Non-meat ingredients 8. Sweeteners a. sucrose (cane sugar)

advertisement

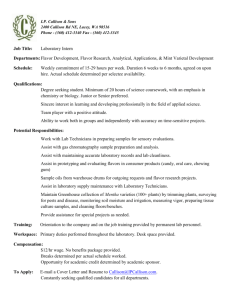

Non-meat ingredients 8. Sweeteners – primarily for flavor but may have other functions also a. sucrose (cane sugar) – 100 on sweetness scale – permitted at levels “sufficient for purpose” – generally used at ~ 1 - 2% – moderates saltiness flavor – may contribute to microbial spoilage – glucose + fructose --- with reducing groups utilized in linkage therefore this is a non-reducing sugar b. dextrose (corn sugar) – 70 on sweetness scale – permitted at “sufficient for purpose” – reducing sugar – free aldehyde/ketone group – will reduce metals – reacts with amino groups on proteins to give browning during heating – useful for grill products – undesirable for bacon – may be helpful for fresh sausage color – common carbohydrate used for fermented sausage to form lactic acid bacterial dextrose lactic acid starter culture ~ 100 degrees F – final product pH is determined by amount of dextrose used dextrose pH 6 oz./100lbs 5.2 8 oz. 4.9 16 oz. 4.6 24 oz. 4.4 – higher levels will begin to give sweetness because fermentation is stopped by pH i.e. Lebanon Bologna c. corn syrup/corn syrup solids – mixture of carbohydrates resulting from corn starch processing/hydrolysis – variable in sweetness therefore limited to 2% – also variable in reducing sugar content and D. E. (dextrose equivalent) is used to indicate reducing sugar content --- most are D.E. 20 - D.E. 70 – contribute significant water binding – retain moisture, improve yields, improve casing peelability for frankfurters d. sorbitol – 50 sweetness scale – natural organic alcohol compound found in berries and plants – will not brown – permitted at 2% only in cooked sausage franks and bologna --- and only if corn syrups and/or corn syrup solids are not used – most common use may be roller-grill franks and sausage products—to prevent excessive browning on the grill e. fructose - 150 on sweetness scale – high fructose corn syrup may be used if: – DE = 93 or more, – fructose is 40% or more of the solids and, sweetness is = sucrose f. Stevia sweeteners - 400X as sweet as sucrose, 0 calories -Rebaudioside A is a compound derived from Stevia rebaudiana and responsible for stevia’s sweet taste. -Approved by FDA on Dec. 17, 2008 as GRAS, available as TRUVIA Non-Meat Ingredients Flavor modifiers / potentiators a. monosodium glutamate (MSG) – intensifies taste, has no flavor itself, sensitizes taste buds – considered to be “umami” – taste (not flavor) – meat-like component which is the 5th basic component that humans taste (sweet, sour, saltiness, bitterness, umami), developed by Ajinomoto (now also promoting “kokumi” taste (“richness) as another basic taste component). – permitted - “sufficient for purpose” – most often used at 6 -8 oz/100 lbs (0.5%) – frequently believed to be the source of “Chinese Restaurant Syndrome” – warm, tingling feeling, flushed face, etc. – no scientific evidence b. nucleotides – 5' nucleotides – very potent flavor “potentiators” – effective at parts per billion levels – disodium 5' inosinate commercial forms disodium 5' guanylate – permitted at “sufficient for purpose” – usual use at 1-2 oz/100 lbs – highly effective/synergistic with salt (NaCl) c. hydrolized proteins – whey, yeast, plant proteins – partially hydrolized proteins contribute meaty flavors – valuable as water binders at the same time Non-meat ingredients 10. Starter cultures – strong flavor contributors with lactic acid “tanginess”, “tartness”, “sourness” – but also produce hydrolized fats, hydrolized proteins and metabolic products like diacetyl, acetoin, etc. which are flavor compounds – must have slow release of acid --- otherwise proteins become quickly denatured and the product will be mushy and/or crumbly – permitted use is 0.5% - most is water added to disperse the starter culture Traditional fermentations 1. add salt, hold for several days – allow inherent lactic organisms to predominate --then ferment problem…. this “wild” population sometimes included heterofermentative lactics – produce lactic acid and carbon dioxide – causing gas pockets and blow-ups – what is necessary is homofermentative organisms – produce only lactic acid (no gas) 2. “back slopping” – using a small amount of meat from successful batches (before fermentation) to mix with fresh meat – serves to inoculate the fresh batch with homofermetative organisms However, the most dependable fermentations come from starter cultures – concentrated frozen or freeze dried preparation of bacterial cells – pure culture of one or sometimes a few selected organisms – typically in U.S. Lactobacillus plantarum Pediococcus cerevesiae – Europeans sometimes use Streptococcus as does dairy industry – starters sometimes include Micrococcus (Kocuria), Staphyloccoccus strains (non-pathogenic) – does not produce lactic acid but are nitrate reducers Starter is critical because: – fermentation is typically done at 90 - 100oF and 95 - 99% relative humidity – maximizes bacterial growth and can be dangerous – Staphylococcus aureus is salt-tolerant, probably present and produces a serious toxin Staph is controlled by the lactic acid – must have fast enough decline in pH to prevent Staph growth – degree-hours requirement – must reach pH 5.3 in less than 1200 degree-hours if less than 90oF, 1000 degree-hours if between 90 - 100oF and 900 degree-hours if over 100oF – degree-hours is time at temperatures above 60oF – some fermentations are done at 75 - 80oF (European-style) and may take several days --- believed to result in a more “complete” flavor Chemical acidulation – alternative to “biological” acidulation from microorganisms – lactic, citric acids encapsulated to be released slowly as the product is heated – glucono delta lactone slowly forms gluconic acid in meat to simulate fermentation Other considerations for fermented sausage 1. meat materials – must be of good microbial quality and low TBA number – a high level of free amines/contaminant bacteria may result in histamines during fermentation histidine histamine tyrosine tyramine – must also be free of excessive connective tissue especially for drying because collagen will become tough and hard – Trichinae-free “certified pork” 2. fermentation – correct temperature for culture – adequate dextrose – salt concentration – over 3% will slow the starters growth – degree-hours requirement for Staph – 3. smoking / cooking / drying – process must achieve equivalent of 5-log reduction of E. coli O157:H7 and heat is most commonly used to complete the requirement Non-meat ingredients 11. Mold inhibitors – dry sausage easily develops mold – can be controlled by very careful drying – dry fast enough to keep the surface too dry for mold but slow enough to prevent case handling on the outside – some dry sausage is characterized by a solid white mold cover – compounds which inhibit mold a. propyl parabens – may use 3.5% solution to spray or dip casings b. potassium sorbate – 10% solutions for spray or dip – also quite effective inhibitor of bacteria i.e. Clostridium botulinum Non-meat ingredients 12. Spices – defined as “aromatic vegetative substances used for seasoning food” – dried plant products – “true” spices --- plants of tropical origin – generally - “herbs” --- dried leaves (mint, sage) and “vegetables” (onion, garlic) are considered separately – no limits on use --- except mustard at 1% Because spices are plant products: – they are variable in intensity due to seasons and environment – are perishable – spice flavor depends on volatile compounds which are lost in time, at warm temperatures and if exposed to light – should not be kept longer than ~ 2 months and should be refrigerated – are highly contaminated with bacteria – can be a serious spoilage cause – pepper is frequently a bacterial problem – most spices are treated to reduce bacteria – ethylene oxide – irradiation Functions of spices in processed meats 1. flavor 2. color ex. paprika - pepperoni 3. antioxidants ex. rosemary 4. affect bacterial growth – some are inhibitors – some can stimulate bacterial growth 5. significant protein source ex. mustard flour - common at 1% in franks and bologna 6. product identity ex. Italian sausage must include anise or fennel, pepperoni - paprika for color and pork sausage - typically pepper and sage Spices may be used as – natural spices – whole – cracked – ground – size is important to appearance and to flavor “release” – small particles give faster quick flavor release – designate size by “mesh” = square holes per linear inch (screen) (50 mesh = 50 holes per inch) ex. 26/50 mesh pepper 95% of particles pass through a 26 screen and are retained on a 50 screen – other terms for size by different spice suppliers – frequent problem with natural spices is contaminating materials – i.e. sand, stems, hulls, etc. --- need to be addressed in purchasing specifications Spices are also available as “soluble” spices or spice extracts – most important quality is flavor – due to essential oils – volatile flavor compounds – true flavor – may be steam distilled, collected, condensed and used for flavor – 100 - 200 x more concentrated than natural spice – also can extract spices with solvent (ethylene dichloride), evaporate the solvent and use the extract = oleoresins – less concentrated than essential oils but still 50 - 100 x that of natural spice – can be used in dry form plated onto salt, sugar or dextrose but this is more susceptible to oxidation and loss of flavor – labeled “flavorings” rather than spices Advantages of essential oils and oleoresins – easily dispersed – consistent flavor – no bacterial contamination --- but --– appearance (flicks of pepper/sage) and color may be different