Continuous Flow Processing of Linezolid

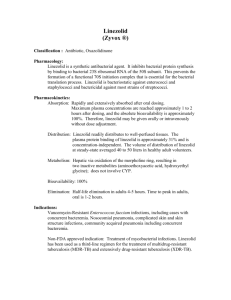

advertisement