Proceedings of GT 2006 May 8-11, 2006, Barcelona, Spain

advertisement

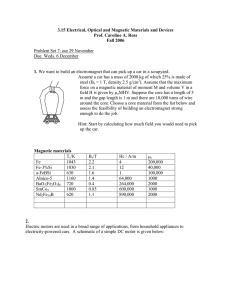

Proceedings of GT 2006 ASME Turbo Expo 2006: Power for Land, Sea & Air May 8-11, 2006, Barcelona, Spain GT2006-90270 FLYWHEEL ENERGY STORAGE SYSTEM FOR NAVAL APPLICATIONS Co Huynh, Patrick McMullen, Alexei Filatov, Shamim Imani Calnetix Inc., 12880 Moore Street, Cerritos, CA 90703, USA Hamid A. Toliyat, Salman Talebi Department of Electrical Engineering, Texas A&M University, 3128 TAMU, College Station, TX 77843, USA ABSTRACT A recent trend in designing naval ships is to improve performance through using more electric equipment. The reliability and quality of the onboard electric power, therefore, becomes critical as the ship functionality would entirely depend on its availability. This paper investigates the possibility of using Flywheel Energy Storage Systems (FESS), similar to those earlier developed for commercial applications, to address issues related to onboard power supplies. A design of a FESS for onboard power backup and railroad electrical stations is presented. The FESSs power output parameters are 500kW×30sec in high-duty mode and up to 2MW in pulse mode. High power output is one of the main advantages of FESS over commercially available electrochemical batteries. The other advantages include essentially an unlimited number of charge/discharge cycles, observable state of charge and environmental friendliness. Designs of the main FESS components are discussed: low-loss magnetic bearings, an energy-storage hub, a high-efficiency motor/generator and power electronics. Smaller diesel gensets may additionally be used as power backups for certain critical loads, such as computer equipment. There are many unique challenges that must be considered when developing on-board electrical power supply networks [3]. Electrical equipment on a ship will include loads that require very high power for short periods of time, which can be in the order of a few seconds or milliseconds. Examples include electromagnetic aircraft launch systems and highenergy weapons. Another consideration is the wide variety of electrical loads that range from propulsion engines to highly sensitive computer equipment. The uninterruptible power supply for the latter is of special concern as computers control all vital functions of a modern ship. An extremely important requirement for a shipboard electrical network is high survivability. Should the ship experience some damage in a battle, it cannot become completely paralyzed because of the loss of its primary electrical power supplies. Several leading defense contractors are currently involved in development of a distributed onboard electrical power network which would address this issue. Finally, the equipment installed on a ship needs to be as compact and power-dense as possible as cargo space is a premium onboard ships. INTRODUCTION Similar to the aerospace industry with its more electric aircraft initiative to improve the overall system performance, military vessels are moving towards more electric based equipment. Gas turbines in combination with electrical generators are expected to be the main sources of the electrical power for the new ships [1,2]. Their advantages over diesel generators include higher power to weight ratio, very low maintenance, and higher frequencies of acoustic noises, which are better absorbed by water making a ship harder to detect. Most of these issues are not exactly new and specific to naval applications. They are quite often encountered in modern commercial electrical installations. For example, coexistence of high-power machinery and sophisticated computer equipment is very common these days in such applications as aircrafts, modern trains and cars. Another example is in manufacturing plants where process machinery demands high power during initialization and grids need to be stiffened with supplemental power sources. 1 Copyright © 2006 by ASME These and other power quality issues are addressed by using Uninterruptible Power Supplies, Power Conditioning, Load Leveling and Energy Storage Systems. Traditionally, these are based around electrochemical batteries. Commercially available batteries, however, are not capable of high charge/discharge rates, have limited cycle life, unobservable state of charge, require high maintenance and impose disposal problems. Aggressive chemicals used in batteries, such as acids, are especially dangerous for naval applications where they can be released if the ship is damaged in a battle. FESSs provide an attractive alternative to electrochemical batteries, free of all of the above mentioned disadvantages. A FESS stores energy in the form of kinetic energy in a rotor spinning at a high-speed in a vacuum. In a modern FESS, the rotor is supported in non-contact magnetic bearings offering essentially unlimited lifetime and charge/discharge cycles. Recent advances in permanent magnet motor/generator technology resulted in flywheel charge/discharge rates many times higher than those achievable with electrochemical batteries. In the commercial realm, a new and very promising application for FESSs is in load leveling and energy recovering at electrical train stations. Electrical trains consume extremely high power for short periods of time during acceleration, dissipating this power in the form of heat later when the train brakes. The current approach to this problem is sizing the electrical grid for the peak power rather than the average. Besides being expensive by itself, this solution implies higher operational cost in the future since customers pay a premium for peak power consumption. In addition, existing electrical infrastructure is both difficult and expensive to upgrade to accommodate larger and/or more frequent trains required to address growing commuter needs. FESSs installed at the train stations allow accumulating the energy released during the train brake in order to reuse it later for the train acceleration. In contrast to conventional electrochemical batteries, a FESS is capable of sustaining a large number of charge/discharge cycles required in this application for many years without degradation. a much smaller flywheel hub and a motor/generator than designs relying on ball bearings. In spite of higher speeds, the life of magnetic bearings was essentially unlimited due to the non-contact nature of the suspension. On the other hand, the flywheel hub design was rather conservative as it was made of high strength 4340 steel rather than more exotic composite materials [11]. Using the 4340 steel avoids issues associated with integration of composites which results in a robust and predictable design. One of the most important issues related to application of the flywheel onboard a ship is dynamic loading. Whereas a composite rotor offers an advantage of smaller dynamic inertia forces due to a lower rotor weight, the magnetic suspension system described in this paper takes advantage of the magnetic properties of a steel rotor to passively lift it using permanent magnets. The entire load capacity of the active magnetic bearings in this case is used to compensate for dynamic loadings. Such a passive magnetic lift would be very difficult to realize with a composite rotor due to the non-magnetic nature of the composite materials. Table 1 below summarizes the requirements for energy storage in several military and commercial applications, comparing what exists today and what is needed for new applications. A 1.7-4.2kWh 500kW high-duty-cycle / 2MW low-duty-cycle FESS described in this paper targets both Navy onboard power backups and commercial railroad applications. In onboard power backup, the FESS works together with a diesel genset, providing power for critical equipment in case of a failure of the main gas turbine or the main electrical network. Higher power output and energy storage capacity values can be obtained by connecting several FESS units in parallel. The starting point for the flywheel described in this paper was a 125kW×16sec flywheel developed earlier for commercial UPS applications [4-10]. This design has been shown to offer an advantageous compromise between novelty and conservatism. On one hand, it utilized state-of-the-art technologies such as patented non-contact magnetic bearings and an advanced permanent-magnet motor/generator. Higher rotational speeds due to the use of magnetic bearings resulted in Existing systems Power Duration Stored energy Recharge time System output voltage, DC* System output current, DC* Vycon 125 kW flywheel DC source 125kW 17 sec 0.6 kWh Variable 400-900V 320A 2MW generator 2MW continuous N/A N/A 800V 2.5kA Aircraft Launch 120MW 2 sec 34kWh 45 sec 1.5-4kV 18-50kA NAVY applications New commercial applications High-Energy Weaponry 50GW 6-10msec 28kWh 6sec 10kV (pulse) 10MA (pulse) Sacramento New York light railroad heavy railroad 500kW 2.5MW 25.8 sec 12.6 sec 3.58 kWh 8.75 kW h 18 sec 10 sec 600-1,000V (typical) 840A max 4.2kA max Onboard Power Backups 1-8MW 0.5-15sec 4.2kWh 1000V 1kA max * DC bus values are used for comparison between applications Table 1. Parameters of the existing Calnetix/Vycon systems and requirements for Navy and commercial applications for FESS. 2 Copyright © 2006 by ASME NOMENCLATURE Fz K r, K z Id, Iq Is iA, iB, iC iR, iS, iT Pout uA, uB, uC uAB, uBC, uAC uR, uS, uT uRS, uST, uRT νA, νB, νC νAB, νBC, νAC νR, νS, νT νRS, νST, νRT δ ωr θ axial force exerted on the rotor by the passive lifter radial and axial rotor suspension stiffnesses due to the passive lifter RMS (Root-Mean-Square) values of the direct and quadrature components of the motor/generator control currents RMS value of the motor/generator phase current phase currents on the grid side of the power electronic unit phase currents on the motor/generator side of the power electronic unit Output power of the generator phase to neutral voltages on the grid side of the power electronic unit phase to phase voltages on the grid side of the power electronic unit phase to neutral voltages on the motor/generator side of the power electronic unit phase to phase voltages on the motor/generator side of the power electronic unit phase to neutral EMFs (Electromotive Force) on the grid side of the power electronic unit phase to phase EMFs on the grid side of the power electronic unit phase to neutral EMFs on the motor/generator side of the power electronic unit phase to phase EMFs on the motor/generator side of the power electronic unit torque angle in vector motor / generator control circular rotational frequency of the rotor (rad/sec) angular position of the rotor (rad) FLYWHEEL TOPOLOGY The flywheel layout is schematically shown in Figure 1. It consists of the following major components: 1) Flywheel hub made of high-strength 4340 steel 2) A system of two homopolar PM (Permanent Magnet) biased magnetic bearings; radial on the top and combo at the bottom 3) Passive PM lifter 4) PM Surface-Mounted (PMSM) 4-pole motor/generator Another critical element to the FESS is the power electronics. While not shown in Figure 1, it will be discussed in more detail along with the function and operation of each of the major FESS components below. FLYWHEEL HUB Similar to its smaller 125kW predecessor, the proposed flywheel utilizes a hub made of high-strength 4340 steel. A possible alternative to 4340 steel would be to use modern composite materials offering much higher strength in certain directions combined with much lower density. For example, Top radial magnetic bearing Radial load capacity: 1350N PMSM motor 500kW @ 6500RPM 750kW @ 10000RPM Passive lifter Load capacity: 15600N 1500 Flywheel hub (4340 steel) Combo magnetic bearing Radial load capacity: 2700N Axial load capacity: 5350N Figure 1. Proposed layout and major dimensions of 500-750kW, 1.7-4.2kWh high-duty cycle FESS (the same flywheel is expected to be capable of delivering 2-3MW in pulse mode). All dimensions are in mm. T1000GB-12000 composite material manufactured by TORAYCA [12] has maximal ultimate tensile strength of 6370MPa (924ksi) combined with 1800kg/m3 (0.065 lb/in3) density, whereas the corresponding values for 4340 steel are 1790MPa (260ksi) and 7800 kg/m3 (0.28 lb/in3) respectively [13]. There are, however, serious risks associated with using composite materials. In particular, their integration into the rotor is significantly complicated by strong anisotropy of the mechanical characteristics, low elasticity modulus and large differences between temperature expansion coefficients of the composite and metallic parts of the rotor. The main advantage of using the composites in the application considered in this paper would be lower weight of the rotor for the same amount of stored energy. The lower weight would also result in smaller magnetic bearings needed to support this rotor and smaller bearing power consumption. However, with a steel rotor an alternative strategy can be applied to achieve the same result: utilize large magnetically permeable surface of the steel rotor to passively lift it with permanent magnets. Active magnetic bearings in this case are only utilized to stabilize an otherwise unstable system and compensate for dynamic loads. The dynamic loads due to the linear accelerations will be higher in the case of a steel rotor due to higher weight. However, since the active bearings do not have to deal with the static weight, they can offer more dynamic load capacity within the same envelope. The details of the passive lift feature are given below. An important factor that must be considered when sizing the flywheel hub is the duty cycle of the flywheel operation. This factor varies greatly between the applications for power backup, Electromagnetic Aircraft Launch (EMALS), high energy weaponry and commercial railroad. 3 Copyright © 2006 by ASME In power backup applications, the flywheel stays in a fully charged state most of the time, with the rotor spinning at a constant speed and subjected to constant centrifugal stresses. The flywheel is discharged only during power supply failures which are not expected to occur on a regular basis. stresses caused by rotor unbalance. The samples were failing after 450,000 cycles, indicating significant safety margins for UPS applications with a cycle life requirement of 2,000 cycles. In contrast, when using railroad applications for comparison, the flywheel is charged and discharged many times during a day whenever a train comes into a station and leaves it. Since the life of the flywheel rotor is limited mainly by the fatigue issues during stress cycling, the same flywheel will last much longer when used in power backup than in the railroad applications. A unique feature of the 500kW flywheel design is a passive permanent magnet lifter which effectively supports the entire weight of the flywheel rotor (approximately 15600N or 3,500lb). The steel hub serves as a part of the magnetic circuit producing the lift force. This feature would be much more difficult to implement in the case of a composite rotor since composite materials are magnetically neutral. Because requirements for the energy storage capacity in two applications were rather close, it was tempting to develop a single flywheel design that could be used in both cases. The above mentioned differences between the applications could be addressed by using different operating speeds in order to store more energy with smaller cycle life in power backup, and ensure longer cycle life in railroad systems by sacrificing some of the energy storage capacity. While this lifter can support the weight of the entire rotor, by itself it is not sufficient to realize a stable non-contact suspension of the rotor in all directions. This is because, as with any magnetostatic system, the proposed passive lifter obeys a very old physics theorem attributed to Earnshaw [14] with a later expansion by Braunbek [15,16]. In a simple form tailored to magnetic suspension, this theorem states that the sum of suspension stiffnesses in all directions in any static system composed entirely of permanent magnets and softmagnetic components is always less than or equal to zero. In particular, for an axisymmetric system such as shown in Figure 1, the Earnshaw’s theorem is reduced to the following equation: Table 2 gives a few examples of possible combinations of the system parameters resulting from operation at different speeds. Higher speeds allow for higher energy storage capacities but result in fewer cycles to failure. Note that at this point the parameters are calculated without taking advantage of advanced power electronics being developed at Texas A&M University, which would allow boosting the output power of the system by approximately a factor of four for short periods of time. All parameters in Table 2 are calculated for the same flywheel design shown in Figure 1. Preliminary estimates of the rotor cycle life shown in Table 2 are based on the analysis conducted on the existing 0.64kWh 125kW product. This configuration has gone through extensive fracture mechanics analysis and fatigue sample testing. Possible material voids and their imparted limitation on the rotor life have been taken into account during the analysis. Fatigue samples have been exposed to stresses varying in time from the maximum value which would be encountered in the flywheel rotor under real operating conditions to zero and back. With regards to the maximum stress value, it should be noted that the Adaptive Open Loop Cancellation feature [6] implemented in the active magnetic bearing supporting the flywheel rotor allows it to spin about the center of mass, eliminating additional Specification Rated Power Output Output Duration at Rated Power Usable Energy Operational Speed at Full Charge Maximum Duty Cycle, discharges/hour Rotor Cycle Life, cycles to failure Footprint Weight PASSIVE LIFTER K z + 2K r ≤ 0 where K z = − Kr = − ∂Fr ∂r ∂Fz ∂z is the axial suspension stiffness, and is the radial suspension stiffness. Since the necessary condition for stability is that the suspension stiffness is positive in all directions, the above equation implies that stability is not possible. Figure 2 shows the magnetic flux distribution in one of the possible designs of the passive lifter producing 15600N of the axial force. The suspension is stabilized by means of two PM-biased active magnetic bearings: a combo (axial and radial) bearing at the bottom of the unit and a radial bearing at the top. In addition to stabilizing the system, these bearings compensate for inaccuracies of the passive weight offset and react dynamic loading. Because of the PM-biased and homopolar construction, the bearings feature low rotational losses and high efficiency, which makes them very well suited for flywheel 500 kW 500 kW 12 sec 1.7 kw-hr 8000 RPM 60 1,500,000 1.98 m x 0.85 m 3400 kg 500 kW 500 kW 24 sec 3.4 kw-hr 9000 RPM 30 200,000 1.98 m x 0.85 m 3400 kg 750 kW 750 kW 20 sec 4.2 kw-hr 12000 RPM 4 5,000 1.98 m x 0.85 m 3400 kg Table 2. Possible combinations of the energy storage system parameters as functions of the operating speed range. The flywheel rotor and the motor/generator are the same in all cases (refer to Figure 1.) 4 Copyright © 2006 by ASME applications. variation due to the above negative stiffness will be limited to ±2555N (584lbf), less than a half of the axial load capacity of the combo bearing shown in Figure 1. A more intensely detailed system design during the next phase of the program is expected to lead to even lower variation in force due to axial movement. ACTIVE MAGNETIC BEARINGS Figure 2. Magnetic flux in one of the designs of the passive magnetic lifter producing 15600N (3,500lbf) of axial force. Sintered 32MGOe NdFeB magnets are assumed. While there are plenty of ways to design a passive magnetic system capable of producing 15600N of force, it is desirable to do it so that the passive lifter exerts as little stiffness (force gradient) in all directions as possible. In other words, the force produced by the lifter should not be strongly dependent upon the position of the flywheel rotor. This is because the design of the active bearing control algorithm becomes much more complicated in the presence of significant negative stiffness and the performance of the final design is negatively affected by it. In the present design, the lift force is produced by exposing the top steel surface of the hub to a magnetic field generated by stationary permanent magnets. Because the surface is large, the required force can be obtained with a relatively low magnetic flux density and large air gaps, resulting in very low values of the force gradients. Two active magnetic bearings installed on the opposite ends of the flywheel rotor are used to stabilize an otherwise unstable system, compensate for the inaccuracy of the passive rotor weight compensation and react dynamic loading. The top bearing provides radial support of the corresponding rotor end while the bottom bearing has a dual function of radial and axial support. Because of homopolar PM-biased construction, both bearings feature high efficiency and low rotational losses. The design and operation of the top radial active magnetic bearing are clarified by Figures 4 and 5. Radial control windings Rotor laminations Bias magnet Solid iron rotor parts Solid iron stator poles Figure 4. Axial section of the Radial Magnetic Bearing and bias flux flow. Y Bias Flux Figure 3 shows how the axial force produced by this lifter depends on the axial gap. With the nominal gap (7.6mm or 0.3in), the axial force gradient was calculated to be 5.11⋅106 N/m (29,200 lbf/in). If the axial movements of the rotor are limited by backup bearings to ±0.5mm (0.02in), the axial force Control Flux FY X Passive lifter, Fz vs z Axial force, N Stator laminations 20000 18000 16000 14000 12000 10000 8000 6000 4000 2000 0 Control Coils Figure 5. Radial section of the Radial Magnetic Bearing and explanation of the radial force generation. 0 2 4 6 8 10 12 Axial gap, mm Figure 3. Axial force produced by the passive lifter as a function of the axial gap. The bias flux in this bearing is generated by axially magnetized permanent magnets, a solution that results in a more compact and efficient design than when current-carrying coils are used for this purpose. The bias flux flow in the bearing axial plane is illustrated in Figure 4. Currents in the control 5 Copyright © 2006 by ASME coils produce magnetic flux in the radial plane of the laminated active pole and the laminated rotor part, which, when superimposed on the bias flux, result in radial force proportional to the control current. Figure 5 clarifies the mechanism of generating a radial force. In the upper pole, the control and bias fluxes add up, while in the lower pole they subtract. Higher net flux density in the upper air gap results in the radial force acting in the positive Y direction. An advantageous feature of this design is that the control flux does not flow through high reluctance permanent magnets. This minimizes size of the control coils as well as their power dissipation. The mechanism of generating a radial force in the combination bearing is very similar to that in the radial bearing. The distribution of the bias flux in the combo bearing is illustrated in Figure 6. Within the stator lamination stack flux flows similar to the radial bearing, and introduction of a radial control flux results in a radial force (see Figure 5). The difference between the two bearings is an additional axial control coil which produces the control flux in the axial plane. The axial control flux, when superimposed on the bias flux, results in the axial force. This mechanism is illustrated in Figure 6. The bias and control fluxes sum at the upper axial pole and subtract in the lower, resulting in higher flux density at the upper pole and a force directed upwards. MOTOR / GENERATOR Successful application of flywheel energy storage technology requires compact, reliable and highly efficient motors/generators to transfer energy into and out of flywheels. High-speed operation and high reliability requirements limit selection of motors/generators to brushless and windinglessrotor types. Among these, permanent magnet (PM) machines have the most advantages, including higher efficiency and smaller size when compared with other types of motors/generators of the same power rating, such as induction or variable reluctance machines. They also exhibit lower rotor losses and lower winding inductances, which make them more suitable for a vacuum operating environment and the rapid energy transfer in flywheel applications. Very low cogging torque and robust rotor construction with very low part count are additional arguments for using PM motor/generators in flywheel applications. Due to its robust rotor construction, a PM machine is well suited for high-speed operation. High speeds allow one to obtain the required power output with a small torque, making the machine power dense and compact. To illustrate this point, Figure 7 shows a comparison of a 2MW PM generator of similar topology that was developed at Calnetix for a marine application, side by side with a conventional low speed machine of the same rating. Rotor laminations Radial control windings Solid iron stator poles 73” (1.85m) high 28” (0.71m) high Stator laminations Bias magnet Axial control winding Figure 6. Axial section of the combo magnetic bearing and explanation of the axial force generation. Red (continuous) lines indicate bias flux, blue (dashed) – axial control flux. The new design, similar to the 125kW flywheel, will accommodate mechanical backup bearings to support the rotor in the event of magnetic bearings failure or overload. Since active magnetic bearings continuously monitor rotor position, some of the rotor failures can be detected in advance and the system shutdown before a serious damage occurs. This feature, along with large design safety margins and adequate containment, results in a very safe operation. Figure 7. Dimensional comparison between Calnetix existing high-speed PM generator (in front in color) and conventional 2 MW machine (in the back). With comparable power electronics that is designed for pulsed mode of operation (to be discussed in more details in the next section), the 2MW generator shown in Figure 7 would be capable of a short output pulse of at least 6 MW or 3 times its continuous rating. This is typical for PM machines where a machine’s pulsed output rating is 2 to 5 times its continuous power rating, with the latter being mainly limited by thermal issues. Rotor overheating is a particularly dangerous thermal issue for flywheels as the rotor is suspended without a mechanical contact and cooling possibilities are limited to radiation. 6 Copyright © 2006 by ASME POWER ELECTRONICS A control strategy that was found to be very effective for producing a high power on the output of a PMSM machine is maintaining a torque angle δ, which is the angle between the current vector and the rotor field axis at 900 in vector control. This advanced control strategy can be implemented even with the rapidly changing speeds of the FESS application [17]. A back-to-back three-phase IGBT-based (Insulated-Gate Bipolar Transistor) FESS power electronics topology is shown in Figure 8. In the motoring mode, when the flywheel is charged, the front-end converter operates as a rectifier and the machine-side converter operates as an inverter. In the discharge mode inversely, the machine-side converter works as a controlled rectifier while the utility side converter works as an inverter. TAp vA vB vC iA Lr TBp A more detailed analysis of the armature reaction and saturation effects revealed that in fact even higher output power TCp TRp uA iB TSp TTp uR iR C uS uB iC uC TAn TBn TCn TSn TRn iS uT TTn vRS PMSM vST Flywheel iT Cr Figure 8. Three-phase back-to-back IGBT-based FESS power electronics. As mentioned earlier, the power output from a PM machine depends not only on the machine itself but also on the power electronics, defining the character of the load on the machine terminals. With the same basic topology shown in Figure 8, the power output from the generator can be changed significantly by applying different control algorithms such as constant torque angle control, optimum torque per ampere control, unity power factor control, constant mutual air gap flux linkages control, and flux weakening control. Compared to purely resistive generator loading, a 2-5 times increase of the machine’s power output can be expected. A possibility of increasing power output of a PMSM (Permanent Magnet Surface Mounted) machine in pulse mode using advanced control algorithms has been investigated. To evaluate potential advantages of different control strategies, the existing 0.64kWh 125kW 25-35kRPM FESS has been used as an example. The effects of applying different control algorithms have been evaluated through modeling the entire system in PSIM, a power electronics and motor drive simulation software. The block diagram of the flywheel control system is shown in Figure 9. Vt Terminal OP Voltage Volts L-N rms can be obtained with δ being somewhat different from 900. Table 3 below shows output power of the existing FESS calculated for different power factors and torque angles at 35,000 rpm. In case of the first operating point (OP1) the torque angle has been set equal to 900 (Id = 0, Iq =579.5 Arms), while in the second case (OP2), the torque angle is set at 700. As it can be noticed, the power output in the second case is significantly higher. The explanation for this phenomenon lies in the effects of the armature reaction and saturation effects, however, a detailed explanation is beyond the scope of this paper. As can be learned from Table 3, utilizing advanced control strategies allows power increase by a factor of three or more compared to simple passive rectification featuring lagging power factor, which can be close to unity in the best case scenario. Very high powers can be produced only in a lowduty-cycle operation in order to avoid overheating the machine. A part which is especially vulnerable to overheating is the rotor since it is suspended in vacuum without any mechanical contact and the heat extract is limited to radiation only. Is Phase Current Amps-rms Iq Torque Component amps-rms Id Flux Component amps-rms 1 523.0 579.5 579.5 0.0 2 3 4 5 446.1 318.4 88.5 37.9 579.5 579.5 579.5 579.5 537.5 406.8 125.1 58.5 216.5 412.8 565.8 576.5 P.F. Pout Output Power Power Factor kW 0.5132 466.6 (leading) 542.9 .7 (leading) 482.1 .871 (leading) 153.9 unity 62.6 .95 (lagging) Table 3. FESS generator output power with different terminal load power factors and torque angles at 35kRPM. 7 Copyright © 2006 by ASME Machin-Side Converter T Rp TSp TTp uR ias C uS v dsr PI + Vbs a, b ,c PI i dsr uT TTn PMSM vST Flywheel ics resolver TTn TSn TTp TSp TSn vRS Vas d, q v qsr - TRn TRp T Rn ibs Vcs PWM Generator i qsr d, q + i * i dsr = 0 a b,c - ibs θ * qsr Current ias T ec Speed ∗ PI calculator + - ω r calculator θ Software ω ref Figure 9. Block diagram of FESS power electronics control system. CONCLUSIONS The use of commercial flywheel energy storage technology to address the needs of modern electric navy ships has been investigated. The advantages of FESS over commercially available electrochemical batteries include: 1) 2) 3) 4) 5) Much higher charge/discharge rate (output power) Essentially unlimited cycle life Observable state of charge Minimal, if any, maintenance Environmental friendliness A FESS capable of producing 500kW×30sec in high-duty mode and up to 2MW in pulse mode described in this paper targets applications in power backups for onboard electrical power network. This power network is being developed by the Navy for a new generation of more electric ships. There is also a very promising commercial application for this FESS in load leveling and energy recovering at electrical train stations. The proposed flywheel utilizes a hub made of conventional high-strength steel, proprietary high-performance magnetic bearings and a permanent magnet brushless motor/generator. The steel is chosen over more modern composite materials in order to avoid integration problems associated with the latter. Instead of minimizing the rotor weight through using lowdensity high-strength composites, the large magnetic surface area of a steel rotor is used to passively lift it using permanent magnets. Active magnetic bearings are used to stabilize an otherwise unstable system, compensate for inaccuracies of the passive rotor weight offset and react dynamic loadings. Since they do not have to deal with static weight, they can offer larger dynamic load capacities overcoming the disadvantage of having a heavier rotor. Due to PM-biased homopolar construction, the active magnetic bearings used in the design offer very high efficiency and very low rotational losses. These features are further enhanced by utilizing the passive rotor lift. PMSM motor/generator used in this design is well suited for high-speed operation. High-speeds allow one to obtain the 8 Copyright © 2006 by ASME required power output with small torque, making the machine extremely power dense and compact. Advanced power electronics control algorithms developed at Texas A&M University are demonstrated to increase power outputs of Calnetix’s PMSM machines by several times. These power electronics make the machines more versatile as higher power can be delivered in low-duty operational regimes when thermal limitations are not as severe as in high-duty applications. High power density, high efficiency and high reliability of the proposed design make it very attractive for both Navy and commercial applications. ACKNOWLEDGMENTS This work is performed under US Navy STTR contract N00014-04-M-0272. The authors greatly appreciate the support and insightful technical suggestions provided by the Program Officer Lynn Petersen. REFERENCES [1] Harvey E., Kingsley J., Matthew S., 2002, “United States Navy (USN) Integrated Power System (IPS) Gas Turbine Generator Set Test Experience”, ASME paper no. GT-200230260. [2] Newell, J. M., Young S. S., 2000, “Beyond Electric Ship” (preprint), publication of the Institute of Marine Engineers, London, UK. [3] Vander Meer, J., et al., 2005, “Improved Ship Power System – Generation, Distribution, and Fault Control for Electric Propulsion and Ship Service”, Proceedings of the IEEE Electric Ship Technologies Symposium, Philadelphia, Pennsylvania, pp. 284-291. [4] Hawkins, L. A. et al., 2005, “Development of an AMB Energy Storage Flywheel for Commercial Application”, Proceedings of the 8th International Symposium on Magnetic Suspension Technology, Dresden, Germany, pp. 261-265. [5] Hawkins, L. A. et al., 2003, “Development of an AMB Energy Storage System for Industrial Applications”, Proceedings of the 7th International Symposium on Magnetic Suspension Technology, Fukoka, Japan, pp. 156-163. [6] McMullen, P. T. et al., 2003, Design and Development of a 100kW Energy Storage Flywheel for UPS and Power Conditioning Applications, Proceedings of the 24th International PCIM Conference, Nurenberg, Germany, pp. 213218. [7] Hawkins, L. A. et al., 2002, “Shock and Vibration Testing of an AMB Supported Energy Storage Flywheel”, Proceedings of the 8th International Symposium on Magnetic Bearings, Mito, Japan, pp. 581-586. [8] Hawkins, L. A. et al, 2001, “Influence of Control Strategy on Measured Actuator Power Consumption in an Energy Storage Flywheel with Magnetic Bearings, Proceedings of the 6th International Symposium on Magnetic Suspension Technology, Turin, Italy, pp. 42-47. [9] Hawkins, L. A. et al, 2000, “Analysis and Testing of a Magnetic Bearing Energy Storage Flywheel with GainScheduled MIMO Control”, ASME paper no. 2000-GT-405. [10] Hawkins, L. A. et al, 1999, “Application of Permanent Magnet Bias Magnetic Bearings to an Energy Storage Flywheel”, Proceedings of the 5th International Symposium on Magnetic Suspension Technology, Santa Barbara, California, pp. 309-324. [11] McGroarty J., Schmeller J., Hockney R., Polimeno M., 2005, “Flywheel Energy Storage System for Electric Start and an All-Electric Ship”, Proceedings of the IEEE Electric Ship Technologies Symposium, Philadelphia, Pennsylvania, pp. 400-406. [12] www.torayca.com [13] Genta, G., 1985, Kinetic Energy Storage, Butterworth & Co. Ltd., London, UK, p.53. [14] Earnshaw, S., 1842, “On the nature of the molecular forces, which regulate the constitution of the luminiferous ether”, Transactions of Cambridge Philosophical Society, vol. 7, pp. 97-112. [15] Braunbek, W., 1939, “Freischwebende korperim elektrischen und magnetischen feld,” Z. Phys., vol. 112, pp. 753–763. [16] Braunbek, W., 1939, “Freies schweben diamagnetischer korperim magnetfeld,” Z.Phys.,vol. 112, pp. 764–769. [17] Toliyat H.A. et al., 2005, “Advanced High-Speed Flywheel Energy Storage Systems for Pulsed Power Applications”, Proceedings of the IEEE Electric Ship Technologies Symposium, Philadelphia, Pennsylvania, pp. 379386. 9 Copyright © 2006 by ASME