ﭘﻴﺶ ﮔﻔﺘﺎر

FOREWORD

The Iranian Petroleum Standards (IPS) reflect the

views of the Iranian Ministry of Petroleum and are

intended for use in the oil and gas production

facilities,

oil

refineries,

chemical

and

petrochemical plants, gas handling and processing

installations and other such facilities.

IPS is based on internationally acceptable

standards and includes selections from the items

stipulated in the referenced standards. They are

also supplemented by additional requirements

and/or modifications based on the experience

acquired by the Iranian Petroleum Industry and the

local market availability. The options which are

not specified in the text of the standards are

itemized in data sheet/s, so that, the user can select

his appropriate preferences therein.

The IPS standards are therefore expected to be

sufficiently flexible so that the users can adapt

these standards to their requirements. However,

they may not cover every requirement of each

project. For such cases, an addendum to IPS

Standard shall be prepared by the user which

elaborates the particular requirements of the user.

This addendum together with the relevant IPS

shall form the job specification for the specific

project or work.

The IPS is reviewed and up-dated approximately

every five years. Each standards are subject to

amendment or withdrawal, if required, thus the

latest edition of IPS shall be applicable

The users of IPS are therefore requested to send

their views and comments, including any

addendum prepared for particular cases to the

following address. These comments and

recommendations will be reviewed by the relevant

technical committee and in case of approval will

be incorporated in the next revision of the

standard.

Standards and Research Department

No.19, Street14, North kheradmand

Karimkhan Avenue, Tehran, Iran .

Postal Code- 1585886851

Tel: 88810459-60 & 66153055

Fax: 88810462

Email: Standards@nioc.org

( ﻣﻨﻌﻜﺲ ﻛﻨﻨﺪه دﻳﺪﮔﺎﻫﻬﺎيIPS ) اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮان

وزارت ﻧﻔﺖ اﻳﺮان اﺳﺖ و ﺑﺮاي اﺳﺘﻔﺎده در ﺗﺄﺳﻴﺴﺎت ﺗﻮﻟﻴﺪ ﻧﻔﺖ

، واﺣﺪﻫﺎي ﺷﻴﻤﻴﺎﺋﻲ و ﭘﺘﺮوﺷﻴﻤﻲ، ﭘﺎﻻﻳﺸﮕﺎﻫﻬﺎي ﻧﻔﺖ،و ﮔﺎز

ﺗﺄﺳﻴﺴﺎت اﻧﺘﻘﺎل و ﻓﺮاورش ﮔﺎز و ﺳﺎﻳﺮ ﺗﺄﺳﻴﺴﺎت ﻣﺸﺎﺑﻪ ﺗﻬﻴﻪ

.ﺷﺪه اﺳﺖ

ﺑﺮ اﺳﺎس اﺳﺘﺎﻧﺪاردﻫﺎي ﻗﺎﺑﻞ ﻗﺒﻮل،اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ

ﺑﻴﻦاﻟﻤﻠﻠﻲ ﺗﻬﻴﻪ ﺷﺪه و ﺷﺎﻣﻞ ﮔﺰﻳﺪهﻫﺎﺋﻲ از اﺳﺘﺎﻧﺪاردﻫﺎي

ﻫﻤﭽﻨﻴﻦ ﺑﺮ اﺳﺎس ﺗﺠﺮﺑﻴﺎت ﺻﻨﻌﺖ.ﻣﺮﺟﻊ در ﻫﺮ ﻣﻮرد ﻣﻲﺑﺎﺷﺪ

ﻧﻔﺖ ﻛﺸﻮر و ﻗﺎﺑﻠﻴﺖ ﺗﺄﻣﻴﻦ ﻛﺎﻻ از ﺑﺎزار داﺧﻠﻲ و ﻧﻴﺰ ﺑﺮ ﺣﺴﺐ

ﻣﻮاردي ﺑﻄﻮر ﺗﻜﻤﻴﻠﻲ و ﻳﺎ اﺻﻼﺣﻲ در اﻳﻦ اﺳﺘﺎﻧﺪارد ﻟﺤﺎظ،ﻧﻴﺎز

ﻣﻮاردي از ﮔﺰﻳﻨﻪﻫﺎي ﻓﻨﻲ ﻛﻪ در ﻣﺘﻦ اﺳﺘﺎﻧﺪاردﻫﺎ.ﺷﺪه اﺳﺖ

آورده ﻧﺸﺪه اﺳﺖ در داده ﺑﺮگﻫﺎ ﺑﺼﻮرت ﺷﻤﺎره ﮔﺬاري ﺷﺪه

.ﺑﺮاي اﺳﺘﻔﺎده ﻣﻨﺎﺳﺐ ﻛﺎرﺑﺮان آورده ﺷﺪه اﺳﺖ

ﺑﺸﻜﻠﻲ ﻛﺎﻣﻼً اﻧﻌﻄﺎف ﭘﺬﻳﺮ ﺗﺪوﻳﻦ ﺷﺪه،اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ

.اﺳﺖ ﺗﺎ ﻛﺎرﺑﺮان ﺑﺘﻮاﻧﻨﺪ ﻧﻴﺎزﻫﺎي ﺧﻮد را ﺑﺎ آﻧﻬﺎ ﻣﻨﻄﺒﻖ ﻧﻤﺎﻳﻨﺪ

ﺑﺎ اﻳﻦ ﺣﺎل ﻣﻤﻜﻦ اﺳﺖ ﺗﻤﺎم ﻧﻴﺎزﻣﻨﺪيﻫﺎي ﭘﺮوژه ﻫﺎ را ﭘﻮﺷﺶ

در اﻳﻦ ﮔﻮﻧﻪ ﻣﻮارد ﺑﺎﻳﺪ اﻟﺤﺎﻗﻴﻪاي ﻛﻪ ﻧﻴﺎزﻫﺎي ﺧﺎص آﻧﻬﺎ.ﻧﺪﻫﻨﺪ

اﻳﻦ اﻟﺤﺎﻗﻴﻪ ﻫﻤﺮاه ﺑﺎ.را ﺗﺎﻣﻴﻦ ﻣﻲﻧﻤﺎﻳﺪ ﺗﻬﻴﻪ و ﭘﻴﻮﺳﺖ ﻧﻤﺎﻳﻨﺪ

ﻣﺸﺨﺼﺎت ﻓﻨﻲ آن ﭘﺮوژه و ﻳﺎ ﻛﺎر ﺧﺎص را،اﺳﺘﺎﻧﺪارد ﻣﺮﺑﻮﻃﻪ

.ﺗﺸﻜﻴﻞ ﺧﻮاﻫﻨﺪ داد

اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ ﺗﻘﺮﻳﺒﺎً ﻫﺮ ﭘﻨﺞ ﺳﺎل ﻳﻜﺒﺎر ﻣﻮرد ﺑﺮرﺳﻲ ﻗﺮار

در اﻳﻦ ﺑﺮرﺳﻲﻫﺎ ﻣﻤﻜﻦ اﺳﺖ.ﮔﺮﻓﺘﻪ و روزآﻣﺪ ﻣﻲﮔﺮدﻧﺪ

اﺳﺘﺎﻧﺪاردي ﺣﺬف و ﻳﺎ اﻟﺤﺎﻗﻴﻪاي ﺑﻪ آن اﺿﺎﻓﻪ ﺷﻮد و ﺑﻨﺎﺑﺮاﻳﻦ

.ﻫﻤﻮاره آﺧﺮﻳﻦ وﻳﺮاﻳﺶ آﻧﻬﺎ ﻣﻼك ﻋﻤﻞ ﻣﻲ ﺑﺎﺷﺪ

درﺧﻮاﺳﺖ ﻣﻲﺷﻮد ﻧﻘﻄﻪ ﻧﻈﺮﻫﺎ و،از ﻛﺎرﺑﺮان اﺳﺘﺎﻧﺪارد

ﭘﻴﺸﻨﻬﺎدات اﺻﻼﺣﻲ و ﻳﺎ ﻫﺮﮔﻮﻧﻪ اﻟﺤﺎﻗﻴﻪاي ﻛﻪ ﺑﺮاي ﻣﻮارد

ﻧﻈﺮات و. ﺑﻪ ﻧﺸﺎﻧﻲ زﻳﺮ ارﺳﺎل ﻧﻤﺎﻳﻨﺪ،ﺧﺎص ﺗﻬﻴﻪ ﻧﻤﻮدهاﻧﺪ

ﭘﻴﺸﻨﻬﺎدات درﻳﺎﻓﺘﻲ در ﻛﻤﻴﺘﻪﻫﺎي ﻓﻨﻲ ﻣﺮﺑﻮﻃﻪ ﺑﺮرﺳﻲ و در

ﺻﻮرت ﺗﺼﻮﻳﺐ در ﺗﺠﺪﻳﺪ ﻧﻈﺮﻫﺎي ﺑﻌﺪي اﺳﺘﺎﻧﺪارد ﻣﻨﻌﻜﺲ

.ﺧﻮاﻫﺪ ﺷﺪ

ﻛﻮﭼﻪ، ﺧﺮدﻣﻨﺪ ﺷﻤﺎﻟﻲ، ﺧﻴﺎﺑﺎن ﻛﺮﻳﻤﺨﺎن زﻧﺪ، ﺗﻬﺮان،اﻳﺮان

19 ﺷﻤﺎره،ﭼﻬﺎردﻫﻢ

اداره ﺗﺤﻘﻴﻘﺎت و اﺳﺘﺎﻧﺪاردﻫﺎ

1585886851 : ﻛﺪﭘﺴﺘﻲ

66153055 و88810459 - 60 : ﺗﻠﻔﻦ

021-88810462 : دور ﻧﮕﺎر

Standards@nioc.org

:آدرس اﻟﻜﺘﺮوﻧﻴﻜﻲ

: ﺗﻌﺎرﻳﻒ ﻋﻤﻮﻣﻲ

GENERAL DEFINITIONS:

Throughout this Standard the following definitions

shall apply.

: ﺷﺮﻛﺖ

COMPANY :

Refers to one of the related and/or affiliated

companies of the Iranian Ministry of Petroleum

such as National Iranian Oil Company, National

Iranian Gas Company, National Petrochemical

Company and National Iranian Oil Refinery And

Distribution Company.

ﻣﺜﻞ،ﺑﻪ ﻳﻜﻲ از ﺷﺮﻛﺖﻫﺎي اﺻﻠﻲ و ﻳﺎ واﺑﺴﺘﻪ ﺑﻪ وزارت ﻧﻔﺖ

ﺷﺮﻛﺖ ﻣﻠﻲ، ﺷﺮﻛﺖ ﻣﻠﻲ ﮔﺎز اﻳﺮان،ﺷﺮﻛﺖ ﻣﻠﻲ ﻧﻔﺖ اﻳﺮان

ﺻﻨﺎﻳﻊ ﭘﺘﺮوﺷﻴﻤﻲ و ﺷﺮﻛﺖ ﻣﻠﻲ ﭘﺎﻻﻳﺶ و ﭘﺨﺶ ﻓﺮآوردهﻫﺎي

.ﻧﻔﺘﻲ اﺗﻼق ﻣﻲﺷﻮد

:ﺧﺮﻳﺪار

PURCHASER :

Means the "Company" where this standard is a

part of direct purchaser order by the "Company",

and the “Contractor” where this Standard is a part

of contract document

ﻳﻌﻨﻲ ﺷﺮﻛﺘﻲ ﻛﻪ اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﺨﺸﻲ از ﻣﺪارك ﺳﻔﺎرش ﺧﺮﻳﺪ

ﻣﺴﺘﻘﻴﻢ آن "ﺷﺮﻛﺖ" ﻣﻲﺑﺎﺷﺪ و ﻳﺎ "ﭘﻴﻤﺎﻧﻜﺎري" ﻛﻪ اﻳﻦ

.اﺳﺘﺎﻧﺪارد ﺑﺨﺸﻲ از ﻣﺪارك ﻗﺮار داد آن اﺳﺖ

:ﻓﺮوﺷﻨﺪه و ﺗﺎﻣﻴﻦ ﻛﻨﻨﺪه

VENDOR AND SUPPLIER:

Refers to firm or person who will supply and/or

fabricate the equipment or material.

ﺑﻪ ﻣﻮﺳﺴﻪ و ﻳﺎ ﺷﺨﺼﻲ ﮔﻔﺘﻪ ﻣﻲﺷﻮد ﻛﻪ ﺗﺠﻬﻴﺰات و ﻛﺎﻻﻫﺎي

.ﻣﻮرد ﻟﺰوم ﺻﻨﻌﺖ را ﺗﺎﻣﻴﻦ ﻣﻲﻧﻤﺎﻳﺪ

:ﭘﻴﻤﺎﻧﻜﺎر

CONTRACTOR:

Refers to the persons, firm or company whose

tender has been accepted by the company.

ﻣﻮﺳﺴﻪ و ﻳﺎ ﺷﺮﻛﺘﻲ ﮔﻔﺘﻪ ﻣﻲﺷﻮد ﻛﻪ ﭘﻴﺸﻨﻬﺎدش،ﺑﻪ ﺷﺨﺺ

.ﺑﺮاي ﻣﻨﺎﻗﺼﻪ ﭘﺬﻳﺮﻓﺘﻪ ﺷﺪه اﺳﺖ

: ﻣﺠﺮي

EXECUTOR :

Executor is the party which carries out all or part of

construction and/or commissioning for the project.

ﻣﺠﺮي ﺑﻪ ﮔﺮوﻫﻲ اﺗﻼق ﻣﻲﺷﻮد ﻛﻪ ﺗﻤﺎم ﻳﺎ ﻗﺴﻤﺘﻲ از ﻛﺎرﻫﺎي

.اﺟﺮاﺋﻲ و ﻳﺎ راه اﻧﺪازي ﭘﺮوژه را اﻧﺠﺎم دﻫﺪ

:ﺑﺎزرس

INSPECTOR :

The Inspector referred to in this Standard is a

person/persons or a body appointed in writing by

the company for the inspection of fabrication and

installation work

ﮔﺮوه ﻳﺎ ﻣﻮﺳﺴﻪاي اﺗﻼق/در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﺎزرس ﺑﻪ ﻓﺮد

ﺳﺎﺧﺖ و ﻧﺼﺐ،ﻣﻲﺷﻮد ﻛﻪ ﻛﺘﺒﺎً ﺗﻮﺳﻂ ﻛﺎرﻓﺮﻣﺎ ﺑﺮاي ﺑﺎزرﺳﻲ

.ﺗﺠﻬﻴﺰات ﻣﻌﺮﻓﻲ ﺷﺪه ﺑﺎﺷﺪ

:ﺑﺎﻳﺪ

SHALL:

. اﺳﺘﻔﺎده ﻣﻲﺷﻮد،ﺑﺮاي ﻛﺎري ﻛﻪ اﻧﺠﺎم آن اﺟﺒﺎري اﺳﺖ

Is used where a provision is mandatory.

:ﺗﻮﺻﻴﻪ

SHOULD:

Is used where a provision is advisory only.

. ﺑﻜﺎر ﻣﻲرود،ﺑﺮاي ﻛﺎري ﻛﻪ ﺿﺮورت اﻧﺠﺎم آن ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد

:ﺗﺮﺟﻴﺢ

WILL:

Is normally used in connection with the action by

the “Company” rather than by a contractor,

supplier or vendor.

ﻣﻌﻤﻮﻻً در ﺟﺎﻳﻲ اﺳﺘﻔﺎده ﻣﻲﺷﻮد ﻛﻪ اﻧﺠﺎم آن ﻛﺎر ﺑﺮ اﺳﺎس

.ﻧﻈﺎرت ﺷﺮﻛﺖ ﺑﺎﺷﺪ

: ﻣﻤﻜﻦ اﺳﺖ

MAY:

Is used where

discretionary.

.در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺗﻌﺎرﻳﻒ زﻳﺮ ﺑﻪ ﻛﺎر ﻣﻲرود

a

provision

is

completely

. ﺑﻜﺎر ﻣﻲرود،ﺑﺮاي ﻛﺎري ﻛﻪ اﻧﺠﺎم آن اﺧﺘﻴﺎري ﻣﻲﺑﺎﺷﺪ

IPS-C-IN-120(1)

0

CONSTRUCTION (INSTALLATION) STANDARD

FOR

TEMPERATURE INSTRUMENTS

FIRST REVISION

MARCH 2009

اﺳﺘﺎﻧﺪارد ﻧﺼﺐ

ﺑﺮاي

ادوات اﺑﺰار دﻗﻴﻖ دﻣﺎ

وﻳﺮاﻳﺶ اول

1388 ﻓﺮوردﻳﻦ

This Standard is the property of Iranian Ministry of

Petroleum. All rights are reserved to the owner. Neither

whole nor any part of this document maybe disclosed to any

third party, reproduced, stored in any retrieval system or

transmitted in any form or by any means without the prior

written consent of the Iranian Ministry of Petroleum.

ﺗﻤﺎم ﺣﻘﻮق آن ﻣﺘﻌﻠﻖ ﺑﻪ.اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﺘﻌﻠﻖ ﺑﻪ وزارت ﻧﻔﺖ اﻳﺮان اﺳﺖ

ﺗﻤﺎم ﻳﺎ ﺑﺨﺸﻲ،ﻣﺎﻟﻚ آن ﺑﻮده و ﻧﺒﺎﻳﺪ ﺑﺪون رﺿﺎﻳﺖ ﻛﺘﺒﻲ وزارت ﻧﻔﺖ اﻳﺮان

، اﻧﺘﻘﺎل، ذﺧﻴﺮه ﺳﺎزي، ﺑﻪ ﻫﺮ ﺷﻜﻞ ﻳﺎ وﺳﻴﻠﻪ ازﺟﻤﻠﻪ ﺗﻜﺜﻴﺮ،از اﻳﻦ اﺳﺘﺎﻧﺪارد

.ﻳﺎ روش دﻳﮕﺮي در اﺧﺘﻴﺎر اﻓﺮاد ﺛﺎﻟﺚ ﻗﺮار ﮔﻴﺮد

Mar. 2009/ 1388 ﻓﺮوردﻳﻦ

Page

No

CONTENTS:

IPS-C-IN-120(1)

:ﻓﻬﺮﺳﺖ ﻣﻄﺎﻟﺐ

1. SCOPE................................................................ 2

2 ...................................................... داﻣﻨﻪ ﻛﺎرﺑﺮد-1

2. REFERENCES .................................................. 2

2 ............................................................. ﻣﺮاﺟﻊ-2

3. UNITS................................................................. 4

4 ............................................................ واﺣﺪﻫﺎ-3

4. DEFINITION & TERMINOLOGY ................ 4

4 ................................................ ﺗﻌﺎرﻳﻒ و واژﮔﺎن-4

5. GENERAL ......................................................... 5

5 ............................................................ ﻋﻤﻮﻣﻲ-5

6. FILLED SYSTEM AND BIMETALLIC

DIAL THERMOMETERS ............................... 6

دﻣﺎﺳﻨﺞ ﻫﺎي ﭘﺮﺷﺪه-6

6 ............................................. و ﻋﻘﺮﺑﻪاي دو ﻓﻠﺰي

7. RESISTANCE AND THERMOCOUPLE

TEMPERATURE MEASUREMENTS........... 7

7 ................... اﻧﺪازه ﮔﻴﺮي دﻣﺎ ﺑﺎ ﻣﻘﺎوﻣﺖ و ﺗﺮﻣﻮﻛﻮﭘﻞ-7

8. THERMOWELLS............................................. 20

20 ........................................... ﭼﺎﻫﻚ ﻫﺎي ﺣﺮارﺗﻲ-8

9. TEMPERATURE SWITCHES........................ 21

21 ............................................... ﻛﻠﻴﺪﻫﺎي ﺣﺮارﺗﻲ-9

1

Mar. 2009/ 1388 ﻓﺮوردﻳﻦ

IPS-C-IN-120(1)

داﻣﻨﻪ ﻛﺎرﺑﺮد-1

1. SCOPE

This standard represents the minimum and general

technical requirements for the construction and

installation of different types of temperature.

measuring and control instruments, which are used

in oil, gas and petrochemical industries.

اﻳﻦ اﺳﺘﺎﻧﺪارد ﻧﻤﺎﻳﺎﻧﮕﺮ ﺣﺪاﻗﻞ ﺷﺮاﻳﻂ ﻻزم ﺗﻜﻨﻴﻜﻲ ﻋﻤﻮﻣﻲ ﺑﺮاي

In any case, manufacturer installation instructions

should be strictly followed.

دﺳﺘﻮراﻟﻌﻤﻞ ﻫﺎي ﻧﺼﺐ ﺳﺎزﻧﺪه ﺑﺎﻳـﺪ ﻣﻮﻛـﺪاً دﻧﺒـﺎل،ﺑﻪ ﻫﺮ ﺣﺎل

.ﮔﺮدﻧﺪ

ﺳﺎﺧﺖ و ﻧﺼﺐ اﻧﻮاع ﻣﺨﺘﻠﻒ اﺑﺰار دﻗﻴﻖ اﻧﺪازه ﮔﻴـﺮي و ﻛﻨﺘـﺮل

.اﺳﺖ

:1 ﻳﺎدآوري

Note 1:

ﺗﻮﺳﻂ ﻛﻤﻴﺘﻪ ﻓﻨﻲ1376 اﻳﻦ اﺳﺘﺎﻧﺪارد در ﻣﻬﺮ ﻣﺎه ﺳﺎل

ﻣﺮﺑﻮﻃﻪ ﺑﺮرﺳﻲ و روز آﻣﺪ ﺷﺪ و ﻣﻮارد ﺗﺎﻳﻴﺪ ﺷﺪه ﺑﻪ ﻋﻨﻮان

. اﺑﻼغ ﮔﺮدﻳﺪ8 ﻃﻲ ﺑﺨﺸﻨﺎﻣﻪ ﺷﻤﺎره1 اﺻﻼﺣﻴﻪ ﺷﻤﺎره

This standard specification is reviewed and

updated by the relevant technical committee on

Oct. 1997, as amendment No. 1 by circular No. 8.

:2 ﻳﺎدآوري

Note 2:

اﻳﻦ اﺳﺘﺎﻧﺪارد دو زﺑﺎﻧﻪ ﻧﺴﺨﻪ ﺑﺎزﻧﮕﺮي ﺷﺪه اﺳﺘﺎﻧﺪارد ﻣﻴﺒﺎﺷﺪ

ﺗﻮﺳﻂ ﻛﻤﻴﺘﻪ ﻓﻨﻲ ﻣﺮﺑﻮﻃﻪ اﻧﺠﺎم1388ﻛﻪ در ﻓﺮوردﻳﻦ ﻣﺎه ﺳﺎل

(0) از اﻳﻦ ﭘﺲ وﻳﺮاﻳﺶ.( اراﻳﻪ ﻣﻲﮔﺮدد1) و ﺑﻪ ﻋﻨﻮان وﻳﺮاﻳﺶ

.اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﻨﺴﻮخ ﻣﻲﺑﺎﺷﺪ

This bilingual standard is a revised version of the

standard specification by the relevant technical

committee on March 2009, which is issued as

revision (1). Revision (0) of the said standard

specification is withdrawn.

:3 ﻳﺎدآوري

Note 3:

ﻣﺘﻦ اﻧﮕﻠﻴﺴﻲ،در ﺻﻮرت اﺧﺘﻼف ﺑﻴﻦ ﻣﺘﻦ ﻓﺎرﺳﻲ و اﻧﮕﻠﻴﺴﻲ

.ﻣﻼك ﻣﻲﺑﺎﺷﺪ

In case of conflict between Farsi and English

languages, English language shall govern.

ﻣﺮاﺟﻊ-2

2. REFERENCES

در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﻪ آﻳﻴﻦ ﻧﺎﻣﻪ ﻫﺎ و اﺳﺘﺎﻧﺪاردﻫﺎي ﺗﺎرﻳﺦ دار و

ﺗﺎ ﺣﺪي ﻛﻪ در، اﻳﻦ ﻣﺮاﺟﻊ.ﺑﺪون ﺗﺎرﻳﺦ زﻳﺮ اﺷﺎره ﺷﺪه اﺳﺖ

ﺑﺨﺸﻲ از اﻳﻦ،اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﮔﺮﻓﺘﻪاﻧﺪ

وﻳﺮاﻳﺶ ﮔﻔﺘﻪ، در ﻣﺮاﺟﻊ ﺗﺎرﻳﺦ دار.اﺳﺘﺎﻧﺪارد ﻣﺤﺴﻮب ﻣﻲﺷﻮﻧﺪ

ﺷﺪه ﻣﻼك ﺑﻮده و ﺗﻐﻴﻴﺮاﺗﻲ ﻛﻪ ﺑﻌﺪ از ﺗﺎرﻳﺦ وﻳﺮاﻳﺶ در آﻧﻬﺎ

ﭘﺲ از ﺗﻮاﻓﻖ ﺑﻴﻦ ﻛﺎرﻓﺮﻣﺎ و ﻓﺮوﺷﻨﺪه ﻗﺎﺑﻞ اﺟﺮا،داده ﺷﺪه اﺳﺖ

آﺧﺮﻳﻦ وﻳﺮاﻳﺶ آﻧﻬﺎ ﺑﻪ اﻧﻀﻤﺎم، در ﻣﺮاﺟﻊ ﺑﺪون ﺗﺎرﻳﺦ.ﻣﻲﺑﺎﺷﺪ

.ﻛﻠﻴﻪ اﺻﻼﺣﺎت و ﭘﻴﻮﺳﺖﻫﺎي آن ﻣﻼك ﻋﻤﻞ ﻣﻲﺑﺎﺷﻨﺪ

Throughout this Standard the following dated and

undated standards/codes are referred to. These

referenced documents shall, to the extent specified

herein, form a part of this standard. For dated

references, the edition cited applies. The

applicability of changes in dated references that

occur after the cited date shall be mutually agreed

upon by the Company and the Vendor. For

undated references, the latest edition of the

referenced documents (including any supplements

and amendments) applies.

API

(AMERICAN

INSTITUTE)

( )ﻣﻮﺳﺴﻪ ﻧﻔﺖ آﻣﺮﻳﻜﺎAPI

PETROLEUM

RP 556

"Instrumentation

RP 551-Sec. 5

"Fired Heaters and Inert Gas

and

Control Systems for Fired

Heaters

and

Steam

Generators"

Generators"

2

"اﺑﺰاردﻗﻴﻖ و ﺳﺎﻣﺎﻧﻪﻫﺎي ﻛﻨﺘﺮل

"ﺑﺮاي ﻛﻮره ﻫﺎ و ﻣﻮﻟﺪﻫﺎي ﺑﺨﺎر

RP 556

""ﻛﻮره ﻫﺎ و ﻣﻮﻟﺪﻫﺎي ﮔﺎز ﺧﻨﺜﻲ

5 ﻗﺴﻤﺖRP 551

Mar. 2009/ 1388 ﻓﺮوردﻳﻦ

IPS-C-IN-120(1)

( )اﻧﺠﻤﻦ ﺑﻴﻦاﻟﻤﻠﻠﻲ اﺗﻮﻣﺎﺳﻴﻮنISA

ISA (THE INTERNATIONAL SOCIETY OF

AUTOMATION)

"Temperature Measurement:

Mc 96.1

" ﺗﺮﻣﻮﻛﻮﭘﻠﻬﺎ:"اﻧﺪازه ﮔﻴﺮي دﻣﺎ

Thermo-Couples"

( )ﻛﻤﻴﺴﻴﻮن ﺑﻴﻦ اﻟﻤﻠﻠﻲ اﻟﻜﺘﺮوﺗﻜﻨﻴﻚIEC

IEC (INTERNATIONAL

ELECTROTECHNICAL

COMMISSION)

IEC-60584

"Thermocouples Part 1:

Reference

Edition"

IEC-60751

ASME

Mc 96.1

Table

ﺟﺪول: "ﺗﺮﻣﻮﻛﻮﭘﻠﻬﺎ ﻗﺴﻤﺖ اول

"ﻣﺮﺟﻊ ﭼﺎپ دوم

"ﺣﺴﮕﺮﻫﺎي دﻣﺎ از ﻧﻮع ﻣﻘﺎوﻣﺘﻲ

ﭘﻼﺗﻴﻦ ﺻﻨﻌﺘـــﻲ ﭼـــﺎپ اول

,

1986-1

اﺻـــﻼﺣﻴــﻪ

1995،60751-2اﺻﻼﺣﻴﻪ

"1996: BSEN

2nd

"Industrial

Platinum

Resistance

Thermometer

Sensors

First

Edition,

Amendment

1-1986,

Amendment 2-1995 , BS EN

60751 :1996"

IEC-60584

IEC-60751

( )اﻧﺠﻤﻦ ﻣﻬﻨﺪﺳﺎن ﻣﻜﺎﻧﻴﻚ آﻣﺮﻳﻜﺎASME

(AMERICAN

SOCIETY

OF

MECHANICAL ENGINEERS)

ASME-PTC 19.3 "Performance Test CodeTemperature Measurement"

اﻧﺪازه-"اﺳﺘﺎﻧﺪارد آزﻣﺎﻳﺶ ﻋﻤﻠﻜﺮد

"ﮔﻴﺮي دﻣﺎ

ASME-PTC 19.3

ASME-B40.200

ASME-B40.200

"Temperatures,

Direct

Reading & Remote Reading

Incorporating ASME B40.3,

B40.4, and B40.9"

"ﺧﻮاﻧﺪن ﻣﺴﺘﻘﻴﻢ و از دور دﻣﺎ

ASME ﺷﺎﻣﻞ اﺳﺘﺎﻧﺪاردﻫﺎي

وASME B40.9 وB40.3

"ASME B40.4

ASME-B1.20.3

"Dry seal Pipe Thread(Inch)"

ASME-B1.20.3

اﻳﻨﭻ( رزوه1) "آب ﺑﻨﺪي ﺧﺸﻚ

"ﻟﻮﻟﻪ

( )ﻣﻮﺳﺴﻪ اﺳﺘﺎﻧﺪاردﻫﺎي ﺑﺮﻳﺘﺎﻧﻴﺎBSI

BSI (BRITISH STANDARDS INSTITUTE)

BS 1041-Part III "Guide to Selection and Use

of Industrial Resistance

Thermometers"

"راﻫﻨﻤــﺎي اﻧﺘﺨــﺎب و اﺳــﺘﻔﺎده از

"دﻣﺎﺳﻨﺞﻫﺎي ﻣﻘﺎوﻣﺘﻲ ﺻﻨﻌﺘﻲ

( )اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮانIPS

IPS (IRANIAN PETROLEUM STANDARDS)

IPS-E-GN-100

"Engineering Standard for

Units"

IPS-C-IN-190

IPS-C-PI-290

BS1041-PartIII

IPS-E-GN-100

"Installation

"اﺳﺘﺎﻧﺪارد

"واﺣﺪﻫﺎ

"اﺳﺘﺎﻧﺪارد ﺳﺎﺧﺖ و ﻧﺼﺐ ﺑﺮاي

"ﺳﺎﻣﺎﻧﻪﻫﺎي اﻧﺘﻘﺎل

"Construction Standard for

Welding of Plant Piping

Systems"

ﺑﺮاي

ﺳﺎﺧﺖ

"اﺳﺘﺎﻧﺪارد

ﺟﻮﺷﻜﺎري ﺳﺎﻣﺎﻧﻪﻫﺎي ﻟﻮﻟﻪ ﻛﺸﻲ

"واﺣﺪ

IPS-C-PI-290

ﺑﺮاي

and

Construction Standard for

Transmission Systems"

3

ﻣﻬﻨﺪﺳﻲ

IPS-C-IN-190

Mar. 2009/ 1388 ﻓﺮوردﻳﻦ

IPS-M-EL-271(1) "Material Standard for Low

Voltage Cables & Wires"

IPS-C-IN-120(1)

"اﺳــﺘﺎﻧﺪارد ﻣــﻮاد ﺑــﺮاي ﻛﺎﺑﻠﻬــﺎ وIPS-M-EL-271 (1)

"ﺳﻴﻤﻬﺎي وﻟﺘﺎژ ﺿﻌﻴﻒ

واﺣﺪﻫﺎ-3

3. UNITS

ﻣﻨﻄﺒﻖ،(SI) ﺑﺮﻣﺒﻨﺎي ﻧﻈﺎم ﺑﻴﻦ اﻟﻤﻠﻠﻲ واﺣﺪﻫﺎ،اﻳﻦ اﺳﺘﺎﻧﺪارد

ﻣﮕﺮ آﻧﻜﻪ در ﻣﺘﻦ، ﻣﻲﺑﺎﺷﺪIPS-E-GN-100 ﺑﺎ اﺳﺘﺎﻧﺪارد

.اﺳﺘﺎﻧﺪارد ﺑﻪ واﺣﺪ دﻳﮕﺮي اﺷﺎره ﺷﺪه ﺑﺎﺷﺪ

This standard is based on International System of

Units (SI), as per IPS-E-GN-100 , except where

otherwise specified.

ﺗﻌﺎرﻳﻒ و واژﮔﺎن-4

4. DEFINITION & TERMINOLOGY

ﺗﺮﻣﻮﻛﻮﭘﻞ ﻳﻚ وﺳﻴﻠﻪ دو ﻓﻠﺰي اﺳـﺖ ﻛـﻪ ﺑـﺎ: ﺗﺮﻣﻮﻛﻮﭘﻞ ﻫﺎ1-4

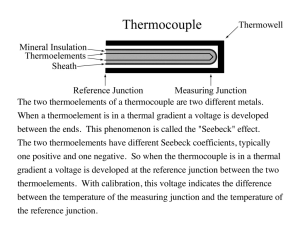

4.1 Thermocouple is a bimetallic set, the potential

difference across which varies with temperature

when heated and forms basis for temperature

measuring and control devices. There are different

types of thermocouples used in industry such as

EX, JX, KX, SX and TX as shown in table – 1.

ﺗﻐﻴﻴﺮ ﺣﺮارت اﺧﺘﻼف ﭘﺘﺎﻧﺴﻴﻞ دو ﺳـﺮ آن ﻧﻴـﺰ ﺗﻐﻴﻴـﺮ ﻧﻤـﻮده و

از ﺗﺮﻣﻮﻛﻮﭘﻠﻬـﺎي.ﺑﺮاي اﻧﺪازهﮔﻴﺮي دﻣﺎ و ﻛﻨﺘﺮل آن ﻛﺎرﺑﺮد دارد

KX , ﻛـﻪ ﻣﻴﺘـﻮان از،ﻣﺨﺘﻠﻔﻲ در ﺻﻨﻌﺖ اﺳﺘﻔﺎده ﺷﺪه اﺳـﺖ

ﻧـﺸﺎن1- ﻫﻤﺎن ﮔﻮﻧـﻪ ﻛـﻪ در ﺟـﺪول، ﻧﺎم ﺑﺮدTX وJX , EX

.داده ﺷﺪهاﻧﺪ

دﻣﺎﺳﻨﺞ دو ﻓﻠﺰي اﺑﺰار اﻧﺪازهﮔﻴﺮي دﻣﺎ ﻫﺴﺘﻨﺪ ﻛﻪ در آﻧﻬـﺎ2-4

4.2 Bimetallic Thermometers: Are temperature

measuring instruments in which the differential

expansion of two metals is used as a means of

temperature measurement. They consist of an

indicating or recording device, a sensing element

called a bimetallic thermometer bulb, and a means

for operatively connecting the two.

از اﺧﺘﻼف اﻧﺒﺴﺎط دو ﻓﻠﺰ ﺑﺮاي اﻧﺪازهﮔﻴﺮي دﻣـﺎ اﺳـﺘﻔﺎده ﺷـﺪه

، اﻳﻦ وﺳﻴﻠﻪ ﺷﺎﻣﻞ دﺳﺘﮕﺎﻫﻬﺎي ﻧـﺸﺎن دﻫﻨـﺪه و ﻳـﺎ ﺛﺒـﺎت.اﺳﺖ

اﻟﻤﺎنﻫﺎي ﺣﺲ ﻛﻨﻨﺪه ﺑﻨﺎم ﺻﻔﺤﻪ ﺗﺮﻣﻮﻣﺘﺮ دو ﻓﻠﺰي و وﺳﻴﻠﻪاي

.ﺟﻬﺖ اﺗﺼﺎل اﻳﻦ دو ﻣﻲﺷﻮد

دﺳﺘﮕﺎﻫﻬﺎي اﻧﺪازهﮔﻴﺮي دﻣﺎ ﻫﺴﺘﻨﺪ: دﻣﺎﺳﻨﺞﻫﺎي ﭘﺮ ﺷﺪه3-4

4.3 Filled System Thermometers: Are temperature

measuring instruments in which the change in

volume of a liquid, a change in pressure of a gas,

or the change in vapor pressure of a volatile liquid

is used as a means of temperature measurement.

They consist of an all metal assembly comprised

of a bulb, capillary tube and Bourdon tube,

provided with a temperature responsive fill.

ﻳـﺎ ﺗﻐﻴﻴـﺮ، ﺗﻐﻴﻴـﺮ ﻓـﺸﺎر ﮔـﺎز،ﻛﻪ در آﻧﻬﺎ از ﺗﻐﻴﻴﺮات ﺣﺠﻢ ﻣﺎﻳﻊ

ﻓﺸﺎر ﺑﺨﺎر ﻣﺎﻳﻊ ﻓﺮار ﺑﺮاي اﻧﺪازهﮔﻴـﺮي درﺟـﻪ ﺣـﺮارت دﺳـﺘﮕﺎه

اﻳﻦ دﻣﺎﺳـﻨﺞﻫـﺎ از ﻣﺠﻤﻮﻋـﻪ ﻓﻠـﺰي ﺷـﺎﻣﻞ.اﺳﺘﻔﺎده ﺷﺪه اﺳﺖ

ﻟﻮﻟﻪ ﻣﻮﺋﻴﻦ و ﻟﻮﻟﻪ ﺑﻮردون ﺗﺸﻜﻴﻞ ﺷﺪهاﻧـﺪ ﻛـﻪ ﺗﻮﺳـﻂ، ﺻﻔﺤﻪ

. ﭘﺮ ﺷﺪهاﻧﺪ،ﻣﺎﻳﻊ ﺣﺴﺎس در ﻣﻘﺎﺑﻞ دﻣﺎ

see section

. ﻣﺮاﺟﻌﻪ ﺷﻮد14-7 ﺑﻪ ﺑﻨﺪ: ﺳﻴﻢ اﺗﺼﺎﻟﻲ ﺗﺮﻣﻮﻛﻮﭘﻞ4-4

4.5

Thermowell:

In

many

temperature

measurements in performance test code work the

sensitive element cannot be placed directly in to

the medium whose temperature is to be measured.

In such cases a well may be used, which by

definition is a pressure tight receptacle adapted to

receive a temperature sensing element and

provided with external threads or other means for

light pressure attachment to a vessel.

در ﺑﺴﻴﺎري از اﻧﺪازه ﮔﻴﺮيﻫـﺎي دﻣـﺎ: ﭼﺎﻫﻚﻫﺎي ﺣﺮارﺗﻲ5-4

4.4 Thermocouple Extension Wire:

7.14

اﻟﻤــﺎن ﺣــﺴﮕﺮ را ﻧﻤﻴﺘــﻮان ﻣــﺴﺘﻘﻴﻤﺎً در ﻣﺤــﻴﻂ واﺳــﻂ ﺑــﺮاي

در ﭼﻨﻴﻦ ﻣـﻮاردي ﻣﻴﺘـﻮان از ﭼﺎﻫـﻚ.اﻧﺪازهﮔﻴﺮي دﻣﺎ ﻗﺮار داد

اﺳﺘﻔﺎده ﻧﻤﻮد ﻛﻪ ﺑﻨﺎ ﺑﻪ ﺗﻌﺮﻳﻒ ﻳﻚ ﻣﺤﻔﻈﻪ ﺑﺴﺘﻪ ﻓـﺸﺎري اﺳـﺖ

ﻛﻪ آﻣـﺎده در ﺑﺮﮔـﺮﻓﺘﻦ ﺣـﺴﮕﺮ دﻣـﺎ اﺳـﺖ و ﺷـﺎﻣﻞ ﭘـﻴﭻﻫـﺎي

.ﺧﺮوﺟﻲ ﻳﺎ ﻣﺘﻌﻠﻘﺎت دﻳﮕﺮي ﺑﺮاي اﺗﺼﺎل ﺑﻪ ﻇﺮف ﻣﻲﺑﺎﺷﺪ

ﺣﺒﺎب6-4

4-6 BULB

ﺣﺒـﺎب،اوﻟﻴﻦ اﻟﻤﺎن در راﺑﻄﻪ ﺑﺎ ﺗﺮﻣﻮﻣﺘﺮ ﻣﻘـﺎوﻣﺘﻲ ﺑـﻪ ﺳـﺎدﮔﻲ

ﺣﺒﺎﺑﻬـﺎي ﻣﻘـﺎوم در اﻧـﻮاع.ﺗﺮﻣﻮﻣﺘﺮ ﻣﻘﺎوﻣﺘﻲ ﻧﺎﻣﻴﺪه ﺷﺪه اﺳـﺖ

ﻛﻪ ﺑﺮ اﺳﺎس ﺷـﻜﻞ ﻓﻠـﺰي،ﻓﺮمﻫﺎ و ﺷﻜﻞﻫﺎ در دﺳﺘﺮس ﻫﺴﺘﻨﺪ

The primary element used in connection with a

resistance thermometer is simply termed a

resistance thermometer bulb. Resistor bulbs are

4

Mar. 2009/ 1388 ﻓﺮوردﻳﻦ

IPS-C-IN-120(1)

available in many forms and shapes , depending

upon their shaped metal stem, the lower end of

which is sealed, while the upper end terminates in

the head or terminal housing. The resistance

winding is located in the lower end of the stem.

The winding always must be in good thermal

contact with the inner surface of the stem or

housing so that proper heat transfer from the

medium being measured will occur and result in an

acceptable speed of response. For obvious reason,

the winding must be electrically insulated from the

stem. Thus, one of the fundamental design

problems is that of achieving the desired electrical

insulation with minimum thermal insulation.

و اﻧﺘﻬﺎي ﻓﻮﻗﺎﻧﻲ آن،ﺳﺎﻗﻪ ﻛﻪ اﻧﺘﻬﺎي ﺗﺤﺘﺎﻧﻲ آن آب ﺑﻨﺪي ﺷﺪه

.در ﺳﺮ ﻳﺎ ﻣﺤﻔﻈـﻪ ﻧﻬـﺎﻳﻲ آن ﭘﺎﻳـﺎن ﻳﺎﻓﺘـﻪ اﺳـﺖ وﺟـﻮد دارﻧـﺪ

.ﺳﻴﻢﭘﻴﭻ ﻣﻘـﺎوﻣﺘﻲ در اﻧﺘﻬـﺎي ﭘـﺎﻳﻴﻦ ﺳـﺎﻗﻪ واﻗـﻊ ﺷـﺪه اﺳـﺖ

ﺳﻴﻢﭘﻴﭻ ﻫﻤﻴﺸﻪ ﺑﺎﻳﺪ در راﺑﻄﻪ دﻣﺎﻳﻲ ﺑﺎ ﺳﻄﺢ داﺧـﻞ ﺳـﺎﻗﻪ ﻳـﺎ

ﻣﺤﻔﻈﻪ ﺑﺎﺷﺪ ﺑﻪ ﻧﺤﻮي ﻛﻪ اﻧﺘﻘﺎل دﻣﺎ از واﺳﻄﻪ اﻧﺪازهﮔﻴﺮي ﺷﺪه

.اﻧﺠﺎم ﮔﺮﻓﺘﻪ و ﺑﻪ ﺳﺮﻋﺖ ﺟﻮاﺑﮕﻮﻳﻲ ﻗﺎﺑـﻞ ﻗﺒـﻮﻟﻲ ﻣﻨـﺘﺞ ﮔـﺮدد

ﺑﺮاي دﻻﺋﻞ واﺿﺢ ﺳﻴﻢ ﭘﻴﭻ ﺑﺎﻳﺪ ﺑﻄﻮر اﻟﻜﺘﺮﻳﻜﻲ از ﺳـﺎﻗﻪ ﻋـﺎﻳﻖ

ﺑﻨﺎﺑﺮاﻳﻦ ﻳﻜﻲ از ﻣﺴﺎﺋﻞ اوﻟﻴﻪ ﻃﺮاﺣﻲ ﻋـﺎﻳﻖ ﻛـﺮدن ﻣـﻮرد.ﺑﺎﺷﺪ

.ﻧﻈﺮ ﺑﺮﻗﻲ ﺑﺎ ﺣﺪاﻗﻞ ﻋﺎﻳﻖ ﻧﻤﻮدن دﻣﺎﻳﻲ اﺳﺖ

Principal factors in resistance thermometer bulb

design include:

ﻋﻮاﻣﻞ اﺳﺎﺳﻲ در ﻃﺮاﺣﻲ ﺗﺮﻣﻮﻣﺘﺮ ﻣﻘﺎوﻣﺘﻲ ﺣﺒﺎﺑﻲ از اﻳـﻦ ﻗـﺮار

:ﻫﺴﺘﻨﺪ

ﺷﻜﻞ-1

اﻧﺪازه-2

ﻣﻮاد اﺳﺘﻔﺎده ﺷﺪه در ﺳﻴﻢ ﭘﻴﭻ ﻣﻘﺎوﻣﺘﻲ-3

ﻋﺎﻳﻖ ﺳﻴﻢ ﭘﻴﭻ-4

ﻧﻮع ﺳﻴﻢ ﭘﻴﭻ-5

1. Shape

2. Size

3. Material used in resistance winding

4. Insulation of the winding

5. Type of winding.

ﻋﻤﻮﻣﻲ-5

5. GENERAL

5.1 All field mounted instruments shall be located

so that they are readable from the point of

operation. Mounting shall be free from vibration

and be accessible for maintenance and services.

ﻛﻠﻴﻪ اﺑﺰار دﻗﻴﻖ ﻣﺤﻮﻃﻪ ﺑﺎﻳﺪ ﺑـﻪ ﻧﺤـﻮي ﻗـﺮار ﮔﻴﺮﻧـﺪ ﻛـﻪ از1-5

5.2 Temperature instruments (such as local

controllers and transmitters) shall not be supported

by the instrument. Adequate independent supports

shall be provided for every instrument process

piping.

اﺑـﺰار دﻗﻴﻖ دﻣﺎ )ﻣﺎﻧﻨﺪ ﻛﻨﺘﺮل ﻛﻨﻨﺪه ﻫــﺎ و ﻓﺮﺳﺘﻨﺪه ﻫـﺎي2-5

5.3 All supports shall not obstruct the footpaths,

vision or access to any item of equipment.

، ﻧﮕﻬﺪارﻧﺪه ﻫـﺎي اﺑـﺰار دﻗﻴـﻖ ﻧﺒﺎﻳـﺪ ﻣـﺎﻧﻌﻲ ﺑـﺮاي ﻋﺒـﻮر3-5

5.4

Instruments

and

instrument

cables,

ducting/conduits shall be installed rigidly and

absolutely normal to the vertical or the horizontal

plane as required, unless otherwise specified.

ﻛﺎﻧـﺪوﻳﺖ ﺑﺎﻳـﺪ، ﻛﺎﻧـﺎل، اﺑﺰار دﻗﻴﻖ و ﻛﺎﺑﻞ ﻫﺎي اﺑﺰار دﻗﻴﻖ4-5

5.5 Installations for which detailed project drawing

and sketches are not supplied shall conform to the

user standard hook-up drawing where applicable if

the hook-up drawings are not applicable, the

installation shall conform to a high engineering

standard and good workmanship to the satisfaction

of the engineer.

ﺑﺮاي ﻧﺼﺐ دﺳﺘﮕﺎﻫﻬﺎﻳﻲ ﻛﻪ ﻧﻘﺸﻪ ﺟﺰﺋﻴﺎت ﻳﺎ ﺷﻜﻠﻲ ﺑـﺮاي5-5

5.6 Transmission systems and inst. piping shall not

introduce obstacles preventing access to the

ﺳﺎﻣﺎﻧﻪ اﻧﺘﻘﺎل و ﻟﻮﻟﻪ ﻛﺸﻲ اﺑﺰار دﻗﻴﻖ ﻧﺒﺎﻳﺪ ﻣﺎﻧﻊ دﺳﺘﺮﺳﻲ6-5

ﻣﺤﻞ ﻧﺼﺐ دﺳﺘﮕﺎه ﺑﺎﻳﺪ ﻋﺎري.ﻣﺤﻞ ﻋﻤﻠﻴﺎت ﻗﺎﺑﻞ ﺧﻮاﻧﺪن ﺑﺎﺷﻨﺪ

.از ارﺗﻌﺎﺷﺎت ﺑﻮده و ﺑﺮاي ﺗﻌﻤﻴﺮات و ﺧﺪﻣﺎت در دﺳﺘﺮس ﺑﺎﺷﺪ

ﻣﺤﻠﻲ( ﻧﺒﺎﻳﺪ ﺗﻮﺳﻂ ﻟﻮﻟﻪ ﻛﺸﻲ ﻓﺮآﻳﻨـﺪي اﺑـﺰار دﻗﻴـﻖ ﻧﮕﻬﺪاﺷـﺘﻪ

ﻧﮕﻬﺪارﻧﺪه ﻣﺴﺘﻘﻞ در ﻧﻈـﺮ ﮔﺮﻓﺘـﻪ، ﺑﺎﻳﺪ ﺑﺮاي ﻫﺮ اﺑﺰار دﻗﻴﻖ.ﺷﻮد

.ﺷﻮد

.دﺳﺘﺮﺳﻲ ﻳﺎ دﻳﺪ ﺑﻪ ﻫﺮ ﻗﺴﻤﺖ از دﺳﺘﮕﺎه ﺑﺎﺷﻨﺪ

ﻣﮕﺮ اﻳﻦ،ﺑﻄﻮر ﻣﺤﻜﻢ و در ﺻﻔﺤﺎت ﻋﻤﻮدي ﻳﺎ اﻓﻘﻲ ﻧﺼﺐ ﮔﺮدﻧﺪ

.ﻛﻪ ﻃﻮر دﻳﮕﺮي ﻣﺸﺨﺺ ﺷﺪه ﺑﺎﺷﺪ

آﻧﻬﺎ اراﺋﻪ ﻧﺸﺪه اﺳﺖ ﺑﻪ ﻧﻘﺸﻪ ﻫﺎي اﺳﺘﺎﻧﺪارد ﻣﺮﺑﻮﻃـﻪ ﻛـﻪ ﻗﺎﺑـﻞ

درﺻـﻮرت ﻋـﺪم ﻛـﺎرﺑﺮي.ﻗﺒﻮل ﺑﻬـﺮهﺑـﺮدار اﺳـﺖ رﺟـﻮع ﺷـﻮد

ﻧﻘﺸﻪﻫﺎي ﻣﺬﻛﻮر ﺑﺎﻳﺪ ﻧﺼﺐ ﻃﺒﻖ اﺳـﺘﺎﻧﺪارد ﺑـﺎﻻي ﻣﻬﻨﺪﺳـﻲ و

.ﺳﺎﺧﺖ ﺧﻮب ﺑﺎ رﺿﺎﻳﺖ ﻣﻬﻨﺪس ﻣﺮﺑﻮﻃﻪ اﻧﺠﺎم ﮔﻴﺮد

5

Mar. 2009/ 1388 ﻓﺮوردﻳﻦ

instruments. etc.

IPS-C-IN-120(1)

.و اﻳﺠﺎد اِﺷﻜﺎل ﺑﻪ ادوات اﺑﺰار دﻗﻴﻖ و ﻏﻴﺮه ﮔﺮدد

5.7 Electrical wiring shall be carried out in

accordance with standard electrical construction

specification. Electrical instruments, fittings, etc.

shall comply with the area requirements of IP

(Ingress Protection), and safety code for electrical

installations.

ﺳﻴﻢ ﻛﺸﻲ ﺑﺮﻗﻲ ﺑﺎﻳﺪ ﻣﻄﺎﺑﻖ ﻣﺸﺨـﺼﺎت ﻓﻨـﻲ اﺳـﺘﺎﻧﺪارد7-5

5.8 Installation of electrical/electronic instruments

associated with temperature devices shall strictly

conform to the manufacturerُs instructions and to

the satisfaction of the engineer.

اﻟﻜﺘﺮوﻧﻴﻜـﻲ ﻣـﺮﺗﺒﻂ ﺑـﺎ/ ﻧﺼﺐ ادوات اﺑﺰار دﻗﻴـﻖ ﺑﺮﻗـﻲ8-5

5.9 No electric welding will be permitted on

existing instrument panels containing electrical

instruments. Any cut outs, brackets etc. shall be

cold cut, drilled or bolted as applicable.

ﻫﻴﭻ ﻧﻮع ﺟﻮﺷﻜﺎري ﺑﺮﻗﻲ در ﺗﺎﺑﻠﻮﻫﺎي اﺑﺰار دﻗﻴﻖ ﺷـﺎﻣﻞ9-5

5.10 All instrument control and/or alarm wiring

shall be tested for continuity and resistance with

respect to ground in accordance with standard

electrical

construction

specifications.

See

IPS-C-IN-240(1) par 9.3.2.1 for ground continuity.

ﻳﺎ ﻫﺸﺪار/ ﻛﻠﻴﻪ ﺳﻴﻢ ﻛﺸﻲ ﻫﺎي ﻛﻨﺘﺮل اﺑﺰار دﻗﻴﻖ و10-5

، ﻧـﺼﺐ ادوات اﺑـﺰار دﻗﻴـﻖ ﺑﺮﻗـﻲ.ﻧﺼﺐ ﺗﺠﻬﻴﺰات ﺑﺮﻗـﻲ ﺑﺎﺷـﺪ

IP اﺗﺼﺎﻻت و ﻏﻴﺮه ﺑﺎﻳﺪ ﻣﻄﺎﺑﻖ اﻟﺰاﻣﺎت ﻣﺤﻮﻃﻪ ﻛﺎري از ﻧﻈﺮ ﻛﺪ

.و اﻳﻤﻨﻲ ﺑﺎﺷﻨﺪ

ادوات دﻣﺎ ﺑﺎﻳﺪ دﻗﻴﻘﺎً ﻣﻄﺎﺑﻖ ﺑﺎ دﺳـﺘﻮراﻟﻌﻤﻞ ﺳـﺎزﻧﺪه و رﺿـﺎﻳﺖ

.ﻣﻬﻨﺪس ﺑﺎﺷﺪ

ﭘﺎﻳـﻪ ﻧﮕﻬﺪارﻧـﺪه و، ﻫﺮ ﺑـﺮش.اﺑﺰار دﻗﻴﻖ ﺑﺮﻗﻲ ﻣﺠﺎز ﻧﻤﻲ ﺑﺎﺷﺪ

ﻏﻴﺮه ﺑﺴﺘﻪ ﺑﻪ ﻛﺎرﺑﺮد ﺑﺎﻳﺪ ﺑﺮش ﺳﺮد داده ﺷﻮد ﻳﺎ ﺳﻮراخ و ﭘـﻴﭻ

.ﺷﻮﻧﺪ

دﻫﻨﺪه ﻫﺎ ﺑﺎﻳﺪ ﻣﻄﺎﺑﻖ ﺑﺎ ﻣﺸﺨﺼﺎت ﻓﻨﻲ اﺳﺘﺎﻧﺪارد ﻧﺼﺐ

آزﻣﺎﻳﺶ ﭘﻴﻮﺳﺘﮕﻲ و ﻣﻘﺎوﻣﺖ ﻧﺴﺒﺖ ﺑﻪ زﻣﻴﻦ،ﺗﺠﻬﻴﺰات ﺑﺮﻗﻲ

ﺟﻬﺖ آزﻣﺎﻳﺶ ﭘﻴﻮﺳﺘﮕﻲ و ﻣﻘﺎوﻣﺖ ﻧﺴﺒﺖ ﺑﻪ زﻣﻴﻦ ﺑﻪ.ﺷﻮﻧﺪ

. ﻣﺮاﺟﻌﻪ ﺷﻮدIPS-C-IN-240(1) اﺳﺘﺎﻧﺪارد1-2-3-9 ﺑﻨﺪ

ﻟﻮﻟﻪﻫﺎي ﻣﻮﺋﻴﻦ و، ﺑﺮاي اﻃﻤﻴﻨﺎن از اﺗﺼﺎل ﺻﺤﻴﺢ ﺳﻴﻢﻫﺎ11-5

5.11 A functional check out shall be made on

systems to ensure that the correct wires,

capillaries, etc., are connected to the correct

terminals.

ﻏﻴﺮه ﺑﻪ ﺗﺮﻣﻴﻨﺎﻟﻬﺎي ﻣﺮﺑﻮﻃﻪ ﺑﺎﻳـﺪ ﻳـﻚ ﺑﺮرﺳـﻲ ﻋﻤﻠﻜـﺮدي روي

.ﺳﺎﻣﺎﻧﻪ اﻧﺠﺎم ﺷﻮد

دﻣﺎﺳﻨﺞ ﻫﺎي ﭘﺮﺷﺪه و ﻋﻘﺮﺑﻪاي دو ﻓﻠﺰي-6

6. FILLED SYSTEM AND BIMETALLIC

DIAL THERMOMETERS

ﻻزم اﺳـﺖ، در ﻧﺼﺐ ﻛﻠﻴﻪ ادوات ﺣﺮارﺗﻲ دﻣﺎﺳﻨﺞ ﭘﺮ ﺷﺪه1-6

6.1 In all installations of filled-system temperature

instruments, it is necessary to protect the bulb and

capillary tubing from mechanical damage.

.ﻛﻪ ﻣﺤﻔﻈﻪ و ﻟﻮﻟﻪ ﻣﻮﺋﻴﻦ از ﺻﺪﻣﺎت ﻣﻜـﺎﻧﻴﻜﻲ ﻣﺤﺎﻓﻈـﺖ ﺷـﻮد

ﻻزم اﺳﺖ ﻛﻪ از ﻟﻮﻟﻪ ﻣﻮﺋﻲ زره دار )ﻣـﺴﻠﺢ( اﺳﺘﻔـــﺎده ﺷـﺪه و

ﻟﻮﻟﻪ ﻛﺸﻲ ﺑﻴﻦ ﺣﺒﺎب و ﻛﻨﺘـﺮل ﻛﻨﻨـﺪه ﻳـﺎ ﻓﺮﺳـﺘﻨﺪه را ﺗﻮﺳـﻂ

ﻟﻮﻟﻪ ﻣﻮﺋﻲ ﻧﺒﺎﻳﺪ ﺑﻪ.ﻧﮕﻬﺪارﻧﺪه از ﺻﺪﻣﺎت اﺣﺘﻤﺎﻟﻲ ﻣﺤﻔﻮظ ﻧﻤﻮد

. ﺑﺎز ﻳﺎ ﻓﺸﺮده ﺷﻮد،ﻫﻴﭻ ﻧﺤﻮ ﺑﺮﻳﺪه

It is required to use armored capillary tubing and

to support the tubing run between the bulb and

controller or transmitter to protect it from

accidental damage. The capillary tubing should not

be cut, opened, or pinched in any manner.

6.2 Instrument work starts from the installation of

the thermowell and includes the running of the

capillary tubing and the mounting of the

instrument. The capillary tubing shall be

adequately supported and clamped.

ﻛﺎر اﺑﺰار دﻗﻴـﻖ از ﻧـﺼﺐ ﭼﺎﻫـﻚ ﺣﺮارﺗـﻲ ﺷـﺮوع ﺷـﺪه و2-6

6.3 The element of thermometers shall be installed

in thermowells, unless other wise specified.

ﻣﮕﺮ، اﻟﻤﺎن دﻣﺎﺳﻨﺞ ﻫﺎ ﺑﺎﻳﺪ در ﭼﺎﻫﻚ ﺣﺮارﺗﻲ ﻧﺼﺐ ﺷﻮد3-6

6.4 Care should be taken to ensure the readability

of the dial from a convenient location. Some times

an adjustable type at various angles may be

recommended.

ﺑﺎﻳﺪ اﻃﻤﻴﻨﺎن ﺣﺎﺻﻞ ﮔﺮدد ﻛﻪ ﺻـﻔﺤﻪ از ﻣﺤـﻞ ﻣﻨﺎﺳـﺒﻲ4-6

ﻟﻮﻟـﻪ ﻣـﻮﺋﻲ. ﺷﺎﻣﻞ ﻛﺸﻴﺪن ﻟﻮﻟﻪ ﻣﻮﺋﻲ و ﻧﺼﺐ اﺑﺰار دﻗﻴﻖ اﺳﺖ

.ﺑﺎﻳﺪ ﺑﻪ اﻧﺪازه ﻛﺎﻓﻲ ﻧﮕﻬﺪاﺷﺘﻪ ﺷﺪه و ﺑﺴﺖ زده ﺷﻮد

.اﻳﻨﻜﻪ ﺑﻪ ﻧﺤﻮ دﻳﮕﺮي ﺧﻮاﺳﺘﻪ ﺷﺪه ﺑﺎﺷﺪ

در ﺑﻌﻀﻲ ﻣﻮاﻗﻊ ﻧﻮع ﻗﺎﺑﻞ ﺗﻨﻈﻴﻢ در زواﻳـﺎي.ﻗﺎﺑﻞ ﺧﻮاﻧﺪن ﺑﺎﺷﺪ

.ﻣﺨﺘﻠﻒ ﻣﻤﻜﻦ اﺳﺖ ﺗﻮﺻﻴﻪ ﮔﺮدد

6

Mar. 2009/ 1388 ﻓﺮوردﻳﻦ

IPS-C-IN-120(1)

6.5 Bimetallic thermometers are used for

indicating or recording. Bimetallic thermometer

has a bimetal bulb and a protective sheet.

Differential thermal expansion of metals cause a

bimetal coil rotation, and therefore, a pointer

attached rotates on a linear scale. Depending on

the type of fluid, the immersion length and

installation methods will vary and the ranges can

also vary from -130 to 540°C (-200 to 1000°F).

For further details refer to ASME PTC 19.3,

chapt.8.

دﻣﺎﺳﻨﺞ ﻫﺎي دو ﻓﻠـﺰي ﺑـﺮاي ﻧـﺸﺎن دادن ﻳـﺎ ﺛﺒـﺖ ﻛـﺮدن5-6

7. RESISTANCE AND THERMOCOUPLE

TEMPERATURE MEASUREMENTS

اﻧﺪازه ﮔﻴﺮي دﻣﺎ ﺑﺎ ﻣﻘﺎوﻣﺖ و ﺗﺮﻣﻮﻛﻮﭘﻞ-7

دﻣﺎﺳﻨﺞ دو ﻓﻠﺰي داراي ﻣﺤﻔﻈﻪ و ﻳﻚ روﻛـﺶ.اﺳﺘﻔﺎده ﻣﻲ ﺷﻮﻧﺪ

اﻧﺒﺴﺎط ﺣﺮارﺗﻲ ﻣﺘﻔﺎوت ﻓﻠﺰﻫـﺎ ﺑﺎﻋـﺚ ﭼـﺮﺧﺶ.ﻣﺤﺎﻓﻆ ﻣﻲ ﺑﺎﺷﺪ

ﻣﻲﺷﻮد و ﺑﻨﺎﺑﺮاﻳﻦ ﻳﻚ ﻋﻘﺮﺑﻪ روي ﻳﻚ ﻣﻘﻴﺎس ﺧﻄﻲ ﺑﻪ ﭼـﺮﺧﺶ

ﺑﺮاﺳﺎس ﻧﻮع ﺳﻴﺎل ﻃﻮل ﻓﺮو رﻓﺘﻦ و روﺷـﻬﺎي ﻧـﺼﺐ. در ﻣﻲ آﻳﺪ

درﺟـﻪ540 ﺗـﺎ-130 ﻣﺘﻔﺎوت اﺳﺖ و ﻣﺤﺪوده ﻛـﺎري آن ﻧﻴـﺰ از

درﺟـﻪ ﻓﺎرﻧﻬﺎﻳـﺖ( ﻣـﻲﺗﻮاﻧـﺪ ﺗﻐﻴﻴـﺮ1000 ﺗـﺎ-200) ﺳﺎﻧﺘﻴﮕﺮاد

ASME PTC 19.3 ﺟﻬﺖ ﺟﺰﺋﻴﺎت ﺑﻴﺸﺘﺮ ﺑـﻪ اﺳـﺘﺎﻧﺪارد. ﻧﻤﺎﻳﺪ

. ﻣﺮاﺟﻌﻪ ﺷﻮد8 ﻓﺼﻞ

ﻫـﺎ ﺑﺎﻳـﺪ در ﭼﺎﻫـﻚRTD اﻟﻤﺎن ﻫـﺎي ﺗﺮﻣﻮﻛﻮﭘـﻞ ﻫـﺎ و1-7

7.1 Thermocouple elements and RTDs shall be

installed in thermowells.

.ﺣﺮارﺗﻲ ﻧﺼﺐ ﺷﻮﻧﺪ

7.2 Electrical measuring and control signal lines

shall not run in the same conduit or trench with

electrical power lines.

ﺧﻄﻮط اﻧﺪازه ﮔﻴـﺮي ﺑﺮﻗـﻲ و ﺳـﻴﮕﻨﺎل ﻛﻨﺘـﺮل ﻧﺒﺎﻳـﺪ در2-7

7.3 Precautions and practices encountered using

thermocouples

also

apply

to resistance

temperature devices with two exceptions,

applicable to RTD only:

ﻣﻼﺣﻈﺎت و اﻗﺪاﻣﺎت ﺑﻜﺎر رﻓﺘﻪ در ﺟﻬﺖ اﺳﺘﻔﺎده از3-7

ﻫﻤﺎن ﻛﺎﻧﺪوﻳﺖ ﻳﺎ ﺗﺮاﻧﺸﻪ اي ﻛﻪ ﺧﻄﻮط ﺗﻐﺬﻳﻪ ﺑﺮق در آن وﺟﻮد

.دارد ﻛﺸﻴﺪه ﺷﻮﻧﺪ

. ﻫﻢ ﺑﻜﺎر ﻣﻲ روﻧﺪRTD ﺗﺮﻣﻮﻛﻮﭘﻞﻫﺎ ﺑﺎ دو اﺳﺘﺜﻨﺎء در ﻣﻮرد

اﻟﻒ( از ﺳﻴﻢ ﻣﻌﻤﻮﻟﻲ ﻣﺴﻲ ﺑﺮاي اﺗﺼﺎل وﺳﻴﻠﻪ ﻗﺮاﺋﺖ ﮔﺮ ﺑﻪ

a) Ordinary copper wire is used to connect the

readout device to the sensor. For three wire

system the most commonly used configuration

provides one wire connection to one end and a

two-wire connection to the other end of the

sensor. This compensates for resistance and

temperature change in the lead wire.

ﺑﺮاي ﺳﺎﻣﺎﻧﻪ ﻫﺎي ﺳﻪ ﺳﻴﻤﻪ در.ﺣﺲ ﮔﺮ اﺳﺘﻔﺎده ﻣﻲ ﺷﻮد

ﻳﻚ ﺳﻴﻢ را ﺑﻪ ﻳﻚ اﻧﺘﻬﺎ دو ﺳﻴﻢ، ﻣﻌﻤﻮﻟﻲ ﺗﺮﻳﻦ ﭘﻴﻜﺮ ﺑﻨﺪي

اﻳﻦ ﻋﻤﻞ.دﻳﮕﺮ را ﺑﻪ اﻧﺘﻬﺎي دﻳﮕﺮ ﺣﺲ ﮔﺮ ﻣﺘﺼﻞ ﻣﻲﻧﻤﺎﻳﻨﺪ

.ﺑﺎﻋﺚ ﺟﺒﺮان ﺗﻐﻴﻴﺮات ﻣﻘﺎوﻣﺖ و دﻣﺎ درﺳﻴﻢ راﺑﻂ ﻣﻲ ﮔﺮدد

b) The reading is absolute, so a reference

junction is not needed. Elements are available

conforming to one of two curves, European R =

0.00385

ohms/ohm/degree

Celsius,

or

American R = 0.00392 ohms/ohm/degree

Celsius. Both curves are based on a sensing

element resistance of 100 ohms at 0 degree

Celsius. (pt 100)

ﺑﻨﺎﺑﺮاﻳﻦ ﺑﻪ ﻳﻚ اﺗﺼﺎل ﻣﺮﺟﻊ اﺣﺘﻴﺎج،ب( ﻗﺮاﺋﺖ ﻣﻄﻠﻖ اﺳﺖ

اﻟﻤـﺎن ﻫـﺎي در دﺳـﺘﺮس ﺑـﺎ ﻳﻜـﻲ از دو ﻣﻨﺤﻨـﻲ.ﻧﻤﻲﺑﺎﺷﺪ

درﺟـﻪ/اﻫـﻢ/ اﻫﻢﻫـﺎ، اروﭘﺎﺋﻲR=0.00385 ، ﻣﻄﺎﺑﻘﺖ دارﻧﺪ

درﺟـﻪ/اﻫـﻢ/ اﻫﻢﻫـﺎ، آﻣﺮﻳﻜﺎﺋﻲR=0.00392 ﻳﺎ، ﺳﺎﻧﺘﻴﮕﺮاد

ﻫﺮ دو ﻣﻨﺤﻨﻲ ﺑﺮ اﺳﺎس اﻟﻤﺎن ﺣﺴﻲ ﺑـﺎ ﻣﻘﺎوﻣـﺖ.ﺳﺎﻧﺘﻴﮕﺮاد

.( ﻣﻲ ﺑﺎﺷﻨﺪPT 100) اﻫﻢ در ﺻﻔﺮ درﺟﻪ ﺳﺎﻧﺘﻴﮕﺮاد100

ﺳﻴﻢﻫﺎي راﺑﻂ ﺗﻜﻲ )ﻣﻌﻤﻮﻻً ﺳﻪ ﺳﻴﻢ( از اﻟﻤﺎن ﻣﻘﺎوﻣﺘﻲ4-7

7.4 Individual extension wires (usually three) from

the resistance element may terminate in a

connection head or in a quick disconnect fitting or

extend directly to the measuring unit. Generally, a

connection head is employed and the wires are

frequently run in a three-wire cable to the boardmounted resistance temperature measuring

instrument. The wire normally used is minimally

0.75 mm2 stranded copper. Where multiple

installations of resistance elements are used, the

wires can be run to a field terminal strip. A

ﻳﺎ،ﻣﻤﻜﻦ اﺳﺖ ﺑﻪ ﻳﻚ ﻛﻼﻫﻚ ﻳﺎ ﻳﻚ اﺗﺼﺎل ﻗﻄﻊ ﺳﺮﻳﻊ

ﻣﻌﻤﻮﻻً از ﻳﻚ.ﻣﺴﺘﻘﻴﻤﺎً ﺑﻪ واﺣﺪ اﻧﺪازه ﮔﻴﺮي ﻣﺘﺼﻞ ﺷﻮﻧﺪ

ﻛﻼﻫﻚ اﺳﺘﻔﺎده ﺷﺪه و ﺳﻴﻢﻫﺎ در ﻳﻚ ﻛﺎﺑﻞ ﺳﻪ ﺳﻴﻤﻪ ﺑﻪ اﺑﺰار

دﻗﻴﻖ اﻧﺪازه ﮔﻴﺮي دﻣﺎي ﻣﻘﺎوﻣﺘﻲ ﻧﺼﺐ ﺷﺪه در ﺗﺎﺑﻠﻮ ﺑﺮده

ﺳﻴﻢ ﻣﻮرد اﺳﺘﻔﺎده ﻣﻌﻤﻮﻻً ﺳﻴﻢ ﻣﺴﻲ اﻓﺸﺎن ﺑﺎ ﺳﻄﺢ.ﻣﻲﺷﻮﻧﺪ

در ﺟﺎﻫﺎﻳﻲ ﻛﻪ. ﻣﻴﻠﻴﻤﺘﺮ ﻣﺮﺑﻊ ﻣﻲﺑﺎﺷﺪ0/75 ﻣﻘﻄﻊ ﺣﺪاﻗﻞ

ﺳﻴﻢﻫﺎ را ﻣﻲﺗﻮان ﺑﻪ، اﻟﻤﺎﻧﻬﺎي ﻣﻘﺎوﻣﺘﻲ ﻣﺘﻌﺪدي وﺟﻮد دارﻧﺪ

7

Mar. 2009/ 1388 ﻓﺮوردﻳﻦ

IPS-C-IN-120(1)

multiconductor cable is then used to bring the

signals into the control panel. The wire in the

multiconductor cable may be 0.75mm2, however,

for long distances, a check should be made with the

manufacturer on allowable wire resistance.

Generally, no problem exists up to 1.6 kilometers.

Special attention needs to be directed at

maintaining a minimal number of junctions or

terminations in the extension wire. Installation

practices

as

outlined

in

IPS-C-IN-190

“Transmission Systems” should be followed.

ﺳﭙﺲ از ﻳﻚ ﻛﺎﺑﻞ ﭼﻨﺪ ﺳﻴﻤﻪ. ﺷﺎﻧﻪﻫﺎي ﭘﺎﻳﺎﻧﻪ ﻣﺤﻮﻃﻪ ﺑﺮد

ﺳﻴﻢ.ﺑﺮاي آوردن ﺳﻴﮕﻨﺎلﻫﺎ ﺑﻪ ﺗﺎﺑﻠﻮي ﻛﻨﺘﺮل اﺳﺘﻔﺎده ﺷﻮد

ﻣﻴﻠﻴﻤﺘﺮ ﻣﺮﺑﻊ0/75 داﺧﻞ ﻳﻚ ﻛﺎﺑﻞ ﭼﻨﺪ ﺳﻴﻤﻪ ﻣﻤﻜﻦ اﺳﺖ

ﻣﻘﺎوﻣﺖ ﻣﺠﺎز ﺳﻴﻢ ﺑﺎﻳﺪ، ﺑﻨﺎﺑﺮاﻳﻦ ﺟﻬﺖ ﻣﺴﺎﻓﺖ ﻃﻮﻻﻧﻲ،ﺑﺎﺷﺪ

ﻛﻴﻠﻮﻣﺘﺮي ﻣﺴﺌﻠﻪاي1/6 ﻋﻤﻮﻣﺎً ﺗﺎ.ﺑﺎ ﺳﺎزﻧﺪه ﻛﺎﺑﻞ ﺑﺮرﺳﻲ ﮔﺮدد

ﺑﺮاي داﺷﺘﻦ ﺣﺪاﻗﻞ ﺗﻌﺪاد اﺗﺼﺎل ﻳﺎ ﺳﺮ ﺑﻨﺪي در.وﺟﻮد ﻧﺪارد

روشﻫﺎي ﻧﺼﺐ ﺑﺎﻳﺪ ﺑﺮ اﺳﺎس. دﻗﺖ وﻳﮋه ﻻزم اﺳﺖ، ﺳﻴﻢ راﺑﻂ

. »ﺳﺎﻣﺎﻧﻪ ﻫﺎي اﻧﺘﻘﺎل« ﺑﺎﺷﺪIPS-C-IN-190 اﺳﺘﺎﻧﺪارد

7.5 To minimize temperature lags (response time),

it is essential that the thermocouple be in contact

with the bottom of the well.

ﻻزم اﺳﺖ ﻛﻪ، ( ﺑﺮاي ﺗﻘﻠﻴﻞ ﺗﺎﺧﻴﺮ زﻣﺎﻧﻲ دﻣﺎ )زﻣﺎن ﭘﺎﺳﺦ5-7

7.6 The correct type of extension wires for the

particular thermocouple must be used in

connecting the thermocouple to the instrument.

ﺑﺮاي اﺗﺼﺎل ﺗﺮﻣﻮﻛﻮﭘﻞ ﺧﺎص ﺑﻪ اﺑـﺰار دﻗﻴـﻖ ﺑﺎﻳـﺪ از ﻧـﻮع6-7

7.7 Metal-sheathed, mineral-insulated thermocouples where applicable such as fire boxes or

furnaces are sometimes installed with the

thermocouple head separated from the thermowell.

An example of this type of installation is shown in

Fig. 1.

ﺑﺮاي ﻧﺼﺐ ﺗﺮﻣﻮﻛﻮﭘﻞﻫﺎي ﺑﺎ ﻏﻼف ﻓﻠـﺰي و ﻋـﺎﻳﻖ ﻣﻌـﺪﻧﻲ7-7

. ﺗﺮﻣﻮﻛﻮﭘﻞ در ﺗﻤﺎس ﺑﺎ ﺗﻪ ﭼﺎﻫﻚ ﺑﺎﺷﺪ

.درﺳﺖ ﺳﻴﻢ ﻫﺎي راﺑﻂ اﺳﺘﻔﺎده ﺷﻮد

در،ﺷﺪه در ﺟﺎﻫﺎي ﻣﻮرد اﺳﺘﻔﺎده ﻣﺎﻧﻨﺪ آﺗـﺸﺪاﻧﻬﺎ ﻳـﺎ ﻛـﻮره ﻫـﺎ

.ﺑﻌﻀﻲ ﻣﻮاﻗﻊ ﺳﺮ ﺗﺮﻣﻮﻛﻮﭘﻞ از ﭼﺎﻫﻚ ﺣﺮارﺗﻲ ﺟـﺪا ﺷـﺪه اﺳـﺖ

.ﻳﻚ ﻣﺜﺎل اﻳﻦ ﻧﻮع در ﺷﻜﻞ ﺷﻤﺎره ﻳﻚ ﻧﺸﺎن داده ﺷﺪه اﺳﺖ

ﻛﺎرﺑﺮدﻫﺎﻳﻲ وﺟﻮد دارﻧﺪ ﻛﻪ ﺗﺮﻣﻮﻛﻮﭘﻞ ﻫﺎي ﺑﺎ ﻏﻼف ﻓﻠﺰي8-7

7.8 There are applications where metal-sheathed,

mineral insulated thermocouples are sometimes

installed as bare elements without thermowells,

usually to obtain better speed of response. Where

thermocouples are installed without the use of

thermowells, special wiring tags of a distinct color

and durable material are usually attached as a

warning to maintenance personnel. An example of

this type of installation is shown in Fig. 2.

و ﻋﺎﻳﻖ ﻣﻌﺪﻧﻲ ﺷﺪه در ﺑﻌﻀﻲ ﻣﻮاﻗﻊ ﺑﺼﻮرت اﻟﻤﺎن ﻟﺨـﺖ ﺑـﺪون

ﭼﺎﻫﻚ ﺣﺮارﺗﻲ ﻧﺼﺐ ﺷﺪهاﻧﺪ ﻛـﻪ ﻣﻌﻤـﻮﻻً ﺑـﺮاي ﺑﺪﺳـﺖ آوردن

در ﺟﺎﻫـﺎﻳﻲ ﻛـﻪ ﺗﺮﻣﻮﻛﻮﭘـﻞ ﻫـﺎ ﺑـﺪون.ﺳﺮﻋﺖ ﺑﻬﺘﺮ ﭘﺎﺳﺦ اﺳﺖ

ﻣﻌﻤـﻮﻻً ﺑﺮﭼـﺴﺐ ﻫـﺎي اﺧﻄـﺎر،ﭼﺎﻫﻚ ﺣﺮارﺗﻲ ﻧﺼﺐ ﺷﺪه اﻧـﺪ

ﻣﺨﺼﻮص ﺑﺎ رﻧﮓ ﻣﺸﺨﺺ از ﺟﻨﺲ ﺑﺎ دوام زده ﺷﺪه اﻧﺪ ﺗﺎ اﻋﻼم

ﻳﻚ ﻣﺜﺎل از اﻳﻦ ﻧﻮع ﻧﺼﺐ.ﺧﻄﺮي ﺑﺮاي ﭘﺮﺳﻨﻞ ﺗﻌﻤﻴﺮاﺗﻲ ﺑﺎﺷﺪ

. ﻧﺸﺎن داده ﺷﺪه اﺳﺖ2 در ﺷﻜﻞ ﺷﻤﺎره

ﺗﺮﻣﻮﻛﻮﭘﻞﻫﺎي ﺑﺎ ﻏﻼف ﻓﻠﺰي ﻋﻤﺮ زﻳﺎدﺗﺮي دارﻧﺪ و در دراز9-7

7.9 Metal-sheathed thermocouples provide longer

life and improved long-term accuracy when

compared to bare wire thermocouples. Metalsheathed thermocouples have generally been more

satisfactory in applications requiring long

installation lengths, such as in reactors.

ﻣﺪت در ﻣﻘﺎﻳﺴﻪ ﺑﺎ ﺗﺮﻣﻮﻛﻮﭘﻞ ﻫﺎي از ﻧﻮع ﺳﻴﻢ ﻟﺨﺖ داراي دﻗﺖ

، در ﻛﺎرﺑﺮدﻫﺎي ﺑﺎ ﻃﻮل زﻳـﺎد ﻫﻤﺎﻧﻨـﺪ رآﻛﺘﻮرﻫـﺎ.ﺑﻬﺘﺮي ﻫﺴﺘﻨﺪ

.ﻣﻌﻤﻮﻻً اﻳﻦ ﺗﺮﻣﻮﻛﻮﭘﻞ ﻫﺎ رﺿﺎﻳﺖ ﺑﺨﺶ ﺗﺮ ﺑﻮده اﻧﺪ

8

)IPS-C-IN-120(1

ﻓﺮوردﻳﻦ Mar. 2009/ 1388

ﺑﻪ ﻳﺎدآوري ﻣﺮاﺟﻌﻪ ﺷﻮد

ﻛﻼﻫﻚ ﺑﺮاي ﺗﺮﻣﻮﻛﻮﭘﻞ

ﺗﻚ اﻟﻤﺎﻧﻲ

ﭼﺎﻫﻚ ﺣﺮارﺗﻲ

ﺑﻮش

اﺗﺼﺎل ﻟﻮﻟﻪ

ﻛﺎﻧﺪوﻳﺖ

آب ﺑﻨﺪي

)ﺣﺪاﻗﻞ 3اﻳﻨﭻ (

ﺑﻮش ﻛﺮﻧﺶﮔﻴﺮ ﻻﺳﺘﻴﻜﻲ

THERMOCOUPLE

ﻏﻼف ﻣﺴﻠﺢ اﻧﻌﻄﺎف ﭘﺬﻳﺮ ﺑﻠﻨﺪ ﻫﻤﺮاه ﺑﺎ ﺗﺮﻣﻮﻛﻮﭘﻞ

Fig. 1 - SHEATHED-TYPE THERMOCOUPLE AND HEAD ASSEMBLY

ﺷﻜﻞ - 1ﺗﺮﻣﻮﻛﻮﭘﻞ ﻧﻮع ﻏﻼفدار و ﻣﺠﻤﻮﻋﻪ ﻛﻼﻫﻚ

ﻳﺎدآوري:

Note:

اﺗﺼﺎﻻت ﻟﻮﻟﻪ رزوه رو ﺑﺮاي ﻋﺒﻮر دادن ﻣﻲﺑﺎﺷﺪ .ﻣﻐﺰي و ﻣﻬﺮه

را ﻧﺼﺐ ﻧﻤﻮده و ﺗﺮﻣﻮﻛﻮﭘﻞ را ﺑﻪ ﺗﻪ ﭼﺎﻫﻚ ﻓﺸﺎر داده ﻣﻬﺮه ﻟﻮﻟﻪ

را ﺳﻔﺖ ﻛﻨﻴﺪ ﺗﺎ ﺗﺮﻣﻮﻛﻮﭘﻞ در ﭼﺎﻫﻚ ﻣﺤﻜﻢ ﻧﮕﻬﺪاﺷﺘﻪ ﺷﻮد.

Male tubing fitting for thermocouple to pass

through. Install ferrule and nut and push couple to

bottom of well then tighten tubing nut to secure

thermocouple in well.

10-7ﺑﺮاي ﻧﺼﺐ در ﻣﺤﻮﻃﻪ ﻛﺎر ،در ﺟﺎﻫﺎﻳﻲ ﺗﺮﻣﻮﻛﻮﭘﻞﻫﺎ را

7.10 For field installation where the thermocouple

cannot be directly connected to rigid conduit, a

flexible conduit may be used as shown in Figs 1

and 3. A seal-off with drain at the thermocouple

end of the conduit and seal-off with drain at the

control room entry provides a double block and

bleed in case the thermowell should fail and

process fluid or gas enter the conduit.

11-7اﻧﺘﺨﺎب ﺗﺮﻣﻮﻛﻮﭘﻞ ﺑﺎ ﻳﺎ ﺑﺪون اﺗﺼﺎل زﻣﻴﻦ ﺑﺴﺘﮕﻲ ﺑﻪ

7.11 The choice of grounded or ungrounded

thermocouples is dictated by the application.

ﻧﻤﻲ ﺗﻮان ﻣﺴﺘﻘﻴﻤﺎً ﺑﻪ ﻟﻮﻟﻪ ﻛﺎﻧﺪوﻳﺖ ﺳﺨﺖ وﺻﻞ ﻧﻤﻮد ،ﻣﻤﻜﻦ

اﺳﺖ از ﻳﻚ ﻟﻮﻟﻪ ﻛﺎﻧﺪوﻳﺖ اﻧﻌﻄﺎف ﭘﺬﻳﺮ ﻛﻪ در ﺷﻜﻞﻫﺎي 1و 3

ﻧﺸﺎن داده ﺷﺪه اﺳﺘﻔﺎده ﻧﻤﻮد .ﻳﻚ اﺗﺼﺎل آب ﺑﻨﺪي ﺑﺎ ﺗﺨﻠﻴﻪ در

اﻧﺘﻬﺎي ﺗﺮﻣﻮﻛﻮﭘﻞ و ﻳﻚ اﺗﺼﺎل آب ﺑﻨﺪي ﺑﺎ ﺗﺨﻠﻴﻪ در ورود ﺑﻪ

اﺗﺎق ﻛﻨﺘﺮل ،ﻳﻚ ﻗﻄﻊ دو ﮔﺎﻧﻪ و ﺗﺨﻠﻴﻪ را ،در ﺻﻮرت ﺧﺮاﺑﻲ

ﭼﺎﻫﻚ ﺣﺮارﺗﻲ و ورود ﻣﺎﻳﻊ ﻳﺎ ﮔﺎز ﻓﺮآﻳﻨﺪ ﺑﻪ داﺧﻞ ﻟﻮﻟﻪ

ﻛﺎﻧﺪوﻳﺖ ،ﺑﻪ وﺟﻮد ﻣﻲ آورد.

ﻛﺎرﺑﺮد آن دارد .ﺻﺮف ﻧﻈﺮ از ﻧﻮع اﺳﺘﻔﺎده ﺷﺪه ﺑﺮاي اﻧﺪازه

9

Mar. 2009/ 1388 ﻓﺮوردﻳﻦ

Regardless of the type used for measurement,

grounding should only be done at one point.

IPS-C-IN-120(1)

. اﺗﺼﺎل ﺑﻪ زﻣﻴﻦ ﺑﺎﻳﺪ ﺗﻨﻬﺎ در ﻳﻚ ﻧﻘﻄﻪ اﻧﺠﺎم ﮔﻴﺮد، ﮔﻴﺮي

ﺟﻬﺖ اﻃﻼﻋﺎت ﺑﻴﺸﺘﺮ در راﺑﻄﻪ ﺑﺎ ﻧﺼﺐ ﺗﺮﻣﻮﻛﻮﭘﻞ ﻫﺎ ﺑﻪ12-7

7.12 For additional information on installation of

thermocouples, refer to IPS-C-IN-190 "Transmission Systems"

. »ﺳﺎﻣﺎﻧﻪ اﻧﺘﻘﺎل« ﻣﺮاﺟﻌﻪ ﺷﻮدIPS-C-IN-190

ﻣﺤﻔﻈﻪ آب ﺑﻨﺪي

GATE VALVE

ﺷﻴﺮ دروازه اي

ﺗﺮﻣﻮﻛﻮﭘﻞ ﺑﺎ ﻋﺎﻳﻖ

ﻣﻌﺪﻧﻲ ﭘﻮﺷﺶ

ﻓﻠﺰي

ﺗﺮﻣﻮﻛﻮﭘﻞ

اﺗﺼﺎﻻت ﻟﻮﻟﻪ

ﺑﺪون ﭼﺎﻫﻚ

WITHOUT WELL

دﻳﻮاره ﻟﻮﻟﻪ ﻳﺎ ﻇﺮف

ﺗﺮﻣﻮﻛﻮﭘﻞ

Fig. 2 - INSTALLATION OF THERMOCOUPLES WITHOUT WELLS

ﻧﺼﺐ ﺗﺮﻣﻮﻛﻮﭘﻠﻬﺎي ﺑﺪون ﭼﺎﻫﻚ- 2ﺷﻜﻞ

10

ﻓﺮوردﻳﻦ Mar. 2009/ 1388

)IPS-C-IN-120(1

3

2

1

4

6

9

5

7

8

10

-1اﺗﺼﺎﻻت " "Lﺷﻜﻞ ﻛﺎﻧﺪوﻳﺖ

-4ﻣﻬﺮه ﻣﺎﺳﻮره ﻧﺮ

-7ﻣﺠﺮاي ﺧﺮوﺟﻲ رﻃﻮﺑﺖ

-9ﻛﺎﻫﻨﺪه

-2ﻛﻼﻫﻚ ﺗﺮﻣﻮﻛﻮﭘﻞ

-5آب ﺑﻨﺪي ﺑﺮاي ﺗﺨﻠﻴﻪ ﻻزم اﺳﺖ

-3ﻣﺠﺮاي ﺧﺮوﺟﻲ رﻃﻮﺑﺖ

-6اﺗﺼﺎل دﻫﻨﺪه 3/4اﻳﻨﭽﻲ

-8ﻛﺎﻧﺪوﻳﺖ اﻧﻌﻄﺎف ﭘﺬﻳﺮ 3 4اﻳﻨﭽﻲ ﭘﻮﺷﺶ دار ﺑﺎ ﭼﺎﻫﻚ آزﻣﺎﻳﺶ )ﺑﻪ ﻳﺎدآوري ﻣﺮاﺟﻌﻪ ﺷﻮد(

-10ﺑﻮش ﻓﻮﻻدي

Fig. 3 - THERMOCOUPLE -TO-CONDUIT CONNECTIONS

ﺷﻜﻞ - 3اﺗﺼﺎﻻت ﺗﺮﻣﻮﻛﻮﭘﻞ ﺑﻪ ﻛﺎﻧﺪوﻳﺖ

ﻳﺎدآوري:

Note:

در ﺟﺎﻫﺎﻳﻲ ﻛﻪ از ﻛﺎﻧﺪوﻳﺖ اﻧﻌﻄـﺎف ﭘـﺬﻳﺮ ﻓـﻮﻻدي ﭘﻮﺷـﺶ دار

ﭼﺎﻫﻚ ﺣﺮارﺗﻲ اﺳﺘﻔﺎده ﺷﺪه ،ﺑﺎﻳﺪ اﻣﻜﺎن ﺗﺨﻠﻴﻪ ﻓﺸﺎر را داﺷـﺘﻪ

ﺑﺎﺷﺪ ﺗﺎ درﺻﻮرت ﺧﺮاﺑﻲ ﭼﺎﻫﻚ ﺗﺮﻣﻮﻛﻮﭘﻞ ،ﻓﺸﺎر را ﺑﺸﻜﻨﺪ.

Where "TW" jacketed flexible steel conduit is

used, it should be vented to relieve the pressure in

case of thermocouple well failure.

13-7اﻧﺪازه ﮔﻴﺮي دﻣﺎي ﺳﻄﺢ ﻟﻮﻟﻪ

7.13 Tube Surface Temperature Measurement

ﻳﻜﻲ از ﻛﺎرﺑﺮدﻫـﺎي ﺧـﺎص ﺗﺮﻣﻮﻛﻮﭘـﻞﻫـﺎ ،اﻧـﺪازه ﮔﻴـﺮي ﻧﻘﻄـﻪ

ﺳﻄﺤﻲ ﻳﺎ دﻣﺎي ﺳﻄﺢ ﻓﻠﺰ ﻟﻮﻟﻪﻫﺎي ﻛﻮرهﻫﺎ اﺳﺖ .اﻳﻦ ﻧﻮع ﻧﺼﺐ

ﺑﻪ دﻗﺖ زﻳﺎدي اﺣﺘﻴﺎج دارد ﺗﺎ از ﺗﻤـﺎس درﺳـﺖ ﺗﺮﻣﻮﻛﻮﭘـﻞ ﺑـﻪ

ﻟﻮﻟﻪ و ﻣﺤﺎﻓﻈﺖ ﻟﻮﻟﻪ از ﺗﺸﻌﺸﻌﺎت ﻛﻮره اﻃﻤﻴﻨﺎن ﺣﺎﺻﻞ ﮔـﺮدد.

ﺑﺎﻳﺪ دﻗﺖ ﺷﻮد ﻛﻪ از اﺿﺎﻓﻪ ﻛﺮدن ﺟﺮم ﺑـﻪ ﻧﻘﻄـﻪ اﻧـﺪازه ﮔﻴـﺮي

اﺟﺘﻨﺎب ﮔﺮدد .اﺿﺎﻓﻪ ﺷﺪن ﺟـﺮم ﻣﻤﻜـﻦ اﺳـﺖ ﺑﺎﻋـﺚ اﺧـﺘﻼف

دﻣﺎﻳﻲ ﺑﺠﺰ دﻳﻮاره ﻟﻮﻟﻪ ﻧﺴﺒﺘﺎً ﺳﺮد ﻣﺘﺼﻞ ﺑـﻪ آن ﮔـﺮدد .ﻓﺎﺻـﻠﻪ

ﺑﻴﻦ دﻳﻮاره ﻟﻮﻟـﻪ و اﺗـﺼﺎل ﺗﺮﻣﻮﻛﻮﭘـﻞ ﺑﺎﻳـﺪ ﺑـﻪ ﺣـﺪاﻗﻞ ﺑﺮﺳـﺪ.

ﺑﺴﻴﺎري از ﺷﺮﻛﺖ ﻫﺎ ﺑﺮاي اﻳﻦ ﻛﺎرﺑﺮد اﺳﺘﺎﻧﺪارد ﺧـﻮد را دارﻧـﺪ.

اﻳﻦ ﻧﻮع ﺗﺄﺳﻴﺴﺎت ﻫﺰﻳﻨﻪ ﺑﺮ ،ﭘﻴﭽﻴﺪه ﺑﻮده و ﻣﻤﻜﻦ اﺳـﺖ ﻛـﺎﻣﻼً

ﻣﻮرد اﻋﺘﻤﺎد ﻧﺒﺎﺷﻨﺪ.

ﻳﻚ ﻃﺮح ﺑﺮاي ﺗﻤﺎس اﻳﻦ ﻧـﻮع ﺗﺮﻣﻮﻛﻮﭘـﻞ ﺑـﻪ ﻟﻮﻟـﻪ ﻫـﺎي ﮔـﺮم

A special application of thermocouples is the

measurement of skin-point or tube-metal surface

temperature of furnace tubes. Such installations

require careful attention to ensure that the

thermocouple is properly attached to the tube and

is shielded from furnace radiation. Care must be

exercised to avoid adding mass at the point of

measurement. The addition of mass may result in a

temperature different from that of the relatively

cool tube wall to which it is attached. Gaps

between the tube wall and the thermocouple

junction should be minimized. Many companies

have their own standards for this application.

These installations can be costly, are complex, and

may not be entirely reliable.

One design for attaching this type of thermocouple

11

ﻓﺮوردﻳﻦ Mar. 2009/ 1388

)IPS-C-IN-120(1

to heater tubes is shown in Fig. 4. Other designs

give satisfactory service. Thermocouples of this

type are also used to measure external wall surface

temperature of reactors or other vessels. They

require the same care as the furnace tube surface

temperature installations.

ﻛﻨﻨﺪه در ﺷﻜﻞ 4ﻧﺸﺎن داده ﺷـﺪه اﺳـﺖ .ﻃﺮاﺣـﻲﻫـﺎي دﻳﮕـﺮ

ﺧﺪﻣﺎت رﺿﺎﻳﺖ ﺑﺨﺸﻲ را اراﺋﻪ ﻣﻲﻧﻤﺎﻳﻨﺪ .ﺗﺮﻣﻮﻛﻮﭘﻞﻫﺎﻳﻲ از اﻳﻦ

ﻧﻮع ﻫﻤﭽﻨﻴﻦ ﺑﺮاي اﻧﺪازه ﮔﻴـﺮي دﻣـﺎي ﺳـﻄﺢ ﺧـﺎرﺟﻲ دﻳـﻮار

رآﻛﺘﻮر ﻳﺎ ﺳﺎﻳﺮ ﻇﺮوف ﺗﺤﺖ ﻓﺸﺎر ﺑﻜـﺎر ﻣـﻲ روﻧـﺪ .آﻧﻬـﺎ ﻫﻤـﺎن

دﻗﺘﻲ را ﻻزم دارﻧﺪ ﻛﻪ دﻣﺎي ﺳﻄﺢ ﻛـﻮرهﻫـﺎ ﺑـﺮاي ﻧـﺼﺐ اﺑـﺰار

دﻗﻴﻖ دﻣﺎ اﺣﺘﻴﺎج دارﻧﺪ.

ﻏﻼف اﻟﻤﺎن

ﻟﻮﻟﻪ ﮔﺮم ﻛﻨﻨﺪه

ﺣﻠﻘﻪ ﮔﺴﺘﺮش اﻟﻤﺎن ﺑﺎﻧﺪازه دو ﺑﺮاﺑﺮ ﻗﻄﺮ ﻟﻮﻟﻪ

ﭘﻮﺷﺶ اﻟﻤﺎن

ﻟﻮﻟﻪ ﮔﺮم ﻛﻨﻨﺪه

ﺑﺴﺖ ﻓﺸﺎري

ﻣﺤﻞ اﺗﺼﺎل ﻧﻘﻄﻪ ﮔﺮم

ﺑﻪ ﺟﺰﺋﻴﺎت ﺗﻮﺟﻪ ﺷﻮد

درزﺧﺮوﺟﻲ

دﻳﻮاره ﮔﺮم

ﻛﻨﻨﺪه

ﻛﻼﻫﻚ ﺗﺮﻣﻮﻛﻮﭘﻞ

ﺟﺰﺋﻴﺎت

ﻟﻮﻟﻪ ﮔﺮم ﻛﻨﻨﺪه

ﻃﻮل ﻛﺎﻣﻞ ﺟﻮش اﺗﺼﺎل در

دو ﻃﺮف ﺗﺮﻣﻮﻛﻮﭘﻞ ﻟﺒﻪ ﺗﻴﻐﻲ

ATTACHMENT WELD ON

BOTH SIDES OF KNIFE-EDGE

ﺟﻮش ﮔﻠﻮﺋﻲ ﻳﺎﺟﻮش ﻧﻮاري ﻛﺎﻣﻼً ﻣﻤﺎس

Fig. 4 - KNIFE EDGE TUBE SURFACE THERMOCOUPLE FOR HEATER TUBE

ﺷﻜﻞ - 4ﺗﺮﻣﻮﻛﻮﭘﻞ ﺳﻄﺢ ﻟﻮﻟﻪ از ﻧﻮع ﻟﺒﻪ ﺗﻴﻐﻲ ﺟﻬﺖ ﻟﻮﻟﻪ ﮔﺮم ﻛﻨﻨﺪه

12

Mar. 2009/ 1388 ﻓﺮوردﻳﻦ

IPS-C-IN-120(1)

اﻧﺪازه ﮔﻴﺮي دﻣﺎي آﺗﺶ دان14-7

7.14 Firebox Temperature Measurement

ﻛﺎرﺑﺮد ﺗﺮﻣﻮﻛﻮﭘﻞ ﻫﺎ در آﺗﺶ دان ﻫﺎ ﺑﻪ ﻋﻠﺖ ﺳـﺎﺧﺘﻤﺎن دﻳـﻮاره

5 ﺟﻬﺖ ﻧﺼﺐ ﻧﻤﻮﻧـﻪ ﺑـﻪ ﺷـﻜﻞ.اﺣﺘﻴﺎج ﺑﻪ ﻇﺮاﻓﺖ ﺧﺎﺻﻲ دارد

ﺟﻬﺖ اﻃﻼﻋﺎت ﺑﻴﺸﺘﺮ در ﺑﺎره اﻳﻦ اﻧﺪازه ﮔﻴﺮي ﺑﻪ.ﻣﺮاﺟﻌﻪ ﮔﺮدد

5 و ﻧﻘـﺸﻪ ﻧﻤﻮﻧـﻪ ﺷـﻜﻞAPI RP 556 sec. 3.4.1 اﺳﺘﺎﻧﺪارد

.ﻣﺮاﺟﻌﻪ ﺷﻮد

The application of thermocouples in fireboxes

requires some special handling because of the wall

construction. For typical installation, refer to Fig.

5. and for further information on this

measurement, refer to API-RP-556, Section 3.4.1.

ﺳﻴﻤﻬﺎي راﺑﻂ ﺗﺮﻣﻮﻛﻮﭘﻞ15-7

7.15 Thermocouple Extension Wires

Thermocouple extension wires must have the same

electromotive

force

(emf)

temperature

characteristics as the thermocouple to which they

are connected. This will, in effect, transfer the

reference junction to the end away from the

thermocouple to a point where the temperature is

reasonably stable and where the effect of

temperature variations can be compensated. The

use of incorrect extension wire will cause errors in

the temperature readings by creating spurious

thermocouples at the thermocouple terminal block

or in the instrument.

ﺳﻴﻤﻬﺎي راﺑﻂ ﺗﺮﻣﻮﻛﻮﭘﻞ ﺑﺎﻳﺪ داراي ﻫﻤﺎن ﻣﺸﺨﺼﺎت ﺣﺮارﺗﻲ

( ﺗﺮﻣﻮﻛﻮﭘﻞ ﻫﺎي ﻣﺘﺼﻞ ﺑﻪ آن را داﺷﺘﻪemf) ﻧﻴﺮوي ﻣﺤﺮﻛﻪ

ﺑﻄﻮر ﻣﻮﺛﺮ ﻧﻘﻄﻪ ﻣﺮﺟﻊ را ﺑﻪ ﻧﻘﻄﻪ دور از، اﻳﻦ ﻣﺸﺨﺼﺎت.ﺑﺎﺷﻨﺪ

ﺗﺮﻣﻮﻛﻮﭘﻞ ﻛﻪ دﻣﺎ ﺑﻄﻮر ﻣﻨﻄﻘﻲ ﺛﺎﺑﺖ و در آن اﺛﺮ ﺗﻐﻴﻴﺮات دﻣﺎ

، اﺳﺘﻔﺎده از ﺳﻴﻢ راﺑﻂ ﻧﺎدرﺳﺖ.ﺟﺒﺮان ﺷﺪه اﺳﺖ اﻧﺘﻘﺎل ﻣﻲدﻫﺪ

ﺑﺪﻟﻴﻞ اﻳﺠﺎد ﺗﺮﻣﻮﻛﻮﭘﻞﻫﺎي ﻛﺎذب در ﺗﺮﻣﻴﻨﺎل ﺗﺮﻣﻮﻛﻮﭘﻞﻫﺎ ﻳﺎ

.ادوات اﺑﺰار دﻗﻴﻖ ﺑﺎﻋﺚ اﺷﺘﺒﺎه در ﺧﻮاﻧﺪن دﻣﺎ ﺧﻮاﻫﺪ ﺷﺪ

Thermocouple extension wires (available either in

pairs or bundles with multiple pairs) should be

installed as described in IPS-C-IN-190 installation

construction standard for transmission systems”.

ﺳﻴﻤﻬﺎي راﺑﻂ ﺗﺮﻣﻮﻛﻮﭘﻞ )از ﻧﻮع ﺗﻚ زوﺟﻲ ﻳﺎ دﺳﺘﻪ اي ﺑﺎ

IPS-C-IN-190 زوﺟﻬﺎي ﻣﺘﻌﺪد( ﺑﺎﻳﺪ ﺑﺮ اﺳﺎس اﺳﺘﺎﻧﺪارد

.اﺳﺘﺎﻧﺪارد ﺳﺎﺧﺖ و ﻧﺼﺐ ﺑﺮاي ﺳﻴﺴﺘﻤﻬﺎي اﻧﺘﻘﺎل ﻧﺼﺐ ﺷﻮﻧﺪ

Materials for thermocouple extension wires are

listed in Table 1. For limits of error associated

with extension wire, refer to ISA MC96.1. The

wire sizes normally used for extension wire either

singly or in pairs are 2, 1.3 and 0.75 mm2 with 1.5

mm2 (16 gage) being the most common size used.

When bundled and reinforced to provide strength

for pulling, 0.5 mm2 (20 gage) may be used.

ﺟﻨﺲ ﺳﻴﻤﻬﺎي راﺑﻂ ﺗﺮﻣﻮﻛﻮﭘﻞ ﻫﺎ در ﺟﺪول ﺷﻤﺎره ﻳﻚ ﻓﻬﺮﺳﺖ

ﺟﻬـﺖ ﻣﺤـﺪوده ﺧﻄـﺎ در راﺑﻄـﻪ ﺑـﺎ ﺳـﻴﻤﻬﺎي راﺑـﻂ ﺑـﻪ.ﺷﺪهاﻧﺪ

اﻧـﺪازه ﺳـﻴﻤﻬﺎ ﺑـﺮاي ﺳـﻴﻤﻬﺎي. ﻣﺮاﺟﻌﻪ ﺷﻮدISA MC 96.1

ﻣﻴﻠﻴﻤﺘﺮ ﻣﺮﺑﻊ ﻣﻲﺑﺎﺷﺪ0/75 و1/5 ، 2 راﺑﻂ ﻳﻚ و ﻳﺎ ﭼﻨﺪ زوﺟﻲ

ﻣﻴﻠﻴﻤﺘﺮ ﻣﺮﺑﻊ اﺳﺖ ﻛﻪ ﻣـﻮرد اﺳـﺘﻔﺎده1/5 ﻛﻪ ﻣﻌﻤﻮﻟﻲ ﺗﺮﻳﻦ آﻧﻬﺎ

در ﻣـﻮاﻗﻌﻲ ﻛـﻪ از ﺳـﻴﻤﻬﺎي دﺳـﺘﻪ اي ﺑـﺎ.ﺑﻴﺸﺘﺮ ﻗﺮار ﻣﻲ ﮔﻴـﺮد

0/5 ﻧﻴﺮوي ﻛﺸﺸﻲ ﺑﻴﺸﺘﺮ اﺳﺘﻔﺎده ﻣﻲ ﺷﻮد ﻣﻤﻜﻦ اﺳﺖ از ﺳـﻴﻢ

.ﻣﻴﻠﻴﻤﺘﺮ ﻣﺮﺑﻊ اﺳﺘﻔﺎده ﺷﻮد

TABLE 1 - THERMOCOUPLE EXTENSION WIRE

ﺟﻨﺲ ﺳﻴﻢ ﻫﺎي راﺑﻂ ﺗﺮﻣﻮﻛﻮﭘﻠﻬﺎ-1 ﺟﺪول

ANSI

Extension Wire Materials

Thermocouple Materials

ﻣﺸﺨﺼﻪ

ﺟﻨﺲ ﺳﻴﻤﻬﺎي راﺑﻂ

ﺟﻨﺲ ﺗﺮﻣﻮﻛﻮﭘﻞ ﻫﺎ

EX

JX

KX

SX

TX

CHROMEL-CONSTANTAN

IRON-CONSTANTAN

CHROMEL-ALUMEL

PLATINUM, 10% OR 13%

PLATINUM

COPPER-CONSTANTAN

CHROMEL-CONSTANTAN

IRON-CONSTANTAN

CHROMEL-ALUMEL

RHODIUM-

COPPER-COPPER NICKEL ALLOY

COPPER-CONSTANTAN

13

)IPS-C-IN-120(1

ﻓﺮوردﻳﻦ Mar. 2009/ 1388

ﻧﺴﻮز و ﻋﺎﻳﻖ

ﭘﻴﭻ ﻧﺼﺐ

ﭘﻮﺷﺶ ﻓﻮﻻدي

ﻟﻮﻟﻪ

ﻛﻮﭘﻠﻴﻨﮓ ﭘﻴﭽﻲ ﻳﺎ ﻓﻠﻨﺞ

ﺗﻘﺮﻳﺒﺎ 75ﻣﻴﻠﻴﻤﺘﺮ ) 3اﻳﻨﭻ(

THREADED

ﺗﻘﺮﻳﺒﺎ 75ﻣﻴﻠﻴﻤﺘﺮ ) 3اﻳﻨﭻ(

ﻓﻠﻨﺞ

ﻓﻠﻨﺞ ﻛﻒ

ﭘﻴﭽﻲ

ﭘﻮﺷﺶ ﻓﻮﻻدي

ﺑﺪون ﭼﺎﻫﻚ

اﺗﺼﺎل ﻓﺸﺎري

ﺣﺪاﻛﺜﺮ 24اﻳﻨﭻ ﺑﺪون ﻧﮕﻬﺪارﻧﺪه

ﺗﻘﺮﻳﺒﺎ 75ﻣﻴﻠﻴﻤﺘﺮ ) 3اﻳﻨﭻ(

)ﺑﻪ ﻳﺎداوري 3ﻣﺮاﺟﻌﻪ ﻛﻨﻴﺪ(

Fig. 5 - TYPICAL FIREBOX THERMOCOUPLE INSTALLATION

ﺷﻜﻞ - 5ﻧﺼﺐ ﻧﻤﻮﻧﻪ ﺗﺮﻣﻮﻛﻮﭘﻞ آﺗﺸﺪان

ﻳﺎدآوري ﻫﺎ:

(1ﺟﻨﺲ ﺧﺎرﺟﻲ آﺗﺶ دان ﻣﻤﻜﻦ اﺳﺖ ﻏﻴﺮ از ﺟﻨﺴﻲ

ﺑﺎﺷﺪ ﻛﻪ در ﺟﺪول داده ﺷﺪه اﺳﺖ

(2ﻗﻄﺮ ﺧﺎرﺟﻲ ﺗﺮﻣﻮﻛﻮﭘﻞ ﺑﺎﻳﺪ 13ﻣﻴﻠﻴﻤﺘﺮ در 3ﻣﻴﻠﻴﻤﺘﺮ

ﺿﺨﺎﻣﺖ دﻳﻮاره ،و ﺳﻴﻢ ﺗﺮﻣﻮﻛﻮﭘﻞ 2ﻣﻴﻠﻴﻤﺘﺮ ﻣﺮﺑﻊ ﺑﺎ ﻋﺎﻳﻖ

اﻛﺴﻴﺪ ﻣﻨﮕﻨﺰ و ﻫﺎدي 90درﺻﺪ ﻧﻴﻜﻞ و 10درﺻﺪ ﻛﺮوم

ﺑﺎﺷﺪ .ﻏﻼف ﺳﻴﻢ ﺗﺮﻣﻮﻛﻮﭘﻞ از ﺟﻨﺲ ﻓﻮﻻد ﺿﺪ زﻧﮓ 446و

ﻳﺎ از ﻣﻮادي ﻛﻪ در اﺳﺘﺎﻧﺪارد API RP 556 sec. 3.4.5ﺑﻪ

آﻧﻬﺎ اﺷﺎره ﺷﺪه اﺳﺖ اﺳﺘﻔﺎده ﺷﻮد.

(3اﻧﺘﻬﺎي ﻛﻼﻫﻚ ﺗﺮﻣﻮﻛﻮﭘﻞ ﺑﺎﻳﺪ 50ﻣﻴﻠﻴﻤﺘﺮ ﺳﻴﻢ ﻟﺨﺖ

ﺷﺪه ﺑﺎﺷﺪ .ﻋﺎﻳﻖ ﻣﻌﺪﻧﻲ ﺑﺎﻳﺪ ﺑﻪ ﻋﻤﻖ ﺣﺪاﻗﻞ 6ﻣﻴﻠﻴﻤﺘﺮ و

ﺑﺎ ﻣﻮاد اﻧﺪود ﺷﺪه ﺑﺎﺷﺪ.

Notes:

1) Materials external of firebox may be other

than those specified in Table 1.

)2) Thermocouple should be 13 mm (0.500-inch

outside diameter by 3 mm (0.120-inch) wall,

MgO insulated 2 mm2 (14 gage) nickel (90

percent)-chromium(10 percent) thermocouple

wire with 446 stainless sheath, or material listed

in API-RP556, section 3.4.5.

3) The head end of the thermocouple should

have 50 mm (2 inches) of exposed wire. The

mineral insulation shall be removed to a depth

of at least 6 mm (1/4 -inch) and potted with

compound.

14

Mar. 2009/ 1388 ﻓﺮوردﻳﻦ

4) The 600 mm (24-inch) maximum immersion

does not apply to top-entering installations.

IPS-C-IN-120(1)

( در ﺻﻮرت ﻧﺼﺐ از ﺑﺎﻻ ﻧﻴﺎزي ﺑﻪ ﻓﺮو ﻧﻤـﻮدن ﺗﺮﻣﻮﻛﻮﭘـﻞ4

. ﻣﻴﻠﻴﻤﺘﺮ ﻧﻴﺴﺖ600 ﺣﺪاﻛﺜﺮ

7.16 The signal from any thermocouple used in

conjunction with a shut-down system may not be

connected to any other device.

ﺳﻴﮕﻨﺎل ﻫﺮ ﺗﺮﻣﻮﻛﻮﭘﻞ در راﺑﻄﻪ ﺑﺎ ﺳﻴﺴﺘﻢ ﺗﻮﻗﻒ ﻛﺎﻣـﻞ16-7

7.17 When a thermocouple is used for automatic

control, a duplicate thermocouple may be provided

in the same pocket. In this case the second

thermocouple shall be connected to a precision

indicating instrument.

ﻣﻮﻗﻌﻲ ﻛـﻪ از ﻳـﻚ ﺗﺮﻣﻮﻛﻮﭘـﻞ ﺑـﺮاي ﻛﻨﺘـﺮل اﺗﻮﻣﺎﺗﻴـﻚ17-7

7.18 When two or more thermocouples are located

in the same pocket they must be separately and

permanently identified regarding function, e.g.

TRC or TI.

ﻣﻮﻗﻌﻲ ﻛﻪ دو ﻳﺎ ﭼﻨﺪ ﺗﺮﻣﻮﻛﻮﭘﻞ در ﻳـﻚ ﻣﺤﻔﻈـﻪ ﻗـﺮار18-7

7.19 To measure the same temperature for two

different purposes, a duplex thermocouple should

be used. When two or more thermocouples are

used to measure the same temperature they shall be

located in the same pocket. When this is not

possible and a single thermocouple must be used

for two measurements, e.g. skin thermocouples,

care shall be taken to avoid significant interaction

between instruments connected to the same

thermocouple.

ﺟﻬﺖ اﻧﺪازه ﮔﻴﺮي ﻳﻚ دﻣﺎ ﺑﺮاي دو ﻫﺪف ﻣﺨﺘﻠﻒ ﺑﺎﻳﺪ19-7

.( ﻣﻤﻜﻦ اﺳﺖ ﺑﻪ ﻫﻴﭻ وﺳﻴﻠﻪ دﻳﮕﺮي وﺻﻞ ﻧﺸﻮدShut down)

ﻳﻚ ﺗﺮﻣﻮﻛﻮﭘﻞ دوﺑﻞ ﻣﻤﻜﻦ اﺳﺖ در ﻫﻤـﺎن،اﺳﺘﻔﺎده ﺷﺪه اﺳﺖ

در اﻳﻦ ﺣﺎﻟﺖ ﺗﺮﻣﻮﻛﻮﭘﻞ دوﻣﻲ ﺑﺎﻳﺪ ﺑﻪ ﻳـﻚ.ﻣﺤﻔﻈﻪ ﺗﻌﺒﻴﻪ ﺷﻮد

.اﺑﺰار دﻗﻴﻖ ﻧﺸﺎن دﻫﻨﺪه ﺑﺎ دﻗﺖ ﺑﺎﻻ وﺻﻞ ﺷﻮد

ﺑﺎﻳﺪ ﺟﺪاﮔﺎﻧـﻪ و ﺑﻄـﻮر داﺋﻤـﻲ در ﺧـﺼﻮص ﻋﻤﻠﻜﺮدﺷـﺎن،دارﻧﺪ

.TI ﻳﺎTRC ﺑﺮاي ﻣﺜﺎل،ﺷﻨﺎﺳﺎﻳﻲ ﮔﺮدﻧﺪ

ﻣﻮﻗﻌﻲ ﻛﻪ از دو ﻳﺎ ﭼﻨﺪ.از ﺗﺮﻣﻮﻛﻮﭘﻞ دوﺑﻞ اﺳﺘﻔﺎده ﺷﻮد

ﻫﻤﻪ،ﺗﺮﻣﻮﻛﻮﭘﻞ ﺑﺮاي اﻧﺪازه ﮔﻴﺮي ﻳﻚ دﻣﺎ اﺳﺘﻔﺎده ﺷﺪه

در ﺻﻮرت ﻋﺪم.ﺗﺮﻣﻮﻛﻮﭘﻞ ﻫﺎ ﺑﺎﻳﺪ در ﻳﻚ ﻣﺤﻔﻈﻪ ﻗﺮار ﮔﻴﺮﻧﺪ

اﻣﻜﺎن و ﻟﺰوم اﺳﺘﻔﺎده از ﻳﻚ ﺗﺮﻣﻮﻛﻮﭘﻞ ﺑﺮاي دو اﻧﺪازه ﮔﻴﺮي

)ﺑﻄﻮر ﻣﺜﺎل از ﺗﺮﻣﻮﻛﻮﭘﻞﻫﺎي ﭘﻮﺳﺘﻲ( ﺑﺎﻳﺪ دﻗﺖ ﺷﻮد ﻛﻪ از

ﺗﺎﺛﻴﺮ ﻣﺘﻘﺎﺑﻞ ﻣﻬﻢ ﺑﻴﻦ دو اﺑﺰار دﻗﻴﻖ وﺻﻞ ﺷﺪه ﺑﻪ ﻳﻚ

.ﺗﺮﻣﻮﻛﻮﭘﻞ ﺟﻠﻮﮔﻴﺮي ﺷﻮد

ﺑﺮاي اﻳﻦ ﻣﻮارد ﺑﺎﻳﺪ ﺑﻪ اﺳﺘﻔﺎده ﻛﻨﻨﺪه رﺟﻮع ﺷﻮد ﺗـﺎ اﻃﻤﻴﻨـﺎن

ﺣﺎﺻﻞ ﮔﺮدد ﻛﻪ اﻣﭙﺪاﻧﺲ ﻛﺎﻓﻲ در دﺳـﺘﮕﺎه اﻧـﺪازه ﮔﻴـﺮ وﺟـﻮد

.دارد ﺗﺎ از ﺗﺪاﺧﻞ آﻧﻬﺎ و اﺷﺘﺒﺎﻫﺎت اﻧﺪازه ﮔﻴﺮي ﺟﻠﻮﮔﻴﺮي ﺷﻮد

Such cases shall be referred to the user to ensure

there is adequate impedance on the measuring

equipment to avoid interference or measurement

errors.

ﻫﻤﻪ ﺳﻴﻤﻬﺎي ﻣﺜﺒﺖ ﺗﺮﻣﻮﻛﻮﭘﻞﻫﺎ ﺑﻪ ﺳﺮ ﻧﻘﺎط اﺗﺼﺎل20-7

7.20 All thermocouple positive leads to the

terminating points shall be sleeved and marked

“+”. They shall also be color coded in accordance

with ISA-ANSI/MC96.1 (latest edition) to identify

the metals used.

." ﻋﻼﻣﺖ ﮔﺬاري ﮔﺮدﻧﺪ+" ﺑﺎﻳﺪ ﻏﻼف دار )ﻣﺎ ﻛﺎروﻧﻲ( ﺷﺪه و ﺑﺎ

)آﺧﺮﻳﻦISA-ANSI/MC 96.1 آﻧﻬﺎ ﺑﺎﻳﺪ ﺑﺮ ﻃﺒﻖ اﺳﺘﺎﻧﺪارد

.ﭼﺎپ( ﺑﺮاي ﻓﻠﺰﻫﺎي اﺳﺘﻔﺎده ﺷﺪه ﺑﺎ ﻛﺪ رﻧﮕﻲ ﻣﺸﺨﺺ ﺷﻮﻧﺪ

، ﺑﺮاي ﻧﻮع ﻋﺎﻳﻖ ﻣﻌﺪﻧﻲ، ﺳﻴﻤﻬﺎي راﺑﻂ ﺗﺮﻣﻮﻛﻮﭘﻞ ﻫﺎ21-7

7.21 Thermocouple extension wires, except

mineral insulated type, shall be run in conduit or

trunking and connected to the thermocouple head

by a 1 meter minimum. length flexible conduit.

Mineral insulated cable may be run in trays or

trunking.

ﺑﺎﻳﺪ در داﺧﻞ ﻛﺎﻧﺪوﻳﺖ ﻳﺎ ﻛﺎﻧﺎل ﻛﺎﺑﻞ رﺳﺎﻧﻲ ﻛﺸﻴﺪه ﺷﺪه و ﺑﺎ

ﻣﺘﺮ ﺑﻪ ﻛﻼﻫﻚ1 ﻛﺎﻧﺪوﻳﺖ ﻗﺎﺑﻞ اﻧﻌﻄﺎف ﺑﺎ ﻃﻮل ﺣﺪاﻗﻞ

ﻣﻤﻜﻦ اﺳﺖ ﻛﺎﺑﻞﻛﺸﻲ ﻛﺎﺑﻠﻬﺎي ﻋﺎﻳﻖ.ﺗﺮﻣﻮﻛﻮﭘﻞ وﺻﻞ ﺷﻮﻧﺪ

.ﻣﻌﺪﻧﻲ در ﺳﻴﻨﻲ ﻳﺎ ﻛﺎﻧﺎل ﻛﺎﺑﻞ رﺳﺎﻧﻲ اﻧﺠﺎم ﺷﻮد

ﻛﺎﺑﻠﻬﺎي ﭼﻨﺪ زوﺟﻲ ﺑﺎ ﺳﻴﻢ اﻓﺸﺎن ﺗﻜﻲ ﺑﺎ ﭘﻮﺷﺶ ﭘﻲ،در ﻋﻮض

اﻣﺎ اﺣﺘﻴـﺎج ﺑـﻪ،وي ﺳﻲ در ﻣﺤﻠﻬﺎي ﺧﺎص ﻣﻮرد ﻗﺒﻮل ﻣﻲﺑﺎﺷﺪ

ﭘﻮﺷـﺶ ﻛﺎﺑﻠﻬـﺎي زﻳﺮزﻣﻴﻨـﻲ )اﮔـﺮ.ﺗﺎﻳﻴﺪ اﺳـﺘﻔﺎده ﻛﻨﻨـﺪه دارد

ﻛــــﺎرﺑﺮد دارد( ﺑﺎﻳــــﺪ ﺑــــﺮ اﺳــــﺎس اﻟﺰاﻣــــﺎت اﺳــــﺘﺎﻧﺪارد

" " ﻛﺎﺑﻠﻬــﺎ و ﺳــﻴﻤﻬﺎي ﻓــﺸﺎر ﺿــﻌﻴﻒIPS-M-EL-271 (1)

.ﺑﺎﺷﺪ

Alternatively multicore cable with single stranded

wire and PVC sheathing is acceptable in specified

locations, but is subject to the approval of the user.

Sheathing for under ground cables if applicable

shall be in accordance with the requirements of

IPS-M-EL-271(1) "Low Voltage Cables & Wires".

15

Mar. 2009/ 1388 ﻓﺮوردﻳﻦ

IPS-C-IN-120(1)

ﻛﺎﻧﺎل ﻛﺎﺑﻞ رﺳﺎﻧﻲ و ﻛﺎﻧﺪوﻳﺖ ﺑﺎﻳﺪ اﻧﺪازه ﻛﺎﻓﻲ داﺷﺘﻪ و22-7

7.22 Trunking and conduit must be of adequate

size and provided with sufficient inspection covers,

etc.; to facilitate maintenance and sealing where

necessary.

درب ﻫﺎي ﺑﺎزرﺳﻲ و ﻏﻴﺮه ﺟﻬﺖ ﺗﻌﻤﻴﺮات و آب ﺑﻨﺪي در

.ﺟﺎﻫﺎﻳﻲ ﻛﻪ ﻻزم ﺑﺎﺷﺪ ﺗﻌﺒﻴﻪ ﮔﺮدد

a) Conduits should normally be sized to carry

the total required leads plus two.

اﻟﻒ( ﻛﺎﻧﺪوﻳﺖﻫﺎ ﻣﻌﻤﻮﻻً ﺑﺎﻳﺪ ﺑﻪ اﻧﺪازهاي ﺑﺎﺷﺪ ﻛﻪ ﻛﻞ

b) The complete installation shall be weather

and

dustproof,

thermocouples

and

thermocouple extension wires are solid drawn

conductors normally 0.75 mm2 in size and shall

meet the application requirements according to

the practice of ISA-ANSI/MC96.1.chapter 3

sections 31-40.

.ب( ﻧﺼﺐ ﻛﺎﻣﻞ ﺑﺎﻳﺪ ﺿﺪ رﻃﻮﺑﺖ و ﺿﺪ ﮔﺮد و ﺧـﺎك ﺑﺎﺷـﺪ

. ﺳﻴﻢ اﺿﺎﻓﻪ را ﺟﺎ دﻫﺪ2 ﺳﻴﻤﻬﺎي ﻣﻮرد ﻧﻴﺎز ﺑﻌﻼوه

ﺗﺮﻣﻮﻛﻮﭘﻞ ﻫﺎ و ﺳﻴﻤﻬﺎي راﺑـﻂ ﺗﺮﻣﻮﻛﻮﭘـﻞ ﻫـﺎ ﺑﺎﻳـﺪ از ﻧـﻮع

0/75 ﻫﺎدي ﻣﻔﺘﻮﻟﻲ ﻛـﺸﻴﺪه ﺷـﺪه ﻛـﻪ ﻣﻌﻤـﻮﻻً در اﻧـﺪازه

ﻣﻴﻠﻴﻤﺘﺮ ﻣﺮﺑﻊ ﺑﻮده و ﺑﺎﻳﺪ اﻟﺰاﻣـﺎت ﻛـﺎرﺑﺮدي را ﻃﺒـﻖ روش

ISA-ANSI/MC 96.1 Chapter3, Sec. 31-40

.ﺑﺮآورده ﻧﻤﺎﻳﺪ

ﺳﻴﻤﻬﺎي ﺗﺮﻣﻮﻛﻮﭘﻞ ﻫﺎ ﺑﺎﻳﺪ ﺑﺎ، در ﻣﻮرد ﻛﺎرﺑﺮد در ﻛﻮره ﻫﺎ23-7

7.23 On furnaces applications, leads from

thermocouples shall be brought out clear from the

furnace to reduce the possibility of fire damage.

For these locations mineral insulated extension

leads, shall be used.

ﻓﺎﺻﻠﻪ از ﻛﻮره ﺑﻴﺮون آورده ﺷﻮﻧﺪ ﺗﺎ اﺣﺘﻤﺎل ﺻﺪﻣﻪ زدن آﺗﺶ ﺑﻪ

ﺟﻬﺖ ﭼﻨﻴﻦ ﻣﺤﻠﻬﺎﻳﻲ ﺑﺎﻳﺪ از ﺳﻴﻢ راﺑﻂ از ﻧﻮع ﻋﺎﻳﻖ.آﻧﻬﺎ ﻛﻢ ﻛﻨﺪ

.ﻣﻌﺪﻧﻲ اﺳﺘﻔﺎده ﺷﻮد

و ﻫﻤﭽﻨﻴﻦ ﺑﻪ ﻧﻘﺸﻪAPI RP 556 Sec. 3.4.5 ﺑﻪ اﺳﺘﺎﻧﺪارد

. ﻣﺮاﺟﻌﻪ ﺷﻮد23 در ﺻﻔﺤﻪ1،2،3 ﻧﻤﻮﻧﻪ ﭘﻴﻮﺳﺖ

ﺗﺮﻣﻮﻛﻮﭘﻞ ﻫﺎي از ﻧﻮع ﭘﻮﺳﺖ ﻟﻮﻟﻪاي ﺟﻬﺖ اﻧﺪازه ﮔﻴﺮي دﻣﺎي

ﺷﺪﻳﺪ از ﻧﺰدﻳﻚ ﻣﻲﺑﺎﺷﻨﺪ و ﻛﺎرﺑﺮد آﻧﻬﺎ در ﻛﻮرهﻫﺎﺋﻲ اﺳﺖ ﻛﻪ

درﺟﻪ ﺣﺮارت ﺑﻪ ﻋﻠﺖ ﻛﻢ ﺷﺪن ﺟﺮﻳﺎن ﻳﺎ ﺳﻮﺧﺘﻦ ﺟﺪاره ﻟﻮﻟﻪﻫﺎ

ﻟﻮﻟﻪ ﻳﺎ ﺑﻴﺸﺘﺮ3 ﺗﺎ2 ﻣﻌﻤﻮﻻً درﺟﻪ ﺣﺮارت ﺧﺮوﺟﻲ.ﺑﺎﻻ ﻣﻴﺮود

ﺑﺎ در ﻧﻈﺮ ﮔﺮﻓﺘﻦ ﻗﺎﺑﻠﻴﺖ اﻧﻌﻄﺎف ﻻزم ﻛﻪ.اﻧﺪازه ﮔﻴﺮي ﻣﻲﺷﻮﻧﺪ

ﺳﻴﻢ ﺗﺮﻣﻮﻛﻮﭘﻞﻫﺎ،در اﺛﺮ اﻧﺒﺴﺎط ﻟﻮﻟﻪﻫﺎي ﻛﻮره ﺑﻮﺟﻮد ﻣﻲآﻳﺪ

ﺟﻬﺖ ﻣﺤﻴﻂﻫﺎي ﺧﻮرﻧﺪه ﺑﺎ ﻏﻼف ﭘﻮﺷﺸﻲ ﻟﻮﻟﻪاي ﻣﻨﺎﺳﺐ ﻳﺎ

ﻋﺎﻳﻖﻫﺎي ﻣﻌﺪﻧﻲ ﻋﺎﻳﻖﺑﻨﺪي ﻣﻲﺷﻮﻧﺪ

Refer to: API-RP 556, section 3.4.5, also see the

attached typical drawings Fig.1, Fig.2, Fig.3 on

page 23.

Tube skin type thermocouples are for severe and

intimate temperature measurements and are used in

furnaces against tube overheating as a result of

flow reduction, or coking within the tubes .

Usually the temperature for 2 to 3 or more tube

outlets are measured , and thermocouple wires for

corrosive atmosphere in the firebox are adequately

insulated by tubular sheath, or mineral insulation ,

considering the flexibility required in furnace tube

expansion.

، ﺳﻴﻢ ﻫﺎي راﺑﻂ ﺗﺤﺖ ﻫﻴﭻ ﺷﺮاﻳﻄﻲ ﻧﺒﺎﻳﺪ در ﺗﺮاﻧﺸﻪ ﻫﺎ24-7

ﻛﺎﻧﺪوﻳﺖ ﻫﺎ و ﻳﺎ ﻛﺎﻧﺎل ﻫﺎي ﻛﺎﺑﻞ رﺳﺎﻧﻲ ﻫﻤﺮاه ﺳﻴﻢ ﻫﺎي ﺗﻐﺬﻳﻪ

ﻣﻌﻤﻮﻻ ﺳﻴﻢ ﻫﺎي راﺑﻂ ﺑﺎﻳﺪ ﻓﻘﻂ ﺑﺎﻻي زﻣﻴﻦ.ﺑﺮق ﻛﺸﻴﺪه ﺷﻮﻧﺪ

ﻫﺮ ﭘﻴﺸﻨﻬﺎد ﺟﺎﻳﮕﺰﻳﻦ ﺑﺎﻳﺪ ﺑﺎ ﻣﻮاﻓﻘﺖ و ﺗﺎﻳﻴﺪ.ﻛﺸﻴﺪه ﺷﻮﻧﺪ

ﺟﻬﺖ ﺟﺰﻳﻴﺎت ﺑﻴﺸﺘﺮ ﺑﻪ ﺑﻨﺪﻫﺎي.اﺳﺘﻔﺎده ﻛﻨﻨﺪه )ﺷﺮﻛﺖ( ﺑﺎﺷﺪ

"ﻧﺼﺐ ﺳﻴﺴﺘﻢ ﻫﺎيIPS-C-IN-190 اﺳﺘﺎﻧﺪارد6-6 اﻟﻲ4-6

.اﻧﺘﻘﺎل "ﻣﺮاﺟﻌﻪ ﺷﻮد

ﻃﻮل ﻓﺮورﻓﺘﻪ ﻓﺎﺻﻠﻪ اﻧﺘﻬﺎي آزاد اﻟﻤﺎن ﺣﺴﻲ دﻣﺎ ﻳﺎ25-7

7.24 Under no circumstances shall extension wires

run in cable trays, conduits, or trunking with power

wiring. Normally extension wires should run above

ground only. Any alternative proposal should be

agreed with the company . For more details see

IPS-C-IN-190 "Transmission Systems", sections

6.4 to 6.6.

7.25 The immersion length is the distance from the

free end of the temperature sensing element or well

to the point of immersion in the medium, the

temperature of which is being measured. In order

to obtain optimum accuracy and response time, the

immersion length for a thermocouple installation

shall be at least ten times the outside diameter of

the thermocouple sheath . This value shall be

increased where space permits with flowing

liquids.

ﻛﻪ دﻣﺎي آن،ﭼﺎﻫﻚ اﺳﺖ ﺗﺎ ﻧﻘﻄﻪ ﻏﻮﻃﻪ ور ﺷﺪن داﺧﻞ ﻣﺎﻳﻌﻲ

ﺟﻬﺖ دﺳﺘﻴﺎﺑﻲ ﺑﻪ دﻗﺖ و زﻣﺎن ﭘﺎﺳﺦ.اﻧﺪازه ﮔﻴﺮي ﻣﻲ ﺷﻮد

10 ﺑﻬﻴﻨﻪ ﻃﻮل ﻓﺮو ﺑﺮي ﺟﻬﺖ ﻧﺼﺐ ﺗﺮﻣﻮﻛﻮﭘﻞ ﺑﺎﻳﺪ ﺣﺪاﻗﻞ

ﺑﺮاي ﻣﺎﻳﻌﺎت در.ﺑﺮاﺑﺮ ﻗﻄﺮ ﺧﺎرﺟﻲ ﻏﻼف ﺗﺮﻣﻮﻛﻮﭘﻞ ﺑﺎﺷﺪ

ﺟﺮﻳﺎن در ﺟﺎﻫﺎﻳﻲ ﻛﻪ ﻓﻀﺎ اﺟﺎزه ﻣﻴﺪ ﻫﻴﺪ اﻳﻦ ﻣﻘﺪار ﺑﺎﻳﺪ اﺿﺎﻓﻪ

.ﺷﻮد

16

Mar. 2009/ 1388 ﻓﺮوردﻳﻦ

Six diameters immersion may be used if the pipe

and the external portion of protecting tube are well

insulated.

IPS-C-IN-120(1)

اﮔﺮ ﻟﻮﻟﻪ و ﻗﺴﻤﺖ ﺧﺎرﺟﻲ ﻟﻮﻟﻪ ﺣﻔﺎﻇﺘﻲ ﺑﻪ ﻃﻮر ﻣﻄﻠﻮب ﻋﺎﻳﻖ

ﺑﺮاﺑﺮ ﻗﻄﺮ ﻣﻤﻜﻦ اﺳﺖ اﺳﺘﻔﺎده6 ﺷﺪه ﺑﺎﺷﻨﺪ از ﻃﻮل ﻓﺮورﻓﺘﻪ

.ﺷﻮد

ﭼﺎﻫﻚ ﻫﺎي ﺣﺮارﺗﻲ-8

8. THERMOWELLS

8.1 It is important to maintain good contact

between all temperature sensing elements and the

bottom of their wells.

ﺟﻬﺖ ارﺗﺒﺎط ﺧﻮب ﺑﻴﻦ اﻟﻤﺎنﻫﺎي ﺣﺲ ﻛﻨﻨﺪه ﺣﺮارت و1-8

8.2 The installation of thermowells shall be as

prescribed under the relevant section of the piping

specification.

ﻧﺼﺐ ﭼﺎﻫﻚ ﻫﺎي ﺣﺮارﺗﻲ ﺑﺎﻳﺪ ﺑﺮ اﺳﺎس ﻗﺴﻤﺖ ﻫﺎي2-8

8.3 Spare thermowells, i.e. those for which a

sensing element or instrument is not supplied, shall

be plugged as soon as installed in the line.

آﻧﻬﺎﻳﻲ ﻛﻪ اﻟﻤﺎن، ﺑﺮاي ﻣﺜﺎل، ﭼﺎﻫﻚﻫﺎي ﺣﺮارﺗﻲ ﻳﺪﻛﻲ3-8

.اﻧﺘﻬﺎي ﭼﺎﻫﻜﺸﺎن ﺑﺮﻗﺮاري ﺗﻤﺎس ﺧﻮب ﻣﻬﻢ اﺳﺖ

.ﻣﺮﺑﻮﻃﻪ از ﻣﺸﺨﺼﺎت ﻓﻨﻲ ﻟﻮﻟﻪ ﻛﺸﻲ ﺑﺎﺷﺪ

ﺣﺴﻲ ﻳﺎ ادوات اﺑﺰار دﻗﻴﻖ ﺑﺮاي آﻧﻬﺎ ﺗﻬﻴﻪ ﻧﺸﺪه اﺳﺖ ﺑﺎﻳﺪ ﭘﺲ

. در ﭘﻮش ﮔﺬاري ﺷﻮﻧﺪ،از ﻧﺼﺐ روي ﺧﻂ

8.4 The thermowell should extend sufficiently

deep into the medium for the temperature-sensitive

portion of the measuring element subject to the

medium’s

actual

temperature.

Insufficient

immersion can result errors because heat will be

conducted to or away from the sensitive end of the

thermowell.

ﭼﺎﻫﻚ ﻫﺎي ﺣﺮارﺗﻲ ﺑﺎﻳﺪ ﺑﻪ اﻧﺪازه ﻛﺎﻓﻲ ﻋﻤﻴﻖ در داﺧﻞ4-8

8.5 When the thermowell is installed perpendicular

to or at a 45 degree angle to the pipe wall, the tip

of the thermowell should be located in the center

third of the pipe on lines up to 760 mm (30 inches)

in diameter. If the thermowell is installed at an

angle or in an elbow, the tip should point toward

the flow in the process line. See Dwg. No. 1 page

12.

45 ﻣﻮﻗﻌﻲ ﻛﻪ ﭼﺎﻫﻚ ﺣﺮارﺗﻲ ﺑﻄﻮر ﻋﻤﻮدي ﻳﺎ ﺑﺎ زاوﻳﻪ5-8

8.6 Thermowells installed in lines having high

velocities may be subject to vibration, which may

cause a rupture of the well below the mounting.

Tapered stems and U lengths established from a

stress analysis are recommended for high velocity

lines (see ASME PTC 19.3 ,chapter 1, section 8) .

ﭼﺎﻫﻚﻫﺎي ﺣﺮارﺗﻲ ﻧﺼﺐ ﺷﺪه در ﺧﻄﻮﻃﻲ ﺑﺎ ﺳﺮﻋﺖ6-8

ﻛﻪ ﺑﺎﻋﺚ،زﻳﺎد ﺟﺮﻳﺎن ﻣﻤﻜﻦ اﺳﺖ در ﻣﻌﺮض ﻟﺮزش ﻗﺮار ﮔﻴﺮﻧﺪ

ﻣﻴﻠﻪﻫﺎي ﻣﺨﺮوﻃﻲ و ﻃﻮل.ﭘﺎرهﮔﻲ ﭼﺎﻫﻚ زﻳﺮ ﻣﺤﻞ ﻧﺼﺐ ﺷﻮد

ﺑﺮاي ﺧﻄﻮط ﺑﺎ ﺳﺮﻋﺖ، ﻛﻪ از آﻧﺎﻟﻴﺰ ﻓﺸﺎري ﺑﺪﺳﺖ آﻣﺪهاﻧﺪU

ASME PTC 19.3 Chapter 1, زﻳﺎد ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮﻧﺪ ﺑﻪ

ﭼﺎﻫﻚﻫﺎي ﺣﺮارﺗﻲ ﻣﺨﺮوﻃﻲ ﺷﻜﻞ ﺑﺮاي. ﻣﺮاﺟﻌﻪ ﺷﻮدSec. 8

ﻳﻌﻨﻲ ﺳﺮﻋﺖ ﺑﻴﺶ از،ﺧﻄﻮط ﺑﺎ ﺳﺮﻋﺖ زﻳﺎد ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮﻧﺪ

اﺳﺘﻔﺎده از اﻳﻦ ﭼﺎﻫﻚﻫﺎي ﺣﺮارﺗﻲ ﺑﺮاي،ﻣﺘﺮ ﺑﺮ ﺛﺎﻧﻴﻪ21 ﺣﺪ

.ﻓﺎﺋﻖ آﻣﺪن ﺑﺮ ﻓﺸﺎرﻫﺎي ﻣﻜﺎﻧﻴﻜﻲ ﻧﺎﺷﻲ از ﻟﺮزش اﺳﺖ

ﻣﺤﻴﻂ اداﻣﻪ ﻳﺎﻓﺘﻪ ﺗﺎ ﻗﺴﻤﺖ ﺣﺴﺎس ﺑﻪ دﻣﺎي اﻟﻤﺎن اﻧﺪازه

ﻓﺮو ﺑﺮدن ﻧﺎﻛﺎﻓﻲ ﻣﻲﺗﻮاﻧﺪ.ﮔﻴﺮي در ﻣﻌﺮض واﻗﻌﻲ ﻣﺤﻴﻂ ﺑﺎﺷﺪ

ﺑﺎﻋﺚ اﺷﺘﺒﺎه ﺷﻮد ﭼﻮن ﺣﺮارت ﺑﻪ اﻧﺘﻬﺎي ﻗﺴﻤﺖ ﺣﺴﺎس

.ﭼﺎﻫﻚ ﻫﺎي ﺣﺮارﺗﻲ و ﻳﺎ دور از آن ﻫﺪاﻳﺖ ﺧﻮاﻫﺪ ﺷﺪ

ﻧﻮك ﭼﺎﻫﻚ،درﺟﻪ ﻧﺴﺒﺖ ﺑﻪ دﻳﻮاره ﻟﻮﻟﻪ ﻧﺼﺐ ﺷﺪه اﺳﺖ

760 ﺣﺮارﺗﻲ ﺑﺎﻳﺪ در ﻣﺮﻛﺰ ﻳﻚ ﺳﻮم ﻟﻮﻟﻪ روي ﺧﻄﻮط ﺗﺎ ﻗﻄﺮ

اﮔﺮ ﭼﺎﻫﻚ ﺣﺮارﺗﻲ در ﻳﻚ زاوﻳﻪ. اﻳﻨﭻ( ﻗﺮار ﮔﻴﺮد30) ﻣﻴﻠﻴﻤﺘﺮ

ﻧﻮك آن ﺑﺎﻳﺪ ﺑﻪ ﻃﺮف ﺟﺮﻳﺎن ﻓﺮآﻳﻨﺪ در،و ﻳﺎ زاﻧﻮﻳﻲ ﻧﺼﺐ ﺷﻮد

. ﻣﺮاﺟﻌﻪ ﺷﻮد10 ﺻﻔﺤﻪ1 ﺑﻪ ﻧﻘﺸﻪ ﺷﻤﺎره.ﺧﻂ ﺑﺎﺷﺪ

Tapered thermowells are recommended for high

velocity lines,i.e. more than 21 m/sec. (70 feet per

sec.), to overcome the mechanical stresses due to

vibration.

8.7 Unless otherwise agreed, temperature detecting

elements and dial thermometers, shall be installed

in thermowells. See Dwgs. on pages 23 through

30.

ﺑﺎﻳﺪ، اﻟﻤﺎﻧﻬﺎي ﺣﺲ ﻛﻨﻨﺪه دﻣﺎ و دﻣﺎﺳﻨﺞﻫﺎي ﺻﻔﺤﻪ اي7-8

8.8 In case where thermowells are installed in

erosive catalyst systems, they should be fitted with

lubricated plug cocks between the well and the

element to be sheared and the well sealed in the

در ﻣﻮاردي ﻛﻪ ﭼﺎﻫﻚﻫﺎي ﺣﺮارﺗﻲ در ﺳﻴﺴﺘﻤﻬﺎي8-8

ﻣﮕﺮ ﻃﻮر دﻳﮕﺮي ﺗﻮاﻓﻖ ﺷﺪه،در ﭼﺎﻫﻚ ﻫﺎي ﺣﺮارﺗﻲ ﻧﺼﺐ ﺷﻮﻧﺪ

. ﻣﺮاﺟﻌﻪ ﺷﻮد30 ﺗﺎ23 ﺑﻪ ﻧﻘﺸﻪ ﻫﺎي ﺻﻔﺤﻪ.ﺑﺎﺷﺪ

ﺑﺮاي آﻧﻬﺎ ﺑﺎﻳﺪ ﺷﻴﺮ روﻏﻨﻜﺎري،ﻛﺎﺗﺎﻟﻴﺴﺖ ﻓﺮﺳﺎﻳﺸﻲ ﻧﺼﺐ ﺷﺪهاﻧﺪ

ﻣﺸﺘﺮك ﺑﻴﻦ ﭼﺎﻫﻚ و اﻟﻤﺎن ﺗﻌﺒﻴﻪ ﮔﺮدد و در ﺻﻮرت ﺧﺮاﺑﻲ

17

Mar. 2009/ 1388 ﻓﺮوردﻳﻦ

IPS-C-IN-120(1)

event of pocket failure. The length of extension (UDimension) shall not be more than 600 mm.

ﻃﻮل ﻟﻮﻟﻪ. ﭼﺎﻫﻚ ﺑﺎﻳﺪ ﻛﺎﻣﻼً آب ﺑﻨﺪي ﺷﺪه ﺑﺎﺷﺪ،ﭘﻮﺷﺶ آﻧﻬﺎ

. ﻣﻴﻠﻴﻤﺘﺮ ﺑﺎﺷﺪ600 ( ﻧﺒﺎﻳﺪ ﺑﻴﺶ ازU راﺑﻂ )اﻧﺪازه

8.9 Thermowells inserted in furnaces tubes or

headers shall meet the specifications of the furnace

designer and shall conform to the tube or header

plug design.

ﭼﺎﻫﻚ ﻫﺎي ﺣﺮارﺗﻲ ﺑﻜﺎر رﻓﺘﻪ در ﻟﻮﻟﻪ ﻛﻮره ﻫﺎ ﻳﺎ ﻟﻮﻟﻪ ﻫﺎي9-8

اﺻﻠﻲ ﺑﺎﻳﺪ ﺑﺮ اﺳﺎس ﻣﺸﺨﺼﺎت ﻓﻨﻲ ﻃﺮاح ﻛﻮره ﺑﻮده و ﺑﺎ ﻃﺮاﺣﻲ

.ﻟﻮﻟﻪ ﻳﺎ ﻟﻮﻟﻪ ﻫﺎي اﺻﻠﻲ ﺑﺎﻳﺪ ﻫﻤﺎﻫﻨﮓ ﺑﺎﺷﺪ

در ﺧﻄﻮط ﻛﻮﭼﻚ ﻛﻪ ﻓﺮوﺑﺮي ﭼﺎﻫﻚ ﺣﺮارﺗﻲ ﺑﺼﻮرت10-8

8.10 On small lines where adequate immersion

cannot be obtained by the thermowell inserted

perpendicular to the line, the well shall be inserted

at 90 degrees bend in the line. Alternatively a short

section of the line may be enlarged to accommodate

the thermowell, but this method should only be used

when normal methods are impracticable, see

Related typical Drawing on page 22.The maximum

immersion length shall be 150 mm (6 in.) for pipes

of 300 mm (12 in.) and above.

90 ﭼﺎﻫﻚ ﺑﺎﻳﺪ در ﺧﻢ زاوﻳﻪ،ﻋﻤﻮد ﺑﻪ ﺧﻂ ﻣﻤﻜﻦ ﻧﺒﺎﺷﺪ

و ﻳﺎ ﻣﻲ ﺗﻮان ﻳﻚ ﻗﺴﻤﺖ.درﺟﻪاي در داﺧﻞ ﺧﻂ ﻓﺮو ﺑﺮده ﺷﻮد

،از ﻟﻮﻟﻪ را ﺑﺰرگ ﻛﺮده و ﭼﺎﻫﻚ ﻫﺎي ﺣﺮارﺗﻲ را در آن ﺟﺎ داد

اﻣﺎ اﻳﻦ روش در ﺻﻮرﺗﻲ ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﻣﻲﮔﻴﺮد ﻛﻪ

در اﻳﻦ ﻣﻮرد ﺑﻪ ﻧﻘﺸﻪ ﻫﺎي،روﺷﻬﺎي ﻣﻌﻤﻮﻟﻲ ﻏﻴﺮ ﻋﻤﻠﻲ ﺑﺎﺷﺪ

ﺣﺪاﻛﺜﺮ ﻃﻮل ﻓﺮوﺑﺮي ﺑﺮاي. ﻣﺮاﺟﻌﻪ ﺷﻮد22 ﻧﻤﻮﻧﻪ در ﺻﻔﺤﻪ

. ﻣﻴﻠﻴﻤﺘﺮ ﺑﺎﺷﺪ150 ﻣﻴﻠﻴﻤﺘﺮ و ﺑﺎﻻﺗﺮ ﺑﺎﻳﺪ300 ﻟﻮﻟﻪ ﻫﺎي

، در ﺻﻮرﺗﻴﻜﻪ ﻓﺮآﻳﻨﺪي ﺑﻪ ﺟﻮاب ﺳﺮﻳﻊ دﻣﺎ اﺣﺘﻴﺎج دارد11-8

ﺑﺎﻳﺪ،ﭼﺎﻫﻚﻫﺎي ﺣﺮارﺗﻲ ﻛﻨﺘﺮل ﻛﻨﻨﺪهﻫﺎي درﺟﻪ ﺣﺮارت

ﺗﺎ آﻧﺠﺎﻳﻴﻜﻪ ﺷﺮاﻳﻂ ﻓﺮآﻳﻨﺪي اﺟﺎزه ﻣﻲدﻫﺪ،دﻳﻮارهﻫﺎي ﻧﺎزك

.ﺳﺎﺧﺘﻪ ﺷﻮد

8.11 When process requires rapid temperature

response, thermowells for temperature controllers,

shall be constructed with wall thickness as thin as

operating conditions will permit.

ﻛﻠﻴﺪﻫﺎي ﺣﺮارﺗﻲ-9

9. TEMPERATURE SWITCHES

اﻟﻤﺎن دﻣﺎﻳﻲ ﻣﺠﻤﻮﻋﻪ ﻛﻠﻴﺪ ﺑﺎﻳﺪ در ﭼﺎﻫﻚﻫﺎي ﺣﺮارﺗﻲ1-9

9.1 The temperature element of the switch

assembly is to be mounted in a thermowell and the

switch should be mounted on a pedestal or a stand

pipe with brackets wherever applicable, such as

capillary type switches.

،ﻧﺼﺐ ﺷﺪه و ﻛﻠﻴﺪ ﺑﺎﻳﺪ روي ﻳﻚ ﭘﺎﻳﻪ ﻳﺎ ﻟﻮﻟﻪ ﻧﮕﻬﺪارﻧﺪه ﺑﺎ ﭘﺎﻳﻪ

ﻣﺜﻞ ﻛﻠﻴﺪﻫﺎي ﻧﻮع،در ﺟﺎﻳﻲ ﻛﻪ ﻣﻨﺎﺳﺐ ﺑﺎﺷﺪ ﻧﺼﺐ ﮔﺮدد

.ﻣﻮﻳﻴﻦدار

9.2 The capillary tubing shall be adequately

supported and clamped.

ﻟﻮﻟﻪ ﻣﻮﻳﻴﻦ ﺑﺎﻳﺪ ﺑﻪ ﺣﺪ ﻛﺎﻓﻲ ﻣﺤﻜﻢ ﻧﺼﺐ و ﻧﮕﻬﺪاﺷﺘﻪ2-9

.ﺷﻮد

18

ﻓﺮوردﻳﻦ Mar. 2009/ 1388

)IPS-C-IN-120(1

)Thermowell Installation (General Service

ﻧﺼﺐ ﭼﺎﻫﻚ ﺣﺮارﺗﻲ )ﺧﺪﻣﺎت ﻋﻤﻮﻣﻲ(

اﺗﺼﺎل ﺧﺮوﺟﻲ ﺟﺎﻧﺒﻲ

اﺗﺼﺎل ﺧﺮوﺟﻲ رزوه اي

ﺑﻪ ﻳﺎدآوري 1رﺟﻮع ﺷﻮد

ﺑﻪ ﻳﺎدآوري 1رﺟﻮع ﺷﻮد

ﺑﻪ ﻳﺎدآوري

1رﺟﻮع ﺷﻮد

اﺗﺼﺎل ﺧﺮوﺟﻲ زاﻧﻮﺋﻲ

ﺷﻜﻞ 1

ﺷﻜﻞ 2

ﺷﻜﻞ 3

TABLE 2 – THERMOWELL INSTALLATION

12

ﺟﺪول - 2ﻧﺼﺐ ﭼﺎﻫﻚ ﺣﺮارﺗﻲ )در ﻟﻮﻟﻪ(

١٣

"20

"18

"16

"14

"12

"10

"8

"6

"4

"3

300

300

300

300

200

200

150

100

100

100

750

750

750

750

600

600

600

450

450

450

7

7

7

7

15

15

25

19

Line Size

"Length "U

)(mm

Length T/C

)(mm

Max. Velocity

m/s

Mar. 2009/ 1388 ﻓﺮوردﻳﻦ

14

IPS-C-IN-120(1)

TABLE 3 - D & D NOMINAL LINE SIZE

D,d – اﻧﺪازه ﻧﺎﻣﻲ ﺧﻂ3 ﺟﺪول

١٥

16

19

4ﺷﻜﻞ

d

2"

17

20

D

4"

18

21

U

100 mm

5 ﺷﻜﻞ

TYPICAL DRAWING 1

THERMOWELL INSTALLATION (SCREWED)

( – ﻧﺼﺐ ﭼﺎﻫﻚ ﺣﺮارﺗﻲ)ﭘﻴﭽﻲ1 ﻧﻘﺸﻪ ﻧﻤﻮﻧﻪ

:ﻳﺎدآوري ﻫﺎ

Notes:

ﻳﺎ، ﻳﺎ اﺗﺼﺎل ﺧﺮوﺟﻲ ﺟﺎﻧﺒﻲ، اﺗﺼﺎل ﺧﺮوﺟﻲ رزوهاي.1

3000 ﺣﺪاﻗﻞ از ﻛﻼسAPI اﻳﻨﭻ1 اﺗﺼﺎل ﺧﺮوﺟﻲ زاﻧﻮﻳﻲ

.ﭘﻮﻧﺪ اﺳﺘﻔﺎده ﺷﻮد

. اﻧﺘﻬﺎي ﺧﺮوﺟﻲ ﭼﺎﻫﻚ ﺣﺮارﺗﻲ ﺑﺎﻳﺪ ﺑﻪ ﻃﺮف ﺑﺎﻻ ﺑﺎﺷﺪ.2

1) (1"API) thread let, latrolet, or elbowlet

minimum rating class 3000 lb.

2) Outer end of thermowell shall face upward.

3) For 80 mm(3") or 100 mm (4") lines, elbow

installation is preferable if practicable.

ﻧﺼﺐ زاﻧﻮ در ﺻﻮرت ﻋﻤﻠﻲ ﺑﻮدن4" ﻳﺎ3" ﺑﺮاي ﺧﻄﻮط.3

.ﺗﺮﺟﻴﺢ داده ﺷﻮد

4) On an insulated line, the thermowell shall be

insulated up to the bottom of the hexagon head.

"T" DIM. shall include a 50 mm. lagging

extension.

5) Welding to

IPS-C-PI-290.

be

in

accordance

ﭼﺎﻫﻚ ﺣﺮارﺗﻲ ﺑﺎﻳﺪ ﺗﺎ اﻧﺘﻬﺎي، روي ﻳﻚ ﺧﻂ ﻋﺎﻳﻖ ﺷﺪه.4

“ ﺑﺎﻳﺪT” اﻧﺪازه.ﭘﺎﻳﻴﻦ ﻛﻼﻫﻚ ﺷﺶ ﮔﻮش ﻋﺎﻳﻖ ﺷﻮد

. ﻣﻴﻠﻴﻤﺘﺮ ﻃﻮل اﺿﺎﻓﻪ ﺑﺮاي ﻋﺎﻳﻖ ﺑﺎﺷﺪ50 ﺷﺎﻣﻞ

IPS-C-PI-290 ﺟﻮﺷﻜﺎري ﺑﺎﻳﺪ ﺑﺮ اﺳﺎس اﺳﺘﺎﻧﺪارد.5

.ﺑﺎﺷﺪ

“ ﻣﺮﺑﻮط ﺑﻪ ﻃﻮل ﭼﺎه از اﻧﺘﻬﺎي رزوه ﺗﺎ ﻧﻮكU” اﻧﺪازه.6

.ﭼﺎﻫﻚ اﺳﺖ

“ ﺑﺎﻳﺪ ﺑﻪ ارﻗﺎم داده ﺷﺪه درU” ﺣﺪاﻛﺜﺮ ﻣﺠﺎز ﻃﻮل.7

. ﻣﺤﺪود ﺷﻮد2 ﺟﺪول

with

6) Dimension "U" refers to length of well from

end of thread to tip of well.

7) Maximum allowable "U" length shall be

limited to the figures given in Table 2.

20

ﻓﺮوردﻳﻦ Mar. 2009/ 1388

)IPS-C-IN-120(1

20 -1ﻣﻴﻠﻴﻤﺘﺮ ﭘﻴﭻ ﻛﺎﻧﺪوﻳﺖ -2اﻧﺪازه""A

-5ﭘﻴﭻ اﺗﺼﺎل 1اﻳﻨﭽﻲ

-6اﻧﺪازه T

-4ﻃﻮل ""U

-8ﻧﻴﻢ اﻳﻨﭻ API

-3اﻧﺪازه T

-7ﻣﻬﺮه ﻣﺎﺳﻮره ﭘﻴﭽﻲ ﻧﻴﻢ اﻳﻨﭻ

ALL DIMENSIONS ARE IN MILLIMETERS.

1

ﻫﻤﻪ اﻧﺪازه ﻫﺎ ﺑﻪ ﻣﻴﻠﻴﻤﺘﺮ ﻫﺴﺘﻨﺪ،

TYPICAL DRAWING 2

2

)THERMOWELL AND THERMOMETER POCKET (SCREWED

ﻧﻘﺸﻪ ﻧﻤﻮﻧﻪ 2

ﭼﺎﻫﻚ ﺣﺮارﺗﻲ و ﻣﺤﻔﻈﻪ ﺗﺮﻣﻮﻣﺘﺮ )ﭘﻴﭽﻲ(

21

3

Mar. 2009/ 1388 ﻓﺮوردﻳﻦ

IPS-C-IN-120(1)

:ﻳﺎدآوريﻫﺎ

Notes:

ﺟﺰﻳﻴﺎت ﻧﺸﺎن داده ﺷﺪه ﺳﺮ ﺷﺶ ﮔﻮش و درﭘﻮش ﻓﻘﻂ.1

اﺳﺘﺎﻧﺪارد ﻫﺎي ﺳﺎزﻧﺪﮔﺎن را ﻧﻴﺰ.ﺑﺼﻮرت ﻧﻤﻮﻧﻪ ﻫﺴﺘﻨﺪ

.ﻣﻲﺗﻮان در ﻧﻈﺮ ﮔﺮﻓﺖ

زﻧﺠﻴﺮ و رﻳﻨﮕﻬﺎ ﺑﺎﻳﺪ از ﻧﻮع ﻓﻮﻻد ﺿﺪ، درﭘﻮش، ﭼﺎﻫﻚ.2

. ﺑﺎﺷﻨﺪAISI 316 زﻧﮓ

ﺣﻔﺮه. ﭼﺎﻫﻚ ﺑﺎﻳﺪ از ﻳﻚ ﻣﻴﻠﻪ ﺗﻮﭘﺮ ﺳﺎﺧﺘﻪ ﺷﺪه ﺑﺎﺷﺪ.3

ﻫﻢ ﻣﺮﻛﺰ، درﺻﺪ ﺿﺨﺎﻣﺖ دﻳﻮاره10 ﭼﺎﻫﻚ ﺑﺎﻳﺪ ﺗﺎ ﺣﺪ

.ﺑﺎﺷﺪ

1) The details shown of the hexagon and plug

are typical only. Manufacturers standards may

also be considered.

2) The well, plug, chain and rings shall be

stainless steel type AISI-316

3) The well shall be fabricated from solid bar

stock. The bore shall be concentric to 10% of

wall thickness.

ﭼﺎﻫﻚ ﺑﺎﻳﺪ ﺗﺎ زﻳـﺮﭘﻴﭻ ﺳـﻮارﻛﻨﻨﺪه ﺻـﻴﻘﻞ داده ﺷـﺪه و.4

4) The well shall be polished below mounting

threads to 0.25 microns surface finish.

. ﻣﻴﻜﺮون ﭘﺮداﺧﺖ ﺷﺪه ﺑﺎﺷﺪ0/25 ﺳﻄﺢ آن ﺗﺎ

دارايASME B1.20.3 ﭼﺎﻫﻚ ﺑﺎﻳﺪ ﻃﺒﻖ اﺳﺘﺎﻧﺪارد.5

ﺑﺎﺷﺪ و، اﻳﻨﭻ ﻟﻮﻟﻪ اﺻﻼح ﺷﺪه1 ﭘﻴﭻ آب ﺑﻨﺪي ﺧﺸﻚ

ﻛﻪ دوﺗﺎي آن زﻳﺮ رﻳﻨﮓ اﻧﺪازه، ﭘﻴﭻ ﻣﻮﺛﺮ12 ﺣﺪاﻗﻞ

ً اﻳﻦ ﺑﺎﻋﺚ ﻣﻴﺸﻮد دو ﭘﻴﭻ ﻛﺎﻣﻼ. ﺑﺎﺷﺪ،اﺳﺘﺎﻧﺪارد ﻧﺸﺎن دﻫﻨﺪ

اﺿﺎﻓﻲ در ﻫﺮ اﻧﺘﻬﺎ ﺑﺎ اﺗﺼﺎل ﭘﻴﭽﻲ ﻟﻮﻟﻪ ﺑﻴﺸﺘﺮ از درﮔﻴﺮ

.ﺑﻮدن ﭘﻴﭻ ﻟﻮﻟﻪ اﺳﺘﺎﻧﺪارد ﺑﺎﺷﺪ

ﺑﺎر140 ﭼﺎه ﺑﺎﻳﺪ ﻗﺎدر ﺑﻪ ﺗﺤﻤﻞ ﻓﺸﺎر داﺧﻠﻲ ﺑﺎ.6

.آزﻣﺎﻳﺶ اﻳﺴﺘﺎﺑﻲ ﺑﺎﺷﺪ

. ﺑﺎر اﺳﺖ70 ﺣﺪاﻛﺜﺮ ﻓﺸﺎر ﻛﺎر ﺳﺮد.7

5) The well shall have an (ASME B1 .20.3

Dryseal Pipe Threads-1 inch) modified to have

at least twelve effective threads, two of which

are below a standard ring gage. This provides

two additional full threads at each end beyond a

standard pipe thread engagement.

6) The well shall withstand an internal

hydrostatic test pressure of 140 bar.

7) The maximum cold working pressure is 70

barg.

ﭼﺎﻫـﻚ ﺣﺮارﺗـﻲ ﺑﺎﻳـﺪ ﺗـﺎ اﻧﺘﻬـﺎي، روي ﺧﻂ ﻋﺎﻳﻖ ﺷﺪه.8

8) On an insulated line, the thermowell shall be

insulated up to the bottom of the hexagon head.

"T" dimension shall include a 50 mm lagging

extension.

“ ﺑﺎﻳـﺪT” اﻧـﺪازه.ﭘﺎﻳﻴﻦ ﻛﻼﻫﻚ ﺷـﺶ ﮔـﻮش ﻋـﺎﻳﻖ ﺷـﻮد

. ﻣﻴﻠﻴﻤﺘﺮ ﻃﻮل اﺿﺎﻓﻪ ﺑﺮاي ﻋﺎﻳﻖ ﺑﺎﺷﺪ50 ﺷﺎﻣﻞ

22

)IPS-C-IN-120(1

۴

۵

ﻓﺮوردﻳﻦ Mar. 2009/ 1388

-2ﺗﺮﻣﻮﻛﻮﭘﻞ ﺑﺎ ﻋﺎﻳﻖ ﻣﻌﺪﻧﻲ

-1ﻛﻤﻴﻨﻪ 450ﻣﻴﻠﻴﻤﺘﺮ

1

1

-3اﺗﺼﺎل ﻓﺸﺎري ﺑﻪ اﻧﺪازه اﻳﻨﭻ ﺟﻬﺖ ﺗﻴﻮب )ﻧﺎﻳﻪ(در

4

2

-4رزوه ﻳﻚ اﻳﻨﭻ API

اﻳﻨﭻ روﭘﻴﭻ

TYPICAL DRAWING 3

6

THERMOWELL AND THERMOCOUPLE INSTALLATION FOR LINES SUBJECTED TO

VIBRATION

ﻧﻘﺸﻪ ﻧﻤﻮﻧﻪ 3

ﻧﺼﺐ ﭼﺎﻫﻚ ﺣﺮارﺗﻲ و ﺗﺮﻣﻮﻛﻮﭘﻞ ﺑﺮاي ﺧﻄﻮط در ﻣﻌﺮض ﻟﺮزش

23

7

ﻓﺮوردﻳﻦ Mar. 2009/ 1388

)IPS-C-IN-120(1

See Notes:

-2ﻛﺎﺑﻞ ﺑﺮاي ﺳﺮوﻳﺴﻬﺎي زﻳﺮزﻣﻴﻨﻲ

-1ﺑﻴﺸﻴﻨﻪ ﺟﺎﺑﺠﺎﻳﻲ 300ﻣﻴﻠﻴﻤﺘﺮ

-3ﻣﻬﺮه ﻗﻔﻠﻲ

-6زﻳﻦ و ﮔﻴﺮه

-4ﻧﻤﻮﻧﻪ ﻧﺼﺐ ﺗﺮﻣﻮﻛﻮﭘﻞ از ﻧﻮع ﻋﺎﻳﻖ ﻣﻌﺪﻧﻲ ) -5 (MIﺟﻌﺒﻪ اﺗﺼﺎل

-7ﻛﻤﻴﻨﻪ ﻗﻄﺮ ﺑﺮاﺑﺮ 450ﻣﻴﻠﻴﻤﺘﺮ

-9ﻛﺎﻧﺪوﻳﺖ ﺿﺪ ﻣﺎﻳﻊ ﻗﺎﺑﻞ اﻧﻌﻄﺎف ﺑﺎ اﻧﺪازه 3 4اﻳﻨﭽﻲ

-8اﺗﺼﺎل ﻣﺴﺘﻘﻴﻢ رو ﭘﻴﭻ 3 4اﻳﻨﭽﻲ

-12ﺗﻚ زوﺟﻲ ﺑﺎ ﻋﺎﻳﻖ ﻣﻌﺪﻧﻲ

-11اﺗﺼﺎل ﺛﺎﺑﺖ

-10اﺗﺼﺎل ﻛﺎﻧﺪوﻳﺖ

-14ورودي ﻛﺎﻧﺪوﻳﺖ 20ﻣﻴﻠﻴﻤﺘﺮي

-13ﮔﻠﻨﺪ ﻧﻮع ﺣﻠﻘﻮي ﻓﺸﺎري

-15ﮔﻠﻨﺪﻛﺎﺑﻞ ﭼﻨﺪ رﺷﺘﻪ اي

-17رزوه ﻓﻮﻻدي

-16ﺳﻴﻢ راﺑﻂ ﺗﺮﻣﻮﻛﻮﭘﻞ رزوهدار ﭼﻨﺪ رﺷﺘﻪ اي ﺑﺎ ﭘﻮﺷﺶ ﭘﻲ وي ﺳﻲ

TYPICAL DRAWING 4

8

THERMOCOUPLE EXTENSION LEAD AND THERMOWELL INSTALLATION ARRANGEMENT

ﻧﻘﺸﻪ ﻧﻤﻮﻧﻪ 4

ﭼﻴﺪﻣﺎن ﻧﺼﺐ ﺳﻴﻢ راﺑﻂ ﺗﺮﻣﻮﻛﻮﭘﻞ و ﭼﺎﻫﻚ ﺣﺮارﺗﻲ

٢٥

24

9

ﻓﺮوردﻳﻦ Mar. 2009/ 1388

)IPS-C-IN-120(1

Notes:

ﻳﺎدآوريﻫﺎ:

-1اﺗﺼﺎﻻت ورودي ﻣﺘﺼﻞ ﻛﻨﻨﺪه ﻛﺎﺑﻞ از ﻧﻮع ﻓﻮﻻدي ﺑﺎ ﺑﻮش

1) Cable connector entry fittings to be of steel

with rubber bushings to provide positive grip on

cable and weather-tight seal.

ﻻﺳﺘﻴﻜﻲ ﺑﺎﺷﺪ ﺗﺎ ﺑﺎ ﻣﺤﻜﻢ ﻛﺮدن آن در ﺑﺮاﺑﺮ آب و ﻫﻮا آب

ﺑﻨﺪي ﺷﻮد

-2ﻛﻠﻴﻪ اﺗﺼﺎﻻت ﺑﻴﺮون ﺟﻌﺒﻪ اﺗﺼﺎل ﺑﺎﻳﺪ ﺑﺎ ﻧﻮار ﭘﻼﺳﺘﻴﻜﻲ ﻳﺎ

2) All fittings outside the junction box to be

weather protected with plastic tape or corrosion

resistant paint.

3) All fittings to be of the safety compression

type.

4) Junction box to be made of welded sheet

steel duly protected against corrosion and the

cover to be fully neoprene gasketed.

رﻧﮓ ﺿﺪ زﻧﮓ از ﻫﻮا ﻣﺤﻔﻮظ ﺑﺎﺷﻨﺪ.

-3ﻛﻠﻴﻪ اﺗﺼﺎﻻت ﺑﺎﻳﺪ در ﻣﻘﺎﺑﻞ ﻓﺸﺎر اﻳﻤﻦ ﺑﺎﺷﻨﺪ.

-4ﺟﻌﺒﻪ اﺗﺼﺎل ﺑﺎﻳﺪ از ﻧﻮع ورق ﺟﻮﺷﻲ ﻓﻮﻻدي ﺑﺎﺷﺪ ﻛﻪ در

ﻣﻘﺎﺑﻞ زﻧﮓ زدﮔﻲ ﺣﻔﺎﻇﺖ ﺷﺪه و درب آن ﺑﺎ واﺷﺮ ﻧﺌﻮﭘﺮﻧﻲ

ﻛﺎﻣﻞ ﺑﺎﺷﺪ.

-5ﻫﺮ اﻧﺘﻬﺎي ﺟﻌﺒﻪ اﺗﺼﺎل ﻓﻀﺎي ﻛﺎﻓﻲ ﺟﻬﺖ اﺗﺼﺎل ﻛﺎﺑﻞ ﭼﻨﺪ

5) Each end of the junction box to have assorted

knockouts to provide adequate accommodations

for multicore junctions and terminations.

6) Terminal block shall be installed as high as

possible in the box.

رﺷﺘﻪاي داﺷﺘﻪ ﺑﺎﺷﺪ.

-6ﺗﺮﻣﻴﻨﺎل اﺗﺼﺎﻻت ﺑﺎﻳﺪ ﺗﺎ آﻧﺠﺎ ﻛﻪ ﻣﻤﻜﻦ اﺳﺖ در ﺑﺎﻻﺗﺮﻳﻦ

ﻗﺴﻤﺖ ﺟﻌﺒﻪ اﺗﺼﺎل ﻧﺼﺐ ﺷﻮﻧﺪ.

8

9

10

12

1

2

13

3

11

4

1

6

5

7

-2ﺳﺮﭘﻮش

-1ﭼﺎﻫﻚ ﺣﺮارﺗﻲ

-6اﺗﺼﺎل ﺧﺮوﺟﻲ ﺟﻮﺷﻲ 40ﻣﻴﻠﻴﻤﺘﺮي

-4ﺳﻪ راﻫﻲ

-3ﺟﺮﻳﺎن

-7ﺿﺨﺎﻣﺖ ﻧﺎﻣﻲ -8 160ﻟﺒﻪ ﮔﺮد

-10دو ﺑﺎر ﺟﻮش ﺑﺎ ﻧﻔﻮذ ﻛﺎﻣﻞ

-11ﻓﻠﻨﺞ 40ﻣﻴﻠﻴﻤﺘﺮي ) (W.N.روﻳﻪ ﺑﺮﺟﺴﺘﻪ ﺑﺎ ﺳﻮراخ 1 12اﻳﻨﭽﻲ

-12ﻓﻠﻨﭻ ﻛﻮر 40ﻣﻴﻠﻴﻤﺘﺮ)" ½ (1ﺑﺮاي ﻟﻮﻟﻪ

-13ﺟﺎي واﺷﺮ را ﺑﺎﻳﺪ ﺑﻌﺪ از ﺟﻮﺷﻜﺎري دوﺑﺎره ﻣﺎﺷﻴﻦ ﻛﻨﻴﻢ.

TYPICAL DRAWING 5

ﻧﻘﺸﻪ ﻧﻤﻮﻧﻪ 5

25

-5در ﺧﻄﻮط 100ﻣﻴﻠﻴﻤﺘﺮ )4اﻳﻨﭻ( ﻳﺎ ﻛﻮﭼﻜﺘﺮ

-9رزوه "API 1/2

Mar. 2009/ 1388 ﻓﺮوردﻳﻦ

IPS-C-IN-120(1)

TABLE 3- THERMOWELL INSTALLATION (FLANGED)

( ﻧﺼﺐ ﭼﺎﻫﻚ ﺣﺮارﺗﻲ)ﻓﻠﻨﺠﻲ-3 ﺟﺪول

Line Size

اﻧﺪازه ﺧﻂ ﺑﻪ اﻳﻨﭻ

Length "U" (mm)

“ ﺑﻪ ﻣﻴﻠﻴﻤﺘﺮU” اﻧﺪازه

Max. Allowable

ﺣﺪاﻛﺜﺮ ﻣﺠﺎز

Max. Velocity m/s

(ﭘﻴﺸﻴﻨﻪ ﺳﺮﻋﺖ )ﻣﺘﺮ ﺑﺮ ﺛﺎﻧﻴﻪ

3"

4"

6"

8"

10"

12"

14"

16"

18"

20"

150

150

200

200

300

300

300

300

300

300

25

25

15

15

7

7

7

7

7

7

U ﻣﻴﻠﻴﻤﺘﺮ و ﻃﻮل50 ﻓﻠﻨﺞ ﻫﺎي ﺑﺴﺘﻪ )ﻛﻮر( ﺑﺎﻳﺪ،ﺑﺮاي ﻇﺮوف

* For vessels, blind flange size shall be 50 mm (2

inches) and Length "U" may be larger than listed.

ﺗﻤﺎم.ﻣﻤﻜﻦ اﺳﺖ ﺑﻴﺸﺘﺮ از آﻧﭽﻪ در ﻟﻴﺴﺖ آﻣﺪه اﺳﺖ ﺑﺎﺷﺪ

.اﻧﺪازه ﻫﺎ ﺑﻪ ﻣﻴﻠﻴﻤﺘﺮ ﻫﺴﺘﻨﺪ

: ﻳﺎدآوريﻫﺎ

Notes:

ﻳﺎ ﻣﻮادAISI 316 ( ﭼﺎﻫﻚ ﺑﺎﻳﺪ از ﻓﻮﻻد ﺿﺪ زﻧﮓ ﺑﺎﺷﺪ1

1) The well shall be AISI -316 stainless steel or

other materials as required for fluid.

.دﻳﮕﺮي ﺑﺮ اﺳﺎس ﻧﻴﺎز ﺳﻴﺎل ﺑﺎﺷﺪ

ﺣﻔﺮه.( ﭼﺎﻫﻚ ﺑﺎﻳﺪ از ﻳﻚ ﻣﻴﻠﻪ ﺗﻮ ﭘﺮ ﺳﺎﺧﺘﻪ ﺷﺪه ﺑﺎﺷﺪ2

2) The well shall be fabricated from solid bar

stock, the bore shall be concentric to 10% of

wall thickness.

. ﻫﻢ ﻣﺮﻛﺰ ﺑﺎﺷﺪ،درﺻﺪ ﺿﺨﺎﻣﺖ دﻳﻮاره10 ﺑﺎﻳﺪ ﺗﺎ ﺣﺪ

( ﭼﺎﻫﻚ ﺑﺎﻳﺪ ﺗﺎ زﻳﺮ ﻓﻠﻨﺞ ﺳﻮار ﻛﻨﻨﺪه ﺻﻴﻘﻞ داده ﺷﺪه و3

3) The well shall be polish finished below

mounting flange to 0.25 microns.

. ﻣﻴﻜﺮون ﺳﻄﺢ آن ﭘﺮداﺧﺖ ﺷﺪه ﺑﺎﺷﺪ0/25 ﻛﺎﻣﻼً ﺗﺎ

( ﺟﻮﺷﻜﺎري ﺑﺎﻳﺪ ﺑﺮ اﺳﺎس ﻋﻤﻠﻜﺮد ﻣﻬﻨﺪﺳﻲ ﻣﻄﺎﺑﻖ4

4) Welding to be in accordance with IPS

engineering practices

. ﺑﺎﺷﺪIPS اﺳﺘﺎﻧﺪارد

( درﭘﻮش وAPI ( ﺑﺮاي ﭼﺎﻫﻚ ﻫﺎي آزﻣﺎﻳﺸﻲ )ﻧﻴﻢ اﻳﻨﭻ5

5) For test wells (½" API) plug and chain shall

be provided.

.زﻧﺠﻴﺮ ﺑﺎﻳﺪ در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﺷﺪه ﺑﺎﺷﺪ

6) The standard lengths "U" for piping

installations are 150, 200, 250 and 300 mm.

،150 “ ﺟﻬﺖ ﻧﺼﺐ در ﻟﻮﻟﻪU” ( ﻃﻮل ﻫﺎي اﺳﺘﺎﻧﺪارد6

7) The well shall withstand a hydrostatic test

pressure according to the flange rating.

( ﭼﺎﻫﻚ ﺑﺎﻳﺪ ﺗﺤﻤﻞ ﻓﺸﺎر آزﻣﺎﻳﺶ اﻳﺴﺘﺎﺑﻲ ﻣﻄﺎﺑﻖ ﺑﺎ7

. ﻣﻴﻠﻴﻤﺘﺮ ﻣﻲ ﺑﺎﺷﺪ300 ،250 ،200

.درﺟﻪ اﺳﺘﺤﻜﺎم ﻓﻠﻨﺞ را داﺷﺘﻪ ﺑﺎﺷﺪ

ANSI ( درﺟﻪ اﺳﺘﺤﻜﺎم ﻓﻠﻨﺞ ﻫﺎ ﺑﺎﻳﺪ داراي ﻛﻤﻴﻨﻪ8

8) Flanges to be ANSI 300 R.F minimum

rating.

. ﺑﺎﺷﺪ300RF

26

)IPS-C-IN-120(1

ﻓﺮوردﻳﻦ Mar. 2009/ 1388

Detail Of Split Plate Cover

ﺟﺰﺋﻴﺎت درب ﺻﻔﺤﻪ ﺟﺪا ﺳﺎز

-4ﻋﺎﻳﻖ درب ﻣﺤﻔﻈﻪ

-2ﺟﻌﺒﻪ اﺻﻠﻲ -3درب ﻣﺤﻔﻈﻪ

-1ﻧﮕﻬﺪارﻧﺪه اﻧﺘﻬﺎي ﺗﻴﻮب )ﻧﺎﻳﻪ(

-6ﻛﻼﻫﻚ ﺗﺮﻣﻮﻛﻮﭘﻞ

-5درب ﺻﻔﺤﻪ ﺟﺪا ﺳﺎز)ﺑﻪ ﺟﺰﺋﻴﺎت ﭘﺎﻳﻴﻦ ﺗﻮﺟﻪ ﺷﻮد(

-10اﺗﺼــﺎﻻت ﻛﺎﻧﺪوﻳﺖ

-9دﻳﻮار ﻧﮕﻬﺪارﻧﺪه

-8ﻃﺎق

-14ﻋﺎﻳﻖ

-13ﺧﺎل ﺟﻮش

-12ﺳﻜﻮ

-16ﺳﻮراخ ﻫﺎ ﺑﺎ ﻗﻄﺮ 14ﻣﻴﻠﻴﻤﺘﺮ -17ﻣﻬﺮه ﻣﺎﺳﻮره آﻫﻨﻲ ﭼﻜﺶ ﺧﻮار 150ﭘﻮﻧﺪ1/2اﻳﻨﭻ

150 -18ﻣﻴﻠﻴﻤﺘـــﺮﻟﻮﻟــﻪ 1/2اﻳﻨـــﭻ از ﻓﻮﻻد ΧS

-20ﻳﺎدآوري :ﻛﺎﺑﻞ راﺑﻂ از ﺟﻨﺲ MICCﺗﺮﺟﻴﺢ داده ﻣﻴﺸﻮد

-22ﻣﻐﺰي ﺑﺎ ﻃﻮل 75ﻣﻴﻠﻴﻤﺘﺮ در ½ اﻳﻨﭻ از ﺟﻨﺲ ﻓﻮﻻد ΧS

-7ﺗﻴﻮب )ﻧﺎﻳﻪ( ﻛﻮره

-11ﻗﺴﻤﺖ ﺗﺎﺑﺎن

-15ﺳﻮراخ روي درب

-19ﺻﻔﺤﻪ1/4اﻳﻨﭽﻲ ﺑﺪون ﭘﻴﻠﻴﺴﻪ ﺑﺎ ﻗﻄﺮ 14اﻳﻨﭻ

-21ﺷﻌﺎع 20ﻣﻴﻠﻴﻤﺘﺮ

-23ﭘﻴﭻ 1 2 1 3 4ﻣﺎﺷﻴﻦ ﻛﺎري ﺷﺪه ﻛﻪ ﺳﺮ ﭘﻴﭻ ﺑﻪ ﭘﺸﺖ درب ﻣﺤﻔﻈﻪ ﺧﺎل ﺟﻮش ﺷﺪه اﺳﺖ.

-24ﺷﻴﻠﻨﮓ ﺑﺮﻧﺰي ﺑﺎ اﺗﺼﺎﻻت ﻗﻔﻞ و ﺑﺴﺖ ﺷﻮﻧﺪه ﭘﺮ ﺷﺪه آز ﺑﺴﺖ اﻧﺘﻬﺎي ﺟﻔﺖ ﺷﻮﻧﺪه ﻧﺮي رزوه ﺷﺪه ﺑﺎ رزوه ﺑﺎرﻳﻚ ﺷﻮﻧﺪه )ﻣﺨﺮوﻃﻲ(

-25ﭼﺎﻫﻚ

TYPICAL DRAWING 6

THERMOWELL INSTALLATION IN FURNACE FIREBOXES

10

11

ﻧﻘﺸﻪ ﻧﻤﻮﻧﻪ 6

ﻧﺼﺐ ﭼﺎﻫﻚ ﺣﺮارﺗﻲ در آﺗﺸﺪان ﻛﻮره

27