ME/ECE 4710 Motion and Control

advertisement

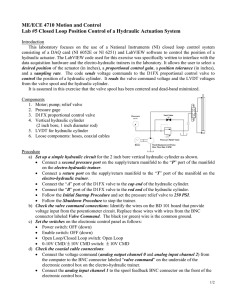

ME/ECE 4710 Motion and Control Lab #4 Data Acquisition for a Hydraulic Actuation System Introduction This exercise focuses on the use of a National Instruments (NI) data acquisition (DAQ) system consisting of a DAQ card (NI 6052E or NI 6251) and LabVIEW software. The LabVIEW code used for this laboratory was specifically written to interface with the data acquisition hardware and the electrohydraulic trainers in the laboratory. It allows the user to send a step voltage command to the D1FX linear proportional control valve. It reads/records the time, command voltage, spool LVDT voltage, and the cylinder LVDT voltage (1 volt per inch). Collection of the command and LVDT voltages are synchronized so transfer functions can be estimated. It also has a user selectable sampling rate. It is assumed in this exercise that the valve spool has been centered and the dead-band minimized. Components 1. Motor; pump; relief valve 2. Pressure gage 3. D1FX proportional control valve 4. Vertical hydraulic cylinder (2 inch diameter bore; 1 inch diameter rod) 5. LVDT for hydraulic cylinder 6. Loose components: hoses, coaxial cables Pressure Vent Valve 0.00 Psi Pressure Relief Valve Motor Fixed Displacem e nt Pum p Max. Flow Rate 3 GPM Procedure a) Set up a simple hydraulic circuit for the 2 inch bore vertical hydraulic cylinder as shown in the diagram. Connect a second pressure port on the supply/return manifold to the “P” port of the manifold on the electro-hydraulic trainer. Connect a return port on the supply/return manifold to the “T” port of the manifold on the electro-hydraulic trainer. Connect the “A” port of the D1FX valve to the cap end of the hydraulic cylinder. Connect the “B” port of the D1FX valve to the rod end of the hydraulic cylinder. Follow the Initial Startup Procedure and set the pressure relief valve to 250 PSI. Follow the Shutdown Procedure to stop the trainer. b) Check the valve command connections: Identify the wires on the BD 101 board that provide voltage input from the potentiometer circuit. Make sure these wires have been replaced with wires from the BNC connector labeled Valve Command. The black (green) wire is the common (ground) wire. c) Set the switches on the electronic control panel as follows: Power switch: OFF (down) Enable switch: OFF (down) Open Loop/Closed Loop switch: Open Loop 0-10V CMD/ 10V CMD switch: 10V CMD 1/2 d) Check the coaxial cable connections: Connect the voltage command (analog output channel 0 and analog input channel 2) generated by the computer to the BNC connector labeled “valve command” on the underside of the electronic control box on the electro-hydraulic trainer. Connect the analog input channel 1 to the spool feedback BNC connector on the front of the electronic control box. Connect the analog input channel 0 to the BNC connector for the cylinder LVDT on the underside of the electronic control box. e) Start LabVIEW and Open the data acquisition program (OLC Step Input.vi). f) Start the hydraulic power, making sure the pressure relief valve is still set to 250 PSI. g) Change the switches on the electronic control panel as follows: Power switch: ON (up) Enable switch: ON (up) h) Select filename and destination: Using the file folder icon on the front panel of the LabVIEW software, browse to the folder “ME471Data” on the Desktop. Select a file from that folder and change the filename to GroupXXCYYRunZZ. Replace XX with your group number, YY with the step command voltage, and ZZ with the run number. i) Set the valve command voltage in the Signal Output box to 3 volts. j) Check the sample rates: Make sure the sample rate (samples per second) in the Sampling Information box is set to 1000 samples per second. Make sure that the “number of samples to read per channel” in the block diagram is this rate divided by 10. k) Record the conditions under which the data was collected (working pressure, valve command level, sampling rate). l) Press the Run Arrow to start the program. You should see data streaming in the Waveform Chart. m) Press the Command button to execute the voltage command and start collecting data. After about 3-5 seconds, press the Command button again to stop sending the command and stop collecting data. n) Set the Reposition voltage to 5 volts to reposition the cylinder to its bottom-most position. o) Press the Write File + Stop button on the bottom right of the front panel. This will write the collected data to a file and stop the program execution. p) Repeat steps (k)-(o) to collect four more data sets at these settings. q) Repeat steps (i)-(p) to collect five data sets using a command voltage of 5 volts. r) Repeat steps (i)-(p) to collect five data sets using a command voltage of 7 volts. s) Follow the Shutdown Procedure to stop the trainer. t) Change the switches on the electronic control panel as follows: Power switch: OFF (down) Enable switch: OFF (down) Questions 1. What was the average steady-state cylinder speed for the 3 volt command? 5 volt command? 7 volt command? 2. What was the settling time for the valve spool dynamics for each of the three cases? 3. What transfer function can be used to model the valve dynamics for the three cases? Assume the valve voltage command is the input and the valve spool position (voltage) is the output. 4. What transfer function can be used to model the cylinder dynamics for the three cases? Assume the valve spool command is the input and the cylinder position (LVDT voltage) is the output. 2/2