HARVESTED FORAGES Silage pp. 267-274

advertisement

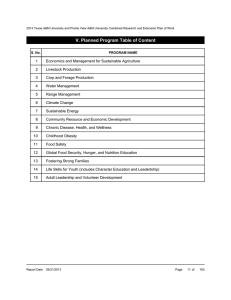

HARVESTED FORAGES Silage pp. 267-274 ENSILING • What is ensiling? – Storing a forage or grain crop at a relatively high moisture concentration in anerobic conditions to have it undergo fermentation to lactic acid. – Lactic acid will preserve silage as long as the silage isn’t exposed to oxygen WHY ENSILE? ENSILING • Goals – Decrease pH of ensiled crop to <4 – Increase lactic acid concentration of ensiled crop to >4% of DM • Requires anerobic conditions • Avoid – Molding and heating of crop • Occurs if forage is exposed to oxygen • Forage DM% > 60% – Butyric acid production, protein degradation, and seepage from silage • Forage DM% < 30% – Dependent of forage species APPROPRIATE MATURITY AND DM PERCENTAGE FOR ENSILING Desired for ensiling Crop Maturity DM% Whole plant corn 50% milk line stage on grain 30-40% Grain or forage sorghum Medium dough stage of grain 30-40% Small grains Late boot stage 35-45% Grasses Boot stage 40-50% Requires wilting Legumes Late bud stage 40-50% Requires wilting THE ENSILING PROCESS THE ENSILING PROCESS • Aerobic phase – Organisms • Plant enzymes • Aerobic bacteria and yeasts – Nutrient Metabolism • Sugars oxidized to CO2 – Changes in forage • O2 is consumed and CO2 produced • Temperature increases to 115oF • Sugars decreased – Length of change • Desire < 24 hours • Extended by: – Too dry – Long chop length – Slow filling – Poor packing – No cover • In extended, results in: – Excessive heating » Increased ADIN • Heterofermentative phase – Organisms • Heterofermentative lactic acid bacteria – Nutrient Metabolism • Sugars fermented to acetic acid, lactic acid, and CO2 – Changes in forage • Increased concentration of acetic acid and lactic acid • pH decreased to 5.0 • Sugars decreased – Length of change • Desire < 1 week • Extended by: – Forage being too wet – If pH never drops to 5 » Causes • Forage too wet • Inadequate sugars » Results • Clostridium bacteria growth • Butyric acid production • Protein degradation to NH3 and other forms of NPN • Homofermentative phase – Organisms • Homofermentative lactic acid bacteria – Nutrient Metabolism • Sugars fermented to lactic acid – Changes in forage • Increased concentration of lactic acid – 6 to 8% of DM • pH decreased to 3.8 to 4.2 • Sugars decreased – Length of change • Desire < 2 weeks • Storage phase – If not exposed to oxygen • Forage well-preserved with little change in composition – If exposed to oxygen • Growth of aerobic bacteria and mold – Results in heating, nutrient loss, and decreased palatability • Growth of listeria bacteria – Results in listeriosis » Encephalitis » Metritis and abortion • Feedout phase – Exposes silage to oxygen – Growth of aerobic bacteria and molds – Results: • Heating • Loss of lactic acid • Nutrient loss – Losses minimized by adequate feedout rate • Match diameter of tower silos or width of bunker silos to herd size Season Silo type Winter Summer Inches removed/day Tower 2 4 Bunker 4 6 SILO TYPES • Tower – 30 to 50% DM – Easy to pack • Good for hay crop or corn silage – Minimal exposed surface – Expensive • Bunker or trench – 30 to 40% DM – Difficult to pack • Not desirable for hay crop silage – Requires polyethylene cover – Considerable surface area at feeding – Less expensive than towers • Silo bags – – – – – – 30 to 50% DM Easy to pack Minimal exposed surface Versatile Bags subject to punctures and tears Relatively low capital investment • Big bale silage – 40 to 60% DM – Advantages • Inexpensive • Allows small amounts of forage ensiled • Transportable • No specialized equipment beyond wrapper – Limitations • • • • • Some large balers can not bale high moisture forage Long forage more difficult to ensile than chopped forage Bales are heavy Plastic wrap subject to puncture and tears Disposal of plastic DM LOSSES FROM DIFFERENT SILO TYPES Silo types Concrete tower Bunker Bag Round bale DM losses, % Respiration 4 4 4 4 Harvesting 2 2 2 4 Storage 9 15 7 18 Feedout 2 4 4 4 Total 17 25 17 30 PROPERTIES OF HIGH QUALITY SILAGE Silage pH 3.6 – 4.2 Lactic acid 4-8% of DM Acetic acid <2% Butyric acid <0.1% Nitrogen fractions Ammonia nitrogen <5% of total N ADIN <12% of total N Microbial assay Total aerobic bacteria <100,000 cfu/gm silage Molds <100,000 cfu/gm silage MAKING HIGH QUALITY SILAGE • Harvest at appropriate maturity and moisture • Set chop length Crop Length of chop Hay crop ¼” Unprocessed corn silage 3/8 to ½” Processed corn silage (Kernel processor) ¾” • Fill silo as rapidly as possible • Pack, pack and pack some more • Cover silos immediately – 6-mil plastic – Weight on bunker silos • Feedout – Adequate rate – Maintain clean face SILAGE ADDITIVES • Water – Added if forage moisture is inadequate – Requires 5 gallons/ton to change DM by 1% • Bacterial inoculants – Lactobacilli – Add a minimum of 100,000 cfu/gm fresh forage – Useful to: • Improve lactic acid production if forage is harvested at excessive moisture concentration • Prevent aerobic damage at feedout or in feed bunk • Enzymes – Cellulases, hemicellulases, amylases, pectinases – Increase sugars to improve lactic acid production – No consistent improvement • NPN sources – Used with corn, sorghum, and cereal silages – Types • Anhydrous ammonia at 5 to 10 lb/ton fresh forage • Urea at 10 to 20 lb/ton fresh forage – Advantages • Increases crude protein content • Increases aerobic stability at feedout • Acids – Propionic or formic acid • Application: 10 to 20 lb/ton fresh forage – Applied to forage that is either too wet or too dry • Formic acid causes a rapid decrease in pH if too wet • Propionic acid inhibits mold growth in too dry • Sugar sources – Molasses, whey, or grain – Added to crops with low concentration of soluble sugars • Grasses and legumes – Increases lactic acid concentration – Loss of energy from the source NUTRITIONAL VALUE OF HIGH QUALITY SILAGE • Lower feed consumption than fresh crop or hay • Lower NDF, but comparable ADF to fresh crop or hay • Comparable net energy concentration to fresh crop or hay • Comparable crude protein concentration to fresh crop, but greater than hay • Greater proportion of crude protein will be degradable in the rumen than fresh crop or hay • Higher carotene content than hay