IPS-E-AR- 120(1)

ff

FOREWORD

The Iranian Petroleum Standards (IPS) reflect

the views of the Iranian Ministry of Petroleum

and are intended for use in the oil and gas

production facilities, oil refineries, chemical and

petrochemical plants, gas handling and

processing installations and other such facilities.

IPS is based on internationally acceptable

standards and includes selections from the items

stipulated in the referenced standards. They are

also supplemented by additional requirements

and/or modifications based on the experience

acquired by the Iranian Petroleum Industry and

the local market availability. The options which

are not specified in the text of the standards are

itemized in data sheet/s, so that, the user can

select his appropriate preferences therein.

The IPS standards are therefore expected to be

sufficiently flexible so that the users can adapt

these standards to their requirements. However,

they may not cover every requirement of each

project. For such cases, an addendum to IPS

Standard shall be prepared by the user which

elaborates the particular requirements of the

user. This addendum together with the relevant

IPS shall form the job specification for the

specific project or work.

The IPS is reviewed and up-dated approximately

every five years. Each standards are subject to

amendment or withdrawal, if required, thus the

latest edition of IPS shall be applicable.

The users of IPS are therefore requested to send

their views and comments, including any

addendum prepared for particular cases to the

following address. These comments and

recommendations will be reviewed by the

relevant technical committee and in case of

approval will be incorporated in the next revision

of the standard.

Standards and Research department

No.19, Street14, North kheradmand

Karimkhan Avenue, Tehran, Iran .

Postal Code- 1585886851

Tel: 021-88810459-60 & 021-66153055

Fax: 021-88810462

Email: Standards@nioc.org

ﭘﻴﺶ ﮔﻔﺘﺎر

( ﻣﻨﻌﻜﺲ ﻛﻨﻨﺪه دﻳﺪﮔﺎﻫﻬﺎيIPS) اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮان

وزارت ﻧﻔﺖ اﻳﺮان اﺳﺖ و ﺑﺮاي اﺳﺘﻔﺎده در ﺗﺄﺳﻴﺴﺎت ﺗﻮﻟﻴﺪ

واﺣﺪﻫﺎي ﺷﻴﻤﻴﺎﻳﻲ و، ﭘﺎﻻﻳﺸﮕﺎﻫﻬﺎي ﻧﻔﺖ،ﻧﻔﺖ و ﮔﺎز

ﺗﺄﺳﻴﺴﺎت اﻧﺘﻘﺎل و ﻓﺮاورش ﮔﺎز و ﺳﺎﻳﺮ ﺗﺄﺳﻴﺴﺎت،ﭘﺘﺮوﺷﻴﻤﻲ

.ﻣﺸﺎﺑﻪ ﺗﻬﻴﻪ ﺷﺪه اﺳﺖ

ﺑﺮاﺳﺎس اﺳﺘﺎﻧﺪاردﻫﺎي ﻗﺎﺑﻞ ﻗﺒﻮل،اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ

ﺑﻴﻦاﻟﻤﻠﻠﻲ ﺗﻬﻴﻪ ﺷﺪه و ﺷﺎﻣﻞ ﮔﺰﻳﺪهﻫﺎﻳﻲ از اﺳﺘﺎﻧﺪاردﻫﺎي

ﻫﻤﭽﻨﻴﻦ ﺑﺮاﺳﺎس ﺗﺠﺮﺑﻴﺎت.ﻣﺮﺟﻊ در ﻫﺮ ﻣﻮرد ﻣﻲﺑﺎﺷﺪ

ﺻﻨﻌﺖ ﻧﻔﺖ ﻛﺸﻮر و ﻗﺎﺑﻠﻴﺖ ﺗﺄﻣﻴﻦ ﻛﺎﻻ از ﺑﺎزار داﺧﻠﻲ و ﻧﻴﺰ

ﻣﻮاردي ﺑﻄﻮر ﺗﻜﻤﻴﻠﻲ و ﻳﺎ اﺻﻼﺣﻲ در اﻳﻦ،ﺑﺮﺣﺴﺐ ﻧﻴﺎز

ﻣﻮاردي از ﮔﺰﻳﻨﻪﻫﺎي ﻓﻨﻲ ﻛﻪ در.اﺳﺘﺎﻧﺪارد ﻟﺤﺎظ ﺷﺪه اﺳﺖ

ﻣﺘﻦ اﺳﺘﺎﻧﺪاردﻫﺎ آورده ﻧﺸﺪه اﺳﺖ در داده ﺑﺮگﻫﺎ ﺑﺼﻮرت

ﺷﻤﺎره ﮔﺬاري ﺷﺪه ﺑﺮاي اﺳﺘﻔﺎده ﻣﻨﺎﺳﺐ ﻛﺎرﺑﺮان آورده ﺷﺪه

.اﺳﺖ

ﺑﺸﻜﻠﻲ ﻛﺎﻣﻼً اﻧﻌﻄﺎف ﭘﺬﻳﺮ ﺗﺪوﻳﻦ ﺷﺪه،اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ

.اﺳﺖ ﺗﺎ ﻛﺎرﺑﺮان ﺑﺘﻮاﻧﻨﺪ ﻧﻴﺎزﻫﺎي ﺧﻮد را ﺑﺎ آﻧﻬﺎ ﻣﻨﻄﺒﻖ ﻧﻤﺎﻳﻨﺪ

ﺑﺎ اﻳﻦ ﺣﺎل ﻣﻤﻜﻦ اﺳﺖ ﺗﻤﺎم ﻧﻴﺎزﻣﻨﺪيﻫﺎي ﭘﺮوژه ﻫﺎ را

در اﻳﻦ ﮔﻮﻧﻪ ﻣﻮارد ﺑﺎﻳﺪ اﻟﺤﺎﻗﻴﻪاي ﻛﻪ ﻧﻴﺎزﻫﺎي.ﭘﻮﺷﺶ ﻧﺪﻫﻨﺪ

اﻳﻦ.ﺧﺎص آﻧﻬﺎ را ﺗﺄﻣﻴﻦ ﻣﻲﻧﻤﺎﻳﺪ ﺗﻬﻴﻪ و ﭘﻴﻮﺳﺖ ﻧﻤﺎﻳﻨﺪ

ﻣﺸﺨﺼﺎت ﻓﻨﻲ آن ﭘﺮوژه،اﻟﺤﺎﻗﻴﻪ ﻫﻤﺮاه ﺑﺎ اﺳﺘﺎﻧﺪارد ﻣﺮﺑﻮﻃﻪ

.و ﻳﺎ ﻛﺎر ﺧﺎص را ﺗﺸﻜﻴﻞ ﺧﻮاﻫﻨﺪ داد

اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ ﺗﻘﺮﻳﺒﺎً ﻫﺮ ﭘﻨﺞ ﺳﺎل ﻳﻜﺒﺎر ﻣﻮرد ﺑﺮرﺳﻲ

در اﻳﻦ ﺑﺮرﺳﻲﻫﺎ ﻣﻤﻜﻦ اﺳﺖ.ﻗﺮار ﮔﺮﻓﺘﻪ و روزآﻣﺪ ﻣﻲﮔﺮدﻧﺪ

اﺳﺘﺎﻧﺪاردي ﺣﺬف و ﻳﺎ اﻟﺤﺎﻗﻴﻪاي ﺑﻪ آن اﺿﺎﻓﻪ ﺷﻮد و ﺑﻨﺎﺑﺮاﻳﻦ

.ﻫﻤﻮاره آﺧﺮﻳﻦ وﻳﺮاﻳﺶ آﻧﻬﺎ ﻣﻼك ﻋﻤﻞ ﻣﻲ ﺑﺎﺷﺪ

درﺧﻮاﺳﺖ ﻣﻲﺷﻮد ﻧﻘﻄﻪ ﻧﻈﺮﻫﺎ و،از ﻛﺎرﺑﺮان اﺳﺘﺎﻧﺪارد

ﭘﻴﺸﻨﻬﺎدات اﺻﻼﺣﻲ و ﻳﺎ ﻫﺮﮔﻮﻧﻪ اﻟﺤﺎﻗﻴﻪاي ﻛﻪ ﺑﺮاي ﻣﻮارد

ﻧﻈﺮات و. ﺑﻪ ﻧﺸﺎﻧﻲ زﻳﺮ ارﺳﺎل ﻧﻤﺎﻳﻨﺪ،ﺧﺎص ﺗﻬﻴﻪ ﻧﻤﻮدهاﻧﺪ

ﭘﻴﺸﻨﻬﺎدات درﻳﺎﻓﺘﻲ در ﻛﻤﻴﺘﻪﻫﺎي ﻓﻨﻲ ﻣﺮﺑﻮﻃﻪ ﺑﺮرﺳﻲ و در

ﺻﻮرت ﺗﺼﻮﻳﺐ در ﺗﺠﺪﻳﺪ ﻧﻈﺮﻫﺎي ﺑﻌﺪي اﺳﺘﺎﻧﺪارد ﻣﻨﻌﻜﺲ

.ﺧﻮاﻫﺪ ﺷﺪ

ﻛﻮﭼﻪ، ﺧﺮدﻣﻨﺪ ﺷﻤﺎﻟﻲ، ﺧﻴﺎﺑﺎن ﻛﺮﻳﻤﺨﺎن زﻧﺪ، ﺗﻬﺮان،اﻳﺮان

19 ﺷﻤﺎره،ﭼﻬﺎردﻫﻢ

اداره ﺗﺤﻘﻴﻘﺎت و اﺳﺘﺎﻧﺪاردﻫﺎ

1585886851 : ﻛﺪﭘﺴﺘﻲ

021-66153055 و021-8810459- 60 : ﺗﻠﻔﻦ

021-88810462 : دور ﻧﮕﺎر

Standards@nioc.org

:ﭘﺴﺖ اﻟﻜﺘﺮوﻧﻴﻜﻲ

: ﺗﻌﺎرﻳﻒ ﻋﻤﻮﻣﻲ

General Definitions:

Throughout this Standard

definitions shall apply.

the

following

Company :

Refers to one of the related and/or affiliated

companies of the Iranian Ministry of Petroleum

such as National Iranian Oil Company, National

Iranian

Gas

Company,

and

National

Petrochemical Company etc.

Purchaser :

Means the "Company" Where this standard is

part of direct purchaser order by the “Company”,

and the “Contractor” where this Standard is a part

of contract ducments.

Vendor And Supplier:

Refers to firm or person who will supply and/or

fabricate the equipment or material.

Contractor:

Refers to the persons, firm or company whose

tender has been accepted by the company.

Executor :

Executor is the party which carries out all or part

of construction and/or commissioning for the

project.

Inspector :

The Inspector referred to in this Standard is a

person/persons or a body appointed in writing by

the company for the inspection of fabrication and

installation work

Shall:

Is used where a provision is mandatory.

Should

Is used where a provision is advisory only.

Will:

Is normally used in connection with the action

by the “Company” rather than by a contractor,

supplier or vendor.

May:

Is used where a provision is completely

discretionary.

.در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺗﻌﺎرﻳﻒ زﻳﺮ ﺑﻪ ﻛﺎر ﻣﻲ رود

: ﺷﺮﻛﺖ

ﺑﻪ ﺷﺮﻛﺖ ﻫﺎي اﺻﻠﻲ و واﺑﺴﺘﻪ وزارت ﻧﻔﺖ ﻣﺜﻞ ﺷﺮﻛﺖ ﻣﻠﻲ

ﺷﺮﻛﺖ ﻣﻠﻲ ﺻﻨﺎﻳﻊ، ﺷﺮﻛﺖ ﻣﻠﻲ ﮔﺎز اﻳﺮان،ﻧﻔﺖ اﻳﺮان

.ﭘﺘﺮوﺷﻴﻤﻲ و ﻏﻴﺮه اﻃﻼق ﻣﻴﺸﻮد

:ﺧﺮﻳﺪار

ﻳﻌﻨﻲ "ﺷﺮﻛﺘﻲ" ﻛﻪ اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﺨﺸﻲ از ﻣﺪارك ﺳﻔﺎرش

ﺧﺮﻳﺪ ﻣﺴﺘﻘﻴﻢ آن "ﺷﺮﻛﺖ" ﻣﻴﺒﺎﺷﺪ و ﻳﺎ "ﭘﻴﻤﺎﻧﻜﺎري" ﻛﻪ اﻳﻦ

. اﺳﺘﺎﻧﺪارد ﺑﺨﺸﻲ از ﻣﺪارك ﻗﺮارداد آن اﺳﺖ

:ﻓﺮوﺷﻨﺪه و ﺗﺎﻣﻴﻦ ﻛﻨﻨﺪه

ﺑﻪ ﻣﻮﺳﺴﻪ و ﻳﺎ ﺷﺨﺼﻲ ﮔﻔﺘﻪ ﻣﻴﺸﻮد ﻛﻪ ﺗﺠﻬﻴﺰات و ﻛﺎﻻﻫﺎي

. ﻣﻮرد ﻟﺰوم ﺻﻨﻌﺖ را ﺗﺎﻣﻴﻦ ﻣﻴﻨﻤﺎﻳﺪ

:ﭘﻴﻤﺎﻧﻜﺎر

ﻣﻮﺳﺴﻪ و ﻳﺎ ﺷﺮﻛﺘﻲ ﮔﻔﺘﻪ ﻣﻴﺸﻮد ﻛﻪ ﭘﻴﺸﻨﻬﺎدش، ﺑﻪ ﺷﺨﺺ

.ﺑﺮاي ﻣﻨﺎﻗﺼﻪ و ﻳﺎ ﻣﺰاﻳﺪه ﭘﺬﻳﺮﻓﺘﻪ ﺷﺪه اﺳﺖ

: ﻣﺠﺮي

ﻣﺠﺮي ﺑﻪ ﮔﺮوﻫﻲ اﺗﻼق ﻣﻲ ﺷﻮد ﻛﻪ ﺗﻤﺎم ﻳﺎ ﻗﺴﻤﺘﻲ از

.ﻛﺎرﻫﺎي اﺟﺮاﻳﻲ و ﻳﺎ راه اﻧﺪازي ﭘﺮوژه را اﻧﺠﺎم دﻫﺪ

:ﺑﺎزرس

در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﺎزرس ﺑﻪ ﻓﺮد ﻳﺎ ﮔﺮوﻫﻲ اﺗﻼق ﻣﻲ ﺷﻮد ﻛﻪ

ﻛﺘﺒﺎً ﺗﻮﺳﻂ ﻛﺎرﻓﺮﻣﺎ ﺑﺮاي ﺑﺎزرﺳﻲ ﺳﺎﺧﺖ و ﻧﺼﺐ ﺗﺠﻬﻴﺰات

.ﻣﻌﺮﻓﻲ ﺷﺪه ﺑﺎﺷﺪ

:ﺑﺎﻳﺪ

.ﺑﺮاي ﻛﺎري ﻛﻪ اﻧﺠﺎم آن اﺟﺒﺎري اﺳﺖ اﺳﺘﻔﺎده ﻣﻴﺸﻮد

:ﺗﻮﺻﻴﻪ

.ﺑﺮاي ﻛﺎري ﻛﻪ ﺿﺮورت اﻧﺠﺎم آن ﺗﻮﺻﻴﻪ ﻣﻴﺸﻮد

:ﺗﺮﺟﻴﺢ

ﻣﻌﻤﻮﻻً در ﺟﺎﻳﻲ اﺳﺘﻔﺎده ﻣﻲﺷﻮد ﻛﻪ اﻧﺠﺎم آن ﻛﺎر ﺑﺮاﺳﺎس

.ﻧﻈﺎرت ﺷﺮﻛﺖ ﺑﺎﺷﺪ

: ﻣﻤﻜﻦ اﺳﺖ

. ﺑﺮاي ﻛﺎري ﻛﻪ اﻧﺠﺎم آن اﺧﺘﻴﺎري اﺳﺖ اﺳﺘﻔﺎده ﻣﻴﺸﻮد

IPS-E-AR- 120(1)

ENGINEERING STANDARD

FOR

BUILDING AIR CONDITIONING SYSTEMS

FIRST REVISION

NOVEMBER 2009

اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ

ﺑﺮاي

ﺳﺎﻣﺎﻧﻪ ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع ﺳﺎﺧﺘﻤﺎن

[

وﻳﺮاﻳﺶ اول

1388 آذر

This Standard is the property of Iranian Ministry of Petroleum.

All rights are reserved to the owner. Neither whole nor any

part of this document may be disclosed to any third party,

reproduced, stored in any retrieval system or transmitted in

any form or by any means without the prior written consent of

the Iranian Ministry of Petroleum.

0

ﺗﻤﺎم ﺣﻘﻮق آن ﻣﺘﻌﻠﻖ ﺑﻪ.اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﺘﻌﻠﻖ ﺑﻪ وزارت ﻧﻔﺖ اﻳﺮان اﺳﺖ

ﺗﻤﺎم ﻳﺎ،ﻣﺎﻟﻚ آن ﺑﻮده و ﻧﺒﺎﻳﺪ ﺑﺪون رﺿﺎﻳﺖ ﻛﺘﺒﻲ وزارت ﻧﻔﺖ اﻳﺮان

ذﺧﻴﺮه، ﺑﻪ ﻫﺮ ﺷﻜﻞ ﻳﺎ وﺳﻴﻠﻪ ازﺟﻤﻠﻪ ﺗﻜﺜﻴﺮ، ﺑﺨﺸﻲ از اﻳﻦ اﺳﺘﺎﻧﺪارد

. ﻳﺎ روش دﻳﮕﺮي در اﺧﺘﻴﺎر اﻓﺮاد ﺛﺎﻟﺚ ﻗﺮار ﮔﻴﺮد، اﻧﺘﻘﺎل،ﺳﺎزي

Nov. 2009 / 1388 آذر

Page

No.

0. INTRODUCTION .....................................................6

CONTENTS:

IPS-E-AR- 120(1)

:ﻓﻬﺮﺳﺖ ﻣﻄﺎﻟﺐ

6.............................................................................. ﻣﻘﺪﻣﻪ-0

1. SCOPE ..........................................................................7

7................................................................... داﻣﻨﻪ ﻛﺎرﺑﺮد-1

2. REFERENCES...........................................................8

8 ............................................................................. ﻣﺮاﺟﻊ-2

3. DEFINITIONS AND TERMINOLOGY............10

10 ................................................................ ﺗﻌﺎرﻳﻒ و واژﮔﺎن-3

3.1 Air Washer ...............................................................10

10 ...................................................................... ﻫﻮاﺷﻮي1-3

3.2 Air-Conditioning System...................................10

10 ................................................ ﺳﺎﻣﺎﻧﻪ ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع2-3

3.3 Azeotrope ..................................................................10

10 ................................................................... ازﺋﻮﺗﺮوپ3-3

3.4 Ceiling Diffuser ......................................................11

11 ...................................... درﻳﭽﻪ ﺗﻮزﻳﻊ ﻫﻮاي ﺳﻘﻔﻲ4-3

3.5 Central Fan Air-Conditioning System........11

11 ...................... ﺑﺎدزن ﻣﺮﻛﺰي ﺳﺎﻣﺎﻧﻪ ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع5-3

3.6 Water Chiller ..........................................................11

11 .................................................................... ﭼﻴﻠﺮ آﺑﻲ6-3

3.7 Comfort Air-Conditioning................................11

11 .............................................. ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع آﺳﺎﻳﺶ7-3

3.8 Conditioned Space ................................................11

11 ................................................. ﻓﻀﺎي ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع8-3

3.9 Coolant .......................................................................11

11 ................................................... ﺳﻴﺎل ﺧﻨﻚ ﻛﻨﻨﺪه9-3

3.10 Damper ....................................................................11

11 ........................................................................... دﻣﭙﺮ10-3

3.11 Design Load...........................................................11

11 ................................................................. ﺑﺎر ﻃﺮاﺣﻲ11-3

3.12 Direct Digital Controls .....................................12

12 ..................................... ﻛﻨﺘﺮﻟﻬﺎي ﻋﺪدي ﻣﺴﺘﻘﻴﻢ12-3

3.13 Heat Pump .............................................................12

12 ........................................................... ﭘﻤﭗ ﺣﺮارﺗﻲ13-3

3.14 HVAC Systems.....................................................12

ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع، ﺗﻬﻮﻳﻪ، ﺳﺎﻣﺎﻧﻪ ﻫﺎي ﮔﺮﻣﺎﻳﺶ14-3

12 .................................................................. و ﺳﺮﻣﺎﻳﺶ

3.15 Induction Unit ......................................................12

12 ............................................................. واﺣﺪ اﻟﻘﺎﻳﻲ15-3

3.16 Optimization .........................................................12

12 ............................................................. ﺑﻬﻴﻨﻪ ﺳﺎزي16-3

3.17 Psychrometric Chart.........................................12

12 ............................................... ﻧﻤﻮدار ﺳﺎﻳﻜﺮوﻣﺘﺮي17-3

1

Nov. 2009 / 1388 آذر

IPS-E-AR- 120(1)

3.18 Relative Humidity...............................................13

13 .......................................................... رﻃﻮﺑﺖ ﻧﺴﺒﻲ18-3

3.19 Variable Air Volume.........................................13

13 ........................................................ ﺣﺠﻢ ﻣﺘﻐﻴﺮ ﻫﻮا19-3

3.20 Zoning ......................................................................13

13 ............................................................ ﻣﻨﻄﻘﻪ ﺑﻨﺪي20-3

4. UNITS ...........................................................................13

13........................................................................... واﺣﺪﻫﺎ-4

5. BASIC DESIGN REQUIREMENTS ...................13

13 ......................................................... ﻧﻴﺎزﻫﺎي ﻃﺮاﺣﻲ ﭘﺎﻳﻪ-5

5.1 General.......................................................................13

13 ........................................................................ ﻋﻤﻮﻣﻲ1-5

5.2 Design Load Factors ............................................14

14 .................................................................. ﺑﺎر ﻃﺮاﺣﻲ2-5

5.3 Design Outside Conditions................................15

15 ............................................... ﺷﺮاﻳﻂ ﻃﺮاﺣﻲ ﺧﺎرج3-5

5.4 Design Inside Conditions ...................................15

15 ............................................... ﺷﺮاﻳﻂ ﻃﺮاﺣﻲ داﺧﻞ4-5

5.5 Solar Heat Gain......................................................15

15 .......................................... ﺑﻬﺮه ﮔﺮﻣﺎﻳﻲ ﺧﻮرﺷﻴﺪي5-5

5.6 Transmission Heat Gain ....................................15

15 .................................................... ﺑﻬﺮه ﮔﺮﻣﺎي اﻧﺘﻘﺎﻟﻲ6-5

5.7 Design Occupancy.................................................16

16 ........................................ ﮔﺮﻣﺎزاﻳﻲ اﻓﺮاد در ﻃﺮاﺣﻲ7-5

5.8 Heat from Appliances & other

Equipment..................................................................17

17 ﺣﺮارت ﻧﺎﺷﻲ از وﺳﺎﻳﻞ ﺧﺎﻧﮕﻲ و ﺗﺠﻬﻴﺰات دﻳﮕﺮ8-5

5.9 Ventilation and Infiltration ..............................17

17 ....................................................... ﺗﻬﻮﻳﻪ و ﻧﻔﻮذ ﻫﻮا9-5

5.10 Air Motion in Conditioned Spaces..............18

18 ....................... ﺣﺮﻛﺖ ﻫﻮا در ﻓﻀﺎي ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع10-5

5.11 Safety Provisions .................................................18

18 ........................................................ ﺗﻤﻬﻴﺪات اﻳﻤﻨﻲ11-5

5.12 Equipment Service Life....................................19

19 ................................................ ﻋﻤﺮ ﻣﻔﻴﺪ ﺗﺠﻬﻴﺰات12-5

6. AIR CONDITIONING SYSTEM

CLASSIFICATION.....................................................19

19 .................................... ﻃﺒﻘﻪ ﺑﻨﺪي ﺳﺎﻣﺎﻧﻪ ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع-6

6.1 General.......................................................................19

19 ......................................................................... ﻋﻤﻮﻣﻲ1-6

6.2 Packaged-Unitary System .................................19

19 .................................................ﺳﺎﻣﺎﻧﻪ واﺣﺪ ﻳﻜﭙﺎرﭼﻪ2-6

6.3 Heat Pump System ...............................................22

22 ................................................. ﺳﺎﻣﺎﻧﻪ ﭘﻤﭗ ﺣﺮارﺗﻲ3-6

2

Nov. 2009 / 1388 آذر

IPS-E-AR- 120(1)

7. METHODS OF FLUID AND AIR

DISTRIBUTION ............................................................23

23 .......................................... روش ﻫﺎي ﺗﻮزﻳﻊ ﺳﻴﺎل و ﻫﻮا-7

7.1 Methods of Distributing Fluid Media ..........23

23 ................................... روش ﻫﺎي ﺗﻮزﻳﻊ ﻋﺎﻣﻞ ﺳﻴﺎل1-7

7.2 Methods of Air Distribution and

Circulation..................................................................26

26 .......................... روش ﻫﺎي ﺗﻮزﻳﻊ ﻫﻮا و ﮔﺮدش آن2-7

8. CENTRAL HVAC SYSTEM...................................32

32 ...... ﺳﺮﻣﺎﻳﺶ و ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع ﻣﺮﻛﺰي، ﺳﺎﻣﺎﻧﻪ ﮔﺮﻣﺎﻳﺶ-8

8.1 General.......................................................................32

32 ........................................................................ ﻋﻤﻮﻣﻲ1-8

8.2 Refrigeration Machines......................................32

32 ................................................... دﺳﺘﮕﺎﻫﻬﺎي ﺗﺒﺮﻳﺪ2-8

8.3 Central Chillers......................................................32

32 ...................................................... ﭼﻴﻠﺮﻫﺎي ﻣﺮﻛﺰي3-8

8.4 Air Cooled Versus Water Cooled System..36

ﺳﺎﻣﺎﻧﻪ ﻫﻮا ﺧﻨﻚ ﺷﻮﻧﺪه در ﻣﻘﺎﺑﻞ آب4-8

36 ..............................................................ﺧﻨﻚ ﺷﻮﻧﺪه

8.5 Chilled/Hot Water Piping .................................38

38 ......................................... ﮔﺮم/ ﻟﻮﻟﻪ ﻛﺸﻲ آب ﺳﺮد5-8

8.6 Water Treatment...................................................39

39 .................................................................. ﺗﺼﻔﻴﻪ آب6-8

9. EQUIPMENT SELECTION

GUIDELINES...................................................................41

41 ............................................... راﻫﻨﻤﺎي اﻧﺘﺨﺎب ﺗﺠﻬﻴﺰات-9

9.1 General.......................................................................41

41 ......................................................................... ﻋﻤﻮﻣﻲ1-9

9.2 Liquid Chiller Selection .....................................41

41 .............................................................. اﻧﺘﺨﺎب ﭼﻴﻠﺮ2-9

9.3 Absorption Chiller Selection............................44

44 .................................................. اﻧﺘﺨﺎب ﭼﻴﻠﺮ ﺟﺬﺑﻲ3-9

9.4 Centrifugal Chiller Selection ...........................47

47 ...................................... اﻧﺘﺨﺎب ﭼﻴﻠﺮ ﮔﺮﻳﺰ از ﻣﺮﻛﺰ4-9

9.5 Air Handling Unit Selection.............................48

48 ........................................ اﻧﺘﺨﺎب دﺳﺘﮕﺎه ﻫﻮارﺳﺎن5-9

9.6 Fan Coil Selection .................................................49

49 ....................................................... اﻧﺘﺨﺎب ﻓﻦ ﻛﻮﻳﻞ6-9

9.7 Air Induction Unit Selection ............................50

50 ................................................. اﻧﺘﺨﺎب واﺣﺪ اﻟﻘﺎﻳﻲ7-9

9.8 Cooling Tower Selection ....................................52

52 ........................................ اﻧﺘﺨﺎب ﺑﺮج ﺧﻨﻚ ﻛﻨﻨﺪه8-9

3

Nov. 2009 / 1388 آذر

IPS-E-AR- 120(1)

9.9 Pump Selection .......................................................53

53 ............................................................... اﻧﺘﺨﺎب ﭘﻤﭗ9-9

9.10 Cooling Coil Selection.......................................54

54 ............................................. اﻧﺘﺨﺎب ﻛﻮﻳﻞ ﺳﺮﻣﺎﻳﻲ10-9

9.11 Heating Coil Selection ......................................56

56 .............................................. اﻧﺘﺨﺎب ﻛﻮﻳﻞ ﮔﺮﻣﺎﻳﻲ11-9

9.12 Condensing Unit Selection..............................58

58 ........................................ اﻧﺘﺨﺎب دﺳﺘﮕﺎه ﭼﮕﺎﻟﺶ12-9

10. REFRIGERANTS.......................................................58

58 ................................................................................ ﻣﺒﺮدﻫﺎ-10

10.1 General ....................................................................58

58 ....................................................................... ﻋﻤﻮﻣﻲ1-10

10.2 Properties ...............................................................61

61 ........................................................................ ﺧﻮاص2-10

10.3 Safety Group Classification ...........................61

61 .......................................... ﻃﺒﻘﻪ ﺑﻨﺪي ﮔﺮوه اﻳﻤﻨﻲ3-10

10.4 Refrigerant Recovery and Recycling.........62

62 .................................. ﺑﺎزﻳﺎﻓﺖ و ﭼﺮﺧﻪ ﻣﺠﺪد ﻣﺒﺮد4-10

11. AUTOMATION AND CONTROLS..................64

64 ........................................................ اﺗﻮﻣﺎﺳﻴﻮن و ﻛﻨﺘﺮﻟﻬﺎ-11

11.1 Automatic Controls ...........................................64

64 ................................................. ﻛﻨﺘﺮﻟﻬﺎي ﺧﻮدﻛﺎري1-11

11.2 Actuators.................................................................64

64 .......................................................... ﻋﻤﻞ ﻛﻨﻨﺪه ﻫﺎ2-11

11.3 Controllers .............................................................65

65 ....................................................... ﻛﻨﺘﺮل ﻛﻨﻨﺪه ﻫﺎ3-11

11.4 Modes of Control ................................................66

66 ........................................................ روﺷﻬﺎي ﻛﻨﺘﺮل4-11

12. BUILDING AUTOMATION AND

CONTROL INTEGRATION...................................66

66 ............................. ﻛﻨﺘﺮل ﻳﻜﭙﺎرﭼﻪ و ﺧﻮدﻛﺎر ﺳﺎﺧﺘﻤﺎن-12

12.1 Integration and Automation Control........66

66 ...................................... ﻛﻨﺘﺮل ﻳﻜﭙﺎرﭼﻪ و ﺧﻮدﻛﺎر1-12

12.2 Direct Digital Controls (DDC)......................67

67 ...................................... ﻛﻨﺘﺮﻟﻬﺎي ﻋﺪدي ﻣﺴﺘﻘﻴﻢ2-12

12.3 ’Gateways’ to Integration...............................68

68 ................... درﻳﭽﻪ ﻫﺎﻳﻲ ﺑﻪ ﺳﻮي ﻳﻜﭙﺎرﭼﻪ ﺳﺎزي3-12

12.4 Communication Protocol Standards .........68

68 .......................... اﺳﺘﺎﻧﺪاردﻫﺎي ﭘﺮوﺗﻜﻞ ارﺗﺒﺎﻃﺎت4-12

ATTACHMENTS:

:ﭘﻴﻮﺳﺖ ﻫﺎ

ATTACHMENT 1 .........................................................70

70 ...............................................................................1 ﭘﻴﻮﺳﺖ

4

Nov. 2009 / 1388 آذر

IPS-E-AR- 120(1)

ATTACHMENT 2 ZONING CLASSIFICATION

PER CLIMATIC CONDITION

IN IRAN ......................................71

ﻃﺒﻘﻪ ﺑﻨﺪي ﻣﻨﻄﻘﻪ ﻫﺎي ﺑﺮﺣﺴﺐ ﺷﺮاﻳﻂ2 ﭘﻴﻮﺳﺖ

71 ................................................. آب و ﻫﻮاي اﻳﺮان

ATTACHMENT 3 SCHEDULE OF IRANIAN

CITIES PER ZONING

AREA ............................................72

ﺟﺪول ﺷﻬﺮﻫﺎي اﻳﺮان ﺑﺮﺣﺴﺐ3 ﭘﻴﻮﺳﺖ

72...............................................ﻣﻨﻄﻘﻪ ﻫﺎي ﻧﻮاﺣﻲ

ATTACHMENT 4 RECOMMENDED RATE OF

HEAT GAIN FROM

SELECTED RESTAURANT

EQUIPMENT a .........................75

ﻧﺮخ ﺑﻬﺮه ﮔﺮﻣﺎﻳﻲ ﺗﻮﺻﻴﻪ ﺷﺪه از ﺗﺠﻬﻴﺰات4 ﭘﻴﻮﺳﺖ

75 .......................................... اﻧﺘﺨﺎب ﺷﺪه رﺳﺘﻮران

ATTACHMENT 5 RECOMMENDED RATE OF

HEAT GAIN FROM SELECTED

OFFICE EQUIPMENT .........80

ﻧﺮخ ﺑﻬﺮه ﮔﺮﻣﺎﻳﻲ ﺗﻮﺻﻴﻪ ﺷﺪه ﺑﺮاي ﺗﺠﻬﻴﺰات5 ﭘﻴﻮﺳﺖ

80........................................ دﻓﺎﺗﺮ ﻛﺎر اﻧﺘﺨﺎب ﺷﺪه

ATTACHMENT 6 RECOMMENDED RATE OF

HEAT GAIN FROM HOSPITAL

EQUIPMENT LOCATED IN

THE AIR CONDITIONED

AREA ............................................82

ﻧﺮخ ﺗﻮﺻﻴﻪ ﺷﺪه ﺑﻬﺮه ﮔﺮﻣﺎﻳﻲ از ﺗﺠﻬﻴﺰات6 ﭘﻴﻮﺳﺖ

ﺑﻴﻤﺎرﺳﺘﺎﻧﻲ ﻛﻪ در ﻓﻀﺎي ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع

82............................................................ ﻗﺮار دارﻧﺪ

ATTACHMENT 7 HEAT GAIN FROM

TYPICAL ELECTRIC

MOTORS ...................................84

84................ ﺑﻬﺮه ﮔﺮﻣﺎﻳﻲ از ﻣﻮﺗﻮرﻫﺎي ﺑﺮﻗﻲ ﻧﻤﻮﻧﻪ7 ﭘﻴﻮﺳﺖ

ATTACHMENT 8 EQUIPMENT SERVICE

LIFE..............................................85

85........................................ ﻋﻤﺮ ﺧﺪﻣﺎت ﺗﺠﻬﻴﺰات8 ﭘﻴﻮﺳﺖ

ATTACHMENT 9 Acceptable Substitutes for

CfCs (Class I ODS *) In

Household & Light

Commercial Ac.............................87

ﻣﺒﺮدﻫﺎي ﺟﺎﻳﮕﺰﻳﻦ ﻗﺎﺑﻞ ﻗﺒﻮل ﺑﺮاي9 ﭘﻴﻮﺳﺖ

*( در ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮعODS 1 )ردهCfCs

87 ...............................ﺧﺎﻧﮕﻲ و ﺗﺠﺎري ﺳﺒﻚ

5

Nov. 2009 / 1388 آذر

IPS-E-AR- 120(1)

0. INTRODUCTION

ﻣﻘﺪﻣﻪ-0

With the advent of the 1990s new issues and

terminologies are setting trends in the entire

(HVAC&R)* industry. Environmental authorities

are diffusing new culture format in the industry

with particular emphasis to substances that

possess ozone depletion potential. With a result

indoor air quality, air contaminants, clean air act,

Chlorofluorocarbons (CFC) issues, safety codes

etc. are now either being introduced or redefined.

Changes on each of these issues have a direct

effect on (HVAC&R)* engineering, installation,

operation, maintenance and replacements.

ﺻﻨﻌﺖ،1990 ﺑﺎ ﻇﻬﻮر اﻧﺘﺸﺎرات و واژﮔﺎن ﺟﺪﻳﺪ در ﺳﺎل

( HVAC&R) * ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع و ﺳﺮﻣﺎﻳﺶ، ﺗﻬﻮﻳﻪ،ﮔﺮﻣﺎﻳﺶ

ﻧﻴﺰ ﻋﻤﻼً ﺗﻮﺳﻌﻪ ﻳﺎﻓﺖ و ﺿﺮورت ﻫﺎي زﻳﺴﺖ ﻣﺤﻴﻄﻲ ﺑﻪ

ﺻﻮرت ﻳﻚ ﻓﺮﻫﻨﮓ ﺟﺪﻳﺪ ﺑﺎ ﺗﺄﻛﻴﺪ وﻳﮋه روي ﻣﻮادي ﻛﻪ

.ﭘﺘﺎﻧﺴﻴﻞ ﺗﻬﻲ ﺳﺎزي ازن را داﺷﺘﻪ ﺑﺎﺷﺪ در ﺻﻨﻌﺖ ﻣﻄﺮح ﺷﺪ

، ﺗﻤﻴﺰي ﻫﻮا، آﻟﻮدﮔﻲ ﻫﻮا،ﺗﻮﺟﻪ ﺑﻪ ﻛﻴﻔﻴﺖ ﻫﻮاي دروﻧﻲ

ﻧﻈﺎرت اﻳﻤﻨﻲ و ﻏﻴﺮه ﺑﺮاي اﻳﻦ،اﻧﺘﺸﺎرات ﻛﻠﺮو ﻓﻠﻮﺋﻮرو ﻛﺮﺑﻦ

ﺗﻐﻴﻴﺮ در ﻫﺮ ﻳﻚ از. ﺗﻌﺎرﻳﻔﻲ ﺗﺎزه ﭘﻴﺪا ﺷﺪ،ﮔﻮﻧﻪ ﻣﻮاد

، ﺗﻬﻮﻳﻪ، اﺛﺮات ﻣﺴﺘﻘﻴﻤﻲ در ﻣﻬﻨــﺪﺳﻲ ﮔﺮﻣﺎﻳﺶ،اﻧﺘﺸﺎرات

، ﻧﺼﺐ،(HVAC&R) * ﺗﻬﻮﻳﻪ ﻣﻄﺒــــﻮع و ﺳﺮﻣﺎﻳـــﺶ

.راﻫﺒﺮي و ﺗﻌﻤﻴﺮات اﻳﻦ ﺳﺎﻣﺎﻧﻪ ﮔﺬاﺷﺖ

This Standard has been developed to help

facilitate the requisites of building air

conditioning, its selection procedures and system

layout required to provide a comfort and healthy

atmosphere in an air conditioning space. A simple

approach to load calculation per ARI and

ASHRAE procedures has been included as a

ready reckoner for the design engineer.

اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﻪ ﻣﻨﻈﻮر اﻳﺠﺎد ﺳﻬﻮﻟﺖ در اﻧﺠﺎم درﺧﻮاﺳﺖﻫﺎي

روشﻫﺎي اﻧﺘﺨﺎب و اﺳﺘﻘﺮار،ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع ﺳﺎﺧﺘﻤﺎن

دﺳﺘﮕﺎﻫﻬﺎ و ﺷﺮاﻳﻂ راﺣﺘﻲ و ﺳﻼﻣﺘﻲ اﻧﺴﺎن در ﻳﻚ ﻓﻀﺎ ﺑﻪ

ﺑﺮاي دﺳﺘﺮﺳﻲ ﻣﻬﻨﺪﺳﻴﻦ. ﺑﻪ ﻛﺎر ﻣﻴﺮود،ﻃﻮر ﺗﻮﺳﻌﻪ ﻳﺎﻓﺘﻪ

وARI ﻃﺮاح ﺑﻪ ﻣﺤﺎﺳﺒﻪ ﻇﺮﻓﻴﺖ و روشﻫﺎي آن ﺑﻪ ﻣﺮاﺟﻊ

. ﻣﺮاﺟﻌﻪ ﺷﻮدASHRAE

In view of the Montreal Protocol which also

addresses the production phase-out of CFC by

Dec. 31, 1995, special importance has been

provided towards the status of Refrigerants as

described in Clause 10. However due to its

continuous development changes, from HCFC*

to HFC* to blending technique, the subject on

Refrigerants are based on purely information

gathering-stage complying with ASHRAE

Standard 34- 2007.

ﺑﺎ ﺗﻮﺟﻪ ﺑﻪ ﭘﺮوﺗﻜﻞ ﻣﻮﻧﺘﺮال ﻛﻪ ﻓﺎز ﻧﻬﺎﻳﻲ ﺗﻮﻟﻴﺪ ﻣﺒﺮدﻫﺎي

اﻫﻤﻴﺖ، ﻣﻄﺮح ﺷﺪه اﺳﺖ1995 دﺳﺎﻣﺒﺮ31 در ﺗﺎرﻳﺦCFC

ﻫﺮ ﭼﻨﺪ ﺑﺮ ﺣﺴﺐ. درج ﮔﺮدﻳﺪه اﺳﺖ10 اﻳﻦ ﻣﻄﻠﺐ در ﺑﻨﺪ

* HVAC & R Heating,

Ventilating,

Conditioning and Refrigerating

ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع و، ﺗﻬﻮﻳﻪ،ﮔﺮﻣﺎﻳﺶ

*

ﺑﻪHCFC اﺳﺘﻤﺮار ﺗﻐﻴﻴﺮات ﺗﻮﺳﻌﻪ آن ﻓﻦ آوري ﺗﺮﻛﻴﺐ از

ﻣﻮﺿﻮع ﻣﺒﺮدﻫﺎ ﺑﺮاﺳﺎس ﭼﻜﻴﺪه اﻃﻼﻋﺎت و ﺑﺎ رﻋﺎﻳﺖ. HFC*

ASHRAE Standard 34- 2007 ﻣﻘﺮرات اﺳﺘﺎﻧﺪارد

.ﻣﻲﺑﺎﺷﺪ

Air-

HVAC&R*

.ﺳﺮﻣﺎﻳﺶ

ﻫﻴﺪروﻛﻠﺮوﻓﻠﻮﺋﻮرﻛﺮﺑﻦ

HCFC*

Hydro Fluorocarbon

ﻫﻴﺪروﻓﻠﻮﺋﻮرﻛﺮﺑﻦ

HFC*

Chlorofluorocarbons

ﻛﻠﺮوﻓﻠﻮﺋﻮر ﻛﺮﺑﻦﻫﺎ

CFC*

*HCFC

Hydro Chlorofluorocarbon

*HFC

*CFC

6

Nov. 2009 / 1388 آذر

IPS-E-AR- 120(1)

1. SCOPE

داﻣﻨﻪ ﻛﺎرﺑﺮد-1

This Standard covers the minimum requirement

for practical approach towards, design,

application and various methods of building air

conditioning system together with relevant

automatic controls.

اﻳﻦ اﺳﺘﺎﻧﺪارد ﺷﺎﻣﻞ ﺣﺪاﻗﻞ اﻟﺰاﻣﺎت ﺿﺮوري ﺟﻬﺖ دﺳﺘﺮﺳﻲ

ﻛﺎرﺑﺮد و روشﻫﺎي ﻣﺨﺘﻠﻒ ﺳﺎﻣﺎﻧﻪ ﺗﻬﻮﻳﻪ،ﻋﻤﻠﻲ ﺑﺮاي ﻃﺮاﺣﻲ

.ﻣﻄﺒﻮع ﺳﺎﺧﺘﻤﺎن ﺑﺎ ﻛﻨﺘﺮلﻫﺎي اﺗﻮﻣﺎﺗﻴﻚ ﻣﺮﺑﻮﻃﻪ ﻣﻲﺑﺎﺷﺪ

System components are not individually

described, but guidelines for selection procedure

of equipment and supporting components are

covered in this Standard. It also includes a section

on "central chillers" to describe the importance on

the combination of absorption and centrifugal

chiller system in the HVAC&R industry.

اﻣﺎ ﺑﺮاي روش،اﺟﺰاء ﺳﺎﻣﺎﻧﻪ ﺑﻄﻮر ﺟﺪاﮔﺎﻧﻪ ﺗﺸﺮﻳﺢ ﻧﻤﻲﺷﻮد

رﻫﻨﻤﻮدﻫﺎﻳﻲ در اﻳﻦ،اﻧﺘﺨﺎب ﺗﺠﻬﻴﺰات و اﺟﺰاء ﻧﮕﻬﺪارﻧﺪه آن

This Standard shall be used, when required, in

conjunction with relevant standard drawings.

اﻳﻦ اﺳﺘﺎﻧﺪارد در ﺻﻮرت ﻧﻴﺎز ﺑﺎﻳﺪ ﻫﻤﺮاه ﺑﺎ ﻧﻘﺸﻪﻫﺎي اﺳﺘﺎﻧﺪارد

.ﻣﺮﺑﻮﻃﻪ ﺑﻜﺎر رود

This Standard does not cover the following

subjects which are covered in relevant IPS as

shown below:

ﻫﺎي ﻣﺮﺑﻮﻃﻪ ذﻳﻞIPS اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﻮﺿﻮﻋﺎت ذﻳﻞ را ﻛﻪ در

:اﺳﺖ ﭘﻮﺷﺶ ﻧﻤﻲ دﻫﺪ

a) Building Heating System (IPS-E-AR-100).

.(IPS-E-AR-100) اﻟﻒ( ﺳﺎﻣﺎﻧﻪ ﮔﺮﻣﺎﻳﺶ ﺳﺎﺧﺘﻤﺎن

ﻫﻤﭽﻨﻴﻦ داراي ﻳﻚ ﻓﺼﻞ در ﺧﺼﻮص.اﺳﺘﺎﻧﺪارد وﺟﻮد دارد

ﭼﻴﻠﺮﻫﺎي ﻣﺮﻛﺰي ﻣﻴﺒﺎﺷﺪ ﻛﻪ اﻫﻤﻴﺖ ﺳﺎﻣﺎﻧﻪ ﺗﺮﻛﻴﺐ ﭼﻴﻠﺮﻫﺎي

ﺗﻬﻮﻳﻪ، ﺗﻬﻮﻳﻪ،ﺟﺬﺑﻲ و ﮔﺮﻳﺰ از ﻣﺮﻛﺰ را در ﺻﻨﻌﺖ ﮔﺮﻣﺎﻳﺶ

.ﻣﻄﺒﻮع و ﺳﺮﻣﺎﻳﺶ را ﺗﺸﺮﻳﺢ ﻣﻲ ﻧﻤﺎﻳﺪ

b) Venting, Ventilation and Pressurizing

System (IPS-E-AR-160).

ﻓﺸﺎر

c) Humidification and Dehumidification

System (IPS-E-AR-130).

رﻃﻮﺑﺖﮔﻴﺮي

ﺗﻬﻮﻳــﻪ و ﺗﺤﺖ،ب( ﺳﺎﻣﺎﻧﻪ ﻫﻮاﮔﻴﺮي

.(IPS-E-AR-160)

و

زﻧﻲ

رﻃﻮﺑﺖ

ﺳﺎﻣﺎﻧــﻪ

(ج

(IPS-E-AR-130)

Note 1:

:1 ﻳﺎدآوري

This standard specification is reviewed and

updated by the relevant technical committee on

Nov 2000, as amendment No. 1 by circular No.

136.

Note 2:

ﺗﻮﺳﻂ ﻛﻤﻴﺘﻪ ﻓﻨﻲ1379 اﻳﻦ اﺳﺘﺎﻧﺪارد در آﺑﺎن ﻣﺎه ﺳﺎل

1 ﻣﺮﺑﻮﻃﻪ ﺑﺮرﺳﻲ و ﻣﻮارد ﺗﺄﻳﻴﺪ ﺷﺪه ﺑﻪ ﻋﻨﻮان اﺻﻼﺣﻴﻪ ﺷﻤﺎره

. اﺑﻼغ ﮔﺮدﻳﺪ136 ﻃﻲ ﺑﺨﺸﻨﺎﻣﻪ ﺷﻤﺎره

This standard specification is reviewed and

updated by the relevant technical committee on

May 2004, as amendment No. 2 by circular No.

236.

ﺗﻮﺳﻂ ﻛﻤﻴﺘﻪ1383 اﻳﻦ اﺳﺘﺎﻧﺪارد در اردﻳﺒﻬﺸﺖ ﻣﺎه ﺳﺎل

ﻓﻨﻲ ﻣﺮﺑﻮﻃﻪ ﺑﺮرﺳﻲ و ﻣﻮارد ﺗﺄﻳﻴﺪ ﺷﺪه ﺑﻪ ﻋﻨﻮان اﺻﻼﺣﻴﻪ

. اﺑﻼغ ﮔﺮدﻳﺪ236 ﻃﻲ ﺑﺨﺸﻨﺎﻣﻪ ﺷﻤﺎره2 ﺷﻤﺎره

:2 ﻳﺎدآوري

:3 ﻳﺎدآوري

Note 3:

اﻳﻦ اﺳﺘﺎﻧﺪارد دو زﺑﺎﻧﻪ ﻧﺴﺨﻪ ﺑﺎزﻧﮕﺮي ﺷﺪه اﺳﺘﺎﻧﺪارد ﻣﻲﺑﺎﺷﺪ

ﺗﻮﺳﻂ ﻛﻤﻴﺘﻪ ﻓﻨﻲ ﻣﺮﺑﻮﻃﻪ اﻧﺠﺎم و1388 ﻛﻪ در آذر ﻣﺎه ﺳﺎل

(0) از اﻳﻦ ﭘﺲ وﻳﺮاﻳﺶ.( اراﻳﻪ ﻣﻲﮔﺮدد1) ﺑﻪ ﻋﻨﻮان وﻳﺮاﻳﺶ

.اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﻨﺴﻮخ ﻣﻲﺑﺎﺷﺪ

This bilingual standard is a revised version of the

standard specification by the relevant technical

committee on ***, which is issued as revision

(1). Revision (0) of the said standard specification

is withdrawn.

:4 ﻳﺎدآوري

Note 4:

ﻣﺘﻦ اﻧﮕﻠﻴﺴﻲ،در ﺻﻮرت اﺧﺘﻼف ﺑﻴﻦ ﻣﺘﻦ ﻓﺎرﺳﻲ و اﻧﮕﻠﻴﺴﻲ

.ﻣﻼك ﻣﻲﺑﺎﺷﺪ

In case of conflict between Farsi and English

languages, English language shall govern.

7

Nov. 2009 / 1388 آذر

IPS-E-AR- 120(1)

2. REFERENCES

ﻣﺮاﺟﻊ-2

Throughout this Standard the following dated and

undated standards/codes are referred to. These

referenced documents shall, to the extent

specified herein, form a part of this standard. For

dated references, the edition cited applies. The

applicability of changes in dated references that

occur after the cited date shall be mutually agreed

upon by the Company and the Vendor. For

undated references, the latest edition of the

referenced

documents

(including

any

supplements and amendments) applies.

در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﻪ آﻳﻴﻦ ﻧﺎﻣﻪﻫﺎ و اﺳﺘﺎﻧﺪاردﻫﺎي ﺗﺎرﻳﺦ دار و

ﺗﺎ ﺣﺪي ﻛﻪ در، اﻳﻦ ﻣﺮاﺟﻊ.ﺑﺪون ﺗﺎرﻳﺦ زﻳﺮ اﺷﺎره ﺷﺪه اﺳﺖ

ﺑﺨﺸﻲ از اﻳﻦ،اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﮔﺮﻓﺘﻪاﻧﺪ

وﻳﺮاﻳﺶ، در ﻣﺮاﺟﻊ ﺗﺎرﻳﺦ دار.اﺳﺘﺎﻧﺪارد ﻣﺤﺴﻮب ﻣﻲﺷﻮﻧﺪ

ﮔﻔﺘﻪ ﺷﺪه ﻣﻼك ﺑﻮده و ﺗﻐﻴﻴﺮاﺗﻲ ﻛﻪ ﺑﻌﺪ از ﺗﺎرﻳﺦ وﻳﺮاﻳﺶ در

ﭘﺲ از ﺗﻮاﻓﻖ ﺑﻴﻦ ﻛﺎرﻓﺮﻣﺎ و ﻓﺮوﺷﻨﺪه ﻗﺎﺑﻞ،آﻧﻬﺎ داده ﺷﺪه اﺳﺖ

آﺧﺮﻳﻦ وﻳﺮاﻳﺶ آﻧﻬﺎ ﺑﻪ، در ﻣﺮاﺟﻊ ﺑﺪون ﺗﺎرﻳﺦ.اﺟﺮا ﻣﻲﺑﺎﺷﺪ

.اﻧﻀﻤﺎم ﻛﻠﻴﻪ اﺻﻼﺣﺎت و ﭘﻴﻮﺳﺖﻫﺎي آن ﻣﻼك ﻋﻤﻞ ﻣﻲﺑﺎﺷﻨﺪ

SMACNA(SHEET

METAL

AND

AIR

CONDITIONING

CONTRACTOR’S

NATIONAL ASSOCIATION)

)ﻣﺠﻤﻊ ﻣﻠﻲ ﭘﻴﻤﺎﻧﻜﺎران ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع وSMACNA

.(ورﻗﻪﻫﺎي ﻓﻠﺰي

ﺗﻬﻮﻳﻪ و، "ﺳﺎﻣﺎﻧﻪ ﻃﺮاﺣﻲ ﮔﺮﻣﺎﻳﺶSMACNA 2007

"ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع

SMACNA 2007 "HVAC System Design"

ARI

(AIR

CONDITIONING

REFRIGERATION INSTITUTE)

( )اﻧﺠﻤﻦ ﺗﻬﻮﻳﻪ و ﺗﺒﺮﻳﺪARI

AND

ARI 550/590

"Standard for Performance

Rating of Water Chilling

Package,

Vapor

Compression Cycle"2003

"اﺳﺘﺎﻧﺪارد ﺑﺮاي ﻣﻴﺰان ﻛﺎرآﻳﻲ واﺣﺪ ﺳﺮدARI 550/590

ﭼﺮﺧﻪ ﺗﺮاﻛﻤﻲ،ﻛﻨﻨﺪه آﺑﻲ ﻳﻜﭙﺎرﭼﻪ

2003"ﺗﺒﺨﻴﺮي

ARI 575-94

"Method of Measuring

Machinery Sound within

an Equipment Space"

"روش اﻧﺪازهﮔﻴﺮي ﺻﺪاي ﻣﺎﺷﻴﻦآﻻت درARI 575-94

"ﻳﻚ ﻓﻀﺎي ﻛﺎرﮔﺎﻫﻲ

ARI 410

"Forced-circulation

AirCooling and Air Heating

Coils"2002

"ﺟﺮﻳﺎن راﻧﺸﻲ ﻫﻮاي ﺧﻨﻚ و ﻛﻮﻳﻞﻫﺎي

2002" ﮔﺮﻣﺎﻳﺸﻲ

ARI 430-99

"Central

Station

Heating Units"

"اﻳﺴﺘﮕﺎه ﻣﺮﻛﺰي دﺳﺘﮕﺎﻫﻬﺎي ﮔﺮﻣﺎﻳﺶARI 430-99

"ﻫﻮا

ARI 560

"Absorption

Water

Chilling and Water Heating

Package"2000

"دﺳﺘﮕﺎه ﺟﺬﺑﻲ ﺳﺮﻣﺎﻳﺶ آب و دﺳﺘﮕﺎهARI 560

2000"ﻳﻜﭙﺎرﭼﻪ ﮔﺮﻣﺎﻳﺶ آب

ARI 700

"Specification

for

Fluorocarbon Refrigerants"

2004

ﻣﺒﺮدﻫﺎي

Air

ﺑﺮاي

"ﻣﺸﺨﺼﺎت

2004 "ﻓﻠﻮﺋﻮروﻛﺮﺑﻦ

ﻓﻨﻲ

ARI 410

ARI 700

"اﺳﺘﺎﻧﺪارد ﺑﺮاي ﺗﺠﻬﻴﺰات ﺑﺎزﻳﺎﻓﺖ ﻣﺒﺮدARI 740-98

"ﻳﺎ ﭼﺮﺧﻪ ﻣﺠﺪد

ARI 740-98 "Standard for Refrigerant

Recovery/Recycling

Equipment"

8

Nov. 2009 / 1388 آذر

ASHRAE(AMERICAN

SOCIETY

HEATING REFRIGERATING &

CONDITIONING ENGINEERS)

ASHRAE 135

IPS-E-AR- 120(1)

)اﻧﺠﻤﻦ ﻣﻬﻨﺪﺳﺎن ﺗﺄﺳﻴﺴﺎت ﺣﺮارﺗﻲ وASHRAE

OF

AIR

(ﺑﺮودﺗﻲ آﻣﺮﻳﻜﺎ

"ﭘﺮوﺗﻜﻞﻫﺎي ارﺗﺒﺎﻃﻲ دادهﻫﺎ

ﺑﺮاي اﺗﻮﻣـﺎﺳﻴﻮن ﺳﺎﺧﺘﻤﺎن و

2007 "ﻛﻨﺘﺮل ﺷﺒﻜﻪﻫﺎ

"Data

Communication

Protocols for Building

Automation and Control

Networks (BACnet)"2007

ASHRAE 135

ASHRAE STD 15 "Safety

Code

for

Mechanical Refrigeration"

2007

"آﺋﻴﻦ ﻧﺎﻣﻪ اﻳﻤﻨﻲ ﺑﺮاي ﺑﺮورتASHRAE STD 15

2007 "ﻣﻜﺎﻧﻴﻜﻲ

ASHRAE STD 34 "Number Designation and

Safety Classification of

Refrigerants"2007

و

ASHRAE

"Fundamental

guidebook" 2005

and

ASME (AMERICAN

SOCIETY

MECHANICAL ENGINEERS)

OF

ASME B31.5

2007

2005 ""ﻣﺒﺎﻧﻲ وﻛﺘﺎب راﻫﻨﻤﺎ

ASHRAE

( )اﻧﺠﻤﻦ ﻣﻬﻨﺪﺳﺎن ﻣﻜﺎﻧﻴﻚ آﻣﺮﻳﻜﺎASME

"ﻟﻮﻟﻪﻛﺸﻲ ﺗﺒﺮﻳﺪ و اﺟﺰاء اﻧﺘﻘﺎل

2006"ﺣﺮارت

"Refrigeration Piping and

Heat Transfer Component"

2006

ASME B31.5

( )ﻣﺠﻤﻊ ﻛﻨﺘﺮل و ﺣﺮﻛﺖ ﻫﻮاAMCA

AMCA (AIR MOVEMENT AND CONTROL

ASSOCIATION)

AMCA 500-D

ﺷﻨﺎﺳﺎﻳﻲ

"ﺷﻤــﺎرهASHRAE STD 34

"ﻃﺒﻘﻪﺑﻨﺪي اﻳﻤﻨﻲ ﻣﺒﺮدﻫﺎ

"روشﻫﺎي آزﻣﺎﻳﺶ ﻣﺮﺑﻮط ﺑﻪ

آزﻣﻮن داﻣﭙﺮﻫﺎ از ﻟﺤﺎظ ﻣﻴﺰان

2007 "ﺟﺮﻳﺎن

"Laboratory Methods of

Testing

Dampers

for

Rating"2007

AMCA 500-D

( )اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮانIPS

IPS (IRANIAN PETROLEUM STANDARDS)

IPS-E-AR-100 "Engineering Standard for

Building Heating System"

"اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي ﺳﺎﻣﺎﻧﻪIPS-E-AR-100

"ﮔﺮﻣﺎﻳﺶ ﺳﺎﺧﺘﻤﺎن

IPS-E-AR-160 "Engineering Standard for

Venting, Ventilation and

Pressurizing System"

"اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي ﺳﺎﻣﺎﻧﻪIPS-E-AR-160

" ﺗﻬﻮﻳﻪ و ﺗﺤﺖ ﻓﺸﺎر،ﻫﻮاﮔﻴﺮي

IPS-E-AR-130 "Engineering Standard for

Humidification

&

Dehumidification System"

"اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي ﺳﺎﻣﺎﻧﻪIPS-E-AR-130

"رﻃﻮﺑﺖ زﻧﻲ و رﻃﻮﺑﺖ ﮔﻴﺮي

IPS-E-AR-180 "Engineering Standard for

Cold Stores and Ice Plants"

"اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي ﺳﺮدﺧﺎﻧﻪ وIPS-E-AR-180

"ﻳﺨﺴﺎزﻫﺎ

IPS-M-AR-125 "Material and Equipment

Standard for Packaged Air

Conditioners"

"اﺳﺘﺎﻧﺪارد ﻛﺎﻻ و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-AR-125

"دﺳﺘﮕﺎﻫﻬﺎي ﻳﻜﭙﺎرﭼﻪ ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع

9

Nov. 2009 / 1388 آذر

IPS-E-AR- 120(1)

IPS-M-AR-225 "Material and Equipment

Standard

for

General

HVAC&R Equipment"

"اﺳﺘﺎﻧﺪارد ﻛﺎﻻ و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-AR-225

ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع و، ﺗﻬﻮﻳﻪ،ﮔﺮﻣﺎﻳﺶ

"ﺗﺠﻬﻴﺰات ﺳﺮﻣﺎﻳﺸﻲ

IPS-M-AR-245 "Material and Equipment

Standard for Room Air

Conditioners (Window and

Thru-the-Wall Type)"

"اﺳﺘﺎﻧﺪارد ﻛﺎﻻ و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-AR-245

ﺧﻨﻚ ﻛﻨﻨﺪهﻫﺎي اﺗﺎﻗﻲ )ﻧﻮع ﭘﻨﺠﺮهاي

"(و دﻳﻮاري

IPS-M-AR-235 "Material and Equipment

Standard for Insulation of

HVAC&R Field"

"اﺳﺘﺎﻧﺪارد ﻛﺎﻻ و ﺗﺠﻬﻴﺰات ﺑﺮاي ﻋﺎﻳﻖIPS-M-AR-235

ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع و، ﺗﻬﻮﻳﻪ،ﮔﺮﻣﺎﻳﺶ

"ﺳﺮﻣﺎﻳﺶ در ﻣﺤﻞ

IPS-E-GN-100 "Engineering Standard for

Units"

" "اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي واﺣﺪﻫﺎIPS-E-GN-100

( )اﻧﺠﻤﻦ ﻣﻠﻲ ﺣﻔﺎﻇﺖ در ﻣﻘﺎﺑﻞ آﺗﺶNFPA

NFPA (NATIONAL FIRE PROTECTION

ASSOCIATION)

" "ﺁﻳﻴﻦ ﻧﺎﻣﻪ ﻣﻠﻲ ﺑﺮﻗﻲNFPA-70-2007

NFPA-70-2007 "National Electrical Code"

( )ﺗﺄﻳﻴﺪﻛﻨﻨﺪﮔﺎن ﺗﺠﻬﻴﺰات آزﻣﺎﻳﺸﮕﺎﻫﻲUL

UL (UNDER WRITERS LABORATORY /

INC.)

UL

STD

94

"اﺳﺘﺎﻧﺪارد ﺑﺮاي آزﻣﻮن ﻗﺎﺑﻠﻴﺖ اﺷﺘﻌﺎلUL STD 94

ﻣﻮاد ﭘﻼﺳﺘﻴﻜﻲ ﺑﺮاي درون وﺳﺎﻳﻞ و

"دﺳﺘﮕﺎﻫﻬﺎ

"Standard for Test for

Flammability of Plastic

Material for Part in Device

and Appliances"

3. DEFINITIONS AND TERMINOLOGY

ﺗﻌﺎرﻳﻒ و واژﮔﺎن-3

3.1 Air Washer

ﻫﻮاﺷﻮي1-3

Unit for spraying or atomizing clean water into an

air supply system; capable of heating, cooling,

humidifying, or dehumidifying the air, depending

on whether the water is heated or chilled.

دﺳﺘﮕﺎﻫﻲ ﻛﻪ ﺑﺮاي ﭘﺎﺷﺶ ﻳﺎ ﺗﻮﻟﻴﺪ ذرات رﻳﺰ آب ﺗﻤﻴﺰ ﺑﻪ

ﺳﺎﻣﺎﻧﻪ ﺟﺮﻳﺎن ﻫﻮا ﺑﻪ ﻛﺎر ﻣﻲرود و ﺑﺮ اﺳﺎس ﭘﺎﺷﺶ آب ﮔﺮم ﻳﺎ

رﻃﻮﺑﺖ زﻧﻲ و، ﺳﺮﻣﺎﻳﺶ،ﺳﺮد ﻣﻲﺗﻮاﻧﺪ ﻣﻮﺟﺐ ﮔﺮﻣﺎﻳﺶ

.رﻃﻮﺑﺖ ﮔﻴﺮي در ﻫﻮا ﺑﺸﻮد

3.2 Air-Conditioning System

ﺳﺎﻣﺎﻧﻪ ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع2-3

Assembly of equipment for air treatment to

control simultaneously its temperature, humidity,

cleanliness, contamination, and distribution to

meet the requirements of a conditioned space.

دﺳﺘﮕﺎه ﻳﺎ ﻣﻮﻧﺘﺎژ ﺗﺠﻬﻴﺰاﺗﻲ ﻛﻪ ﺑﺘﻮاﻧﺪ ﺑﻪ ﻃﻮر ﻫﻤﺰﻣﺎن ﻛﻨﺘﺮل

آﻟﻮدﮔﻲ و ﺗﻮزﻳﻊ ﻫﻮا را در ﻳﻚ ﻓﻀﺎي ﺗﻬﻮﻳﻪ، ﭘﺎﻛﻲ، رﻃﻮﺑﺖ،دﻣﺎ

.ﻣﻄﺒﻮع ﺗﺄﻣﻴﻦ ﻧﻤﺎﻳﺪ

3.3 Azeotrope

ازﺋﻮﺗﺮوپ3-3

A blend of two or more components whose

equilibrium vapor phase and liquid phase

compositions are the same at a given pressure.

ﻣﺨﻠﻮﻃﻲ از دو ﻳﺎ ﭼﻨﺪ ﺟﺰء ﻛﻪ در ﻳﻚ ﻓﺸﺎر ﻣﻌﻴﻦ ﻓﺎز ﺑﺨﺎر و

ﻛﻪ ازR-502 )ﻣﺎﻧﻨﺪ ﺳﻴــﺎل ﻣﺒﺮد.ﻣﺎﻳﻊ آن در ﺗﻌﺎدل ﺑﺎﺷﻨﺪ

ﺑﻪ وﺟﻮدR-115 از%51/2 وR-22 از ﻣﺒﺮد%48/8 اﺧﺘﻼط

(ﻣﻲآﻳﺪ

(R-502= 48.8% of R-22 %51.2 of R-115)

10

Nov. 2009 / 1388 آذر

3.4 Ceiling Diffuser

IPS-E-AR- 120(1)

درﻳﭽﻪ ﺗﻮزﻳﻊ ﻫﻮاي ﺳﻘﻔﻲ4-3

Round, square, rectangular, or linear air diffuser

in the ceiling which usually provides a horizontal

distribution pattern of primary and secondary air

over the occupied zone and induces low velocity

secondary air motion through the zone.

ﭼﻬﺎرﮔﻮش ﻳﺎ ﺧﻄﻲ، ﻣﺮﺑﻊ،درﻳﭽﻪ ﻫﻮاي ﺳﻘﻔﻲ از ﻧﻮع ﻣﺪور

ﻣﻌﻤﻮﻻً ﻫﻮاي اوﻟﻴﻪ و ﺛﺎﻧﻮﻳﻪ را در ﻓﻀﺎي ﻣﻮرد ﻧﻈﺮ ﺑﻪ ﺻﻮرت

اﻓﻘﻲ ﺗﻮزﻳﻊ ﻣﻲﻛﻨﺪ و ﺣﺮﻛﺖ ﻫﻮاي ﺛﺎﻧﻮﻳﻪ ﺑﻪ ﺳﻮي ﻣﻨﻄﻘﻪ

.ﺗﺠﻤﻊ ﺑﺎ ﺳﺮﻋﺖ ﻛﻢ ﺻﻮرت ﻣﻲﮔﻴﺮد

3.5 Central Fan Air-Conditioning System

ﺑﺎدزن ﻣﺮﻛﺰي ﺳﺎﻣﺎﻧﻪ ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع5-3

System in which air is treated at a central plant

and carried to and from the rooms by one or more

fans and a system of ducts.

ﺳﺎﻣﺎﻧﻪاي ﻛﻪ ﻫﻮاي ﻣﻄﺒﻮع را در ﺗﺄﺳﻴﺴﺎت ﻣﺮﻛﺰي اﻳﺠﺎد

ﻣﻲﻛﻨﺪ و ﺗﻮﺳﻂ ﻳﻚ ﻳﺎ ﭼﻨﺪ دﻣﻨﺪه ﻳﺎ ﻣﻜﻨﺪه ﺑﻪ وﺳﻴﻠﻪ

.ﻛﺎﻧﺎلﻫﺎﻳﻲ ﺑﻪ اﺗﺎﻗﻬﺎ ﻫﺪاﻳﺖ ﻳﺎ ﺑﺮﮔﺸﺖ داده ﻣﻲﺷﻮد

3.6 Water Chiller

ﭼﻴﻠﺮ آﺑﻲ6-3

ﭼﻴﻠﺮﻫﺎي آﺑﻲ ﻳﺎ واﺣﺪ ﻳﻜﭙﺎرﭼﻪ ﺧﻨﻚ ﻛﻨﻨﺪه ﻣﺎﻳﻊ دﺳﺘﮕﺎﻫﻲ

آب،اﺳﺖ ﻛﻪ در ﻛﺎرﺧﺎﻧﻪ ﻃﺮاﺣﻲ ﺷﺪه و ﺑﺮاي ﺧﻨﻚ ﻛﺮدن آب

ﺗﺒﺮﻳﺪ ﻳﺎ ﻓﺮاﻳﻨﺪ،ﻧﻤﻚ ﻳﺎ ﺳﻴﺎﻻت دﻳﮕﺮ ﻛﻪ در ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع

.ﺳﺮﻣﺎﻳﺸﻲ ﺑﻜﺎر ﻣﻲ روﻧﺪ

Water chillers or a liquid chilling package is a

factory-fabricated assembly designed to cool

water, brine, or other fluids for air-conditioning,

refrigeration, or process cooling purposes .

3.7 Comfort Air-Conditioning

ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع آﺳﺎﻳﺶ7-3

It is the control of ventilation, air circulation, air

cleaning, temperature, and humidity to provide

maximum human efficiency, health, and comfort.

، ﺗﺼﻔﻴﻪ ﻫﻮا، ﮔﺮدش ﻫﻮا،ﺳﺎﻣﺎﻧﻪاي ﻛﻪ ﺑﺘﻮاﻧﺪ ﺑﺎ ﻛﻨﺘﺮل ﺗﻬﻮﻳﻪ

ﺳﻼﻣﺖ و آﺳﺎﻳﺶ را ﺑﺮاي اﻧﺴﺎن،دﻣﺎ و رﻃﻮﺑﺖ ﺣﺪاﻛﺜﺮ ﻛﺎرآﻳﻲ

.ﻓﺮاﻫﻢ آورد

3.8 Conditioned Space

ﻓﻀﺎي ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع8-3

Space within a building provided with heated or

cooled air, or both (or surfaces); and, where

required, with humidification or dehumidification

means, to maintain conditions for an acceptable

thermal environment.

ﻓﻀﺎي داﺧﻞ ﻳﻚ ﺳﺎﺧﺘﻤﺎن ﻛﻪ ﺑﺮاي آن ﺗﻤﻬﻴﺪات ﮔﺮﻣﺎﻳﺶ ﻳﺎ

ﺳﺮﻣﺎﻳﺶ ﻫﻮا ﻳﺎ ﻫﺮ دو )ﻳﺎ ﺳﻄﻮح آﻧﻬﺎ( ﭘﻴﺶ ﺑﻴﻨﻲ ﻣﻲ ﮔﺮدد و

ﻳﺎ ﺟﺎﺋﻲ ﻛﻪ ﻧﻴﺎز ﺑﻪ رﻃﻮﺑﺖ زﻧﻲ ﻳﺎ رﻃﻮﺑﺖ زداﻳﻲ ﺟﻬﺖ ﺷﺮاﻳﻂ

ﻗﺎﺑﻞ ﻗﺒﻮل و ﻣﻄﻠﻮب ﻣﺤﻴﻂ ﺑﺎﺷﺪ ﻓﻀﺎي ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع ﻧﺎﻣﻴﺪه

.ﻣﻲ ﺷﻮد

3.9 Coolant

ﺳﻴﺎل ﺧﻨﻚ ﻛﻨﻨﺪه9-3

Fluid employed for transferring heat from one

place to another.

ﺑﻪ،ﺳﻴﺎﻟﻲ ﻛﻪ ﺑﻪ ﻣﻨﻈﻮر اﻧﺘﻘﺎل ﺣﺮارت از ﺟﺎﻳﻲ ﺑﻪ ﺟﺎي دﻳﮕﺮ

.ﻛﺎر ﮔﺮﻓﺘﻪ ﻣﻲﺷﻮد

3.10 Damper

دﻣﭙﺮ10-3

Device used to vary the volume of air passing

through outlet, inlet or ducts.

وﺳﻴﻠﻪاي ﻛﻪ ﺑﺮاي ﺗﻐﻴﻴﺮ ﺣﺠﻢ ﻋﺒﻮري ﻫﻮا از ﻛﺎﻧﺎل ورودي ﻳﺎ

.ﺧﺮوﺟﻲ ﺑﻪ ﻛﺎر ﻣﻲ رود

3.11 Design Load

ﺑﺎر ﻃﺮاﺣﻲ11-3

It is the capacity required to produce specified

inside conditions when specified outside

conditions of temperature and humidity prevail,

and when all sources of load are taken at the

maximum that will then occur coincidentally.

ﻇﺮﻓﻴﺖ ﻣﻮرد ﻧﻴﺎز ﺑﺮاي اﻳﺠﺎد ﺷﺮاﻳﻂ ﻣﻄﻠﻮب ﺗﻌﻴﻴﻦ ﺷﺪه

داﺧﻠﻲ در ﺷﺮاﻳﻄﻲ ﻛﻪ دﻣﺎ و رﻃﻮﺑﺖ ﺧﺎرج از ﺳﺎﺧﺘﻤﺎن ﻏﺎﻟﺐ

ﺑﻮده و ﻛﻠﻴﻪ ﻣﻨﺎﺑﻊ ﻣﺤﺎﺳﺒﺎﺗﻲ ﺑﺎر ﺑــﻪ ﻃﻮر ﺗﺼﺎدﻓﻲ ﺣﺪاﻛﺜﺮ در

.ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﺷﺪه ﺑﺎﺷﺪ

11

Nov. 2009 / 1388 آذر

3.12 Direct Digital Controls

IPS-E-AR- 120(1)

ﻛﻨﺘﺮلﻫﺎي ﻋﺪدي ﻣﺴﺘﻘﻴﻢ12-3

Micro-processor based controller integrating

automation and control in a stand alone or system

network operation. It collects all the input and

accumulates it in a computer which relays each

individual output by digitally based controllers as

required.

ﻛﻨﺘﺮل ﻛﻨﻨﺪه ﺑﺮ ﭘﺎﻳﻪ رﻳﺰ ﭘﺮدازﻧﺪه ﻋﻤﻞ ﻛﻨﺘﺮل اﺗﻮﻣﺎﺳﻴﻮن را

ﺑﺼﻮرت ﻣﺴﺘﻘﻞ ﻳﺎ ﻋﻤﻠﻜﺮد ﺷﺒﻜﻪ اي ﻳﻜﭙﺎرﭼﻪ ﺳﺎزي ﻣﻲ ﻛﻨﺪ و

ﺗﻤﺎم ورودي ﻫﺎ را در ﻛﺎﻣﭙﻴﻮﺗﺮ ﺟﻤﻊ آوري ﻛﺮده و وﻇﻴﻔﻪ

ارﺳﺎل ﺧﺮوﺟﻲ ﺗﻜﻲ را ﺑﻮﺳﻴﻠﻪ ﻛﻨﺘﺮل ﻛﻨﻨﺪه ﻫﺎي ﻋﺪدي اﻧﺠﺎم

.ﻣﻲ دﻫﺪ

3.13 Heat Pump

ﭘﻤﭗ ﺣﺮارﺗﻲ13-3

ﺳﺮﻣﺎﻳﺸﻲ ﺗﺮﻣﻮ دﻳﻨﺎﻣﻴﻜﻲ اﺳﺖ ﻛﻪ در،ﻧﻮﻋﻲ ﺳﺎﻣﺎﻧﻪ ﮔﺮﻣﺎﻳﺸﻲ

در آن ﻣﻤﻜﻦ اﺳﺖ.آن ﻋﻤﻞ ﺗﺒﺎدل ﺣﺮارت ﺻﻮرت ﻣﻲﮔﻴﺮد

ﭼﮕﺎﻟﻨﺪه و ﺗﺒﺨﻴﺮ ﻛﻨﻨﺪه ﺑﻪ ﺟﺎي ﻳﻜﺪﻳﮕﺮ ﻋﻤﻞ ﻧﻤﻮده و ﺣﺮارت

ﺑﺎ ﺗﻮﺟﻪ ﺑﻪ ﮔﺬر ﺟﺮﻳﺎن ﻫﻮا ﻳﺎ.را ﺑﻪ ﺟﻬﺖ دﻳﮕﺮي ﻫﺪاﻳﺖ ﻧﻤﺎﻳﺪ

ﭘﻤﭗ ﺣﺮارﺗﻲ ﻣﻤﻜﻦ اﺳﺖ ﺑﺮاي ﺳﺮﻣﺎﻳﺶ ﻳﺎ،ﺳﻴﺎل دﻳﮕﺮ

.ﮔﺮﻣﺎﻳﺶ ﺑﻪ ﻛﺎر رود

Thermodynamic heating/refrigerating system to

transfer heat. The condenser and evaporator may

change roles to transfer heat in either direction.

By receiving the flow of air or other fluid, a heat

pump is used to cool or heat.

3.14 HVAC Systems

ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع و، ﺗﻬﻮﻳﻪ، ﺳﺎﻣﺎﻧﻪﻫﺎي ﮔﺮﻣﺎﻳﺶ14-3

ﺳﺮﻣﺎﻳﺶ

،ﺳﺎﻣﺎﻧﻪاي ﻛﻪ ﺑﻪ ﻃﻮر ﻣﺠﻤﻮع ﻳﺎ ﺗﻜﻲ ﺑﺮاي ﻓﺮاﻳﻨﺪﻫﺎي ﮔﺮﻣﺎﻳﺶ

ﺗﻬﻮﻳﻪ و ﻳﺎ ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع ﻣﻄﻠﻮب در ﻳﻚ ﻳﺎ ﻣﺠﻤﻮﻋﻪ ﺳﺎﺧﺘﻤﺎﻧﻲ

.ﺑﻪ ﻛﺎر ﻣﻲرود

System that provides either collectively or

individually the processes of comfort heating,

ventilating, and/or air conditioning within, or

associated with, a building.

3.15 Induction Unit

واﺣﺪ اﻟﻘﺎﻳﻲ15-3

Air terminal device that delivers a small quantity

of conditioned (primary) air through highvelocity jets, to induce a large quantity of room

(secondary) air into the supply air stream. A

heating coil may be located in the primary or

secondary air stream. Primary air often is

predominantly outside air. Units generally

discharge directly through a grille into the space

due to limited downstream static pressure

capability.

ﻧﻮﻋﻲ وﺳﻴﻠﻪ ﻛﻪ در آن ﻣﻘﺪار ﻛﻤﻲ از ﻫﻮاي ﻣﻄﺒﻮع )اوﻟﻴﻪ( ﺑﺎ

ﻓﺸﺎر زﻳﺎد از ﻣﺠﺮاي ﺷﻴﭙﻮري ﺟﻬﺖ اﻟﻘﺎء ﺑﻪ ﺟﺮﻳﺎن ﻫﻮاي

ﻛﻮﻳﻞ ﮔﺮﻣﺎﻳﺶ ﻣﻤﻜﻦ.)ﺛﺎﻧﻮﻳﻪ( ورودي از اﺗﺎقﻫﺎ وارد ﻣﻲﮔﺮدد

ﺟﺮﻳﺎن ﻫﻮاي.اﺳﺖ در ﻣﺴﻴﺮ ﻫﻮاي اوﻟﻴﻪ ﻳﺎ ﺛﺎﻧﻮي ﻗﺮار ﮔﻴﺮد

دﺳﺘﮕﺎهﻫﺎ ﻋﻤﻮﻣﺎً ﻫﻮا.اوﻟﻴﻪ اﻏﻠﺐ ﺑﻴﺸﺘﺮ از ﻫﻮاي ﺧﺎرﺟﻲ اﺳﺖ

را ﺑﻪ ﻃﻮر ﻣﺴﺘﻘﻴﻢ از درﻳﭽﻪﻫﺎ ﺑﻪ ﻣﻨﻈﻮر ﻣﺤﺪود ﺳﺎﺧﺘﻦ ﻓﺸﺎر

. وارد ﻓﻀﺎ ﻣﻲﺳﺎزﻧﺪ،اﺳﺘﺎﺗﻴﻜﻲ

3.16 Optimization

ﺑﻬﻴﻨﻪ ﺳﺎزي16-3

It is defined as an act, process or methodology of

making something - design, systems or decision as fully perfect, functional or effective as

possible.

ﺑﻬﻴﻨﻪ ﺳﺎزي ﺑﺪﻳﻦ ﮔﻮﻧﻪ ﺗﻌﺮﻳﻒ ﻣﻴﺸﻮد ﻛﻪ ﻓﺮاﻳﻨﺪ ﻳﺎ روش

ﺳﺎﺧﺖ ﻳﺎ ﻃﺮاﺣﻲ ﺳﺎﻣﺎﻧﻪﻫﺎ ﻳﺎ ﺗﺼﻤﻴﻤﻲ ﻛﻪ ﺗﺎ ﺣﺪ اﻣﻜﺎن ﺑﺪون

. ﻋﻤﻠﻴﺎﺗﻲ و ﻣﻮﺛﺮ ﺑﺎﺷﺪ،ﻧﻘﺺ

3.17 Psychrometric Chart

ﻧﻤﻮدار ﺳﺎﻳﻜﺮوﻣﺘﺮي17-3

Graphical representation of the properties of

moist air, usually including wet and dry bulb

temperatures, specific and relative humidities,

enthalpy, and density.

ﻛﻪ ﺷﺎﻣﻞ،ﻧﺸﺎن دﻫﻨﺪه ﻧﻤﻮداري ﺧﺼﻮﺻﻴﺎت ﻫﻮاي ﻣﺮﻃﻮب

اﻧﺘﺎﻟﭙﻲ و، رﻃﻮﺑﺖ ﻣﺨﺼﻮص و ﻧﺴﺒﻲ،دﻣﺎي ﺣﺒﺎب ﺗﺮ و ﺧﺸﻚ

.ﭼﮕﺎﻟﻲ ﻫﻮا ﻣﻲ ﺑﺎﺷﺪ

12

Nov. 2009 / 1388 آذر

3.18 Relative Humidity

IPS-E-AR- 120(1)

رﻃﻮﺑﺖ ﻧﺴﺒﻲ18-3

1) Ratio of the partial pressure or density of

water vapor to the saturation pressure or

density, respectively, at the same dry-bulb

temperature, and barometric pressure of the

ambient air.

( ﻧﺴﺒﺖ ﻓﺸﺎر ﺟﺰﺋﻲ ﻳﺎ ﭼﮕﺎﻟﻲ ﺑﺨﺎر آب ﺑﻪ ﻓﺸﺎر اﺷﺒﺎع ﻳﺎ1

2) Ratio of the mole fraction of water vapor to

the mole fraction of water vapor saturated at

the same temperature and barometric pressure.

( ﺣﺎﺻﻞ ﺗﻘﺴﻴﻢ ﻧﺴﺒﺖ ﻣﻮﻟﻲ ﺑﺨﺎر آب ﺑﻪ ﻧﺴﺒﺖ ﻣﻮﻟﻲ2

و در دﻣﺎي ﺣﺒﺎب ﺧﺸﻚ ﻳﻜﺴﺎن و ﻓﺸﺎر، ﺑﻪ ﺗﺮﺗﻴﺐ،ﭼﮕﺎﻟﻲ

.ﺟﻮ ﻫﻮاي ﻣﺤﻴﻂ

.ﺑﺨﺎر آب اﺷﺒﺎع ﺷﺪه در دﻣﺎ و ﻓﺸﺎر ﺟﻮ ﻳﻜﺴﺎن

3.19 Variable Air Volume

ﺣﺠﻢ ﻣﺘﻐﻴﺮ ﻫﻮا19-3

Variable air volume (VAV) system maintains

room temperature by supplying a variable volume

of constant temperature supply air, wherein

ﺳﺎﻣﺎﻧﻪ ﻫﻮا ﺑﺎ ﺣﺠﻢ ﻣﺘﻐﻴﺮ ﺑﻪ ﻣﻨﻈﻮر ﺗﺜﺒﻴﺖ دﻣﺎي اﺗﺎق ﺑﻮﺳﻴﻠﻪ

: ﺗﻐﻴﻴﺮ ﺣﺠﻢ ﻫﻮاي ﺧﺮوﺟﻲ ﺑﺎ دﻣﺎي ﺛﺎﺑﺖ ﺑﻪ اﻳﻦ ﺷﺮح

- The volume is modulated by a damper in

response to room temperature;

ﺣﺠﻢ ﻫﻮا ﺑﻮﺳﻴﻠﻪ دﻣﭙﺮ،( ﺑﺮ ﺣﺴﺐ دﻣﺎي اﺗﺎق )ﻣﻮرد ﻧﻴﺎز.ﺗﻌﺪﻳﻞ ﻣﻲ ﮔﺮدد

- The damper can be powered by duct pressure

powered controls, pneumatic controls, or

electric controls.

، ﻛﻨﺘﺮل ﻛﻨﻨﺪه دﻣﭙﺮ ﻣﻲﺗﻮاﻧﺪ از ﻃﺮﻳﻖ ﻓﺸﺎر ﻛﺎﻧﺎﻟﻲ.ﻧﻴﻮﻣﺎﺗﻴﻚ و ﻳﺎ ﺑﺮﻗﻲ ﻋﻤﻞ ﻧﻤﺎﻳﺪ

3.20 Zoning

ﻣﻨﻄﻘﻪ ﺑﻨﺪي20-3

( ﺗﻘﺴﻴﻢ ﻳﻚ ﻳﺎ ﮔﺮوﻫﻲ از ﺳﺎﺧﺘﻤﺎنﻫﺎ ﺑﻪ ﻣﻨﺎﻃﻖ ﻣﺠﺰا1

1) Division of a building or group of buildings

into separately controlled spaces (zones),

where different conditions can be maintained

simultaneously.

ﻛﻪ ﺑﺘﻮان در آﻧﻬﺎ ﺷﺮاﻳﻂ ﻣﺨﺘﻠﻒ را ﺑﺼﻮرت ﻫﻤﺰﻣﺎن ﻛﻨﺘﺮل

.و ﺗﺜﺒﻴﺖ ﻧﻤﻮد

( ﺗﻘﺴﻴﻢ ﻳﻚ ﺳﺎﺧﺘﻤﺎن ﺑﻪ ﻗﺴﻤﺖﻫﺎي ﻛﻮﭼﻜﺘﺮ ﺑﻪ ﻣﻨﻈﻮر2

2) Practice of dividing a building into smaller

sections for control of heating and cooling.

Each section is selected so that one thermostat

can be used to determine its requirements.

ﻫﺮ ﺑﺨﺶ ﺑﻪ ﮔﻮﻧﻪ اي اﻧﺘﺨﺎب.ﻛﻨﺘﺮل ﮔﺮﻣﺎﻳﺶ و ﺳﺮﻣﺎﻳﺶ

.ﺷﻮد ﻛﻪ ﺑﺎ ﻳﻚ ﺗﺮﻣﻮﺳﺘﺎت ﺑﺘﻮان ﻧﻴﺎز آﻧﻬﺎ را ﺑﺮآورده ﻧﻤﻮد

4. UNITS

واﺣﺪﻫﺎ-4

ﻣﻨﻄﺒﻖ،(SI) ﺑﺮﻣﺒﻨﺎي ﻧﻈﺎم ﺑﻴﻦ اﻟﻤﻠﻠﻲ واﺣﺪﻫﺎ،اﻳﻦ اﺳﺘﺎﻧﺪارد

ﻣﮕﺮ آﻧﻜﻪ در ﻣﺘﻦ، ﻣﻲﺑﺎﺷﺪIPS-E-GN-100 ﺑﺎ اﺳﺘﺎﻧﺪارد

.اﺳﺘﺎﻧﺪارد ﺑﻪ واﺣﺪ دﻳﮕﺮي اﺷﺎره ﺷﺪه ﺑﺎﺷﺪ

This Standard is based on International System of

Units (SI), as per IPS-E-GN-100 except where

otherwise is specified.

5. BASIC DESIGN REQUIREMENTS

ﻧﻴﺎزﻫﺎي ﻃﺮاﺣﻲ ﭘﺎﻳﻪ-5

5.1 General

ﻋﻤﻮﻣﻲ1-5

5.1.1 A reasonable and accurate requirement of

air conditioning system shall be capable to

promote physical wellbeing of human or provide

improvement to industrial processes.

ﻳﻚ ﺳﺎﻣﺎﻧﻪ ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع ﻣﻨﻄﻘﻲ و دﻗﻴﻖ ﺑﺎﻳﺪ ﺑﻪ1-1-5

5.1.2 Temperature, relative humidity, motion of

the air, and the temperature of the surrounding

surfaces are important determining factors in the

sensation of warmth and comfort because they

ﺟﺮﻳﺎن ﻫﻮا و دﻣﺎي ﺳﻄﻮح، رﻃﻮﺑﺖ ﻧﺴﺒﻲ، دﻣﺎ2-1-5

ﮔﻮﻧﻪاي ﺑﺎﺷﺪ ﻛﻪ ﻣﻮﺟﺐ آﺳﺎﻳﺶ اﻧﺴﺎن و ﻳﺎ ﺗﻮﺳﻌﻪ ﻋﻤﻠﻴﺎت در

.ﺻﻨﺎﻳﻊ ﮔﺮدد

ﻋﻮاﻣﻞ ﺗﻌﻴﻴﻦ ﻛﻨﻨﺪه و ﻣﻬﻤﻲ در اﺣﺴﺎس ﮔﺮﻣﺎ و،ﺟﺎﻧﺒﻲ

راﺣﺘﻲ ﻣﻲﺑﺎﺷﻨﺪ زﻳﺮا اﻳﻦ ﻋﻮاﻣﻞ ﺑﻪ ﻃﻮر ﻣﺴﺘﻘﻴﻢ در دﻓﻊ

13

Nov. 2009 / 1388 آذر

directly influence the dissipation of body heat.

IPS-E-AR- 120(1)

.ﮔﺮﻣﺎي ﺑﺪن ﻣﻮﺛﺮﻧﺪ

5.1.3 In industrial processes, the temperature and

relative humidity of the air have a great deal to do

with the rate of production, period of storage, and

the weight, strength, appearance and quality of

the product.

دﻣﺎ و رﻃﻮﺑﺖ ﻧﺴﺒﻲ ﻫﻮا در، در ﻓﺮآﻳﻨﺪﻫﺎي ﺻﻨﻌﺘﻲ3-1-5

ﻇﺎﻫﺮ و ﻛﻴﻔﻴﺖ، ﻣﻘﺎوﻣﺖ، وزن، زﻣﺎن اﻧﺒﺎرداري،ﻣﻴﺰان ﺗﻮﻟﻴﺪ

. اﺛﺮ زﻳﺎدي دارد،ﺗﻮﻟﻴﺪ

5.2 Design Load Factors

ﺑﺎر ﻃﺮاﺣﻲ2-5

5.2.1 The following shall be specified as a basis

for the calculation of design loads:

ﻣﻲ ﺑﺎﻳﺴﺖ ﻣﻮارد، در ﻃﺮاﺣﻲ ﺑﺮاي ﻣﺤﺎﺳﺒﻪ ﻇﺮﻓﻴﺖ1-2-5

:ذﻳﻞ ﻣﺸﺨﺺ ﮔﺮدﻧﺪ

a) Design outside conditions (including

temperature, relative humidity and other

factors).

رﻃﻮﺑﺖ،اﻟﻒ( ﺷﺮاﻳﻂ ﻃﺮاﺣﻲ ﻫﻮاي ﺧﺎرج )ﺷﺎﻣﻞ دﻣﺎ

b) Design inside conditions (Including

temperature, relative humidity and other

factors).

رﻃﻮﺑﺖ ﻧﺴﺒﻲ،ب( ﺷﺮاﻳﻂ ﻃﺮاﺣﻲ ﻫﻮاي داﺧﻞ )ﺷﺎﻣﻞ دﻣﺎ

.(ﻧﺴﺒﻲ و ﻋﻮاﻣﻞ دﻳﮕﺮ

.(و ﻋﻮاﻣﻞ دﻳﮕﺮ

c) Average number of occupants.

.ج( ﻣﻴﺎﻧﮕﻴﻦ ﺗﻌﺪاد اﻓﺮاد ﺳﺎﻛﻦ

d) Other sources of substantial load from withindoors when design conditions prevail.

د( ﺳﺎﻳﺮ ﻣﻨﺎﺑﻊ ﻣﻬﻢ ﺑﺎر در داﺧﻞ ﺳﺎﺧﺘﻤﺎن وﻗﺘﻲ ﺷﺮاﻳﻂ

.ﻃﺮاﺣﻲ اﻫﻤﻴﺖ داﺷﺘﻪ ﺑﺎﺷﺪ

.ﻫ( ﻣﻘﺪار ﻫﻮاي در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﺷﺪه ﺑﺮاي ﺗﻬﻮﻳﻪ

e) Quantity of air assumed for ventilation.

f) Time of day at which design load from

indoor sources is estimated to occur.

.و( زﻣﺎﻧﻲ از روز ﻛﻪ ﻣﻨﺎﺑﻊ داﺧﻠﻲ ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﮔﻴﺮﻧﺪ

g) Class of activity assumed for occupants.

.ز( ﭘﻴﺶ ﺑﻴﻨﻲ ﻧﻮع ﻓﻌﺎﻟﻴﺖ اﻓﺮاد

h) Size and physical characteristics of

enclosure.

.ح( اﺑﻌﺎد و ﺧﺼﻮﺻﻴﺎت ﻓﻴﺰﻳﻜﻲ ﻓﻀﺎي ﻣﺤﺼﻮر

i) Quantity of air assumed for infiltration,

including infiltration due to door usage.

ط( ﻣﻘﺪار ﻫﻮاي ﻓﺮض ﺷﺪه ﺑﺮاي ﻧﻔﻮذ ﻫﻮا در زﻣﺎﻧﻲ ﻛﻪ

.درب ﺑﺎز و ﺑﺴﺘﻪ ﻣﻲﺷﻮد

j) Hours of operation.

.ي( ﺳﺎﻋﺎت ﻛﺎر

k) Orientation of building

.ك( ﺟﻬﺖﻳﺎﺑﻲ ﺳﺎﺧﺘﻤﺎن

5.2.2 Calculations of design loads (summer)

should include the following sources of heat gain:

ﻣﺤﺎﺳﺒﻪ ﻇﺮﻓﻴﺖ ﻃﺮاﺣﻲ )ﺗﺎﺑﺴﺘﺎن( ﺑﺎﻳﺪ ﺷﺎﻣﻞ ﻣﻨﺎﺑﻊ2-2-5

:ﺣﺮارﺗﻲ ذﻳﻞ ﺑﺎﺷﺪ

a) Conduction through physical barriers, such

as walls, doors, windows, floors, ceilings, etc.

،اﻟﻒ( ﻫﺪاﻳﺖ از ﻣﻴﺎن ﺣﺼﺎرﻫﺎي ﻓﻴﺰﻳﻜﻲ از ﻗﺒﻴﻞ دﻳﻮارﻫﺎ

. ﺳﻘﻒﻫﺎ و ﻏﻴﺮه، ﻛﻒﻫﺎ، ﭘﻨﺠﺮهﻫﺎ،دربﻫﺎ

b) Heat from sunshine:

:ب( ﺣﺮارت ﻧﺎﺷﻲ از ﺧﻮرﺷﻴﺪ

1) Direct effect through glass areas.

.( اﺛﺮ ﻣﺴﺘﻘﻴﻢ ﺑﻪ ﺳﻄﻮح ﺷﻴﺸﻪﻫﺎ1

2) Additional conduction through opaque

barriers, such as walls, roofs, etc., when these

heat gains contribute to the design load.

( ﻫﺪاﻳﺖ ﻣﻀﺎﻋﻒ ﺑﻪ ﺳﻄﻮح ﻣﻮاﻧﻊ ﻏﻴﺮ ﺷﻔﺎف ﻣﺎﻧﻨﺪ2

ﺳﻘﻒﻫﺎ و ﻏﻴﺮه ﻛﻪ اﻳﻦ ﺣﺮارت ﺑﻪ ﺑﺎر ﺣﺮارﺗﻲ،دﻳﻮارﻫــﺎ

.اﺿﺎﻓﻲ ﺧﻮاﻫﺪ ﺷﺪ

14

Nov. 2009 / 1388 آذر

c) Heat and moisture introduced by incoming

outdoor air.

IPS-E-AR- 120(1)

.ج ( ﺣﺮارت و رﻃﻮﺑﺖ ﻧﺎﺷﻲ از ﻫﻮاي ورودي از ﺧﺎرج

d) Heat and moisture liberated by occupants.

.د( ﺣﺮارت و رﻃﻮﺑﺖ ﻧﺎﺷﻲ از اﻓﺮاد

e) Heat and moisture liberated by appliances,

office

equipment,

illumination,

combustion, electric motors etc.

، ﺗﺠﻬﻴﺰات دﻓﺘﺮ ﻛﺎر،ﻫ( ﺣﺮارت و رﻃﻮﺑﺖ ﻧﺎﺷﻲ از وﺳﺎﻳﻞ

. ﻣﻮﺗﻮرﻫﺎي ﺑﺮﻗﻲ و ﻏﻴﺮه، اﺣﺘﺮاق،روﺷﻨﺎﻳﻲ

5.3 Design Outside Conditions

ﺷﺮاﻳﻂ ﻃﺮاﺣﻲ ﺧﺎرج3-5

The design outside dry-bulb and wet-bulb

temperatures, prevailing wind velocity including

elevation and other factors for calculating cooling

loads shall be not lower than those shown in

Attachments 1-2 and 3 for the cities listed and for

localities that are the same climatically. (The

designer should exercise judgment to insure that

results are consistent with expectations).

، ﺳﺮﻋﺖ ﻏﺎﻟﺐ ﺑﺎد،دﻣﺎﻫﺎي ﺣﺒﺎب ﺧﺸﻚ و ﻣﺮﻃﻮب ﺧﺎرج

ارﺗﻔﺎع از ﺳﻄﺢ درﻳﺎ و دﻳﮕﺮ ﻋﻮاﻣﻞ ﺑﺮاي ﻣﺤﺎﺳﺒﻪ ﺑﺎر ﺳﺮﻣﺎﻳﺶ

3 و2-1 ﺟﻬﺖ ﻃﺮاﺣﻲ ﺑﺎﻳﺪ از ارﻗﺎﻣﻲ ﻛﻪ در ﭘﻴﻮﺳﺖﻫﺎي

ﻣﺮﺑﻮط ﺑﻪ ﺷﻬﺮﻫﺎ درج ﮔﺮدﻳﺪه اﺳﺖ ﻛﻤﺘﺮ ﻧﺒﺎﺷﺪ و ﺑﺮاي ﻧﻮاﺣﻲ

دﻳﮕﺮ ﻛﻪ داراي آب و ﻫﻮاي ﻣﺸﺎﺑﻪ دارﻧﺪ )ﻣﻬﻨﺪس ﻃﺮاح ﺑﺎﻳﺪ

ﻗﻀﺎوت،در اﻳﻦ ﺧﺼﻮص ﺑﺮاي اﻃﻤﻴﻨﺎن از ﻧﺘﺎﻳﺞ ﭘﻴﺶﺑﻴﻨﻲﻫﺎ

.(ﻛﻨﺪ

5.4 Design Inside Conditions

ﺷﺮاﻳﻂ ﻃﺮاﺣﻲ داﺧﻞ4-5

5.4.1 It is recommended that the design inside

temperature and humidity for calculation of the

cooling load should not be higher than 26.7°C

(80°F) dry-bulb temperature and 50 percent

relative humidity. The ventilation rate,

permissible variations and control limits should

also be inclusive.

دﻣﺎي ﺧﺸﻚ داﺧﻠﻲ را، ﺑﺮاي ﻣﺤﺎﺳﺒﻪ ﺑﺎر ﺳﺮﻣﺎﻳﻲ1-4-5

درﺟﻪ ﻓﺎرﻧﻬﺎﻳﺖ( ﻧﺒﺎﻳﺪ در80) درﺟﻪ ﺳﺎﻧﺘﻴﮕﺮاد26/7 ﺑﻴﺶ از

ﻣﻮارد ﻣﻴﺰان. درﺻﺪ ﺑﺎﺷﺪ50 ﻧﻈﺮ ﮔﺮﻓﺖ و رﻃﻮﺑﺖ ﻧﺴﺒﻲ ﻧﻴﺰ

. ﺗﻐﻴﻴﺮات ﻣﺠﺎز و ﺣﺪود ﻛﻨﺘﺮل ﻣﻲ ﺑﺎﻳﺴﺖ ﻟﺤﺎظ ﺷﻮد،ﺗﻬﻮﻳﻪ

5.4.2 For installations which have a load that is

predominantly a "people" load, a slightly-lower

design dry-bulb temperature, along with an

increase in relative humidity, is permissible to

attain a more economical equipment selection.

Under these conditions, the design inside drybulb temperature may decrease to 25°C (77°F)

and the design inside humidity may increase to 55

percent.

دﻣﺎي ﺧﺸﻚ، وﻗﺘﻲ ﻛﻪ ﺑﺎر ﻣﺤﺴﻮس ﻧﻔﺮات زﻳﺎد2-4-5

اﻧﺘﺨﺎب، و اﻓﺰاﻳﺶ رﻃﻮﺑﺖ ﻧﺴﺒﻲ داﺷﺘﻪ ﺑﺎﺷﻴﻢ،ﺗﻘﺮﻳﺒﺎً ﻛﻢ

، در اﻳﻦ ﺷﺮاﻳﻂ.ﻣﻘﺮون ﺑﻪ ﺻﺮﻓﻪ ﺗﺠﻬﻴﺰات اﻣﻜﺎنﭘﺬﻳﺮ اﺳﺖ

77) درﺟﻪ ﺳﺎﻧﺘﻴﮕﺮاد25 دﻣﺎي ﺧﺸﻚ داﺧﻠﻲ ﻣﻤﻜﻦ اﺳﺖ ﺗﺎ

درﺻﺪ اﻓﺰاﻳﺶ55 درﺟﻪ ﻓﺎرﻧﻬﺎﻳﺖ( ﻛﺎﻫﺶ و رﻃﻮﺑﺖ ﻧﺴﺒﻲ ﺗﺎ

.ﻳﺎﺑﺪ

5.5 Solar Heat Gain

ﺑﻬﺮه ﮔﺮﻣﺎﻳﻲ ﺧﻮرﺷﻴﺪي5-5

For factors on sensible heat gain transmitted

through glass and absorbed solar energy,

reference is made to ASHRAE Fundamental 2005

Guidebook Chapter 29.

ﺑﺮاي ﻋﻮاﻣﻞ ﺑﻬﺮه ﮔﺮﻣﺎي ﻣﺤﺴﻮس اﻧﺘﻘﺎﻟﻲ ﻛﻪ از ﻃﺮﻳﻖ ﺷﻴﺸﻪ

ﺟﻠﺪ،ASHRAE 2005 و ﺟﺬب اﻧﺮژي ﺧﻮرﺷﻴﺪي ﺑﻪ ﻣﺮﺟﻊ

. ﻣﺮاﺟﻌﻪ ﮔﺮدد29 ﻓﺼﻞ،اﺻﻮل

5.6 Transmission Heat Gain

Transmission factors shall be used for estimating

the heat gain or heat loss due to transmission

through exterior walls, partitions, roofs, ceilings,

and floors; and the heat loss due to transmission

through windows. For the usual construction,

wall transmissions are only a small proportion of

the over-all load and, therefore, need not be

treated as carefully as glass or roofs exposed to

solar radiation.

ﺑﻬﺮه ﮔﺮﻣﺎي اﻧﺘﻘﺎﻟﻲ6-5

ﺑﺮاي ﻣﺤﺎﺳﺒﻪ ﻣﻴﺰان ﺣﺮارت ﻳﺎ اﺗﻼف ﺣﺮارت ﺑﺎﻳﺪ ﻋﻮاﻣﻞ اﻧﺘﻘﺎل

ﺳﻘﻒﻫﺎ و ﻛﻒﻫﺎ و، ﺑﺎمﻫﺎ، ﺗﻴﻐﻪﻫﺎ،ﮔﺮﻣﺎ از دﻳﻮارﻫﺎي ﺧﺎرﺟﻲ

ﺑﺮاي ﺳﺎزهﻫﺎي.اﺗﻼف ﺣﺮارت از ﭘﻨﺠﺮهﻫﺎ در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﺷﻮد

ﻗﺴﻤﺖ ﻛﻮﭼﻜﻲ از ﺑﺎر ﻛﻠﻲ اﺳﺖ، اﻧﺘﻘﺎل ﮔﺮﻣﺎ از دﻳﻮارﻫﺎ،ﻋﺎدي

و ﺑﻨﺎﺑﺮاﻳﻦ ﺑﺮاي ﺑﻬﻴﻨﻪ ﺳﺎزي ﻧﻴﺎز ﺑﻪ دﻗﺘﻲ ﻫﻤﺎﻧﻨﺪ ﺗﺸﻌﺸﻊ

،ﺧﻮرﺷﻴﺪي از ﭘﻨﺠﺮهﻫﺎ ﻳﺎ ﺳﻘﻒﻫﺎي ﺧﺎرﺟﻲ ﺑﻪ ﻛﺎر ﻣﻲرود

.ﻧﻤﻲﺑﺎﺷﺪ

15

Nov. 2009 / 1388 آذر

IPS-E-AR- 120(1)

5.7 Design Occupancy

ﮔﺮﻣﺎزاﻳﻲ اﻓﺮاد در ﻃﺮاﺣﻲ7-5

The design-load calculations should be based on

the stated average occupancy of the building

during the time of maximum design conditions.

The heat given off by each occupant should be

calculated as not less than that in Table 1.

ﻣﺤﺎﺳﺒﺎت ﺑﺎر ﺑﺎﻳﺪ ﺑﺮ اﺳﺎس ﻣﺘﻮﺳﻂ ﻧﻔﺮات داﺧﻞ،در ﻃﺮاﺣﻲ

اﻧﺘﻘﺎل ﺣﺮارت ﺑﻪ.ﺳﺎﺧﺘﻤﺎن در ﺣﺪاﻛﺜﺮ ﺷﺮاﻳﻂ زﻣﺎﻧﻲ ﺑﺎﺷﺪ

ﻓﻀﺎي اﻃﺮاف ﺗﻮﺳﻂ ﻫﺮ ﻧﻔﺮ ﺑﺎﻳﺪ ﻃﻮري ﻣﺤﺎﺳﺒﻪ ﮔﺮدد ﻛﻪ از

. ﻛﻤﺘﺮ ﻧﺒﺎﺷﺪ1 ﻣﻘﺎدﻳﺮ ﺟﺪول ﺷﻤﺎره

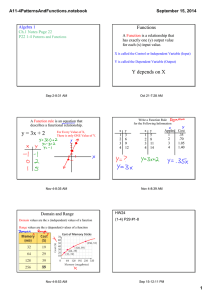

TABLE 1 - RATES OF HEAT GAIN FROM OCCUPANTS OF CONDITIONED SPACES (Notes a.b.c)

(ج.ب. ﻧﺮخ ﻣﻴﺰان ﮔﺮﻣﺎي ﻧﻔﺮات در ﻓﻀﺎﻫﺎي ﺗﻬﻮﻳﻪ ﺷﺪه)ﻳﺎدآوري اﻟﻒ-1 ﺟﺪول

Item

ردﻳﻒ

1

Sensible

Heat,

Btu/h

Latent

Heat,

Btu/h

ﺣﺮارت ﻣﺤﺴﻮس

ﺣﺮارت ﻧﻬﺎن

ﺑﻲ ﺗﻲ ﻳﻮ در

ﺑﻲ ﺗﻲ ﻳﻮ در

ﺳﺎﻋﺖ

ﺳﺎﻋﺖ

Typical Application

ﺣﺮارت ﻛﻞ

ﺣﺮارت ﻛﻞ

درﺟﻪ ﻓﻌﺎﻟﻴﺖ

ﻧﻤﻮﻧﻪ ﻛﺎرﺑﺮد

ﺑﺰرﮔﺴﺎﻻن ﻣﺮد

ﺗﻌﺪﻳﻞ ﺷﺪه ﺑﻲ

ﺑﻲ ﺗﻲ ﻳﻮ

ﺗﻲ ﻳﻮ در

در ﺳﺎﻋﺖ

ﺳﺎﻋﺖ

390

330

225

105

390

350

245

105

450

400

245

155

475

450

250

200

550

450

250

200

550

500

250

250

490

550

275

275

800

750

275

475

900

850

305

345

1000

1000

375

625

1500

1450

580

870

1500

1450

580

870

1600

1600

635

965

2000

1800

710

1090

Seated at theater

Theater – Matinee

Seated at theater

ﺗﺌﺎﺗﺮ – ﻧﻤﺎﻳﺶ ﺑﻌﺪ از ﻇﻬﺮ

Theater – Evening

ﺗﺌﺎﺗﺮ – ﻏﺮوب

ﻧﺸﺴﺘﻪ در ﺗﺌﺎﺗﺮ

ﻧﺸﺴﺘﻪ ﺑﺎ ﻛﺎر ﺧﻴﻠﻲ ﺳﺒﻚ

Offices, hotels,

apartments

4

Moderately active office

work

Offices, hotels,

apartments

5

Standing, light work;

walking

6

Walking; standing

3

Total Heat

Adjusted d,

Btu/h

Degree Of Activity

ﻧﺸﺴﺘﻪ در ﺗﺌﺎﺗﺮ

2

Total Heat

Adults,

Male, Btu/h

Seated, very light work

ﻣﺠﺘﻤﻊ ﻣﺴﻜﻮﻧﻲ، ﻫﺘﻞ،دﻓﺘﺮ ﻛﺎر

ﻓﻌﺎﻟﻴﺖ اداري ﻣﻼﻳﻢ

ﻗﺪم زدن، ﻛﺎر ﺳﺒﻚ،اﻳﺴﺘﺎده

ﻣﺠﺘﻤﻊ ﻣﺴﻜﻮﻧﻲ، ﻫﺘﻞ،دﻓﺘﺮ ﻛﺎر

Department store, retail

store

اﻧﺒﺎر ﺧﺮده ﻓﺮوﺷﻲ، اﻧﺒﺎر

Drug store, bank

داروﺧﺎﻧﻪ – ﺑﺎﻧﻚ

اﻳﺴﺘﺎدن- در ﺣﺎل راه رﻓﺘﻦ

7

Sedentary work Light

bench

Restaurant e

رﺳﺘﻮران

ﻛﺎر ﺳﺒﻚ ﻧﺸﺴﺘﻪ

8

Moderate Practice

Prayer Room

ﺣﺮﻛﺎت ﻣﻮزون ﻣﻼﻳﻢ

9

Walking 3 mph; light

ﻧﻤﺎز ﺧﺎﻧﻪ

Factory

ﻣﺎﻳﻞ در ﺳﺎﻋﺖ؛3 راه رﻓﺘﻦ

ﺳﺒﻚ

10

Machine work

ﻛﺎرﺧﺎﻧﻪ

Factory

ﻛﺎر ﻛﺎرﮔﺎﻫﻲ

11

Bowling f

ﻛﺎرﺧﺎﻧﻪ

Bowling alley

ورزش ﺑﻮﻟﻴﻨﮓ

12

Heavy work

ﺳﺎﻟﻦ ﺑﻮﻟﻴﻨﮓ

Factory

ﻛﺎر ﺳﺨﺖ

13

Heavy machine work;

lifting

ﻛﺎرﺧﺎﻧﻪ

Factory

ﻛﺎرﺧﺎﻧﻪ

ﻛﺎر ﻛﺎرﮔﺎﻫﻲ ﺳﺨﺖ ﺑﺎﻻﺑﺮ

14

Athletics

Gymnasium

ﻣﻮارد ورزﺷﻲ

ورزﺷﮕﺎه

16

Nov. 2009 / 1388 آذر

Notes:

IPS-E-AR- 120(1)

:ﻳﺎدآوريﻫﺎ

a) Tabulated values are based on 24°C (75°F)

room dry-bulb temperature. For (80°F) room

dry-bulb, the total heat remains the same, but

the sensible heat values should be decreased

by approximately 20%, and the latent heat

values increased accordingly.

75) درﺟﻪ ﺳﺎﻧﺘﻴﮕﺮاد24 اﻟﻒ( ﻣﻘﺎدﻳﺮ ﺟﺪول ﺑﺮ اﺳﺎس

80 در دﻣﺎي.درﺟﻪ ﻓﺎرﻧﻬﺎﻳﺖ( دﻣﺎي ﺧﺸﻚ داﺧﻠﻲ اﺳﺖ

ﻳﻜﺴﺎن،درﺟﻪ ﻓﺎرﻧﻬﺎﻳﺖ ﺧﺸﻚ اﺗﺎق ﻣﻘﺪار ﻛﻞ ﺣﺮارت

اﻣﺎ ﻣﻘﺪار ﺣﺮارت ﻣﺤﺴﻮس ﺿﺮورﺗﺎً ﺑﻪ ﻣﻴﺰان،ﻣﻲﻣﺎﻧﺪ

درﺻﺪ ﻛﺎﻫﺶ ﻣﻲﻳﺎﺑﺪ و ﺑﺮ اﻳﻦ اﺳﺎس ﻣﻘﺪار20 ﺗﻘﺮﻳﺒﻲ

. اﻓﺰاﻳﺶ ﻣﻲﻳﺎﺑﺪ،ﺣﺮارت ﻧﻬﺎن

b) Reference is also made to chapter 8 of

ASHRAE 2005 Fundamental Guidebook.

(except item 8)

8 ﻓﺼﻞ، ﺟﻠﺪ اﺻﻮلASHRAE 2005 ب( ﻣﺮﺟﻊ از

c) All values are rounded to nearest 1.5 W

ﺑﻲ ﺗﻲ ﻳﻮ در5) وات1/5 ج( ﻛﻠﻴﻪ ﻣﻘﺎدﻳﺮ ﺑﺎ ﺗﻘﺮﻳﺐ ﺑﻪ

(8 )ﺑﺠﺰ ردﻳﻒ.ﻣﻲﺑﺎﺷﺪ

(5 Btu/h).

.ﺳﺎﻋﺖ( درج ﮔﺮدﻳﺪه اﺳﺖ

d) Adjusted heat gain is based on normal

percentage of men, women, and children for

the application listed, with the postulate that

the gain from an adult female is 85% of that

for an adult male, and that the gain from a

child is 75% of that for an adult male.

زن و،د( ﻣﻘﺪار ﺣﺮارت ﺑﺮ اﺳﺎس درﺻﺪ ﻣﻌﻤﻮل ﻧﻔﺮات ﻣﺮد

ﺑﭽﻪﻫﺎ ﺑﺎ ﻓﺮض اﻳﻦ ﻛﻪ ﻣﻴﺰان ﺣﺮارت ﻧﺎﺷﻲ از زﻧﺎن

درﺻﺪ ﻣﺮدان ﺑﺰرﮔﺴﺎل و ﻣﻴﺰان ﺣﺮارت85 ﺑﺰرﮔﺴﺎل

درﺻﺪ ﻣﺮدان ﺑﺰرﮔﺴﺎل در ﻓﻬﺮﺳﺖ ﻛﺎرﺑﺮدي75 ﺑﭽﻪﻫﺎ

.ﺟﺪول درج ﮔﺮدﻳﺪه اﺳﺖ

e) Adjusted total heat gain for sedentary work,

restaurant, includes 18 W (61 Btu/h) for food

per individual (9 W (30 Btu/h) sensible and

رﺳﺘﻮران،ﻫ( ﻣﻘﺪار ﺣﺮارت ﺗﻨﻈﻴﻤﻲ ﺑﺮاي ﻛﺎر ﻧﺸﺴﺘﻪ

ﺑﻲ ﺗﻲ ﻳﻮ در ﺳﺎﻋﺖ( ﺑﺮاي ﻏﺬاي61) وات18 ﻋﺒﺎرت از

ﺑﻲ ﺗﻲ ﻳﻮ در ﺳﺎﻋﺖ( ﺣﺮارت ﻣﺤﺴﻮس و30) وات9 ،ﺗﻜﻲ

. وات ﮔﺮﻣﺎي ﻧﻬﺎن ﻣﻲﺑﺎﺷﺪ9

9 W latent).

f) For Bowling, figure one person per alley

actually bowling, and all others as sitting (117

W 400 Btu/h) or standing and walking slowly

(161 W- 550 Btu/h).

رﻗﻢ ﻳﻚ ﻧﻔﺮ در ﺣﺎل ورزش و،و( ﺑﺮاي ورزش ﺑﻮﻟﻴﻨﮓ

ﺑﻲ400 وات ﻳﺎ117) ﺗﻤﺎم اﻓﺮاد دﻳﮕﺮ ﺑﻪ ﻋﻨﻮان ﻧﺸﺴﺘﻪ

550 وات ﻳﺎ161) ﺗﻲ ﻳﻮ در ﺳﺎﻋﺖ( ﻳﺎ اﻳﺴﺘﺎده و ﻛﺎر آرام

.ﺑﻲ ﺗﻲ ﻳﻮ در ﺳﺎﻋﺖ( در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﻣﻲﺷﻮد

5.8 Heat from Appliances & other Equipment

ﺣﺮارت ﻧﺎﺷﻲ از وﺳﺎﻳﻞ ﺧﺎﻧﮕﻲ و ﺗﺠﻬﻴﺰات دﻳﮕﺮ8-5

For recommended values of heat gain in Btu per

hour, for a number of commonly-used appliances,

heat gains from selected office equipment,

hospital equipment and electric motors, reference

is made to Attachments 4, 5, 6 and 7.

ﺑﺮاي ﻣﻘﺎدﻳﺮ ﻣﻮرد ﻧﻈﺮ ﻧﺮخ ﺣﺮارﺗﻲ ﺑﺮﺣﺴﺐ ﺑﻲ ﺗﻲ ﻳﻮ در

ﺗﺠﻬﻴﺰات ﺑﻴﻤﺎرﺳﺘﺎﻧﻲ و،ﺳﺎﻋﺖ ﺑﻪ ازاء ﻳﻚ وﺳﻴﻠﻪ ﺧﺎﻧﮕﻲ

اﻳﻦ اﺳﺘﺎﻧﺪارد7 و6 ،5 ،4 ﻣﻮﺗﻮرﻫﺎي ﺑﺮﻗﻲ ﺑﻪ ﭘﻴﻮﺳﺖﻫﺎي

.ﻣﺮاﺟﻌﻪ ﺷﻮد

5.9 Ventilation and Infiltration

ﺗﻬﻮﻳﻪ و ﻧﻔﻮذ ﻫﻮا9-5

5.9.1 Ventilation

ﺗﻬﻮﻳﻪ1-9-5

5.9.1.1 For Ventilation requirements the Table

No. 8 mentioned in IPS-E-AR-160 shall apply.

For maintaining positive pressure the quantity of

air shall not be less than that drawn from the

space by any exhaust fan that may be used.

اﺳﺘﺎﻧﺪارد8 ﺑﺮاي اﻟﺰاﻣﺎت ﺗﻬﻮﻳﻪ ﺟﺪول ﺷﻤﺎره1-1-5-9

ﺑﺮاي ﺗﺄﻣﻴﻦ ﻓﺸﺎر ﻣﺜﺒﺖ. را ﺑﺎﻳﺪ ﺑﻜﺎر ﺑﺮدIPS-E-AR-160

ﻣﻘﺪار ﻫﻮاي رﻓﺖ ﻧﺒﺎﻳﺪ ﻛﻤﺘﺮ از ﻫﻮاي ﺗﺨﻠﻴﻪ ﺷﺪه از ﻓﻀﺎ

.ﺗﻮﺳﻂ ﻫﻮاﻛﺶ ﺑﺎﺷﺪ

17

Nov. 2009 / 1388 آذر

5.9.1.2 The amount of outdoor air depends on the

number of occupants and on the materials and

apparatus that may give off odors within the

space. Generally, outdoor air for ventilation is

introduced at the air conditioning apparatus rather

than directly into the conditioned space, thus it

becomes a cooling coil load instead of a space

load component.

IPS-E-AR- 120(1)

ﺑﺮﺣﺴﺐ ﺗﻌﺪاد ﻧﻔﺮات و وﺳﺎﻳﻞ ﺧﺎﻧﮕﻲ ﻛــﻪ در2-1-9-5

ﻣﻘﺪار ﻫﻮاي ﺗﺎزهاي ﭘﻴﺶ،ﻓﻀﺎي داﺧﻠﻲ ﻣﻮﺟﺐ ﺑﻮ ﻣﻲﮔﺮدد

ﻫﻮاي ﺗﺎزه ﻣﻌﻤﻮﻻً ﺑﺎ ﻫﻮاي ﺑﺮﮔﺸﺘﻲ ﺑﻪ دﺳﺘﮕﺎه.ﺑﻴﻨﻲ ﻣﻲﮔﺮدد

ﻣﻮﺟﺐ ﺑﺎﻻرﻓﺘﻦ ﻇﺮﻓﻴﺖ ﻛﻮﻳﻞ ﺧﻨﻚ ﻛﻨﻨﺪه،ﻣﺨﻠﻮط ﻣﻲﮔﺮدد

.و ﺳﺮاﻧﺠﺎم ﻫﻮاي ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع ﻓﻀﺎ ﻣﻲ ﮔﺮدد

5.9.2 Infiltration

ﻧﻔﻮذ ﻫﻮا2-9-5

ﻫﻮاي ﻧﻔﻮذي از دربﻫﺎ و ﭘﻨﺠﺮهﻫﺎ ﺑﻪ ﻓﻀﺎي داﺧﻞ ﺑﺮﺣﺴﺐ

2005 ﺟﻠﺪ ﺳﺎلASHRAE ﻓﺮﻣﻮل ذﻛﺮ ﺷﺪه ﻛﻪ در ﻣﺮﺟﻊ

ﺑﻬﺮه ﮔﺮﻣﺎﻳﻲ ﻣﺮﺑﻮط ﺑﻪ ﻣﻘﺪار ﻫﻮاي ﺗﻬﻮﻳﻪ ﻳﺎ.ﻣﺤﺎﺳﺒﻪ ﻣﻲﮔﺮدد

(ﻫﻮاي ﻧﻔﻮذي ﻛﻪ ﻳﻜﻲ از اﻳﻦ دو ﻛﻪ ﺑﻴﺸﺘﺮ ﺑﺎﺷﺪ )اﻣﺎ ﻧﻪ ﻫﺮ دو

.در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﻣﻲﺷﻮد

The infiltration through doors and windows shall

be calculated per formula mentioned in ASHRAE

Fundamental 2005 Guidebook and the larger of

the heat gain for ventilation or the infiltration

quantities shall be considered, but not both.

5.10 Air Motion in Conditioned Spaces

ﺣﺮﻛﺖ ﻫﻮا در ﻓﻀﺎي ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع10-5

5.10.1 The air quantity and temperature of the

treated air and the method of introducing it to the

conditioned space shall be designed to limit to

1.6°C (3°F) or less, the simultaneous variation in

dry-bulb temperature at the same level throughout

that portion of a single room which is normally

frequented by persons.

ﻣﻘﺪار و دﻣﺎي ﻫﻮاي ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع و روش ﻫﺪاﻳﺖ1-10-5

5.10.2 In spaces normally frequented by persons

not moving about, it is recommended to avoid air

velocities exceeding 0.25 m/s (50 fpm) in the

zone between the floor and the 1.5 meter level.

ﻣﻌﻤﻮﻻً ﺗﺮدد زﻳﺎد اﻓﺮاد ﻣﻮﺟﺐ ﺣﺮﻛﺖ، در ﻓﻀﺎﻫﺎ2-10-5

5.10.3 Exceptions shall be made to the vicinity of

a supply or return grille when the construction

requires it to be located below the 1.5 meter level

and in a space normally frequented by persons.

ﻫﻨﮕﺎﻣﻲ ﻛﻪ ﻣﻮﻗﻌﻴﺖ ﺳﺎﺧﺘﻤﺎن و ﻓﻀﺎي آن ﻃﻮري3-10-5

5.10.4 Noise level, odor level and indoor air

quality shall be given due considerations in the

equipment selection.

ﺑﻮ و ﻛﻴﻔﻴﺖ ﻫﻮاي داﺧﻞ را، ﻣﻮارد ﻣﻴﺰان ﺳﺮوﺻﺪا4-10-5

آن ﺑﻪ ﻓﻀﺎي داﺧﻞ ﺑﺎﻳﺪ ﻃﻮري ﻃﺮاﺣﻲ ﺷﻮد ﻛﻪ ﺗﻐﻴﻴﺮات دﻣﺎي

( درﺟﻪ ﻓﺎرﻧﻬﺎﻳﺖ3) درﺟﻪ ﺳﺎﻧﺘﻴﮕﺮاد1/6 آن ﺣﺪاﻛﺜﺮ ﺑﻪ

ﺗﻐﻴﻴﺮ ﻫﻤﺰﻣﺎﻧﻲ دﻣﺎي ﺧﺸﻚ در ﺷﺮاﻳﻂ ﻳﻜﺴﺎن.ﻣﺤﺪود ﮔﺮدد

در ﻗﺴﻤﺘﻲ از ﻳﻚ اﺗﺎق ﻣﻌﻤﻮﻻً ﺑﻪ ﺗﻌﺪاد رﻓﺖ و آﻣﺪ اﻓﺮاد

.ﺑﺴﺘﮕﻲ دارد

ﻣﺘﺮ1/5 در ﻣﻨﻄﻘﻪ ﺑﻴﻦ ﻛﻒ و ﺗﺎ ارﺗﻔﺎع.ﺗﻘﺮﻳﺒﻲ ﻫﻮا ﻧﻤﻲﺷﻮد

ﻣﺘﺮ در ﺛﺎﻧﻴﻪ0/25 ﺗﻮﺻﻴﻪ ﻣﻲﮔﺮدد ﻛﻪ از ﺳﺮﻋﺖ ﻫﻮا ﺑﻴﺶ از

. ﻓﻮت در دﻗﻴﻘﻪ( اﺟﺘﻨﺎب ﺷﻮد50)

ﺑﺎﺷﺪ ﻛﻪ در ﻣﺠﺎورت درﻳﭽﻪﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺖ در ارﺗﻔﺎع

ﻣﺘﺮ ﻗﺮار ﮔﻴﺮﻧﺪ و ﻣﻌﻤﻮﻻً در آن ﻓﻀﺎ ﺗﺮدد ﻧﻔﺮات1/5 ﻛﻤﺘﺮ از

. اﻳﻦ ﻣﻮارد را ﺑﺎﻳﺪ ﺑﻪ ﺻﻮرت اﺳﺘﺜﻨﺎء ﻣﺪ ﻧﻈﺮ ﻗﺮار ﮔﻴﺮد،ﺑﺎﺷﺪ

.ﺑﺎﻳﺪ در ﻣﻼﺣﻈﺎت اﻧﺘﺨﺎب ﺗﺠﻬﻴﺰات ﻣﻮرد ﻧﻈﺮ ﻗﺮار ﮔﻴﺮد

5.11 Safety Provisions

ﺗﻤﻬﻴﺪات اﻳﻤﻨﻲ11-5

Comfort air conditioning systems shall be

installed in accordance to safety requirements

called for by relevant codes of OSHA* and

NFPA. The applicable code of ASHRAE 15-2007

(Safety Code Standard for Refrigeration System)

shall also apply to this Standard.

ﺳﺎﻣﺎﻧﻪﻫﺎي ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع آﺳﺎﻳﺶ ﺑﺎﻳﺪ ﺑﺮﺣﺴﺐ اﻟﺰاﻣﺎت اﻳﻤﻨﻲ

. ﺑﺎﺷﺪNFPA وOSHA* ﻣﻄﺎﺑﻖ ﺑﺎ آﻳﻴﻦﻧﺎﻣﻪﻫﺎي اﺳﺘﺎﻧﺪارد

)آﻳﻴﻦ ﻧﺎﻣﻪASHRAE 15- 2007 آﻳﻴﻦﻧﺎﻣﻪ ﻛﺎرﺑﺮدي ﻣﺮﺟﻊ

اﻳﻤﻨﻲ اﺳﺘﺎﻧﺪارد ﺳﺎﻣﺎﻧﻪ ﺗﺒﺮﻳﺪ( ﻧﻴﺰ ﺑﺎﻳﺪ در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﻪ

.ﻛﺎر رود

18

Nov. 2009 / 1388 آذر

* OSHA: Occupational Safety And Health

Administration

اداره اﻳﻤﻨﻲ و ﺳﻼﻣﺖ ﺷﻐﻠﻲ:OSHA *

5.12 Equipment Service Life

ﻋﻤﺮ ﻣﻔﻴﺪ ﺗﺠﻬﻴﺰات12-5

The selected equipment and system shall be

governed by proper maintenance requirements

such that life expectancy of the equipment meets

minimum requirements of those recommended by

ASHRAE as indicated in Attachment 8.

6.

AIR

CONDITIONING

CLASSIFICATION

IPS-E-AR- 120(1)

ﺗﺠﻬﻴﺰات و ﺳﺎﻣﺎﻧﻪ اﻧﺘﺨﺎب ﺷﺪه ﺑﺎﻳﺪ ﺑﺎ در ﻧﻈﺮ ﮔﺮﻓﺘﻦ اﻟﺰاﻣﺎت

ﺗﻐﻴﻴﺮات ﺻﺤﻴﺢ از ﻗﺒﻴﻞ ﻋﻤﺮ اﺣﺘﻤﺎﻟﻲ ﺗﺠﻬﻴﺰات ﻛﻪ ﺑﺎ ﺣﺪاﻗﻞ

ﻛﻪ در ﭘﻴﻮﺳﺖASHRAE اﻟﺰاﻣﺎت ﺗﻮﺻﻴﻪ ﺷﺪه در ﻣﺮﺟﻊ

. ﻣﻄﺎﺑﻘﺖ داﺷﺘﻪ ﺑﺎﺷﺪ، ﻧﻴﺰ ذﻛﺮ ﮔﺮدﻳﺪه8 ﺷﻤﺎره

SYSTEM

ﻃﺒﻘﻪ ﺑﻨﺪي ﺳﺎﻣﺎﻧﻪ ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع-6

ﻋﻤﻮﻣﻲ1-6

6.1 General

6.1.1 Varying air conditioning demands are met

in residential, commercial, institutional, medical

and office buildings. These demands are met

primarily through the use of one of the systems

mentioned below or through combination of these

systems, wherein classification shall be based on

type of refrigeration.

ﺗﻐﻴﻴﺮات در ﻧﻴﺎزﻫﺎي ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع ﻣﺴﺘﻠﺰم ﻫﻤﺨﻮاﻧﻲ1-1-6

6.1.2 The Coefficient Of Performance (COP)

based on recent development addresses the

performance of air conditioning equipment, and

can be determined by the following formula:

( ﺑﺎﻳﺪ ﺑﺮ اﺳﺎس ﻛﺎرآﻳﻲ آﺧﺮﻳﻦCOP) ﺿﺮﻳﺐ ﻛﺎرآﻳﻲ2-1-6

COP =

درﻣﺎﻧﻲ و دﻓﺘﺮﻫﺎي، آﻣﻮزﺷﻲ، ﺗﺠﺎري،ﺑﺎ ﺳﺎﺧﺘﻤﺎﻧﻬﺎي ﻣﺴﻜﻮﻧﻲ

ﻫﻨﮕﺎﻣﻲ ﻛﻪ ﻃﺒﻘﻪﺑﻨﺪي ﺑﺮاﺳﺎس ﻧﻮع ﺳﺎﻣﺎﻧﻪ.ﻛﺎر ﻣﻲ ﺑﺎﺷﺪ

اﻳﻦ ﻧﻴﺎزﻫﺎ ﺑﺎﻳﺪ ﻧﺨﺴﺖ ﺑﺎ ﻳﻜﻲ از ﺳﺎﻣﺎﻧﻪﻫﺎي،ﺳﺮﻣﺎﻳﺸﻲ ﺑﺎﺷﺪ

.ذﻛﺮ ﺷﺪه ذﻳﻞ ﻳﺎ ﺗﺮﻛﻴﺒﻲ از آﻧﻬﺎ ﻣﻄﺎﺑﻘﺖ داﺷﺘﻪ ﺑﺎﺷﺪ

ﺗﻐﻴﻴﺮ و ﺗﻮﺳﻌﻪ ﺗﺠﻬﻴﺰات ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع ﺑﺎﺷﺪ ﻛﻪ ﻣﻲﺗﻮان ﺑﺮ

:ﻣﺒﻨﺎي ﻓﺮﻣﻮل ذﻳﻞ ﺗﻌﻴﻴﻦ ﻧﻤﻮد

TR 12000

HP 2544Btu / HP

6.2 Packaged-Unitary System

ﺳﺎﻣﺎﻧﻪ واﺣﺪ ﻳﻜﭙﺎرﭼﻪ2-6

ﺳﺎﻣﺎﻧﻪ ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع اﻧﺒﺴﺎط ﻣﺴﺘﻘﻴﻢ1-2-6

6.2.1 Packaged direct expansion system

اﻳﻦ واﺣﺪﻫﺎي ﻳﻜﭙﺎرﭼﻪ ﺧﻮدﻛﻔﺎ ﺑﺎ اﺻﻮل ﭼﺮﺧﻪ ﺳﺮﻣﺎﻳﺸﻲ

ﭼﻪ واﺣﺪ ﻳﻜﭙﺎرﭼﻪ ﺗﻜﻲ ﺑﺮاي.اﻧﺒﺴﺎط ﻣﺴﺘﻘﻴﻢ ﻛﺎر ﻣﻲﻛﻨﻨﺪ

ﻫﺮدو ﻧﻴﺎز ﺑﻪ،ﻧﺼﺐ در ﻓﻀﺎي داﺧﻞ اﺗﺎق و ﭼﻪ ﺳﺎﻣﺎﻧﻪ دوﺗﻴﻜﻪ

اﻳﻦ واﺣﺪﻫﺎ.ﻳﻚ دﺳﺘﮕﺎه داﺧﻠﻲ و ﻳﻚ دﺳﺘﮕﺎه ﺧﺎرﺟﻲ دارﻧﺪ

ﻳﺎ ﻫﻮا را از ﻃﺮﻳﻖ درﻳﭽﻪ ﺧﺮوﺟﻲ ﻫﺪاﻳﺖ ﻣﻲﻛﻨﻨﺪ و ﻳﺎ در

. ﺑﻪ ﺟﺮﻳﺎن ﻣﻲاﻧﺪازﻧﺪ،ﻛﺎﻧﺎل ﻓﻠﺰي ﺳﺎﺧﺘﻪ ﺷﺪه

These are packaged self-contained units working

on the principles of direct expansion refrigerating

cycle, either single package for indoor mount or

split-system requiring one indoor and one outdoor

unit. These units either distribute the air through

an integrated discharge plenum or circulate the air

through fabricated sheet metal ducting or fiber

glass duct board.

Note:

:ﻳﺎدآوري

For various ARI standard classifications reference

is made to IPS-M-AR-125. For window air

conditioners or thru-the-wall room air

conditioners reference is made to IPS-M-AR-245.

Subject to the configuration of the computer

system, computer room air conditioning also falls

within this category.

ﺑـــﻪ اﺳﺘﺎﻧﺪاردARI ﺑﺮاي ﻃﺒﻘﻪﺑﻨـﺪي ﻣﺨﺘﻠﻒ اﺳﺘﺎﻧﺪارد

ﺑﺮاي ﻛﻮﻟﺮﻫﺎي ﭘﻨﺠﺮهاي ﻳﺎ. ﻣﺮاﺟﻌﻪ ﺷﻮدIPS-M-AR-125

ﺑﺎ ﺗﻮﺟﻪ. ﻣﺮاﺟﻌﻪ ﺷﻮدIPS-M-AR-245 دﻳﻮاري ﺑﻪ اﺳﺘﺎﻧﺪارد

ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع اﺗﺎق ﻛﺎﻣﭙﻴﻮﺗﺮ ﻧﻴﺰ،ﺑﻪ ﭼﻴﺪﻣﺎن ﺳﺎﻣﺎﻧﻪ ﻛﺎﻣﭙﻴﻮﺗﺮ

.در اﻳﻦ ﻃﺒﻘﻪﺑﻨﺪي ﺧﻮاﻫﺪ ﺑﻮد

19

Nov. 2009 / 1388 آذر

IPS-E-AR- 120(1)

6.2.2 Unitary system

ﺳﺎﻣﺎﻧﻪ واﺣﺪ ﻳﻜﭙﺎرﭼﻪ2-2-6

These are distribution systems where room units

may be used in the central fan system and

classified as non-refrigerant type, into three major

areas:

اﻳﻦ ﻫﺎ ﺳﺎﻣﺎﻧﻪ ﻫﺎي ﺗﻮزﻳﻌﻲ ﻫﺴﺘﻨﺪ ﻛﻪ واﺣﺪﻫﺎي اﺗﺎﻗﻲ در

ﺳﺎﻣﺎﻧﻪ ﺑﺎدزن ﻣﺮﻛﺰي ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﻣﻲ ﮔﻴﺮﻧﺪ و ﺑﻪ ﻋﻨﻮان

:ﻧﻮع ﺑﺪون ﻣﺒﺮد ﺑﻪ ﺳﻪ ﻧﺎﺣﻴﻪ اﺻﻠﻲ ذﻳﻞ ﻃﺒﻘﻪ ﺑﻨﺪي ﻣﻲ ﺷﻮﻧﺪ

a) All water and no air.

اﻟﻒ( ﺗﻤﺎم آب و ﺑﺪون ﻫﻮا

b) Part water and part air.

ب ( ﻗﺴﻤﺘﻲ آب و ﻗﺴﻤﺘﻲ ﻫﻮا

c) All air and no water.

ج ( ﺗﻤﺎم ﻫﻮا و ﺑﺪون آب

6.2.2.1 All water and no air system

ﺳﺎﻣﺎﻧﻪ ﺗﻤﺎم آب و ﺑﺪون ﻫﻮا

Commonly referred to as fan coil units located

under perimeter windows, ceiling or wall

suspended, controlled by room thermostat and/or

motorized valves. Fig. 1 illustrates this system.

1-2-2-6

ﺳﻘﻒ ﻳﺎ آوﻳﺰ،واﺣﺪﻫﺎي ﻛﻮﻳﻠﻲ ﺑﺎدزن وﻗﺘﻲ ﻛﻪ در زﻳﺮ ﭘﻨﺠﺮهﻫﺎ

ﺑﻪ وﺳﻴﻠﻪ ﺗﺮﻣﻮﺳﺘﺎت اﺗﺎﻗﻲ و ﻳﺎ،ﺑﻪ دﻳﻮار ﺑﻪ ﻛﺎر ﻣﻲروﻧﺪ

اﻳﻦ ﺳﺎﻣﺎﻧﻪ1 در ﺷﻜﻞ.ﺷﻴﺮﻫﺎي ﻣﻮﺗﻮري ﻛﻨﺘﺮل ﻣﻲﺷﻮﻧﺪ

.ﻧﺸﺎن داده ﺷﺪه اﺳﺖ

ﻛﻮﻳﻞ

ﺑﺎدزن

ﻫﻮاي اﺗﺎق

ﺻﺎﻓﻲ

Fig. 1-TYPICAL ALL-WATER NO-AIR UNITARY SYSTEM

ﻧﻤﻮﻧﻪ ﺳﺎﻣﺎﻧﻪ واﺣﺪ ﺗﻤﺎم آب و ﺑﺪون ﻫﻮا-1 ﺷﻜﻞ

6.2.2.2 Part water and part air system

ﺳﺎﻣﺎﻧﻪ ﺑﻪ ﺻﻮرت ﻗﺴﻤﺘﻲ آب و ﻗﺴﻤﺘﻲ ﻫﻮا2-2-2-6

These systems are frequently called induction

systems, because part of the air is supplied from

central fan (air handling) system which induces

room air into the unit, whether high or low

pressure. Fig. 2 illustrates this system. The water

for the heating is supplied by the boiler through

the heat exchanger, to the heating coil. (Ducting

for air can be designed by static regain in high

ﺳﺎﻣﺎﻧﻪ اﻟﻘﺎﻳﻲ ﻧﺎﻣﻴﺪه ﻣﻴﺸﻮﻧﺪ زﻳﺮا،ًاﻳﻦ ﻧﻮع ﺳﺎﻣﺎﻧﻪ ﻫﺎ ﻏﺎﻟﺒﺎ

ﺑﺨﺸﻲ از ﻫﻮا از ﺑﺎدزن ﻣﺮﻛﺰي )ﻫﻮا رﺳﺎن( ﺑﻪ ﻫﻤﺮاه ﺟﺮﻳﺎن

2 ﺷﻜﻞ.ﻫﻮاي اﺗﺎق ﺑﺎ ﻓﺸﺎر زﻳﺎد ﻳﺎ ﻛﻢ وارد دﺳﺘﮕﺎه ﻣﻲﺷﻮد

آب ﺳﺎﻣﺎﻧﻪ ﮔﺮﻣﺎﻳﺶ ﺗﻮﺳﻂ دﻳﮓ.اﻳﻦ ﺳﺎﻣﺎﻧﻪ را ﻧﺸﺎن ﻣﻲدﻫﺪ

از ﻃﺮﻳﻖ ﻣﺒﺪل ﺣﺮارﺗﻲ ﺑﻪ ﻛﻮﻳﻞ ﺣﺮارﺗﻲ وارد ﻣﻲﺷﻮد

20

آذر Nov. 2009 / 1388

)IPS-E-AR- 120(1

velocity ducts). These systems are recommended

for location under the window around the

perimeter areas of multi-story multi-room

buildings.

)ﻛﺎﻧﺎلﻫﺎي ﻫﻮا ﺑﺎ ﺳﺮﻋﺖ ﺑﺎﻻ را ﻣﻲﺗﻮان ﺑﻪ روش اﺳﺘﺎﺗﻴﻚ

رﻳﻜﻴﻦ ﻃﺮاﺣﻲ ﻧﻤﻮد( اﻳﻦ ﺳﺎﻣﺎﻧﻪ ﺑﺮاي ﻧﺼﺐ در زﻳﺮ ﭘﻨﺠﺮه و

ﭘﻴﺮاﻣﻮن ﻓﻀﺎﻫﺎي ﭼﻨﺪ ﻣﻨﻈﻮره در ﺳﺎﺧﺘﻤﺎنﻫﺎي ﭼﻨﺪ اﺗﺎﻗﻪ ﺑﻪ

ﻛﺎر ﻣﻲرود.

ﻛﻮﻳﻞ ﺣﺮارﺗﻲ

ﭘﻨﺠﺮه

air injection

nozzles

ﻫﻮاي اﺗﺎق

ﻣﻨﻔﺬﻫﺎي ﺗﺰرﻳﻖ ﻫﻮا

داﻣﭙﺮ ﺗﻴﻐﻪ ﻣﺘﻘﺎﺑﻞ

از ﺳﺎﻣﺎﻧﻪ ﺑﺎدزن ﻋﻤﻮﻣﻲ

Fig. 2-TYPICAL PART-WATER PART-AIR UNITARY SYSTEM

ﺷﻜﻞ -2ﻧﻤﻮﻧﻪ ﺳﺎﻣﺎﻧﻪ واﺣﺪ ﻗﺴﻤﺘﻲ آب و ﻗﺴﻤﺘﻲ ﻫﻮا

6.2.2.3 All-air and no-water systems

3-2-2-6ﺳﺎﻣﺎﻧﻪﻫﺎﻳﻲ ﺑﺎ ﺗﻤﺎم ﻫﻮا و ﺑﺪون آب

1-3-2-2-6اﻳﻦ ﺳﺎﻣﺎﻧﻪﻫﺎ ﻧﻤﻮﻧﻪاي از ﺳﺎﻣﺎﻧﻪ ﮔﺮﻣﻜﻦ ﻣﺠﺪد

6.2.2.3.1 These systems are a form of reheat

system, condition the air at a central location

(central fan system) and deliver the air through

ducts. The system may be low/medium pressure,

single duct or high pressure dual duct

(representing hot and cold deck).

2-3-2-2-6ﻳﻚ ﺟﻌﺒﻪ ﻣﺨﻠﻮط ﻫﻮاي ﺣﺠﻢ ﻣﺘﻐﻴﺮ ﻣﻤﻜﻦ

6.2.2.3.2 A variable air volume mixing box may

be used for maintaining room conditions through

control dampers/ valves to proportion the amount

of hot or cold air required at the mixing box. Fig.

3 illustrates the high velocity dual duct system.

ﻣﻲﺑﺎﺷﺪ ﻛﻪ ﻫﻮاي ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع دﺳﺘﮕﺎه ﻣﺮﻛﺰي )ﺳﺎﻣﺎﻧﻪ ﺑﺎدزن

ﻣﺮﻛﺰي( ﺑﻪ ﻛﺎﻧﺎلﻫﺎ ﻫﺪاﻳﺖ ﻣﻲﺷﻮد .ﺳﺎﻣﺎﻧﻪ ﻣﻤﻜﻦ اﺳﺖ ﺑﺎ

ﻓﺸﺎر ﭘﺎﻳﻴﻦ ﻳﺎ ﻣﺘﻮﺳﻂ ،ﺗﻚ ﻛﺎﻧﺎﻟﻪ ﻳﺎ دوﻛﺎﻧﺎﻟﻪ ﺑﺎ ﻓﺸﺎر ﺑﺎﻻ ﺑﺎﺷﺪ

)ﻧﻤﺎﻳﺎﻧﮕﺮ ﻗﺴﻤﺖ ﮔﺮم و ﺳﺮد(.

اﺳﺖ ﺑﺮاي ﺣﻔﻆ ﺷﺮاﻳﻂ اﺗﺎق ﺗﻮﺳﻂ دﻣﭙﺮﻫﺎ ﻳﺎ ﺷﻴﺮﻫﺎي ﻛﻨﺘﺮل

ﺑﻪ ﻣﻴﺰان ﻣﺘﻨﺎﺳﺐ از ﻫﻮاي ﻣﻮرد ﻧﻴﺎز ﮔﺮم ﻳﺎ ﺳﺮد در ﺟﻌﺒﻪ

ﻣﺨﻠﻮط ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﮔﻴﺮد .ﺷﻜﻞ 3ﺳﺎﻣﺎﻧﻪ دو ﻛﺎﻧﺎﻟﻪ ﻫﻮا

ﺑﺎ ﺳﺮﻋﺖ ﺑﺎﻻ را ﻧﺸﺎن ﻣﻲ دﻫﺪ.

21

Nov. 2009 / 1388 آذر

ﺻﺎﻓﻲ ﻫﻮا

ﻫﻮاي ﺑﺮﮔﺸﺘﻲR.A

ص

IPS-E-AR- 120(1)

ﮔﺮﻣﮕﻦ ﻫﻮا

preheat coil

ﻛﻮﻳﻞ ﭘﻴﺶ ﮔﺮﻣﻜﻦ

ﻫﻮاي ﮔﺮم

ﺑﺎدزن

ﻫﻮاي ﺧﺎرجO.A

To Other units

ﻫﻮاي ﺧﻨﻚ

Cool air

ﺑﻪ واﺣﺪﻫﺎي دﻳﮕﺮ

رﻃﻮﺑﺖ زنhumidifier

ﺧﻨﻚ ﻛﻦ ﻫﻮا

MB

M.B = Mixing Box

ﺟﻌﺒﻪ ﻣﺨﻠﻮط ﻛﻦ ﻫﻮا

Fig. 3-TYPICAL ALL-AIR NO-WATER UNITARY SYSTEM

ﻧﻤﻮﻧﻪ ﺳﺎﻣﺎﻧﻪ واﺣﺪ ﺗﻤﺎم ﻫﻮا و ﺑﺪون آب-3 ﺷﻜﻞ

6.3 Heat Pump System

ﺳﺎﻣﺎﻧﻪ ﭘﻤﭗ ﺣﺮارﺗﻲ3-6

6.3.1 General

ﻋﻤﻮﻣﻲ1-3-6

6.3.1.1 A heat pump is a refrigeration cycle-either

reciprocating or centrifugal-in which the cooling

effect as well as the heat rejected is used to

furnish cooling or heating to the air conditioning

units either simultaneously or separately.

ﭘﻤﭗ ﺣﺮارﺗﻲ ﻳﻚ ﭼﺮﺧﻪ ﺗﺒﺮﻳﺪي اﺳﺖ ﺑﻪ ﺻﻮرت1-1-3-6

رﻓﺖ و ﺑﺮﮔﺸﺘﻲ ﻳﺎ ﮔﺮﻳﺰ از ﻣﺮﻛﺰ ﻛﻪ اﺛﺮ ﺳﺮﻣﺎﻳﺸﻲ ﺑﻪ ﺧﻮﺑﻲ

ﺣﺮارت دﻓﻊ ﺷﺪه ﺑﺮاي ﺗﺄﻣﻴﻦ ﺳﺮﻣﺎﻳﺶ ﻳﺎ ﮔﺮﻣﺎﻳﺶ در دﺳﺘﮕﺎه

.ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع ﺑﻪ ﺻﻮرت ﻫﻤﺰﻣﺎن ﻳﺎ ﺟﺪاﮔﺎﻧﻪ ﺑﻪ ﻛﺎر ﻣﻲرود

6.3.1.2 Any thermodynamic cycle that is capable

of producing a cooling effect may theoretically be

used as heat pump.

ﻫﺮ ﭼﺮﺧﻪ ﺗﺮﻣﻮدﻳﻨﺎﻣﻴﻜﻲ ﻛﻪ ﻗﺎدر ﺑﻪ ﺗﻮﻟﻴﺪ2-1-3-6

ﻣﻤﻜﻦ اﺳﺖ ﺑﻪ ﻃﻮر ﻧﻈﺮي ﺑﻪ ﻋﻨﻮان ﭘﻤﭗ،ﺳﺮﻣﺎﻳﺶ ﺑﺎﺷﺪ

.ﺣﺮارﺗﻲ ﺑﻪ ﻛﺎر رود

6.3.2 Advantages

ﻣﺰاﻳﺎ2-3-6

The heat pump system operation has the

advantages of:

:ﺳﺎﻣﺎﻧﻪ ﻋﻤﻠﻜﺮد ﭘﻤﭗ ﺣﺮارﺗﻲ داراي ﻣﺰاﻳﺎي ذﻳﻞ ﻣﻲﺑﺎﺷﺪ

،اﻟﻒ( در درﺟﻪ اول ﻣﻘﺮون ﺑﻪ ﺻﺮﻓﻪ ﺑﻮدن

a) Over all first cost saving,

،ب( ﺻﺮﻓﻪ ﺟﻮﻳﻲ در ﻓﻀﺎ

b) Space saving,

،ج( ﻛﻢ دردﺳﺮ ﺑﻮدن

c) Nuisance elimination,

22

Nov. 2009 / 1388 آذر

IPS-E-AR- 120(1)

، د ( واﺑﺴﺘﻪ ﺑﻪ ﻳﻚ ﻣﻨﺒﻊ اﻧﺮژي

d) Single energy source,

،ﻫ( اﻳﻤﻨﻲ ﺑﺎﻻ

e) Increased safety,

.و ( ﻛﺎﻫﺶ ﻧﺮخ ﺑﻴﻤﻪ آﺗﺶ ﺳﻮزي

f) Fire insurance rate reduction.

6.3.3 Heat pump types

اﻧﻮاع ﭘﻤﭗ ﺣﺮارﺗﻲ3-3-6

Heat pumps for air conditioning service are

further classified by:

ﭘﻤﭗﻫﺎي ﺣﺮارﺗﻲ از ﻧﻈﺮ ﺧﺪﻣﺎت ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع ﺑﻪ ﺷﺮح ذﻳﻞ

:ﻃﺒﻘﻪﺑﻨﺪي ﻣﻲﺷﻮﻧﺪ

a) Type of heat source and sink.

.اﻟﻒ( ﻧﻮع ﻣﻨﺒﻊ ﺣﺮارﺗﻲ و اﺳﺘﻬﻼك آن

b) Heating and cooling distribution fluid.

.ب( ﺗﻮزﻳﻊ ﺳﻴﺎل ﮔﺮﻣﺎﻳﺸﻲ و ﺳﺮﻣﺎﻳﺸﻲ

.ج( ﻧﻮع ﭼﺮﺧﻪ ﺗﺮﻣﻮدﻳﻨﺎﻣﻴﻜﻲ

c) Type of thermodynamic cycle.

.د( ﻧﻮع ﺳﺎزه ﺳﺎﺧﺘﻤﺎن

d) Type of building structure.

.ﻫ( ﺗﺮﻛﻴﺐ و اﻧﺪازه

e) Size and configuration.

f) Limitation of the source and the sink.

.و ( ﻣﺤﺪودﻳﺖ ﻣﻨﺒﻊ و اﺳﺘﻬﻼك

6.3.4 Unitary heat pumps

ﭘﻤﭗﻫﺎي ﺣﺮارﺗﻲ ﻳﻜﭙﺎرﭼﻪ4-3-6

The two basic types of unitary heat pumps are:

:دو ﻧﻮع ﭘﻤﭗ ﺣﺮارﺗﻲ ﻳﻜﭙﺎرﭼﻪ ﺑﻪ ﺷﺮح ذﻳﻞ ﻣﻲﺑﺎﺷﺪ

اﻳﻦ ﺗﺠﻬﻴﺰات ﺷﺎﻣﻞ اﺟﺰاء ﭼﺮﺧﻪ ﻣﺒﺮدي:اﻟﻒ( ﻫﻮا ﺑﻪ ﻫﻮا

a) Air-to-air: this equipment consists of

factory matched refrigerant cycle components

which are applied in the field to fulfill

requirements of the user. These can be either

in pre-assembled unit or as a split system.

ﻛﻪ در ﻛﺎرﺧﺎﻧﻪ ﺟﻔﺖ و ﺟﻮر ﺷﺪه و ﺑﺮاي ﺗﺄﻣﻴﻦ ﻧﻴﺎزﻫﺎي

و اﻳﻦ ﻣﻤﻜﻦ اﺳﺖ ﺑﻪ،ﻣﺘﻘﺎﺿﻲ در ﻣﺤﻞ ﺑﻪ ﻛﺎر ﻣﻲرود

ﺻﻮرت دﺳﺘﮕﺎﻫﻲ ﻛﻪ در ﻣﺤﻞ ﻣﻮﻧﺘﺎژ ﻣﻲﺷﻮد و ﻳﺎ ﺑﻪ

.ﺻﻮرت ﺳﺎﻣﺎﻧﻪ دوﺗﻴﻜﻪ ﺑﺎﺷﺪ

آب ﺑﻪ ﻋﻨﻮان، در اﻳﻦ ﻧﻮع ﺳﺎﻣﺎﻧﻪ ﮔﺮﻣﺎﻳﺸﻲ:ب( آب ﺑﻪ ﻫﻮا

b) Water-to-air: These use water as the heat

source when in the heating mode and as the

heat sink when in the cooling mode. The water

supply may be closed water loop, a lake or a

well (ground source).

7. METHODS OF

DISTRIBUTION

FLUID

AND

ﻣﻨﺒﻊ ﺣﺮارﺗﻲ ﺑﻪ ﻛﺎر ﻣﻲرود و در ﺳﺎﻣﺎﻧﻪ ﺳﺮﻣﺎﻳﺸﻲ ﺑﻪ

آب ﺗﻐﺬﻳﻪ.ﺻﻮرت دﻓﻊ ﺣﺮارت ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﻣﻲﮔﻴﺮد

ﻳﻚ درﻳﺎﭼﻪ و ﻳﺎ ﭼﺎه،ﻣﻤﻜﻦ اﺳﺖ ﺑﻪ ﺻﻮرت ﻣﺪار ﺑﺴﺘﻪ

.)ﻣﻨﺒﻊ زﻣﻴﻨﻲ( ﺑﺎﺷﺪ

AIR

روشﻫﺎي ﺗﻮزﻳﻊ ﺳﻴﺎل و ﻫﻮا-7

روشﻫﺎي ﺗﻮزﻳﻊ ﻋﺎﻣﻞ ﺳﻴﺎل1-7

7.1 Methods of Distributing Fluid Media

7.1.1 General

ﻋﻤﻮﻣﻲ1-1-7

7.1.1.1 In an air conditioning system, each coil,

washer or heat exchanger is an arrangement of

piping that will convey the cooling or heating

fluid in an effective manner to the refrigeration

machine.

ﺷﺴﺘﺸﻮ، ﻫﺮ ﻛﻮﻳﻞ، در ﻳﻚ ﺳﺎﻣﺎﻧﻪ ﺗﻬﻮﻳﻪ ﻣﻄﺒﻮع1-1-1-7

ﻛﻨﻨﺪه ﻳﺎ ﻣﺒﺪل ﺣﺮارﺗﻲ ﺗﺮﻛﻴﺒﻲ از ﻟﻮﻟﻪﻛﺸﻲ اﺳﺖ ﻛﻪ ﺳﻴﺎل

ﺳﺮﻣﺎﻳﺸﻲ ﻳﺎ ﮔﺮﻣﺎﻳﺸﻲ را در دﺳﺘﮕﺎه ﺑــﻪ روش ﻣﻮﺛﺮ اﻧﺘﻘﺎل

.ﻣﻲدﻫﺪ

23

Nov. 2009 / 1388 آذر

7.1.1.2 When water is used, this arrangement

shall be used with black carbon steel or

galvanized pipes in the form of supply and return

water piping along with the necessary pump to

circulate the water through the piping and other

equipment.

IPS-E-AR- 120(1)

ﺑﺮاي ﺳﻴﺎل آب ﺑﺎﻳﺪ از ﻟﻮﻟﻪﻫﺎي ﻓﻮﻻدي ﺳﻴﺎه ﻳﺎ2-1-1-7

ﺑﺮاي ﺑــﻪ ﺟﺮﻳﺎن اﻧﺪاﺧﺘﻦ آب در.ﮔﺎﻟﻮاﻧﻴﺰه اﺳﺘﻔــﺎده ﮔﺮدد

ﻟﻮﻟﻪﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺖ و ﺗﺠﻬﻴﺰات دﻳﮕﺮ ﺑﺎﻳﺪ از ﭘﻤﭗ اﺳﺘﻔﺎده

.ﺷﻮد

7.1.2 Pipe sizing

ﺗﻌﻴﻴﻦ ﻗﻄﺮ ﻟﻮﻟﻪ2-1-7

7.1.2.1 General

ﻋﻤﻮﻣﻲ

Pressure drop caused by Newtonian fluids often

presented in head or specific energy form is

described by the following Darcey-Weisbach

equation:

1-2-1-7

اﻓﺖ ﻓﺸﺎر در ﺳﻴﺎل ﻧﻴﻮﺗﻨﻲ اﻏﻠﺐ ﺑﺮﺣﺴﺐ ﻓﺸﺎر ﻳﺎ ﺷﻜﻠﻲ از

اﻧﺮژي ﻣﺨﺼﻮص ﻣﻲﺑﺎﺷﺪ ﻛﻪ ﺑﻮﺳﻴﻠﻪ ﻣﻌﺎدﻟﻪ دارﺳﻲ وﻳﺴﺒﺎخ

:ذﻳﻞ ﺗﻌﺮﻳﻒ ﻣﻲﺷﻮد

h f

L v2

D 2g

Where:

:ﺟﺎﻳﻲ ﻛﻪ

h = head loss, ft

= اﻓﺖ ﻓﺸﺎر ﺑﺮﺣﺴﺐ ﻓﻮتh

f = friction factor, dimensionless

ﺑﺪون ﺑﻌﺪ،= ﻋﺎﻣﻞ اﺻﻄﻜﺎكf

ﺑﺮﺣﺴﺐ ﻓﻮت،= ﻃﻮلL

L = length, ft

= ﻗﻄﺮ داﺧﻠﻲ ﺑﺮﺣﺴﺐ ﻓﻮتD

D = Internal diameter, ft

= ﻣﻴﺎﻧﮕﻴﻦ ﺳﺮﻋﺖ ﺑﺮ ﺣﺴﺐ ﻓﻮت ﺑﺮﺛﺎﻧﻴﻪV

V = average velocity, ft/s

= ﺷﺘﺎب ﺛﻘﻞ ﺑﺮﺣﺴﺐ ﻓﻮت ﺑﺮ ﻣﺠﺬور در ﺛﺎﻧﻴﻪg

g = acceleration due to gravity, ft/s2

Note:

:ﻳﺎدآوري

For further information, reference is made to

ASHRAE 2005 Fundamentals, Chapter 33,

35&36.

در ﺟﻠﺪASHRAE 2005 ﺑﺮاي اﻃﻼﻋﺎت ﺑﻴﺸﺘﺮ ﺑﻪ ﻣﺮﺟﻊ

. ﻣﺮاﺟﻌﻪ ﺷﻮد36 و35 ،33 ﻓﺼﻞ،اﺻﻮل

7.1.2.2 Sizing cold water pipes (open system)

( ﺗﻌﻴﻴﻦ ﻗﻄﺮ ﻟﻮﻟﻪﻫﺎي آب ﺳﺮد )ﺳﺎﻣﺎﻧﻪ ﺑﺎز2-2-1-7

1) Sketch the main lines, risers, and branches,

and identify the fixtures to be served.

. اﻧﺸﻌﺎﺑﺎت و ﻟﻮازم ﺛﺎﺑﺖ، راﻳﺰرﻫﺎ،( ﻛﺮوﻛﻲ ﻟﻮﻟﻪﻫﺎي اﺻﻠﻲ1

2) Compute the demand weight of the fixtures.

.( وزن ﻟﻮازم ﻣﻮرد اﺳﺘﻔﺎده ﻣﺤﺎﺳﺒﻪ ﮔﺮدد2

3) Determine the total demand in fixture units,

and find the expected demand in L/s.

( ﺗﻌﻴﻴﻦ ﻛﻞ ﻣﻘﺪار ﺗﻘﺎﺿﺎ ﺑﺮﺣﺴﺐ واﺣﺪ ﻣﺼﺮف و3

ﻣﺸﺨﺺ ﺷﺪن ﻣﻘﺪار ﺗﻘﺎﺿﺎي ﻣﻮرد ﻧﻈﺮ ﺑﺮﺣﺴﺐ ﻟﻴﺘﺮ ﺑﺮ

.ﺛﺎﻧﻴﻪ

4) Determine the equivalent length of pipe in

the main lines, risers, and branches.

راﻳﺰرﻫﺎ و،( ﺗﻌﻴﻴﻦ ﻃﻮل ﻣﻌﺎدل ﻟﻮﻟﻪ در ﻟﻮﻟﻪﻛﺸﻲ4

.اﻧﺸﻌﺎﺑﺎت

5) Determine the average minimum pressure

in the street main and minimum pressure

required for the operation of the top most

fixture. This should be between 55 k Pa (8 psi)

to 172 k Pa (25 psi).

( ﺗﻌﻴﻴﻦ ﻣﻴﺎﻧﮕﻴﻦ ﺣﺪاﻗﻞ ﻓﺸﺎر ﻣﻮرد ﻧﻴﺎز در ﻟﻮﻟﻪ اﺻﻠﻲ و5

55 ﺣﺪاﻗﻞ ﻓﺸﺎر ﻣﻮرد ﻧﻴﺎز در ﺑﺎﻻﺗﺮﻳﻦ ﻣﺼﺮف ﻛﻨﻨﺪه ﺑﻴﻦ