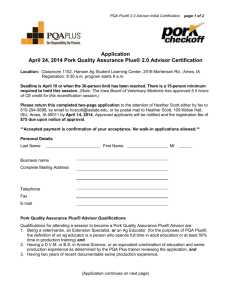

Quality Assurance III A Program of America’s

advertisement