A WAVE DISC ENGINE CONCEPT FOR MICRO POWER GENERATION

advertisement

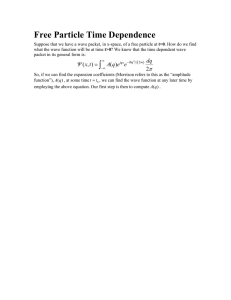

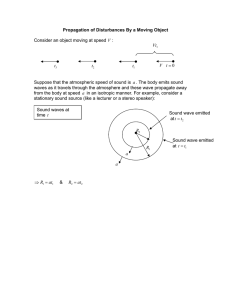

A WAVE DISC ENGINE CONCEPT FOR MICRO POWER GENERATION M. Vagani1, L. Pohořelský2, G. Sun1, D. Alemu3, J.R. Lee1, R.T. Kelly1, T.J. Qualman1, S.A. Bonner1, D.E. Park1, F. Iancu1, P. Akbari1, J. Piechna4, and N. Müller1 1 Michigan State University, East Lansing, USA 2 Czech Technical University in Prague, Prague, Czech Republic 3 Addis Ababa University, Addis Ababa, Ethiopia 4 Warsaw University of Technology, Warsaw, Poland Abstract: Wave disc technology is emerging as a possible replacement for compressors and turbines in engines. This paper presents a new engine concept, the Wave Disc Engine with internal combustion. This new engine concept combines the advantages of (a) higher efficiency confined combustion with (b) the high power density and low maintenance of continuous flow but (c) at a much lower unit cost due to its physical simplicity and compactness. Furthermore, the geometry of the Wave Disc Engine is especially suited for microfabrication and micro power generation. Theoretical validation of the engine has been performed using four simulation models. 1D and 2-D validations were completed with both in-house and commercial software. Keywords: Wave Disc Engine, internal combustion, Humphrey cycle, power generation cycle peak temperature of 1070 K. Accidentally, the engine was destroyed due to over-speeding from an improperly connected fuel line, and the project was canceled. INTRODUCTION The idea of direct energy exchange between two media without using mechanical components such as pistons or vaned impellers started in the early 1900s [1]. The first functional device was developed in the 1940s when the Brown Boveri Company (now ABB) designed a pressure-exchange wave rotor. The wave rotor is a non-steady flow device that uses shock waves to pressurize fluids by transferring energy from a high-pressure flow to a low-pressure flow in a series of channels. The wave rotor consists of many axial channels in a rotating cylindrical drum, usually driven by an external motor. For gas turbine engine applications, the wave rotor employs the hot, high pressure exhaust gas from combustion to generate a shock wave that compresses the cooler, lower pressure air received from the compressor. For car engine applications, the wave rotor has been used as a supercharger and was successfully commercialized by Mazda Company in 1980s and 90s in the serial production of diesel passenger cars [2]. Figure 1. Assembly of successfully working wave engine in axial wave rotor configuration [1](left) and ABB wave rotor combustor cross section [3] (right) The Wave Combustor The wave combustor is a wave rotor with combustion occurring inside the rotor channels. This produces a pressure rise during combustion, unlike a typical steady-flow combustor used in gas turbines. ABB and ETH Zurich commenced the design of a full wave rotor with 36 axial combustor channels in 1992 [3]. Each channel had 165 mm length and 15 x 15 mm cross section, shown in Figure 1 (right). The 200 mm inner-diameter rotor was driven by an electric motor capable of up to 5000 RPM. Spark-plug electric ignition was used for initial start up. Auto ignition, for continuous operation, was achieved by injecting hot gas from the neighboring channels. The fuel injection and ignition worked well and pressures of 9 bar were obtained. The project was canceled in 1994, due to the perception at the time that there was no profitable market for a 100kW gas turbine unit. The Wave Engine The wave engine consists of a wave rotor with curved blades, used for compression of air and expansion of exhaust gas, while producing shaft work. It uses a steady-flow gas turbine type combustor. The Ruston-Hornsby Turbine Company, in the UK, developed one such engine in the mid-1950s [1]. This wave engine, shown in Figure 1 (left), had a 230 mm diameter and a 76 mm length. The engine worked successfully for several hundred hours in a wide range of operating conditions (from 3000 to 18,000 RPM) and produced up to 26 kW at its design point with a 0-9743611-5-1/PMEMS2009/$20©2009TRF 530 PowerMEMS 2009, Washington DC, USA, December 1-4, 2009 tangential momentum at the outlet (jet propulsion) and by the change in angular momentum in the channel (turbomachinery principle). CONCEPT OF THE WAVE DISC ENGINE WITH INTERNAL COMBUSTION The Wave Disc Engine (WDE) combines the principles of the wave engine and wave combustor. While wave rotors use axial flow, the WDE uses a radial-flow wave rotor, or wave disc [4]. The wave disc is particularly suited for microfabrication as it has a simple extruded 2D geometry with a short depth. The wave disc also allows for curved channels, which will allow the rotor to extract energy from the flow. The mechanical simplicity of the engine concept, with only one rotating part allows it to be miniaturized without many of the technical issues faced by other small-scale gas turbine engines [4]. A starter-generator could be built into the engine similar to that designed by MIT for micro gas turbines [5]. The WDE, shown in Figure 2 utilizes a typical engine cycle consisting of compression, combustion, expansion with work extraction, and heat rejection to the ambient atmosphere. The cycle however, occurs completely in the curved disc channels. Using shockwaves for compression reduces the inertia of the hardware and promotes a rapid response to load changes. The compression and expansion are achieved through shockwaves and expansion waves and the momentum of the flow is harnessed to drive the rotor. Fresh Air-Fuel Mixture Burnt Exhaust Gas Rotational Direction Loading Figure 3. Schematic for the internal combustion WDE, incorporating combustion within the shock channels 3) When the inlet port opens the ingestion of fresh fuel/air mixture into the channels begins. The expansion wave created in step 2 draws in this mixture and completes the scavenging process. Centrifugal fluid forces on the rotating disk assist the scavenging and loading processes. 4) After the outlet port is suddenly closed, a “hammer shock” is generated by the deceleration of the flow to zero velocity. The hammer shock compresses the fresh air-fuel mixture. It is favorable to close the inlet port when the hammer shock reaches it. Another operating cycle starts with the ignition of the air-fuel mixture (step 1). Expansion Wave Compression Shock Wave Compression Shock Wave Constant Volume Combustion Reflected Expansion Jet Wave Propulsion Scavenging Figure 2. Schematic engine model and cycle for a twocycle WDE Figure 4. Thermodynamic cycle of the WDE in comparison with the gas turbine engine The schematic in Figure 3 depicts the working cycle of the internal combustion WDE, briefly described in the following four steps: 1) The cycle begins with the channel closed on both sides and filled with a compressed air/fuel mixture. Constant volume combustion takes place within the channel, producing a pressure and temperature rise during the combustion process. 2) As the disk rotates, the exhaust side of the channel opens to ambient conditions. This sudden opening of the channel creates an expansion wave propagating towards the air fuel mixture inlet and scavenging begins. Torque generation is produced by the fluid Thermodynamically, the WDE operates on the Humphrey cycle, where combustion ideally occurs at constant volume, as shown in Figure 4. In the ideal Brayton cycle for gas turbines, the heat addition occurs at constant pressure. Additionally, the WDE is periodically filled with fresh air, cooling the channel wall temperature. Thus, the WDE can achieve a higher cycle peak temperature than a typical gas turbine. As a result, a WDE can be more efficient than a gas turbine for comparable compression pressure ratios. 531 MATHEMATICAL MODELING AND PRELIMINARY RESULTS Quasi 1-D Algebraic Algorithm An analytical algorithm was established to develop an initial WDE porting geometry and a first estimate of the flow velocities and wave propagation pattern in the rotor, shown in Figure 6. It uses the gasdynamic wave equations and the method of characteristics for specified boundary conditions, including postcombustion pressures and temperatures [6]. The algorithm accounts for the effects of centrifugal force, channel curvature, and work generated from angular momentum. Ideal Cycle Efficiency of WDE The ideal cycle efficiency does not consider heat losses across the channel walls, pressure losses during admission and exhaust, and mechanical friction. It is an efficiency that can be achieved in an adiabatic frictionless engine operating with an ideal gas. 0.8 Humphrey 0.7 Brayton 0.6 η 0.5 Otto 0.4 1-D WDE Model in GT-POWER A 1-D model of the WDE was developed in the commercially available GT-POWER, which has successfully completed a 1-D wave rotor model [7]. The model describes pressure waves, combustion heat release, work extraction, friction, heat exchange, and throttling in the distribution ports during the opening and closing phases of an individual rotor channel. The 1-D model wave disc engine has 18 channels, a disc outer diameter of 15 cm, an inlet diameter of 6 cm and an engine height of 3 cm. Combustion inside the channel was modeled using the Wiebe heat release function [8]. The GT-POWER model enables optimization of the WDE geometry and power output, using the Quasi 1-D code results as a starting point. The Euler turbomachinery equation was used to compute the power generation and modeled by extracting the same amount from the energy conservation equation. For this model engine, the maximal predicted power output was 1.2 kW at 18,000 rpm. Diesel 0.3 0.2 0.1 0 0 5 10 15 20 25 P2/P1 Figure 5. Thermal efficiencies of ideal Humphrey, Brayton, Otto, and Diesel cycles as a function of engine compression pressure ratios As can be seen in Figure 5, the Humphrey cycle has the highest efficiency when compared with all gas power cycles. For instance, a WDE operating on the Humphrey cycle can have an overall efficiency of 45% for a compression pressure ratio of 10, assuming 10% heat losses through the wall, 5% scavenging losses, and 5% mechanical losses. The mechanical losses are minimal, as it has only one rotating part. To evaluate the concept and support the design of a working WDE prototype, the engine was modeled and analyzed using four numerical approaches. The results are presented in the following sections. Quasi 2-D CFD Code A Quasi 2-D CFD code was additionally developed to confirm and improve on the results from the Quasi 1-D algebraic algorithm. For this code, it is assumed that the streamlines follow the profile of the channel wall, so no parameters change over the channel cross-section. The Wiebe function was again used to model the heat generation due to combustion [8]. The 4th order MacCormack Scheme was employed to solve the continuity equation, NavierStokes equations and the energy equation. The code calculates the port timing by tracing the waves and the exhaust scavenging. In addition, it yields velocity, pressure, density and temperature profiles in the channel, power generation and engine efficiency and draws the p-v and T-s diagrams for thermodynamic analysis. Velocity Velocity patterns patterns Gas/Air Gas/Air Interface Interface t x Figure 6. WDE wave pattern computed by the developed Quasi 1-D algebraic algorithm 532 The simulation results are presented for a disc of 10 mm outer diameter, 6 mm inner diameter, rotating at 200,000 rpm. Figure 7 shows the shape and locations of the ports, and Figure 8 the p-v and T-s diagrams. The power generation was Figure 7. Geometric design found to be 1.189 kW of the WDE calculated by and the efficiency the Quasi 2-D code 0.2647. 3 x 10 p-v diagram Temperature (K) Pressure (Pa) 1 Air/Fuel Mix Inlet Figure 9: FLUENT temperature distribution results for two cycle WDE Exhaust Outlet Pressure [Pa] Start of Combustion T-s diagram 4000 1.5 Scavenging Rotational Direction 5000 2 Rotational Direction 3000 2000 Compression Shockwave Air/Fuel Mix Inlet Expansion Wave 1000 0.5 0 0 Start of Combustion 6 2.5 Exhaust Outlet Temperature [K] 2 4 6 Specific volume (kg/m3) 8 0 -500 0 500 1000 1500 Figure 10: FLUENT pressure distribution results for two cycle WDE 2000 Specific entropy (kJ/(kg*K)) Figure 8. p-v and T-s diagrams given by Q2D code REFERENCES 2-D CFD FLUENT Code Numerical CFD simulations were also performed using FLUENT 6.2. The 2-D solver was used to model the flow within the wave disc. In order to model the wave disc engine, the heat addition in the channels was achieved by patching a small area of the channel, the “combustion zone” to the pressure and temperature expected after combustion. The resulting pressure and temperature profiles are presented in Figure 9 and Figure 10. The FLUENT pressure profiles show that the pressure and temperature in the channel equalizes before the exhaust port opens. They confirm that the wave pattern in the rotor matches the predicted wave pattern. It also shows that the exhaust gases are completely scavenged before the beginning of each cycle. The scavenging actually happens fast enough that it may be beneficial to close the exhaust port sooner. This will increase the pressure created by the “hammer shock” after the closing of the port. [1] Akbari P., Nalim M. R., Mueller N., 2006, “A Review of Wave Rotor Technology and Its Applications.” ASME J. of Enineering. for Gas Turbines and Power, 128-4, 717-735 [2] Pohořelský L., Obernesser P., et al., 2007, “1-D Model and Experimental Tests of Pressure Wave Supercharger.” ASME IMECE2007-43427 [3] Akbari P. and Nalim M. R., 2009, “Review of Recent Developments in Wave Rotor Combustion Technology.” J. of Propulsion and Power, 25-4, 833-844 [4] Iancu F., Akbari P., and Müller N., 2004, "Feasibility Study of Integrating Four-Port Wave Rotors into Ultra-Micro Gas Turbines." 40th Joint Propulsion Conference, AIAA 2004-3581 [5] Epstein A.H., 2003, “Millimeter-scale, MEMS gas turbine engines.” Proc. of ASME Turbo Expo, GT-2003-38866 [6] Pohořelský L., Sané P. A., et al., 2008, "Wave Rotor Design Procedure for Gas Turbine Engine Enhancement." Proc. of ASME Turbo Expo 2008, GT-2008-51354 [7] Pohořelský L., Macek J., Polašek M., Vítek, O., 2004, “Simulation of a COMPREX Pressure Exchanger in a 1-D Code.” SAE International Paper 2004-01-1000, 13 [8] Heywood J.B., 1988, Internal Combustion Engine Fundamentals, McGraw-Hill CONCLUSIONS Four separate numerical methods were used to model the Wave Disc Engine. Each of the preliminary results confirms that the concept of the engine is feasible. Further investigations will determine possible improvements to the engine before the concept is tested with an experimental prototype. 533