panels V - voltage Zp - plastic section modulus - stress cr - critical stress e - transverse stress xxi ecr - elastic critical stress f - total stress in stiffener flange m - average compressive stress necr - elastic critical after correction o - average yield stress p - proportional limit gradual stress; may be taken as 60 % of o r - residual stress y , fy - yield stress of material uf - axial compression-stiffener flange ul - ultimate stress plate ult - ultimate Strength up - axial compression-plate flange ue - loss of plate stiffness due to compression - slenderness ratio - aspect ratio a/b B - keel hull aspect ratio D - deck hull aspect ratio S - side hull aspect ratio - equal area axis - warping constant a - element of area o - initial deflection - strength factor cp - strength factor critical panel D - deck strength factor S - side hull strength factor - displacement in tones e - initial eccentricity xxii P - eccentricity caused by the loss of plate stiffeners L - change in length of wire - torsion coefficient - column slenderness ratio ε - strain ρm - receptivity of wire material Ω - ohm ε1 - strain for 1st reading ε2 - strain for 2nd reading ρ - density of water (1000 kg/m2) ABS - American Bureau of Shipping Classification l r y E SWATH- Small Water-plane Area Twin Hull DAS Data Acquisition System - NAHRIM - National Hydraulic Research Institute of Malaysia FEM - Finite Element Method DNV - Det Norske Veritas Classification Unit Converter N - Newton x 0.102 = kgf N/m 2 - Newton/Square Meter x 0.00145 = Pound/Square Inch (psi) tsi - Tonne/Square Inch x 2000 = Pound/Square Inch (psi) psi - Pound/Square Inch x 6.894757 = kilopascal (Kpa) x 0.689476 = N/m2 kg/m2 - Kilogram/Square Meter x 9.81 = Newton/Square meter N/m2 x 0.00142233 = Pound/Square Inch (psi) kg/m3 - Kilogram/Cubic Meter x 0.0624279 Pound/Cubic Foot xxiii LIST OF APPENDICES APPENDIX A TITLE PAGE Calculation First Principal Approach By Computer Programming Using Fortran90 127 B Experiments Results 160 C List Paper & Journal 196 D Static Load Analysis – Weight Calculation 198