ANIMAL-RELATED ENVIRONMENTAL ISSUES THAT MAY BE CONTROLLED BY ANIMAL MANAGEMENT Nitrogen

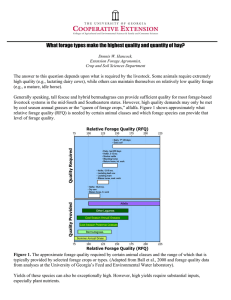

advertisement

ANIMAL-RELATED ENVIRONMENTAL ISSUES THAT MAY BE CONTROLLED BY ANIMAL MANAGEMENT • • • • • • Nitrogen Phosphorus Odors Greenhouse gases Sediment Species diversity TOOLS TO MANAGE ANIMALRELATED ENVIRONMENTAL ISSUES • Nutritional management • Managed grazing CONTROLLING NITROGEN EXCRETION BY OPTIMIZING PROTEIN METABOLISM Monogastrics • Increase protein digestibility • Lower crude protein intake • Dietary balance – Protein:energy ratio – Balance of essential amino acids • • • • • • • • • • Phenyalanine Valine Tryptophan Threonine Isoleucine Methionine Histidine Arginine Leucine Lysine CONTROLLING NITROGEN EXCRETION BY OPTIMIZING PROTEIN METABOLISM Ruminants Protein Escape NPN Protein Metabolizable Protein Degraded NH3 A B S O R B E D Microbial protein Converted to urea in liver Excreted • Increase protein digestibility • Decrease N intake • Decrease protein degradability • Diet balance – Carbohydrate energy – Sulfur – Phosphorus MANAGING NITROGEN EXCRETION BY DAIRY COWS 100 cow herd Crude protein, % 21.3 17.1 17.1 Soybean meal Soybean meal Heat-treated soybean meal Milk production, lb/day 89.8 83.1 88.9 Feed cost, $/cow 3.88 3.62 3.64 Urinary 25,487 17,914 16,366 Fecal 17,597 17,740 17,721 Total 43,085 35,654 34,087 Protein supplement N excretion, lb/yr CONTROLLING PHOSPHORUS EXCRETION BY OPTIMIZING NUTRITION • Lower P intake – Phase feeding • Feed phytase to monogastrics – 50% of the phosphorus in most feeds is bound to phytic acid • Feed low phytate corn and soybeans to monogastrics • Dietary balance – Ca:P ratio – Vitamin D metabolites MANAGING PHOSPHORUS EXCRETION BY DAIRY COWS 100 cow herd P concentration, % .45 .39 .36 Milk production, lb/cow 89.8 90.3 90.6 $/cow 3.88 3.85 3.83 118 108 102 Fecal 4,540 3,565 2,992 Total 4,658 3,673 3,094 +10 -1 -7 Excreted, lb/yr Urinary P balance, g/day GREENHOUSE GASES • Carbon dioxide • Methane (CH4) – 21 x the greenhouse effects of CO2 • Nitrous oxide – 310 x the greenhouse effects of CO2 SOURCE STRENGTHS OF GHG EMISSIONS FROM DIFFERENT BEEF AND DAIRY OPERATIONS U.S. Beef cowfeedlot CA Dairy Wis Dairy NZ Grazingbased Dairy kg carbon dioxide equivalent/kg product Enteric methane 5.5 .36 .41 .60 Manure methane .14 .21 .03 .04 Nitrous oxide 8.1 .37 .42 .76 Carbon dioxide 1.8 .33 .57 .22 Total GHG 15.5 1.26 1.38 1.62 WHY IS METHANE PRODUCED? Carbohydrates CH4 H+ Propionate Microbial energy Acetate Other electron acceptors (Unsaturated fattu acids) CONTROLLING METHANE PRODUCTION BY RUMINANTS THROUGH DIET MANAGEMENT • Increase the proportion of grain and decrease the proportion of forage in the diet – Must have a minimum of 50% forage in dairy diets and 10% in feedlot diets • Grind forage • Feed ionophores – Monensin – Lasalocid – Salinomycin • Feed unsaturated fatty acids – Maximum 5% of diet dry matter EFFECTS OF GRAZING ON ENVIRONMENTAL QUALITY • Well-managed grazing – Optimize forage productivity and nutritional quality – Maximize forage species diversity – Improve efficiency of forage utilization – Maintains forage cover on streambanks – Minimize soil erosion – Minimize P loading of streams – Minimize soil compaction and trailing – Maximize manure nutrient distribution • Poorly managed grazing – Reduced forage productivity and quality – Minimize forage species diversity – Weed infestation – Loss of streambank cover – Stream widening and loss of aquatic habitat – Increased soil erosion – Increased P loading of streams – Increased soil compaction – Increased cow paths – Poor manure distribution KEY TO SUSTAINABILITY OF GRAZING LANDS • Managing vegetative cover through – – – – Feed for grazing livestock Hold soil into place Filter water Recycle nutrients EFFECTS OF FORAGE CANOPY HEIGHT ON GROUND COVER, INFILTRATION RATE, AND EROSION RATE AFTER TREADING AT THREE RATES ON A NEW ZEALAND HILL COUNTRY PASTURE 100 Bare ground, % Infiltration rate, l/sq m/hr Sediment loss, g/sq m/hr 80 60 40 20 0 0 1 2 Canopy height, inches 3 COMPONENTS OF GOOD GRAZING MANAGEMENT • Appropriate stocking rate – Neither too low or high – Flexible management to maintain forage quality • Adjust stocking rate • Hay harvest • Appropriate rest periods – Based on forage growth rate • 15 days early summer • 35 days in mid-summer • Appropriate design – Number of paddocks • 8 – 12 for rest • 24 – 36 for grazing efficiency – Square paddocks – Water in each paddock CALCULATING THE LENGTH OF OCCUPANCY FOR PADDOCKS • Estimate forage yield • Estimate total forage in 5 ac paddock • Estimate available forage in paddock • Estimate forage intake by fifty 1250 lb cow-calf pairs • Calculate days/paddock • Calculate total paddocks • Calculate total acres • 15 cm x 110 lb/ac/cm = 1650 lb/ac • 1650 lb/ac x 10 ac = 16,500 lb • 16,500 lb x 50% = 8250 lb • 50 x 1250 x 3.5% BW = 2188 lb/day • 8250 lb/pad / 2188 lb/day = 3.8 days • 35 days rest/3.8 days + 1 = 10.2 paddocks • 10.2 paddocks x 10 ac/pad = 100 ac Total forage mass, lb/acre FORAGE AVAILABILITY THROUGHOUT THE YEAR 3000 2000 1000 0 Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Months Cool season grass Legumes Warm season grass Stockpiled gr-leg (Hay equiv.) Corn stalks (Hay equiv.) ARRANGEMENT OF TREATMENTS (June, 2002) MEASUREMENT OF SEDIMENT AND PHOSPHORUS LOSSES Rainfall simulations • Frequency – June, August, October, and April • Locations – 3 in 2 slope classes within each paddock – 3 in each buffer strip at paddock base – 3 in each buffer strip 30 ft from paddock base • Rainfall rate – 2.8 inches/hour • Duration – 1.5 hours EFFECTS OF FORAGE TREATMENTS ON ANNUAL SEDIMENT FLOW (Year 1) 7 0 6 0 5 0 4 0 U n g r a z e d b H a y / s t o c k p i l e b 2 " C o n t i n u o u s 2 " R o t a t i o n a l b 4 " R o t a t i o n a l b 3 0 Sedimntao,lb/ac. 2 0 a 1 0 0 G r a z i n g t r e a t m e n t EFFECTS OF FORAGE TREATMENTS ON ANNUAL TOTAL AND SOLUBLE PHOSPHORUS FLOW (Year 1) 0 . 3 5 0 . 3 0 b b c 0 . 2 5 b b b b U n g r a z e d H a y / s t o c k p i l e 2 " C o n t i n u o u s 2 " R o t a t i o n a l 4 " R o t a t i o n a l lb/ac 0 . 2 0 c 0 . 1 5 0 . 1 0 a 0 . 0 5 a 0 . 0 0 T o t a l P S o l u b l e P