PIPE SUPPORTS IRANIAN PETROLEUM STANDARDS COVER SHEET C

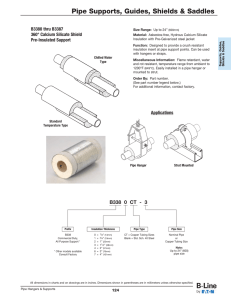

advertisement

PIPE SUPPORTS IRANIAN PETROLEUM STANDARDS C B NO REVISION PERMITTED UNLESS APPROVED BY STANDARD ORGANIZATION A REV. DESCRIPTION DATE COVER SHEET DATE DRAWING No. IPS-D-AR-012 SHT REV. CONCRETE JOISTS HEAVY DUTY BEAM CLAMP EYE SOCKET CONCRETE JOIST SEE PROJECT PLANS CONCRETE INSERT STRUCTURAL STEEL BEAM SEE PROJECT PLANS FOR SIZE HEAVY DUTY CONCRETE INSERT NUT HANGER ROD STEEL JOISTS 1-ALL DIMENSIONS ARE IN MILLIMETERS UNLESS OTHERWISE NOTED. LAG SCREWS SUPPORT NUT WOOD BENT STRAP" " JOIST OR BEAM 40x4mm. SEE PROJECT OVER VERT PLANS LEGS OF ANGLES BOTTOM CHORD OF O.W.S.J. ONE ANGLE EACH SIDE WEB MEMBERS REST ON TOP OF BOTTOM CHORD OF O.W.S.J. BETWEEN PANEL POINTS. SIZE FOR LOAD. HANGER ROD NOTE: WOOD JOISTS WEB MEMBERS O.W.S.J. HANGER NUT HEAVY DUTY CONCRETE JOIST CLAMP CONCRETE SLAB SEE PROJECT PLANS STEEL INSERT WITH ELONGATED SLOT WELDS HANGER ROD ADJUSTABLE STEEL U-SUPPORT HANGER ROD HANGER ROAD HANGER ROD LOCKING NUT HANGER ROD HEAVY DUTY CLEVIS HANGER LOCKING NUT SUPPORT NUT PIPE NO INSULATION HEAVY DUTY CLEVIS HANGER INSULATION WELD PIPE SADDLE AT LEAST 300mm. LONG STAND LOCKING NUT LOCKING NUT 1.6mm.(16 GAGE)STEEL SADLE 300mm. LONG 1.6 mm.(16 GAGE) ZINC COATED INSULATION WHERE SPECIFIED SHALL BUTT AGAINST PIPE HANGERS SHEET STEEL SADOLE AT LEAST 300 mm. LONG. CLEVIS HANGER SUPPORT NUT SUPPORT NUT ROLLER STAND LOCKING NUT BOLT PIPE ROLLER TO CHANNEL BOLT PIPE ROLLERS TO CHANNEL CLEVIS HANGER SINGLE HORIZONTAL RUNS NO VAPOR BARRIER INSULATION HANGER ROD PIPE STAND VAPOR BARRIER INSULATION PIPE VAPOR BARRIER ROLLER SUPPORT NUT 3-THE SPACING SHOWN IN SCHEDULE IS MAXIMUM PIPE WILL SPAN. THE HANGER SUPPORTS AND STRUCTURAL ELEMENTS OF THE BUILDING SHOULD BE CHECKED FOR LOAD SUPPORT. SPACING MAY HAVE TO BE REDUCED TO LIGHTEN LOAD ON CERTAIN HANGER SUPPORTS. INSULATION(NOT VAPOR BARRIER) MAXIMUM SPACING 600 mm. C/C HANGER ROD 2-THE STEEL SADDLE STAND CAN BE REPLACED BY ANY OTHER SUITABLE ALTERNATIVE AS RECOMMENDED BY THE DESIGN ENGINEER. SUPPORT NUT CHANNEL SUITABLE SIZE TRAPEZE HANGER SINGLE HORIZONTAL RUNS WITH VAPOR BARRIER INSULATION ALL MULTIPLE HORIZONTAL RUNS WITH OR WITHOUT VAPOR BARRIER INSULATION PIPE HANGERS-USE APPLICABLE TYPE (SEE NOTE 3) DETAILS OF THE PIPE SUPPORTS (A) (B) (C) (D) (E) PIPE SIZE DN(IN) DN20 (3/4") THRU DN50 (2") DN100( 4") THRU DN125 (5") 10(3/8") 13(1/2") 16(5/8") DN200 (8") THRU DN300 (12") 22(7/8") DN65 (2 1/2") THRU DN80 (3") UP TO DN50 (2") ROD SIZE mm. IN 10 (3/8") DN65(2 1/2") 13 (1/2") THRU DN80(3") 19(3/4") DN150 (6") HANGER ROD SCHEDULE PIPE SIZE DN IN ROD DIAMETER mm.(IN) PIPE SIZE DN IN ROD SIZE mm. IN DN100(4") THRU 16 (5/8") DN125 (5") DN150(6") THRU 22 (7/8") DN300 (12") PIPE SIZE HANGER ROD SPACING C B A REV. IRANIAN PETROLEUM STANDARDS NOTE: FOR TRAPEZE HANGER TAKE SPACING OF SMALLEST PIPE ON TRAPEZE DATE NO REVISION PERMITTED UNLESS APPROVED BY STANDARD ORGANIZATION PIPE SUPPORTS DN25 DN32 DN40 DN50 DN65 DN80 DN100 DN125 DN150 DN200 DN250 DN300 (1") (1 1/4") (1 1/2") (2") (2 1/2") (3") (4") (5") (6") (8") (10") (12") MAX ALLOWABLE 7 FT. 8 FT. 9 FT. 10 FT. 11 FT. 12 FT. 14 FT. 16 FT. 17 FT. 19 FT. 22 FT. 23 FT. SPACING 2.13 m. 2.44 m. 2.74 m. 3 m. 3.35 m.3.66 m.4.27 m. 4.80 m. 5.18 m. 5.79 m. 6.71 m. 7.015 m. DESCRIPTION DATE DRAWING No. IPS-D-AR-012 SHEET REV. 1 6 A B PIPE C L G C H E NOM. MAX. O.D HANGER ADJ. PIPE ROD SOCKET SIZE COVERING SIZE.G. No. 1" 2" 1 1/4" 2 1/2" 1 1/2" 2 3/4" D E F 47 26 19 10 19 10 1-10 119 90 54 122 78 34 22 106 41 25 10 4 1/2" 12 4" 5 1/2" 5" 7" 12 15 6" 8 1/4" 8" 10 1/2" 10" 12 3/4" 12" 14 3/4" 10 1-10 1-10 12 2-12 12 15 2-12 3-12 2-12 3-12 12 15 12 15 19 12 15 19 22 12 15 19 22 15 19 22 2-12 2-15 3-15 2-19 3-19 4-19 2-22 3-22 4-22 5-22 2-22 3-22 4-22 5-22 3-25 4-25 5-22 112 85 131 103 172 137 156 180 194 200 206 236 442 273 280 286 333 339 345 351 386 392 398 405 436 442 448 153 156 165 169 37 25 75 65 95 29 30 36 19 19 J 26 14 10 34 14 12 49 10 22 H 10 12 31 40 55 12 64 119 44 25 12 70 202 145 50 28 16 86 239 172 58 31 19 100 298 222 70 37 22 128 356 275 85 44 22 160 395 312 97 50 25 186 14 14 17 17 19 19 19 19 20 22 22 25 25 23 26 29 30 23 26 29 30 29 31 31 IRANIAN PETROLEUM STANDARDS C B NO REVISION PERMITTED UNLESS APPROVED BY STANDARD ORGANIZATION A REV. C 103 3" 5" B J ALL DIMENSIONS EXCEPT AS SHOWN ARE IN mm. 1-10 3 1/4" 3 1/2" A D 10 2" 2 1/2" 3 3/4" F DESCRIPTION SINGLE PIPE ROLL DATE HANGER DATE DRAWING No. IPS-D-AR-012 SHT REV. 2 6 NT ME G SE OF CONCRETE SLAB SLAB 2- TEE IRON PIPE STAND CAN BE REPLACED BY ANY OTHER SUITABLE ALTERNATIVE AS RECOMMENDED BY THE DESIGN ENGINEER. PIPE INSULATION CEMENT No.6 ANGLE IRON 2000 No.8 TEE IRON CONTINUOUS WELD SEE DETALE"A" 500 250x150x10 mm. PLATE IRON 30 CONCRETE 4" (DN100) HOT WATER HEATING SUPPLY & RETURN PIPES 4" (DN100)HOT WATER PIPE PIPE INSULATION CONTINUOUS WELD No.8 TEE IRON 6" (DN150) MAIN COLD WATER PIPE 80 No. 8 ANGLE IRON No.6 TEE IRON 2" (DN50) RECIRCULATING HOT WATER PIPE 200 40 No.8 TEE IRON 2 1/2" (DN65) GAS PIPE SLOPE 150 F.D. 3" 100 40 3- WHERE SITE CONDITION DEMANDS THE CONSTRUCTION OF INSIDE WALL CAN BE EXPEDITED WITH CONCRETE IN PLACE OF BRICKS. BRICK WALL No. 8 CHANNEL IRON 90 8" (DN200) GHILLED WATER SUPPLY & RETURN PIPES PIPE INSULATION 80 No. 8 ANGLE IRON 0 1-ALL DIMENSIONS ARE IN MILLIMETERS UNLESS OTHERWISE SPECIFIED 600mm. APPROX CONTINUOUS WELD 17 NOTES: 1050 80 BRICK WALL 1800 50 560 N E GL AN PE PI 700 500 6 o. N IRO INSULATION LINE 30 DETAIL "A" 10x150x250 PLATE IRON TYPICAL SECTION OF WALK-THRU TUNNEL IN SITE 3" (DN80) DRAIN PIPE SEGMENT OF PIPE No.8 TEE IRON No.8 TEE IRON CONTINUOUS WELD CONTINUOUS WELD SEGMENT OF PIPE CONTINUOUS WELD No.8 TEE IRON SEGMENT OF PIPE CONTINUOUS WELD 15x15x200 BAR CONTINUOUS WELD 45x10x260 BAR 50 No. 6 ANGLE IRON DETAIL OF ANCHOR No. 6 ANGLE IRON DETAIL OF SUPPORT 50 No. 6 ANGLE IRON DETAIL OF ALIGNMENT GUIDE C B A REV. DESCRIPTION IRANIAN PETROLEUM STANDARDS DATE NO REVISION PERMITTED UNLESS APPROVED BY STANDARD ORGANIZATION TYPICAL DETAIL OF WALKTHRU TUNNEL IN SITE DATE DRAWING No. IPS-D-AR-012 SHEET REV. 3 6 WATER PROOFING ON INTERIOR OF WALL PIPE THRU WALL HEAVY THREADED FLANGES (BOTH SIDES) TAPPED & THREADED TO RECEIVE TWO STUDS PER FLANGE AS SHOWN HEAVY PIPE SLEEVES. THREADED BOTH ENDS TO RECEIVE FLANGES AS SHOWN (SEE SCHED. FOR,SIZES) OAKUM (CAULKED) BITUMASTIC BETWEEN FACE OF FLANGE & WALL HOT LEAD POURED & CAULKING CONCRETE WALL PIPE SLEEVE SCHEDULE DIA. OF PIPE THRU WALL 1/2" (DN15) DN50 (2") 3/4" (DN20) DN50 (2") 1 1/4" (DN32) DN80 (3") 2" (DN50) DN100 (4") 1" (DN25)_ 1 1/2" (DN40) 2 1/2" (DN65) 3" (DN80) DN50 (2") DN80 (3") DN100 (4") DN150 (6") 4" (DN100) DN150 (6") 6" (DN150) DN200 (8") 5" (DN125) 8" (DN200) NOTE: DIA. OF SLEEVE REQUIRED DN200 (8") DN250 (10") PIPE SLEEVE FLANGES 1/2" THRU 2 1/2" CAN BE DELETED AS PER DESIGN ENGINEER RECOMMENDATION. IRANIAN PETROLEUM STANDARDS C B NO REVISION PERMITTED UNLESS APPROVED BY STANDARD ORGANIZATION A REV. DESCRIPTION TYPICAL THRU-WALL DATE SLEEVE DETAIL EXTERIOR DATE DRAWING No. IPS-D-AR-012 SHT REV. 4 6 FINISHED TOPPING 4 6 1 2 1 2 3 UNINSULATED PIPE 4 3 mm.(1/8") P L FLANGE WELDED TO SLEEVE FINISHED FLOOR 5 6 5 6 3 1 FLOOR FLANGE SLEEVES EXPOSED IN ROOMS SHALL BE ASTM A53 GRADE "B" STEEL PIPE CUT SQUARE & REAMED. SLEEVES CONCEALED IN CHASES, PIPE SPACES, ETC. SHALL BE 0.85 mm. (22 GAUGE) GALV.IRON. SLEEVE SHALL BE SET IN SLAB WITH ANCHOR LUGS. A MINIMUM OF 3 LUGES PER SLEEVE. SLEEVE SHALL BE THREADED & HELD IN PLACE W/FLOOR FLANGE. PROVIDE. PLASTIC CAULKING COMPOUND BETWEEN 3 mm. (1/8") PL FLANGE & FLOOR. SLEEVE SHALL BE CAULKED W/OAKUM OR ASBESTOS ROPE. FINISH W/25mm(1") PLASTIC CAULKING COMPOUND. SLEEVE SHALL BE CAULKED W/25mm(1") PLASTIC CAULKING COMPOUND. SLEEVES SHALL EXTEND 13mm.(1/2") ABOVE FINISHED FLOOR EXCEPT IN KITCHENS, TOILETS, LOCKER ROOMS & SIMILAR. DAMP AREAS: IN THESE AREAS THE SLEEVES SHALL EXTEND 40mm. (1 1/2") ABOVE THE FINISHED FLOOR. INSULATED PIPE IRANIAN PETROLEUM STANDARDS C B NO REVISION PERMITTED UNLESS APPROVED BY STANDARD ORGANIZATION A REV. DESCRIPTION TYPICAL MECHANICAL DETAIL DATE FOR PIPE SLEEVES IN DATE FLOORS DRAWING No. IPS-D-AR-012 SHT REV. 5 6 1 3 PIPE 4 1 2 2 INTERIOR WALLS FOR CLEARANCES AND CAULKINGS OF INSULATED PIPE SEE STANDARD DETAIL OF INSULATED PIPE SLEEVED THRU FLOORS. 3 4 5 SLEEVES SHALL BE ASTM A53 GRADE "B" STEEL PIPE CUT SQUARE & REAMED. SLEEVE FULL THICKNESS OF THE WALL FLUSH WITH FINISHED SURFACES. SLEEVES SHALL BE SET W/ANCHOR LUGS INTO MASONRY JOINT, GROUT,OR POURED CONCRETE. SLEEVE SHALL BE OF PROPER SIZE TO ALLOW A MINIMUM OF 13mm.(1/2") CLEARANCE BETWEEN THE SLEEVE AND THE PIPE. IN AREAS REQUIRING AN ACOUSTICAL BARRIER CAULK SLEEVE W/OAKUM OR ASBESTOS ROPE. FINISH BOTH ENDS W/25mm.(1")PLASTIC CAULKING COMPOUND. CAULK SLEEVE W/OAKUM AND LEAD. WHEN SLEEVE OCCURS ABOVE GRADE PROVIDE LEAD ON BOTH SIDES. PIPE EXTERIOR WALLS WHEN INSULATED PIPE IS SLEEVED THRU. EXTERIOR WALLS INTERRUPT THE INSULATION FOR THE LENGHT OF THE SLEEVE IRANIAN PETROLEUM STANDARDS C B NO REVISION PERMITTED UNLESS APPROVED BY STANDARD ORGANIZATION A REV. DESCRIPTION TYPICAL MECHANICAL DETAILS DATE FOR THRU-WALL PIPE DATE SLEEVES DRAWING No. IPS-D-AR-012 SHT REV. 6 6