ENERGY BALANCE AND SYSTEMS

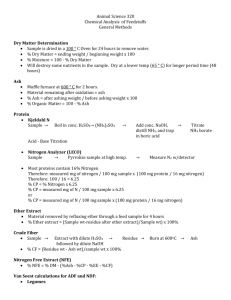

advertisement

ENERGY BALANCE AND SYSTEMS References • Blaxter, K. L. 1989. Energy Metabolism in Animals and Man. Cambidge University Press • Kleiber, M. 1975. The Fire of Life. Krieger Publishing, New York Also Beef, Dairy, and Sheep NRC Basics of Energy Use in Mammals • Simple • Practical – Energy systems to predict and monitor livestock production – The common thread among human weight loss systems ENERGY CONCEPTS • Energy - “ability to do work” • Feedstuffs – protein – carbohydrates – lipids • Physics of energy – Priestly 1700’s - the flame and the mouse Priestly and the discovery of oxygen A candle or an animal can make good air bad. Plants restore to the air whatever breathing animals and burning candles remove. Early discoveries of relevance • Theory of combustion - Both fire and animals produce the same amount of heat per unit of CO2 • Heat production /unit of O2 produced is a more uniform measurement • 1st law of thermodynamics - energy cannot be created or destroyed Hess’ Law of Heat Summation 1. Not concerned with mechanisms or rates of energy change 2. True for living as well as non-living systems 3. Forms basis for bioenergetic investigation even if mechanisms of action is unknown FECES FEED ANIMAL URINE 100% OF GAS HEAT MAINTENANCE PRODUCTION ENERGY INTAKE ATP-ADP CYCLE FUELS O2 CO2 H2O CATABOLISM ADP ATP Pi MECHANICAL WORK Pi TRANSPORT WORK Pi BIOSYNTHETIC WORK Units of Measure • Calorie - energy required to raise the temperature of 1 g of water 1 degree C (from 16.5 to 17.5) – – – – 1 kilocalorie (kcal) = 1,000 calories 1megacalorie (Mcal) = 1,000,000 calories 1kcal/g = 1 Mcal/kg 1 calorie = 4.184 joules Bomb Calorimeter PARTITIONING OF ENERGY Gross Energy (GE) Digestion loss (fecal) Digestible Energy (DE) Urine loss Combustible gases (CH4) Metabolizable Energy (ME) Heat increment (HI) -heat of fermentation -heat of nutrient metabolism Net Energy (NE) NEm -basal metabolism -activity at maintenance -sustaining body temp NEg -retained energy HEAT LOSS •BASAL METABOLISM •VOLUNTARY ACTIVITY •PRODUCT FORMATION •THERMAL REGULATION •WORK OF DIGESTION •HEAT OF FERMENTATION •WASTE FORMATION AND EXCRETION BASAL METABOLISM •VITAL CELLULAR ACTIVITY •RESPIRATION •BLOOD CIRCULATION •IONIC BALANCE •TURNOVER OF PROTEINS RETAINED ENERGY •TISSUE GROWTH •LACTATION •WOOL GROWTH •HAIR GROWTH •PREGNANCY SYNTHESIS OF BODY TISSUES •FAT contains 9.4 Mcal/kg and 3.8 Mcal/kg is lost as heat •13.2 Mcal are required to deposit 1 kg fat •PROTEIN contains 5.6 Mcal/kg (muscle=1.1 Mcal/kg) •7.4 Mcal are lost as heat (1.5 Mcal for muscle) •13 Mcal are required to deposit 1 kg of protein •2.6 Mcal are required to deposit 1 kg of muscle GROSS ENERGY •FEED GE (kcal/g) •Corn meal 4.4 •Oats 4.6 •Wheat bran 4.5 •Timothy hay 4.5 •Clover hay 4.5 •Corn stover 4.3 •Oat straw 4.4 GROSS ENERGY OF FEEDSTUFF COMPONENTS •CARBOHYDRATE 4.2 kcal/g •FAT 9.4 kcal/g •PROTEIN 5.6 kcal/g •ASH 0.0 kcal/g BACON TORCH Calorimetry • DIRECT - direct measurement of heat production • INDIRECT - calculation of heat production from O2 intake, CO2 release and methane and nitrogen losses – HE = 3.886 02 +1.2 CO2 -.518 CH4-1.231N Nitrogen Carbon Balance (Indirect) • Required data: dry matter, nitrogen, carbon and energy of feed, feces, urine, methane and carbon dioxide. • Assumed: – 6 g protein/g N – .5254 g carbon/g. protein – 5.6 kcal/g protein N-C balance cont’ • Carbon gained as fat = Foodc – (Fecesc + Urinec + CO2c + Methanec + Proteinc) • Fat assumptions: – 1.307 g fat/ g carbon – 9.4 kcal/g fat • Heat productionkcal = Intakekcal - (Feceskcal + Urinekcal + Methanekcal +Protein gainedkcal + Fat gainedkcal) Body Size and Metabolism Kleiber Armsby Calorimeter Determination of Nem of timothy hay by a difference trial Feeding Feed level eaten (lb) 1 6.2 ME intake Heat prod. Energy (kcal) (kcal) gain (kcal) 5788 8062 -2296 2 10.2 9544 9812 -268 Diff. 4.0 3766 1748 2028 Armsby (1922) NEm = 2028/4 = 51 Mcal/cwt Of historical importance: 1. H = ME - P 2. Development of comparitive slaughter technique Lofgreen and Garrett (1968) NEm DETERMINATION Item Alfalfa Hay High Concentrate Intake at Equilibrium Heat Prod. an No Feed NEm of the Feed (kcal/g) 35 43 1.23 23 43 1.87 NEp BY THE "DIFFERENCE TRIAL" ENERGY GAIN NEp + 0 FEED INCREASE ACTUAL "DIFFERENCE TRIAL" ON HIGH CONC. RATION Item Feed Intake Energy Gain Level of Feeding Equilibrium Free Choice 23 59 0 40 Differences: Feed Intake, g Energy Gain, kcal --- 36 40 NEp of Feed: kcal per gram -- 1.11 Comparison of Fed and Fasted Steers by Indirect calorimetry (“head box”) Fed Fasted 339 333 Oxygen 197.2 131.0 Carbon dioxide 198.8 96.1 Methane 8.2 1.0 RQ 1.01 0.73 kJ/d per kg BW 147.3 93.7 jJ/d per kg BW0.75 632.6 400.8 Weight (kg) Gas exchange (1/2 h): Heat Production Eisemann and Nienaber (Brit. J. of Nutr. 64:399, 1990) DIGESTIBLE ENERGY (DE) •TOTAL DIGESTIBLE NUTRIENTS (TDN) •1 lb TDN = 2,000 kcal DE •TDN = DCP + DNFE + DCF + 2.25(DEE) •Estimated from ADF •from truly digestible NFC, NDF, CP and FA •Dairy NRC • (http://www.nap.edu/books/0309069971/html/) •pp. 13-27 CONVERSION BETWEEN DE, ME & NE •ME = .82DE •NEm = 1.37 ME - 0.138 ME2 + 0.0105 ME3 -1.12 •NEg = 1.42 ME - 0.174 ME2 + 0.0122 ME3 -1.65 EFFECT OF ENVIRONMENT ON ENERGY REQUIREMENTS Lower Critical Temperature Cold stress Upper Critical Temperature THERMONEUTRAL ZONE Heat Stress Optimum for Performance and Health Low EFFECTIVE AMBIENT TEMPERATURE High Lower Critical Temperature •Coat Description LCT •Summer or wet 59 •Fall 45 •Winter 32 •Heavy winter 18 Effective Temperature Wind Speed Calm 5 15 30 -10 -10 -16 -25 -46 Temperature 0 10 0 10 -6 3 -15 -5 -36 -26 20 20 13 4 -16 30 30 23 14 -6 *Maintenance Requirements increase .7% for each degree of cold stress. NEp (production) •NEg (gain) •NEc (conceptus) •NEl (lactation) Beef NRC Gain equations •NEm (Mcal) = .077 WTkg.75 *(environmental adjustment) •EBW = .891 SBW •EBG = .956 SWG •SRW = 478 kg for animals finishing at small marbling •EQSBW = SBW * (SRW)/(FSBW) •EQEBW = .891 EQSBW •RE = 0.0635 EQEBW0.75 EBG1.097 •SWG = 13.91 RE 0.9116 EQSBW-.6837 Using Net Energy for Gain Projection Step 1. Determine dry matter intake of each ingredient Lb. as fed Corn silage Corn SBM 15 7 1.5 Total 23.5 X DM fraction .4 .85 .9 = Lb DM 6.0 5.95 1.35 13.3 Using Net Energy for Gain Projection Step 2. Determine NEm intake Lb. DM Corn silage Corn SBM 6 5.95 1.35 Total 13.3 X NEm/lb .4 1.02 .93 = NEm (Mcal) 4.44 6.07 1.26 11.77 Ration NEm (DM Basis) = 11.77Mcal/13.3 lb DM = .89 Mcal/lb Using Net Energy for Gain Projection Step 3. Determine NEg intake Lb. DM Corn silage Corn SBM 6 5.95 1.35 Total 13.3 X NEg/lb ..47 .70 .63 = NEg (Mcal) 2.82 4.17 .85 7.84 Ration NEg (DM Basis) = 7.84Mcal/13.3 lb DM = .59 Mcal/lb Using Net Energy for Gain Projection Step 4. Determine Lb of DM for maintenance 1. NEm requirement 500 lb. steer = 4.5 Mcal 4.5 Mcal * environmental adjustment (1.3) = 5.85 Mcal required / .89 Mcal NEm per lb of DM = 6.6 lb. of feed dry matter needed for maintenance Environmental adjustment (maintenance ratio) for calf fed in open lot conditions in November in Iowa. Using Net Energy for Gain Projection Step 5. Determine energy available for gain 1. 13.3 lb DM intake - 6.6 lb (needed for maintenance) = 6.7 lb. of feed DM available for gain. 2. 6.7 lbs of DM X .59 Mcal/lb (NEg) = 3.95 Mcal available for gain. Using Net Energy for Gain Projection • Step 6 - Determine weight gain – – – – 227 kg steer (low choice at 500 kg) EQSBW = 227 * (478/500) = 217 kg SWG = 13.91 * 3.95 0.9116 * 217 -.6837 = 1.23 kg/d ADG = 1.23*2.205 = 2.71 lb/day Energy Calculations for Dairy Cattle •NEm = .08 LW.75 - increased for activity •Growing bulls & heifers have 12% higher req than beef •NEm = .086 LW.75 •or use beef equations and increase Maint 7-10% •NEl~NEm because of similar efficiency •Lactation requirement (Mcal/kg) milk •= .0969(percent fat in milk)+.36 •Feed Energy Values discounted for level of feeding •For a comparison of Dairy Energy Systems see: J Dairy Sci 81:830, 840, 846 (1998) Energy Symposium Unit decline per multiple of Maint Dairy NRC Feed Energy Discounts 4.5 4 3.5 3 2.5 2 1.5 1 0.5 0 = .18 X -10.3 60 65 70 Maintenance TDN 75 80 Energy calculations for Sheep •Maintenance requirement is lower than beef •.056 W.75 •Wool has great insulative value •Fetal number is important (Nep, Mcal/day) #fetuses 1 2 3 Stage of gestation (days) 100 120 140 .070 .145 .260 .125 .265 .440 .170 .345 .570 1996/2001 Beef NRC Model Objectives: • Predict net energy requirements across a continuum of cattle types • Adjust requirements for physiological state • Adjust requirements for environmental conditions • Predict variable lactation requirements • Predict energy reserves fluxes • Describe feeds by fermentation characteristics • Describe rumen and animal tissue N requirements • Compute variable ME and MP from feed analysis • Two levels of solution Maintenance Requirements Factors affecting Maintenance • • • • • Weight Physiological State Acclimatization Sex Breed • Activity • Heat or Cold stress – External Insulation • Coat Condition • Wind speed • Hide Thickness – Internal Insulation • Condition Score • Age Base NEm Requirement • 77 kcal / (BWkg)0.75 • Adjusted for: – – – – Acclimatization Sex Breed Physiological state • Lactation • Condition Score Effect of Condition Score on Maintenance Requirement Maintenance Multiplier 120% 115% 110% 105% 100% 95% 90% 85% 80% 1 2 3 4 5 6 7 Condition Score (1-9 scale) 8 9 Energy Requirements vs. Body Weight NEm Required, Mcal/d 12.00 10.00 8.00 6.00 4.00 2.00 0.00 0 200 400 Body Weight 600 800 NEm Required, Mcal/BW0.75 Energy Requirements vs. Previous Temp. 110 100 90 80 70 60 50 -20 -10 0 10 20 Previous Temperature, 30 O C 40 Effect of Breed on Energy Requirements Relative NEm Required 120% 120% 100% 100% 90% 80% 60% 40% 20% 0% Bos indicus Bos taurus Dairy breeds Effect of Lactation on Energy Requirements 120% Relative NEm Required, % of Basal 120% 100% 100% 80% 60% 40% 20% 0% Nonlactating Lactating Maintenance Adjustment for Grazing (based on a 600 kg cow) 160% Mainenance Adjustment 150% 140% Level Hilly 130% 120% 110% 100% 0.25 0.75 1.25 Forage Availability (T/ha) 1.75 Estimation of Heat Production and Calculation of Lower Critical Temp (LCT) • Calculate Feed for Maintenance (FFM) – NEm Req./ NEm Diet = FFM • Calculate Feed for Production (FFP) – DMI - FFM = FFP • Calculate Net Energy of Production (NEP Tot) – NEP Diet x FFP = NEP Tot – For growing & finishing; NEP Diet = NEg Diet – For other animals; NEP Diet = NEm Diet • Calculate Heat Production (HP) – MEIntake - NEP Tot = HP, Mcal Body Surface Area vs. Body Weight 8.00 Surface Area, M 2 7.00 6.00 5.00 4.00 3.00 2.00 1.00 0.00 0 200 400 Body Weight 600 800 Internal Insulation, Mcal/M 2/OC/d 14 Effect of Condition Score on Internal Insulation 12 Age, d 10 <30 30-183 184-364 >365 8 6 4 2 0 1 2 3 4 5 6 7 8 Condition Score (1-9 scale) 9 Effect of Wind Speed and Coat Condition on External Insulation External Insulation, Mcal/M 2/OC/d 25 20 15 10 5 0 0 5 10 15 20 25 Wind Speed, kph Clean & Dry mud on lower body and sides some mud on lower body heavily covered with mud 30 Effect of Wind Speed and Hide Thickness on External Insulation External Insulation, Mcal/M 2/OC/d 35 30 25 20 15 10 5 0 0 5 10 15 20 25 Wind Speed, kph Thin Hide Medium Hide Thick Hide 30 External Insulation, Mcal/M 2/OC/d Effect of Wind Speed and Hair Depth on External Insulation 50 45 40 35 30 25 20 15 10 5 0 0 5 10 15 20 Wind Speed, kph 1 cm 2 cm 3 cm 25 30 Estimation of Heat Production and Calculation of Lower Critical Temp (LCT) Calculate Heat Loss (HL) – HL = HP / SA, Mcal/M2 Calculate Total Insulation (TI) – TI = EI + II, Mcal/M2/OC/d Calculate Lower Critical Temp (LCT) – LCT = 39 - (HL x TI), OC Calculate Heat Production – MEIntake - NEP Tot = Heat Production Additional ME Required, Mcal/d Energy Requirements vs. Current Temp. 7 6 5 Assumed SA = 6 M2 4 and TI = 28 Mcal/M2/OC/d 3 LCT = 5 LCT = -5 2 1 0 -30 -20 -10 0 10 Current Temperature, 20 O C 30 40 Environmental Effects on Maintenance Requirements Beef Cow Wintering Ration (hay @ .90 mcal ME/lb DM) Hair Coat Code at 30oF 1 3 Hide Code 1 2 3 Hair Coat Code at 10oF 1 3 Wind @ 1 mph 1.19 1.19 1.19 1.19 1.19 1.19 1.29 1.29 1.29 1.68 1.55 1.45 Wind @ 10 mph 1 2 3 1.22 1.19 1.19 1.48 1.41 1.34 1.60 1.47 1.36 1.94 1.84 1.75 Environmental Effects on Maintenance Requirements Typical Calf Wintering Ration ( .35 mcal NEg/lb DM) Hair Coat Code at 30oF 1 3 Hide Code 1 2 3 Hair Coat Code at 10oF 1 3 Wind @ 1 mph 1.19 1.19 1.19 1.47 1.37 1.28 1.50 1.36 1.29 2.93 1.80 1.69 Wind @ 10 mph 1 2 3 1.41 1.30 1.21 1.69 1.61 1.54 1.85 1.71 1.60 2.20 2.10 2.01 Environmental Effects on Maintenance Requirements Typical Finishing Ration ( .62 mcal NEg/lb DM) Hair Coat Code at 30oF 1 3 Hide Code 1 2 3 Hair Coat Code at 10oF 1 3 Wind @ 1 mph 1.19 1.19 1.19 1.19 1.19 1.19 1.33 1.29 1.29 1.76 1.63 1.51 Wind @ 10 mph 1 2 3 1.24 1.19 1.19 1.52 1.44 1.36 1.67 1.54 1.42 2.03 1.93 1.83 Growth Requirements Factors we must account for to predict NEg required in North America • Genotype - over 80 types have been identified • Sex – – – – Feedlot steers, heifers & bulls Replacement heifers Bulls Cows • Implant combinations • Feeding systems Relationship between Body Fat & Grade Marbling % Body Score Fat USDA Grade Trace Slight Small Standard Select Choice 25.2% 26.8% 27.8% Canadian Grade A1 A2 A3 NEg Required for Growth 8 0.6 kg/d 1.0 kg/d 1.3 kg/d 7 NEg Mcal/d 6 5 4 3 2 1 0 200 250 300 350 400 Shrunk Body Weight, kg 450 500 % Protein in Gain vs. Rate of Gain 25 0.6 kg/d 1.0 kg/d 1.3 kg/d % Protein in Gain 20 15 10 5 0 200 250 300 350 400 Shrunk Body Weight, kg 450 500 % Fat in Gain vs. Rate of Gain 90 0.6 kg/d 1.0 kg/d 1.3 kg/d 80 % Fat in Gain 70 60 50 40 30 20 10 0 200 250 300 350 400 Shrunk Body Weight, kg 450 500 Shrunk Body Fat 30 28 % Shrunk Body Fat 26 24 22 20 18 16 14 12 10 200 250 300 350 400 Shrunk Body Weight, kg 450 500 Body Fat vs. Shrunk Body Weight Slight Small Traces 30 28 26 % Body Fat 24 22 20 18 16 14 12 10 200 250 300 350 Shrunk Body Weight 400 450 500 Birth to Maturity - Protein Composition 20 120 %PIG EBP,kg 100 % Protein in Gain 16 14 80 12 10 60 8 40 6 4 20 2 0 0 200 400 600 Shrunk Body Weight, kg 800 0 1000 Empty Body Protein, kg 18 Birth to Maturity - Fat Composition 100 700 90 80 500 % Fat in Gain 70 60 400 50 300 40 30 200 20 100 10 0 0 200 400 600 Shrunk Body Weight, kg 800 0 1000 Empty Body Fat, kg 600 %FIG EBF,kg Non-implanted cattle of Fortin et. al., 1980 (50 heifers, 37 steers and 54 bulls) 1 2 3 4 6 15% 1 2 3 4 5 6 = = = = = = Angus heifer Holstein heifer Angus steers Holstein steers Angus bulls Holstein bulls 5% Empty body fat, % 25% 5 100 300 500 700 900 Empty body weight, kg Calculation of Equivalent Weight Actual BW x (SRW / FW) = EQSW Calculation of Retained Energy RE = 0.0635 x EBW0.75 x EBG1.097 RE = 0.0635 x EQEBW0.75 x EBG1.097 Calculation of Daily Gain SWG = 13.91 x RE0.9116 x SBW-0.6837 SWG = 13.91 x RE0.9116 x EQSBW-0.6837