staffs; and the level of staff in a certain period... - relatively stable

advertisement

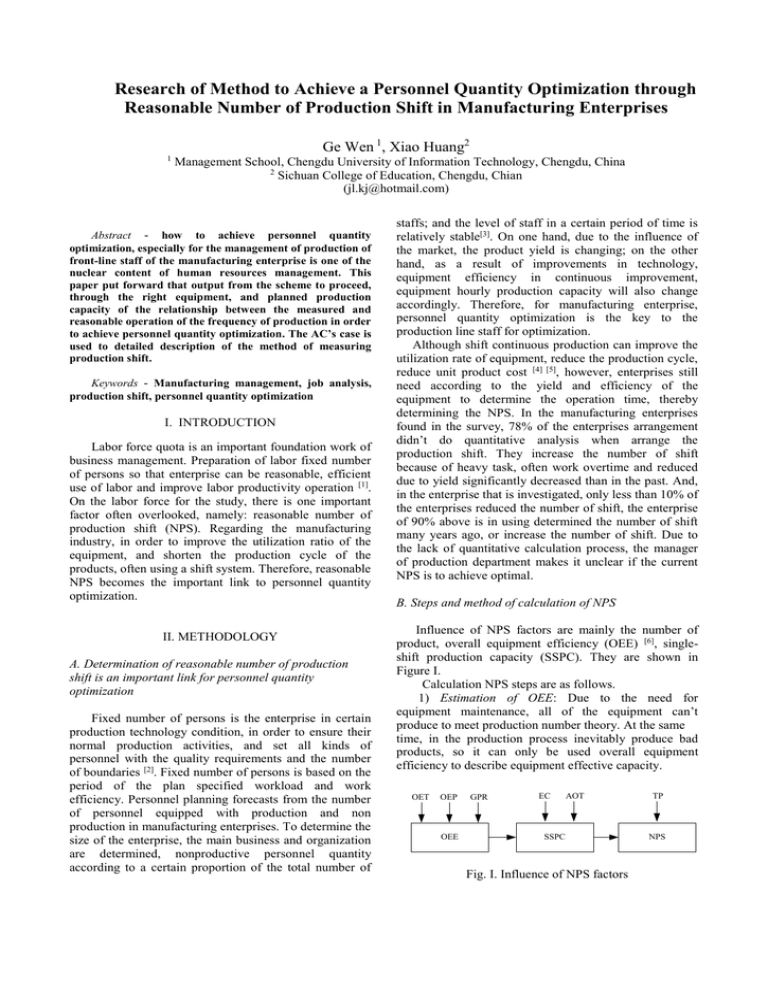

Research of Method to Achieve a Personnel Quantity Optimization through Reasonable Number of Production Shift in Manufacturing Enterprises Ge Wen 1, Xiao Huang2 1 Management School, Chengdu University of Information Technology, Chengdu, China 2 Sichuan College of Education, Chengdu, Chian (jl.kj@hotmail.com) Abstract - how to achieve personnel quantity optimization, especially for the management of production of front-line staff of the manufacturing enterprise is one of the nuclear content of human resources management. This paper put forward that output from the scheme to proceed, through the right equipment, and planned production capacity of the relationship between the measured and reasonable operation of the frequency of production in order to achieve personnel quantity optimization. The AC’s case is used to detailed description of the method of measuring production shift. Keywords - Manufacturing management, job analysis, production shift, personnel quantity optimization I. INTRODUCTION Labor force quota is an important foundation work of business management. Preparation of labor fixed number of persons so that enterprise can be reasonable, efficient use of labor and improve labor productivity operation [1]. On the labor force for the study, there is one important factor often overlooked, namely: reasonable number of production shift (NPS). Regarding the manufacturing industry, in order to improve the utilization ratio of the equipment, and shorten the production cycle of the products, often using a shift system. Therefore, reasonable NPS becomes the important link to personnel quantity optimization. II. METHODOLOGY A. Determination of reasonable number of production shift is an important link for personnel quantity optimization Fixed number of persons is the enterprise in certain production technology condition, in order to ensure their normal production activities, and set all kinds of personnel with the quality requirements and the number of boundaries [2]. Fixed number of persons is based on the period of the plan specified workload and work efficiency. Personnel planning forecasts from the number of personnel equipped with production and non production in manufacturing enterprises. To determine the size of the enterprise, the main business and organization are determined, nonproductive personnel quantity according to a certain proportion of the total number of staffs; and the level of staff in a certain period of time is relatively stable[3]. On one hand, due to the influence of the market, the product yield is changing; on the other hand, as a result of improvements in technology, equipment efficiency in continuous improvement, equipment hourly production capacity will also change accordingly. Therefore, for manufacturing enterprise, personnel quantity optimization is the key to the production line staff for optimization. Although shift continuous production can improve the utilization rate of equipment, reduce the production cycle, reduce unit product cost [4] [5], however, enterprises still need according to the yield and efficiency of the equipment to determine the operation time, thereby determining the NPS. In the manufacturing enterprises found in the survey, 78% of the enterprises arrangement didn’t do quantitative analysis when arrange the production shift. They increase the number of shift because of heavy task, often work overtime and reduced due to yield significantly decreased than in the past. And, in the enterprise that is investigated, only less than 10% of the enterprises reduced the number of shift, the enterprise of 90% above is in using determined the number of shift many years ago, or increase the number of shift. Due to the lack of quantitative calculation process, the manager of production department makes it unclear if the current NPS is to achieve optimal. B. Steps and method of calculation of NPS Influence of NPS factors are mainly the number of product, overall equipment efficiency (OEE) [6], singleshift production capacity (SSPC). They are shown in Figure I. Calculation NPS steps are as follows. 1) Estimation of OEE: Due to the need for equipment maintenance, all of the equipment can’t produce to meet production number theory. At the same time, in the production process inevitably produce bad products, so it can only be used overall equipment efficiency to describe equipment effective capacity. OET OEP OEE GPR EC AOT SSPC Fig. I. Influence of NPS factors TP NPS Method of estimation of overall equipment efficiency is as shown in (1). Equation (2), (3) and (4) indicate the calculation of operation efficiency in time (OET), operation efficiency in performance (OEP) and good product rate (GPR). (1) OEE OET OEP GRP OT (2) OET 100% LT LT TWT PDT (3) SPC TP (4) OEP 100% OT Where OEE represent overall equipment efficiency; OET is operation efficiency in time; OEP denotes operation efficiency in performance; GPR is good product rate; OT is operation time of equipment; LT is load time of equipment; TWT denotes total work time of equipment; PDT is planned down time of equipment; SPC is Standard production cycle; and TP presents total production. 2) Calculation of SSPC: SSPC refers to a shift in the year average operation time in the actual production can product quantity [7] [8]. In calculating the SSPC, in addition to consider the OEE, but also needs to consider the employee statutory working time [9]. Equation (5) is the Calculation formula of SSPC. (5) SSPC OEE EC AOT Where SSPC denotes single-shift production capacity; OEE is overall equipment efficiency; EC is equipment capacity theory; and AOT is average operation time. 3) Calculation of NPS: NPS depends on SSPC and TP [10], it can be calculated as equation (6). TP (6) SSPC Where TP represents total product of a kind of production and SSPC is single-shift production capacity. Sometimes TP can be replaced with the annual production planning number [11]. When the NPS is determined, the need of staff can be calculate. It will show how this method is use to solve practical problems through a case analysis. NPS II. APPLICATION CASE AC Company is a Pieces of Chinese Medicine enterprise, under the jurisdiction of the AC1 and AC2 two production workshop that make different types of production. AC1 workshop executes four shifts three operation organization modes. Every shift has 157 persons; four shifts are total 628 persons. It plans to produce 550000 pieces 2012 year, OEE is 82%, EC is 3058.1 pieces/day. AC2 workshop executes three shifts two operation organization modes. Every shift has 129 persons; three shifts are total 387 persons. It plans to produce 430000 pieces 2012 year, OEE is 82%, EC is 2070.6 pieces/day. 1) Diagnosis of AC Company’s current NPS: Following through on calculation NPS, diagnosis of if AC Company’s current NPS existing two workshop is reasonable. According to the regulations by Ministry of labor and social security, years working time is 250 days. Based on the statistics of staff service time, calculate that employee's average annual leave for 11 days in AC1 workshop and annual leave for 10 days in AC2. Calculations are as Table I. Table I. represents calculations for SSPC and work load rate. The work load rate of AC1 workshop is only 74.77%. Employees of the legal working time utilization rate is poor, which do not meet the personnel quota principle. In this case, AC Company should consider from two ways to solve the problem, one is to increase the order, so as to make full use of equipment and labor, two is to reduce the persons, saves the manpower cost. The work load rate of AC2 workshop is 105%, which exceed 100%. 2) Re arrangement production shift throng estimation of NPS: According to the above calculation,the SSPC of AC1 workshop is 199800 pieces/year. Its NPS can be calculated as equation (7). 580000 pieces / year (7) NPSAC1 2.9 199800 pieces / year Where NSPAC1 is the number of production shift for AC1 workshop. According to NSPAC1, AC1 workshop can arrange three shifts to produce, and reduce one shift. At this time, Work load rate becomes 96.67%. After reduced one shift, it can reduce staff 157, personnel quantity is 471. According to the above calculation , the SSPC of AC2 workshop is 139100 pieces/year. Its NPS can be calculated as equation (8). 430000 pieces / year (8) NPSAC 2 3.09 139100 pieces / year Where NSPAC2 is the number of production shift. TABLE I ESTIMATIONS OF SSPC FOR AC1 AND AC2 WORKSHOP Estimation Data Workshop OEE (%) EC (piece) Years Working Time (day) SSPC (piece/year) Work Load Rate (%) AC1 82 3058.10 239 199800 74.77 AC2 82 2070.60 240 139100 105 for AC2 workshop. If AC2 workshop arrangement four shifts, Work load rate becomes 77.25%. Thus, Work is inadequate. If still according to three shifts for production, Work load rate becomes 103%. Every staff each standard work day increased work time is 14.40 minutes and so throughout the year each staff work more 57.60 hours. In this case, it can be given to employees for overtime, but does not increase the number of shift. Because adding a shift requires increased by 129 persons, labor costs increase significantly. IV. CONCLUSION A. Dynamic management of enterprise Quantity Personnel The reasonable personnel quantity is the important work of enterprise human resources management [12], but also builds harmonious enterprise, implementation manpower cost optimal; effectively avoid the risk of employment base. Because of the goal of enterprise development changed, personnel work ability promoted, technology improved, the continuous upgrading of equipment efficiency, the developing enterprise should do job analysis every 2 to 3 years. Thus enable enterprises to maintain optimal allocation of human resources, reasonable, effective use of labor force. B. Through the estimation of NPS to maintains personnel optimization According to the equipment capacity and the production task to calculate the NPS is the reasonable arrangement of equipments premise, also is the foundation of effective utilization equipment. When annual production planning developed, Human resources department should forecast NPS, which is the important work archive personnel quantity optimization and labor costs controlling. C. Correctly handle relationship the “add” and “decrease” When the work load rate is slightly greater than 1, there are two ways without any increase in personnel of the circumstances. One is that for the personnel quantity from the influence of equipment can account for the post between the work adjustments to balance work load rate. Another is that personnel quantity by the influence of equipment can consider additional overtime to compensation, such as AC1 workshop’s way in this case. REFERENCES [1] B. Dal, P. Tugwell, R. Greatbanks, “Overall equipment effectiveness as a measure of operational improvement” International Journal of Operations and Production Management, 2000 , 12, pp.1488-1502. [2] Hong-zhang An, Liu-jun Yu, “Work quota management and standardization in modern enterprises,” Labor and Social Security Press China, 2008, pp. 218-220(Chinese). [3] Shu-ping Yi, “Fundamental industrial engineering,” Machinery Industry Press, 2006, pp. 159-161(Chinese). [4] D. Gary, “Human resource management (8th ed.),” Tsinghua University Press, 2000, pp. 84-85. [5] H. Jay, R. Barry, “Production and operations management (4th ed.),” Huaxia Publishing House, 1999, pp: 240. [6] Bin Wu, Ke-lin Xu, “Discussion of overall equipment efficiency (OEE),” Mechanical and Electrical Equipment, 2007,2 pp.23-25(Chinese). [7] H. Steven, “Generic work behavior: an investigation into the dimension of entry-level, hourly job performance,” Personnel Psychology, 1996, Vol. 49, pp. 51-83. [8] S. Gilbert, “Job analysis in the TQM environment,” Public Personnel Management, 1997(winter), Vol. 25, no.4 pp. 485-494. [9] K. Drborah, “Reasonable accommodations: job description in the age of ADA, OSHA, and Workers Comp (New York: Van Nostrand Reinhold, 1994), pp. 9. [10] O. Ljungberg, “Measurement of Overall Equipment Effectiveness as A Basis for TPM Activities,” International Journal of Operations and Production Management, 1998, 5, pp. 495-507. [11] S. Daniel, Robert, J. Bulfin, “Production: planning, control and integration,” The Mc-Graw-Hill, Inc., 1997, pp. 89-90. [12] Xing Liu, Xue-gang Miao, “Analysis of approach of fixed workers number for a job in oilfield business.” Journal of Sinopec Management Institute, 2003, 3, pp. 40-41(Chinese).