McDer_OSmaps_1310 1

9/26/13 4:40 PM

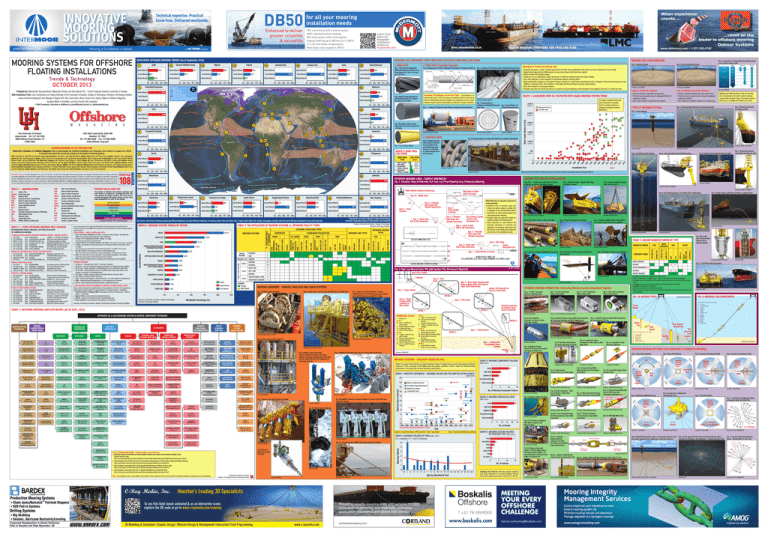

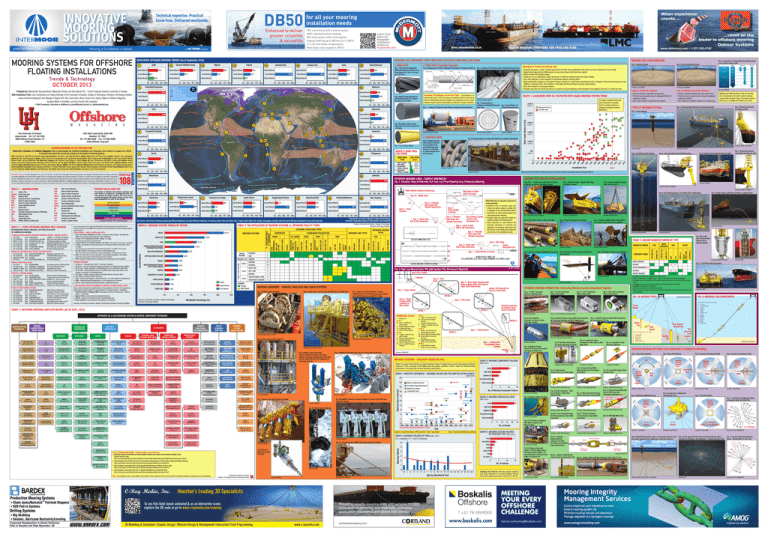

WORLDWIDE OFFSHORE MOORING TRENDS (As of September 2013)

DESIGN & OPERATIONAL ISSUES

1 OTC 24214

2013 SEVAN MARINE

2 OTC 23814-MS 2012 HEIDEMAN / BLUEWATER

3 OMAE2011-49855 2011 SOFEC/DELFT UNIVERSITY

4 IDOTS D-09-004 2009 RESEARH & DEV./SOFEC

Op Experience with Cylindrical FPSO

Arctic Turret Mooring System

Squall Mooring Design

Mooring in Harsh Environments

CONNECTORS

25% 50% 75% 100%

100%

Ghana/Ivory Coast

Spread Moored

48%

Spread Moored

Turret Moored

48%

Turret Moored

20%

Spread Moored

80%

Tendon Moored

Tendon Moored 4%

Cameroon to Congo

11

South Africa

13

66%

Egypt/Libya/Tunisia

15

Spread Moored

50%

Spread Moored

50%

Turret Moored

Turret Moored

17%

Turret Moored

Tendon Moored

17%

Tendon Moored

Qatar/Iran/UAE

17

17%

83%

Tendon Moored

19

Thailand/Myanmar

Spread Moored

50%

Spread Moored

Turret Moored

50%

Turret Moored

Tendon Moored

25% 50% 75% 100%

100%

Turret Moored

25% 50% 75% 100%

0%

25% 50% 75% 100%

25% 50% 75% 100%

0%

0%

GRAPH 1: MOORING SYSTEM TRENDS BY REGION

25% 50% 75% 100%

AUSTRALIA/NEW ZEALAND

SPREAD

MOORING

6.8%

MEDITERRANEAN/CASPIAN/

EGYPT/LIBYA/TUNISIA

5.0%

NIGERIA

5.0%

CAMEROON TO CONGO

4.1%

OTHER AFRICA

1.8%

OTHER AMERICAS

1.8%

OTHER ASIA

1.6%

Tedons

TURRET

CALM

SALM

TAUT

EXTERNAL

D/P

FIXED YOKE

D

SOFT YOKE

D

HAWSER

D

TUBULAR RISER & YOKE

D

CHAIN RISER & HAWSER

D

15%

20%

STEEL PIPE

COMBINED LINE

POLYSTER FIBER

WIREROPE

CHAIN

1B

FIBER ROPES

STEEL WIRES

ANCHORS &

SUCTION PILES

CHAINS

FAIRLEADS, CHAIN

STOPPERS, CHAIN JACKS

WINCHES

CONNECTORS,

SHACKLES, CHASERS

Fig. 2: Chain Jacks: Pusnes Roller RamWinches on Perdido Spar

Fig. 4: Chain Jack on Kikeh Spar Hull

AKER SOLUTIONS

akersolutions.com

ABS

eagle.org

BRIDON

bridon.com

AMOG CONSULTING

Amogconsulting.com

API

API.ORG

CORTLAND COMPANY

cortlandcompany.com

ARCELOMITTAL

Arcelormittal.com/

wiresolutions

COORDINATED

COMPANIES

ceccwrr.com

BRUCE ANCHOR

bruceanchor.co.uk

AMCLYDE

rokrem.com

BARDEX Corporation

bardex.com

BRUCE ANCHOR

bruceanchor.co.uk

CRP

crpgroup.com

BMT SCIENTIFIC

MARINE SERVICES

Scimar.com

LONDON MARINE

CONSULTANTS

londonmarine.co.uk

BOSKALIS OFFSHORE

boskalis.com/offshore

BUREAU VERITAS

Veritas.com

CSL ROPES

cslropes.com.br

BRIDON

INTERNATIONAL LTD

bridonltd.com

DAI HAN ANCHOR CHAIN

MFG. CO., LTD.

dhac.co.kr

CANYON OFFSHORE

helixesg.com

APPLETON MARINE, INC.

Appletonmarine.com

BROHL

Broehl.de

DELMAR SYSTEMS

delmarus.com

DCL MOORING & RIGGING

dcl-usa.com

FUGRO GEOS

Geos.com/

offshore-systems/

nov.com/Production/Floating_

Production_Solutions.aspx

CORTLAND COMPANY

cortlandcompany.com

DNV

DNV.ORG

DSR CORP

dsrcorp.com

BROOKFIELDWIRE

brookfieldwire.com

DCL MOORING & RIGGING

dcl-usa.com

CORTLAND COMPANY

cortlandcompany.com

BODEWES

bodewes.com

NOV

nov.com

FEUERSTEIN GMBH

feubo.com

DELMAR SYSTEMS

delmarus.com

INTERMOOR/PULSE

STRUCTURAL MONITORING

InterMoor.com

ORWELL OFFSHORE

orwelloffshore.com

HEEREMA MARINE

CONTRACTORS (HMC)

hmc.heerema.com

DEEPSEA GROUP LTD.

Deepseaeng.com

LLOYD’S REGISTER

LR.ORG

InterMoor

InterMoor.com

DCL MOORING & RIGGING

dcl-usa.com

DSR CORP

dsrcorp.com

DCL MOORING & RIGGING

dcl-usa.com

BROHL

Broehl.de

ROLLSROYCE

Rolls-royce.com

FIRST SUBSEA

firstsubsea.com

InterMoor

intermoor.com

MEASUREMENT

TECHNOLOGY NW

mtnw-usa.com.com

SBM

sbmoffshore.com

InterMoor

intermoor.com

DELMAR SYSTEMS

delmarus.com

SBM OFFSHORE

sbmoffshore.com

LANKHORST EURO NETE

lankhorsteuronete.com

InterMoor

InterMoor.com

HAMANAKA CHAIN MFG.

CO. LTD.

hamanaka-chain.co.jp

DELMAR SYSTEMS

delmarus.com

OIL STATES SKAGIT

SMATCO

Oilstates.com

SMITHBERGER

smithberger.com

FLINTSTONE TECHNOLOGY

flint-tech.com/subsea.html

NESSCO

Nessco.rig.net

SIGMA OFFSHORE

Sigmaoffshore.com

JUMBO OFFSHORE

Jumbo-offshore.nl

HOUSTON OFFSHORE

ENGINEERING

Houston-offshore.com

InterMoor

InterMoor.com

SIGMA OFFSHORE

SIGMAOFFSHORE.COM

SOFEC

sofec.com

TECHNIP

technip.com

OTS

otsas.no

KISWIRE LTD

kiswire.com

PARKER SCANROPE AS

scanrope.no

SAMSON

samsonrope.com

Aker Pusnes AS

akersolutions.com

AKER SOLUTIONS

akersolutions.com

BALLTEC

Balltec.com

BALMORAL

balmoral-offshore.com

ASTRO TECHNOLOGY

astrotechnology.com

BLUEWATER

bluewater.com

BOSKALIS OFFSHORE

boskalis.com/offshore

DELMAR SYSTEMS

delmarus.com

InterMoor

InterMoor.com

NOV

nov.com

JIANGSU ASIAN STAR

ANCHOR CHAIN CO. LTD

anchor-chain.com

MENCK

menck.com

PARKER HANNIFIN

CORPORATION

parker.com

KETTENFABRIK MESTER

GMBH

mesterkette.com

SOTRA ANCHOR &

CHAIN

SOTRA.NET

ROLLSROYCE

Rolls-royce.com

SPT OFFSHORE

sptoffshore.com

TIMBERLAND

EQUIPMENT

Timberland-group.com

VIKING SEA TECH AS

vikingseatech.com

MOORLINK

moorlink.com

KBR (GRANHERNE

SUBSIDIARY)

KBR.com

VIKING SEA TECH AS

vikingseatech.com

TEUFELBERGER

teufelberger.com/en

REDAELLI TECNA S.P.A.

redaelli.com

LAIWU STEEL ZIBO

ANCHOR CHAIN CO., LTD.

lgchains.com

LOC NORGE AS

LOC-GROUP.COM

VRYHOF

ENGINEERING Ltd.

Vryhof.com

TRION Co., Ltd

trioncorp.co.kr

SCANROPE

scanropemarine.com

MARIT

marit.fr

LONDON MARINE

CONSULTANTS

LONDONMARINE.CO.UK

InterMoor

intermoor.com

RAPP MARINE

Rappmarine.com

TIMBERLAND EQUIPMENT

Timberland-group.com

FRANKLIN OFFSHORE

INTERNATIONAL

franklin.com.sg

TRELLEBORG MARINE

SYSTEMS

Trelleborg.com/marine

NOV (FORMERLY APL)

SOFEC

sofec.com

STRAINSTALL

Strainstall.no

TRELLEBORG MARINE

SYSTEMS

Trelleborg.com/marine

GREENPIN

greenpin.com

Fig. 3: Chain Jacks Aker Solutions - Pusnes

RamWinches™ on the Devil’s Tower spar platform

in the Gulf of Mexico at a depth of 1,720m.

WFS SUBSEA

wfs-tech.com

SBM OFFSHORE

sbmoffshore.com

GUNNEBO JOHNSON CORP

gunnebojohnson.com

MOORLINK

moorlink.com

2HOFFSHORE

2hoffshore.com

SOUTHGATE MARINE &

OFFSHORE SERVICES LTD.

Southgatemarine.com

InterMoor

intermoor.com

OIL STATES

Oilstates.com

UNIROPE

unirope.com

WHITEHILL

MANUFACTURING

whitehillmfg.com

MCS KENNY

mcskenny.com

MOORING SYSTEM

SOLUTIONS PTY LTD.

(MOORSURE)

Moorsure.com.au

TOKYO WIRE ROPE

tokyorope.co.jp

USHA MARTIN

ushamartin.com

WASHINGTON CHAIN

& SUPPLY

wachain.com

OFFSPRING

INTERNATIONAL (OIL)

offspringinternational.com

RAMNAS BRUK AB

ramnas.com

VRYHOF ANCHORS B.V.

vryhof.com

Courtesy: Aker Solutions Pusnes

Fig. 5: Bardex Linear Chain Jack.

Chain is Mechanically Held at All Times.

Latches can not be released while under load.

Used for SPAR, FPSO, and TLP Mooring and

Tensioning Systems.

Seg. 4 - Short Chain Segment with

Rope to Chain (R2C) and Chain to

Rope (C2R) Connections

10

9

7

Fig. 6: BARDEX’s Moveable Chain Jack on LLOG’s Opti-EX Semi-FPS

SANMAR CHAIN

INTERNATIONAL PTE LTD.

sci-chain.com

LHR MARINE/FEURSTEIN

lhrmarine.com

15

13

SOTRA ANCHOR & CHAIN

Sotra.net

KOHLSWA GJUTERI AB

kohlswagjuteri.se

DETAIL 3

7250m x 107 mm R4 Chain

7A150 Ton Green Pin Super

Shackle

8 Polyester Mambo Shackle

91,350m x 1,000 MT Poly with

Thimbles

DETAIL 4

3 30.5m x 107 mm R4 Chain

4 Subsea Mambo Shackle

5A Delmar Subsea Connector (Male)

5BDelmar Subsea Connector

(Female)

6 Subsea Mambo Shackle

7 250m x 107 mm R4 Chain

DETAIL 5

2 Subsea Mambo Shackle

3 30.5m x 107 mm R4 Chain

MILLER LIFTING

millerproducts.net

Courtesy: BARDEX

Fig. 7: Bardex’s BarLatch Fairlead & Stopper

Fig. 10: BARDEX’s BarLatch Fairlead Stoppers On Total’s CLOV FPSO Hull

Fairlead & Stopper

Fig. 9: Fairlead Above Waterline

7

WASHINGTON CHAIN

& SUPPLY

wachain.com

ZHENGMAO GROUP CO. LTD.

Zszhongnan.com

E. Canada

FPSO

W. Africa

CALM

N. Sea FPSO

N. Sea

FPSO

Catastrophic Failure

W. Africa FPSO

12

N. Sea

FPSO

N. Sea Semi

10

S.E. Asia CALM

W. Africa FPSO

N. Sea FPSO

W. Africa FPSO

N. Sea FPSO

N. Sea FPSO

N. Sea STL Buoy

N. Sea FPSO

N. Sea FPSO

N. Sea FPSO

W. Africa FPSO

E. Canada FPSO

W. Africa FPSO

S.E. Asia CALM

N. Sea FPSO

GOM Spar

GOM Spar

W. Africa

W. Africa

W. Africa

W. Africa

FPSO

W. Africa CALM W. Africa FPSO N. Sea FPSO

FPSO

GOM Spar

FPSO

FPSO

N. Sea FPSO

W. Africa FPSO

W. Africa FPSO

Fig. 8: Bardex’s

BarLatch Fairlead

& Stopper

2. Lloyd’s Register Group Limited (LR): List 9a list of Approved Manufacturers of Chain Cable for Ships and Offshore Mooring

https://www.cdlive.lr.org/information/Documents/Approvals/ApprovedManufactures/list9a.pdf

Courtesy: NOV

4. Lloyd’s Register Group Limited (LR): List 11 Approved Manufacturers of Steel Wire Rope

https://www.cdlive.lr.org/information/Documents/Approvals/ApprovedManufactures/list11.pdf

Note 1: T he companies shown on this supplier matrix represent those companies that are service providers, component providers or manufacturers of the components.

C-Ray Media, Inc.

CHAIN

Graph 1 Courtesy: ExxonMobil Study on Mooring

Courtesy: BARDEX

3

0

0

1

2

3

2

2

1

4

Courtesy: Aker Solutions

5

2

1

6

POLYESTER ROPE

1

YOKE COLUMN

1

7

8

9

1

· Rig Skidding

· Seismic, Hurricane Restraints/Leveling

Corporate Headquarters in Goleta California,

Also in Houston and High Wycombe, UK

Bardex_OSmaps_1301 1

www.BARDEX.com

12/10/12 5:13 PM

3D Modeling & Animation | Graphic Design | Website Design & Development | Interactive Flash Programming

CRay_OSmaps_1310 1

www.c-raymedia.com

9/16/13 11:39 AM

cortlandcompany.com

CorCom_OSmaps_1310 1

19

17

20

20

15

13

11

20

20

07

09

20

05

03

20

20

Courtesy: NOV

9/30/13 9:54 AM

Fig. 10: LankoFirst’s Snap

Connector for Fiber Rope to Fiber

Rope (R2R)

Fig. 9: Flintstone Technology’s

FTL Subsea Mooring Connector

FIG. 3: MOORING LINE COMPONENTS

Drop Anchor/

6.

Torpedo Pile

Drag

Anchor

Fig. 11: LankoFirst’s Clam

Connector (Opened)

1.

2.

3.

4.

5.

6.

clump weight

driven pile

drag anchor

suction pile

torpedo pile

vertical load anchor

5

Courtesy: First Subsea

Fig. 13: Closed Socket (Male

End) with Shackle, Wire Rope to

Chain (R2C)

15

10

Courtesy: LeBeon Manufacturing

Fig. 15: Ballgrab Stab-In On Buoy

Fig. 16: Sister Connector – Fiber

Rope Thimble to Fiber Rope

Thimble (R2R)

Fig. 18: H Link With Padeye Chain

to Chain (C2C)

Courtesy: LeBeon Manufacturing

Fig. 17: Open Socket &Y-Link Connectors, Wire Rope to Chain (R2C)

Fig. 14: Closed Socket (Male End)

Link for Wire Rope End,

Technology Indicated in Red

22

Anode

14

Handling Padeye

4

POLYESTER ROPE

1

YOKE COLUMN

1

Courtesy: First Subsea

0

5

10

15

20

25

No. of Breaks

Courtesy: LeBeon Manufacturing

Courtesy: LeBeon Manufacturing

Courtesy: LeBeon Manufacturing

Fig. 20: Y-Link Connection Open

Wire Rope Socket to Chain (R2C)

Connection

Fig. 21: Thimble & Shackle

for Fiber Rope to Chain (R2C)

Connection

Fig. 22: ROV Operable H-Link

Fig. 19: First Subsea’s Ballgrab

SMC Male Connector with

Mooring Chain

3

2

SEMI

1

SEMI FPS

1

FSO

1

Courtesy: First Subsea

10 11 12 13 14 15 16 17 18 19 20

5

10

11.

8.

10.

12.

13.

15.

14.

Courtesy: Vryhof Anchor

Pipeline/

Flowline

Cooridor

(Typ.)

Fig. 2: Semi-FPS Mooring

Fig. 3: External Turret Moored FPSO

Pipeline/

Flowline

Cooridor

(Typ.)

Semi-FPS

Hull

Spar

Hull

4x3

Pattern

Pipeline/

Flowline

Cooridor

(Typ.)

FPSO

FPSO

3x4

Pattern

Courtesy: C-Ray Media

Courtesy: C-Ray Media

Fig. 5: Drilling Rig (MODU) Mooring

Fig. 6: Perspective of MODU Hull

and Mooring Lines

Fig. 7: TLP with Tendons

Pipeline/

Flowline

Cooridor

(Typ.)

Fig. 24 – Delmar’s

Subsea Mooring

Connector for Chain,

Wire Rope, and Polyester

Rope Combinations

Courtesy: LeBeon Manufacturing

Chain

Fig. 23: Ballgrab Connector

Series II, ball and taper, Subsea

Mooring Connector (SMC) – Female Connector in Docking Porch

Ontop of a Suction Pile.

Fig. 25 – Balltec’s MoorLOK Connector On top of Suction Pile (C2C)

Courtesy: First Subsea

Figs. 25 & 26 Courtesy: Balltec

Connecting Link

(Pear Shape)

3x4

Pattern

Courtesy: C-Ray Media

Fig. 8 – Typical Pre-Set Mooring Pattern

On Seafloor (WHO DAT SEMI-FPS)

4 x 2 Pattern

(4 Col. x 2 Tendons/Col.)

Courtesy

Vryhof

Anchors

Courtesy:

Vryhof

Anchor

Courtesy: C-Ray Media

4 x 3 Pattern

Courtesy: LLOG & DELMAR US

Courtesy: LeBeon Manufacturing

Delmar SS Connector

Shackle

Pipeline/

Flowline

Cooridor

(Typ.)

4x3

Pattern

Fig. 4: Internal Turret Moored FPSO

Pipeline/

Flowline

Cooridor

(Typ.)

Courtesy: C-Ray Media

4x3

Pattern

Courtesy: LeBeon Manufacturing

13

7.

Courtesy Vryhof Anchors

Courtesy: C-Ray Media

GRAPH 5: MOORING SYSTEM FAILURES

BY FACILITIES TYPE (2001-2011)

2.

4.

6.

Bend Restrictor

Insulation Sleeve

CHAIN

5.

9.

VLA

(Vertical

Load

Anchor)

Courtesy Vryhof Anchors

Courtesy: First Subsea

Courtesy: LeBeon Manufacturing

(2001-2011)

CONNECTOR

Suction

Pile

3.

wire rope

wire rope socket

swivel

pearlink

shackle

H-link

polyester rope

H-link

shackle

pearlink

swivel

pearlink

chain

shackle

anchor point

OFFSHORE MOORING PATTERNS (FOR TEMPORARY & PERMANENT MOORING)

Fig. 12: Open Socket

(Female End) Link for Wire Rope

GRAPH 4: MOORING BREAKS/COLLAPSE

Shackle

Fig. 9: SPAR Mooring Pattern with 1 of 4 Corridors Used for Flow- Fig. 10: BP’s Quad 204 FPSO with 4x5 Mooring Pattern with 4

line, Water Injection Lines, Umbilicals, and Export Pipelines.

Corridors for Flowlines, and Umbilicals – Location UK Cont. Shelf

Fig. 11: Anchor & Mooring Avoidance

Zones - Typically 500' on each side.

Courtesy: HESS; Graphics By: C-Ray Media

Courtesy: LLOG & DELMAR US

Chain

Connecting Link

(Pear Shape)

Courtesy: Delmar US

Fig. 26 – Balltec’s MoorLOK Male Connector (C2C) with “Y” Link

15

No. of Failures

1

Additional Ref. Material: Mooring Integrity Guidance,

Nov. 2008; Published by The United Kingdom Offshore

Oil and Gas Industry Association Limited (Oil & Gas UK).

T +31 78 6969000

MEETING

YOUR EVERY

OFFSHORE

CHALLENGE

www.boskalis.com

marine.contracting@boskalis.com

BosOff_OSmaps_1310 1

Courtesy: SOFEC

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

5.

120°

Courtesy: First Subsea

TM

Drilling Systems

Courtesy: Vryhof Anchor

4.

Driven

Pile

Fig. 1: Typical Spar Mooring

No. of Mooring Component Failures

0

Age by Operational Year

Providing reliable mooring lines and services through

innovative engineering and materials, extensive

FIG. 10: ANCHOR TYPES

3x4

Pattern

0

www.c-raymedia.com/mooring

(3)

(1) Contracted by Petrobras to fabricate the Torpedo Piles.

(2) SEPLA is proprietary to InterMoor and is solely manufactured and installed by InterMoor.

(3) InterMoor does not manufacture DEAs or VLAs. However, they own, rent, and install these anchor

types.

(4) InterMoor is licensed by Petrobras to fabricate and install Torpedo Piles in GOM.

(5) OMNIMAX is the trade mark of Delmar.

(6) Also includes Stevmanta, and Stevshark anchors.

(7) Delmar maintains a large inventory of Drag Embedment Anchors (DEAs) and VLAs which they own,

rent, and install.

Fig. 7– LankoFirst Rope to Chain (R2C) Connector,

An Alternative to “H” Link

4

CONNECTOR

Production Mooring Systems

· Chain Jacks/BarLatch Fairlead Stoppers

· SCR Pull-in Systems

Figs. 8: Ballgrab Female

Connector Used on a Disconnectable Buoy for FPSO Turret

STL BUOY 0

1

Fig. 6: LankoFirst Rope to Rope (R2R) Clam Connector

for Permanent Mooring and MODU Applications

10

FPSO

3

1

Fig. 5: Inter-M Swivel

Connector for Chain to Chain

(C2C) 360° Rotation

5

WIRE ROPE

SPAR

2

(3)

3.

Year

4

1

3. Lloyd’s Register Group Limited (LR): List 9b Approved Manufacturers of Fittings for Chain Cable

https://www.cdlive.lr.org/information/Documents/Approvals/ApprovedManufactures/list9b.pdf

DETAIL 5

Figs. 2, 3, and 4 Courtesy: Lankhorst Ropes

Courtesy: Flintstone Technology

CALM BUOY

2

(7)

2.

Courtesy: InterMoor

(2001-2011)

GOM FPSO

6

6

(7)

Courtesy: SIGMA OFFSHORE

Fig. 11: CALM Buoy Mooring System

1.

Courtesy: InterMoor

WIRE ROPE

Yr 0 = Installation, Yr 1 = First Yr. of Operation

Fig. 11: Fairleads On Semi MODU Hull ColumnFairlead & Stopper

PLATE

Clump

Weight

W. Africa FPSO

Early Life Failure (Infant Mortality, First Yr. of Ops.)

Courtesy: BARDEX

(4)

GRAPH 3: MOORING COMPONENT FAILURES

GOM Spar

N. Sea FPSO

0

1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013

Courtesy: BARDEX

Fig. 4: “Pear Link” Connector:

Rope to Chain (R2C)

Shackle Connection

for Suction Pile to

Chain Connection

3

Seg. 1 - Suction Pile

Pre-Installed Chain

Section

S. China FPSO

N. Sea FPSO

Fig. 3: “Y-Link” Connector:

Rope to Rope (R2R)

Figs. 6 & 7 Courtesy: Royal Lankhorst

S. China FPSO

Multiple Line Failures

GOM Spar

DEA

Typical mooring points vs water depth

Pre-Emptive Action/Replacement

6

Fig. 2: “H-Link” Connector:

Rope to Rope (R2R)

1

GRAPH 2: MOORING FAILURES BY YEAR (2001 -2011)

Prepared By University of Houston,

College of Technology, Petroleum Technology Initiative

3

Suction

Pile

8

(5)

Seg. 2 - Chain Section

DETAIL 3

Single Line Mooring Failures

14

4

THE CROSBY GROUP

thecrosbygroup.com

LIST OF APPROVED MANUFACTURES – For Mooring Chain, Anchors, Wire Rope

1. AMERICAN BUREAU OF SHIPPING: APPROVED MANUFACTURERS SHIP ANCHOR AND OFFSHORE MOORING CHAIN

(Updated weekly by ABS)

http://www.eagle.org/eagleExternalPortalWEB/ShowProperty/BEA%20Repository/AppProdsMFG/ApprovedListings/27CChain

4

2

(2001-2013)

16

Courtesy: BARDEX

5A

7A 7

5

VICINAY MARINE

Vicinaymarine.com

COMPANY NAME

DROP

ANCHOR

Components in a typical mooring line

8

20

VIKING SEA TECH AS

vikingseatech.com

VICINAY MARINE

Vicinaymarine.com

PILE

FLUKE ENGENHARIA (1)

Fig. 1: “H-Link” Connector:

Anchor to Polyester Rope

3

3

9

Graphs 2, 3, 4, and 5 Data Source is OTC Paper 24181 – Table 1 Data Analysis

UNIROPE

unirope.com

Fig. 9: InterMoor’s SEPLA Pre-Installation

OFFSHORE MOORING CONNECTORS: Connecting Mooring System Components Together

Delmar SS Connector for

Chain to Chain (C2C)

DETAIL 4

GRAPH 1: INDUSTRY EXPERIENCE – MOORING FAILURE AND PRE-EMPTIVE ACTION EVENTS

18

Fig. 10A & 10B:

Non-Disconnectible

Internal Turret

Mooring System

1.

MOORING SYSTEMS – INTEGRITY ISSUES ON FPSs

TECHNIP

technip.com

SMITH BERGER MARINE

smithberger.com

MANUFACTURERS

Courtesy: Bruce Anchor

Courtesy: InterMoor

Courtesy: DELMAR US

SUBSEA 7

le-beon.com

OCEANSIDE

EQUIPMENT LTD.

Courtesy: InterMoor

Fig. 7: Delmar’s Patented OMNIMAX Drop Anchor Fig. 8: InterMoor’s SEPLA (Suction Embedded

Plate Anchor)

7 6

5B

14

Trend: The purpose of this Section is to make the industry aware of integrity issues & trends with regards to Mooring

Systems for FPSs. According to OTC Paper 24181 the analysis “indicates a trend in which the intended design

performance of moorings does not meet operational performance”

Courtesy: BARDEX

LeBeon Manufacturing

le-beon.com

Courtesy: InterMoor

InterMoor

Seg. 3 - Fiber Rope

16 15

1 Suction Pile

DETAIL 1

1350m x 1,100 MT Poly

with Thimbles

14 Polyester Mambo Shackle

15 5 Special End Links

16 107 mm Chain Shackle

DETAIL 2

91,350m x 1,000 MT Poly

with Thimbles

10 Polyester Mambo Shackle

11 5 Special End Links

12 Polyester Mambo Shackle

1350m x 1,100 MT Poly with

Thimbles

2

WORLEYPARSONS

Worleyparsons.com

Courtesy: NOV APL

TABLE 4: ANCHOR MANUFACTURERS BY TYPE

Courtesy: InterMoor

DETAIL 2

MCDERMOTT

INTERNATIONAL, INC.

mcdermott.com

GROFSMEDERII

NIEUWKOOP B.V.

gnweb.com

Courtesy: SBM ATLANTIA

BRUCE ANCHORS

12 11

11

Courtesy: Aker Solutions Pusnes

EMAS AMC

emas.com

OFFSHORE INSTALLATION

SERVICES LTD. (OIS)

ois-ltd.com

Fig. 6: The Bruce DENNLA Mk4, Drag Embedment Near Normal Load Anchor (DENNLA)

Courtesy: DELMAR US

Seg. 7 - Chain Section

Mooring Failures

FLOATEC

Floatec.com

BLADT INDUSTRIES AS

bladt.dk

Fig. 5: Drag Embedment Anchor (DEA)

Courtesy: InterMoor

MOORING EQUIPMENT - WINCHES, FAIRLEADS AND CHAIN STOPPERS

Courtesy: Aker Solutions Pusnes

COLUMBUS MCKINNON

CORPORATION

cmworks.com

Courtesy: Vryhof Anchor

Courtesy: NOV APL

Seg. 1 - Chain Section at Anchor

Seg. 5 - Fiber

Rope

13

MOORING

SYSTEM

INSTALLERS/PM

ALLOY WIRE

INTERNATIONAL

alloywire.com

Fig. 4: Pile Anchor: Driven, Jetted, or Drilled

Seg. 2 -Wire Rope

Anchor

Orientation Tail

1D

Courtesy: Vryhof Anchor

Fig. 9: Single Angle Leg Mooring (SALM) & Loading System

VRYHOF ANCHORS

Fairleads

Seg. 6 - Chain

to Rope (C2R)

Connector &

Short Chain

MOORING BUOYS/

BUOYANCY

Figs. 1A & 1B Courtesy: InterMoor

Semi-FPS or MODU

CONNECTION DETAILS

ACCESSORIES

MODU Moorings are typically composed of

rented moorings:

• S tandard sizes of mooring ropes and

chains are used to design a system that

is adequate for the environmental criteria

• Connectors are made using enlarged end

links and specialty shackles

• Polyester ropes are used with thimbles to

maintain suitable D/d bending ratios

• Chain segments are used between the

polyester segments to maintain the

integrity of the polyester rope jacket and

filter barrier when handling the segments

on the deck of the installation vessel

Fig. 2: Taut Leg Moored Semi FPS with Suction Pile (Permanent Mooring)

Mooring Years in Service

MOORING LINE

COMPONENTS

Courtesy: NOV APL

DELMAR

25%

TURRET

DESIGNERS/

SUPPLIERS

Fig. 3: Vryhof Patented Stemanta

Omni-directional VLA

1D

OFFSHORE OIL & GAS MOORING SYSTEM & SERVICE COMPONENT PROVIDERS

MOORING SYSTEM

ENGINEERING

Seg. 3 - Chain with

R2C & C2R Connectors

1A

DETAIL 1

MOORING

MONITORING/

INSTRUMENTATION

Fig. 2: Vryhof Patented – Stevpris Mk6 Drag

Embedment Anchor

Courtesy: SIGMA OFFSHORE

Seg. 4 - Polyester

Fiber Rope with

Thimble Connectors

PILE

SHUTTLE

TANKER

FLNG SHIP

LNG SHIP

FPSO

SHIP

Worldwide Percentage (%)

Courtesy of University of Houston, College of Technology,

Petroleum Technology Initiative

Present

Fig. 8: Yoke Mooring System for Shallow Water Applications

VLA (Vertical Loaded

Anchor) with

Orientation Tail

1C

P

D/P

Proven

Not Proven

Turret Moored

10%

OFFSHORE ANCHOR

TYPES

MOORING LINE TYPES

CHART 1: OFFSHORE MOORING SUPPLIER MATRIX (AS OF SEPT., 2013)

MOORING

CLASSIFICATION &

CERTIFICATION

Figs: 1A & – Suction Piles with skid rails being

installed from stern of installation vessel

Seg. 5 - Chain 2 with

R2C & C2R Connectors

LEGEND

Spread Moored

5%

1B

P

INTERNAL

Fig. 7: Permanent External

Turret With Wet Mooring Table

ANCHOR TYPES FOR OFFSHORE MOORING

1C

Fig. 1: PUSNES Rotary Windlass

0%

Seg. 7 - Chain with

R2C & C2R Connectors

Seg. 6 - Polyester

Fiber Rope with

Thimble Connectors

P

TENDONS & AP TENSION

5.0%

ANGOLA

CATENARY

BUOY

NON-SHIP FPSO

8.7%

MALAYSIA/INDONESIA

SPAR

CONTROL BUOY

11.2%

TLP SEMI

LOADING/PROD.

BUOY

CHINA/VIETNAM/THAILAND/

MYANMAR/PHILIPPINES

MODU

CELL SPAR

12.1%

GOM

PERMANENT/PRODUCTION

CLASSIC SPAR

14.8%

TEMPORARY

TRUSS SPAR

NORTH SEA

MOORING SYSTEMS

CONVENTIONAL

& MINI-TLP

PRODUCTION

SEMI

22.1%

FLOATEL

BRAZIL

Fig. 6: External Turret With Dry Mooring Table

Data Courtesy of Quest Offshore & Analysis by University of Houston, College of Technology, Petroleum Technology Initiative

Seg. 1 Chain Section

at Anchor

25% 50% 75% 100%

Courtesy of University of Houston, College of Technology,

Petroleum Technology Initiative

OFFSHORE STRUCTURE TYPES

OTHER SOURCES - BOOKS, E-BOOKS, WEB SITES

1BOOK: DEEPWATER MMORING SYSTEMS - Concepts, Design, Analysis, and Materials

Edited by Jun Zhang, Richard Mercier; 2003, 360 Pages

2E-BOOK: JIP FPS MOORING INTEGRITY (2006), 313 Pages

www.hse.gov.uk/research/rrpdf/rr444.pdf

3E-BOOK: VRYHOF 2010 ANCHOR MANUAL; 188 Pages; www.vryhof.com/anchor_manual.pdf

4E-BOOK: Classification of Mooring Systems for Permanent Offshore Units (April, 2012);

54 Pages

www.veristar.com/content/static/veristarinfo/images/4851.32.493NR_2012-04.pdf

5ON-LINE COURSE: Technology University of Delft (Netherlands);

http://ocw.tudelft.nl/courses/offshore-engineering/offshore-moorings/course-home/

6BOOK: The Unviersity of Texas Publication: Spread Mooring Systems, 2nd Edition;

http://www.utexas.edu/ce/petex/aids/pubs/spread-mooring/

7BOOK: Engineers Design Guide to Deepwater Fibre Moorings, By Oil Pub (2005)

Courtesy of University of Houston, College of Technology, Petroleum Technology Initiative

0%

Seg. 8 - Polyester

Fiber Rope with

Thimble Connectors

Seg. 9 – Chain

Sections

Prepared By: University of Houston, College of Technology,

Petroleum Technology Initiative & Amy Hendrix, GIS Consultant

TABLE 3: THE APPLICATION OF MOORING SYSTEMS vs. OFFSHORE FACILITY TYPES

Fig. 5 – Disconnectible External Mooring Buoy

Wire Rope to Chain

(R2C) Connector

PLATE ANCHOR

0%

25% 50% 75% 100%

0%

DEA

25% 50% 75% 100%

DRIVEN PILE

0%

25% 50% 75% 100%

Data Source: UH Research, Mustang Engineering/Offshore Magazine, and Quest Offshore Databases for mooring system data and Source: Esri, i-cubed, USDA, USGS, AEX, GeoEye, Getmapping, Aerogrid, IGN, IGP, and the GIS User Community for the world map data.

MOORING PATTERNS, TYPES, CONFIGURATIONS

Courtesy: NOV APL

1A

SUCTION PILE

0%

Courtesy: NOV APL

Fig. 4: TLP Moored with Tendons

Installation Year

Seg. 10 - MODU Chain

MOORING ANCHORS

MAP

1,000 M

3,280 ft.

Courtesy: Delmar US

>20 Yrs.

MODU (Mobile Offshore Drilling Rig)

Tendon Moored

MOORING SYSTEM ELEVATIONS

Fig. 1: Spread Moored

500

1,640 ft.

OFFSHORE MOORING LINES – SAMPLE ASSEMBLIES

Fig. 1: Elevation View of Polyester VLA Taut-Leg Preset Mooring Leg (Temporary Mooring)

Spread Moored

Tendon Moored

Fig. 3: External Turret with

Dry Mooring Table

0

Up to

10 Yrs.

Up to

15 Yrs.

New Zealand

26

100%

Catenary and Taut describe the way the mooring

line is suspended in the water column. Catenary

systems have parabolic shape. Taut system mooring

lines hang in a straight line between two points.

Courtesy: SIGMA OFFSHORE

0%

9

Fig. 2: Disconnectible Internal Turret Mooring System

Courtesy: BRIDON

Courtesy: SIGMA OFFSHORE

Turret Moored

North Sea

7

TYPES OF MOORING SYSTEMS

Courtesy: HESS

LIFE SPAN

(Yrs.)

1. NON-GALVANIZ ED

WIRE ROPE

2. GALVANIZED

SPIRAL STRAND

3. SHEATHED

SPIRAL STRAND

Tendon Moored

0%

• Used for Polyester Mooring Lines with suction piles.

• Preferred mooring system type for long life deepwater

production facilities.

• 40% reduction in footprint compared to Catenary Type.

STEVPRIS (6)

MOORING LINES

CLASS SOCIETIES GUIDANCE DOCUMENTS ON MOORING SYSTEMS & INSTALLATION

Class societies regulate the implementation of the guidelines set forth in the standards by

giving specific steps to follow for class approval of a mooring system or installation.

1. American Bureau of Shipping (ABS): www.eagle.org then go to Resources > Rules &

Guides > Downloads

2. Bureau Veritas: www.veristar.com/wps/portal/bvrules

3. DNV GL: www.dnv.com/resources/rules_standards/index.asp

4. Lloyd's Register: www.webstore.lr.org/category/1-marine.aspx

HMPE Fiber for DW Mooring

Evaluation of Advance Fibers

Fiber Mooring - Recent Experiences

Changes in Update of AP RP 2SM

Hurricane Proof Mooring System

Polyester Mooring Line RED HAWK System Design & Verif.

MAD DOG Polyester Mooring

100%

• Used for chain/wire rope/chain mooring lines.

• Preferred mooring system type for deepwater MODUs for

temporary mooring.

• Has a larger footprint compared to Taut System.

BRUCE

MK4 & MK5

©2013 Offshore

MOORING EQUIPMENT

MOORING STANDARDS

1 API Spec 2F - Mooring Chain (1997) - Currently in Revision

2 API RP 2I - In-service Inspection of Mooring Hardware for Floating Structures (2008).

3 API RP 2SK - Design & Analysis of Stationkeeping Sys. for Floating Str. (Add.2008)

4API RP 2SM - Recommended Practice for Synthetic Fiber Ropes (Add. 2007) A new

revision is currently in the Balloting Phase.

5 ISO 19901-7 Station-keeping systems for floating offshore structures (Rev)

6 ISO 19904-01 Floating offshore structures

7 2GEO - Geotechnical Analysis of Mooring Anchors - Is a new standard in development.

8 2MIM - Mooring Integrity Management. Is a new standard to be released.

9 DNV GL: http://www.dnv.com/resources/rules_standards/index.asp

INTEGRITY & LESSONS LEARNED

1 OTC 24025-MS 2013 BP/TOTAL/SHELL

Mooring System Integrity Issues

2 OTC 24181

2013 GRANHERNE (KBR)

Lessons Learned from FPS Moorings

3 ISOPE I-12-563 2012 AMOG CINSULTING & Others SCORCH JIP - Chain Corrosion

4 OTC 21012-MS 2010 SOFEC

Anchor Leg System Integrity

5 OTC 19198-MS 2008 STRESS ENGINEERING

Polyester Mooring Integrity

6 OTC 17499-MS 2005 NOBLE DENTON & Others Floating Prod. Mooring Integrity JIP

SYNTHETIC FIBER MOORING SYSTEMS

1 OTC 23333-MS 2012 DYNEEMA/LANKHORST

2 OTC 22218

2011 STRESS ENG.

3 OTC 20838

2010 DEMLAR SYSTEMS

4 OTC 20836-MS 2010 BP & Others

5 OTC 20155-MS 2009 SAMSON/DELMAR

6 OTC 18768-MS 2007 TENSION TECHNOLOGY

7 OTC 17247-MS 2005 TECHNIP/KERR-MCGEE

8 OTC16590

2004 BP/STRESS ENG/UNION

MOORING INTEGRITY

25% 50% 75% 100%

Spread Moored

Turret Moored

Taut Leg Mooring System Key Attributes

SEPLA (2)

MOORING SYSTEM INSPECTION, TESTING, AND QUALIFICATION

1 OTC 24184-MS 2013 WELAPTEGA MARINE LTD. Risk Based Inspection Plan

2 OTC 24080-MS 2013 SBM/LANKHORST

THUNDER HAWK Fatigue Testing

3 OMAE2012-84067 2012 InterMoor

Microbiological Corrosion

4 OTC 20779

2010 WELAPTEGA MARINE LTD. In-Service Inspection Spread Moored

Courtesy: C-Ray Media

Catenary System Key Attributes

Sakhalin

25

SERVICE VESSEL

PLANNING & INSTALLATION OF DEEPWATER MOORING SYSTEMS - VARIOUS PROJECTS

1 OTC 23223

2013 COOEC/COTEC

LIUHUA 11-1 FPS Mooring Upgrade

2 OCT 23083-MS 2012 LLOG/WHITEHILL/DELMAR WHO DAT Project Mooring System

3 ISOPE I-10-470 2010 OFFSHORE OIL ENG. CO.

STP Moooring System in China

4 OTC 21018-MS 2010 InterMoor/ATP OIL & GAS MIRAGE/TELEMARK MinDOC Mooring

5 OTC 18587-MS 2007 ENTERPRISE

INDEPENDENCE HUB Mooring Sys

6 OTC 17294-MS 2005 TECHNIP/DOVE MARINE RED HAWK Spar Mooring System

7 OTC 16702-MS 2004 SHELL/HEEREMA

Na Kika DW Mooring Project

0%

Tendon Moored

The poster is divided into distinct sections and

each section is marked by a background color. The

color denotes the subject section. This color code is

carried throughout the poster. Below are the color

code designations for each of the themes.

Go to www.onepetro.org to order the OTC (Offshore Technology Conference), SPE (Society of

Petroleum Engineers), and ISOPE (The International Society of Offshore and Polar Engineers) papers

listed in Table 2.

Recommended Papers, Manuals, and other documents

for additional knowledge

25% 50% 75% 100%

Mauritania

6

100%

Tendon Moored

26

Courtesy: C-Ray Media

VLA

13

Fig. 2: Taut Leg Mooring System

DEA

Tendon Moored

GRAPH 3: WIRE ROPE

LIFE SPANS

WIRE ROPE

TYPE

Turret Moored

SEMI SUBMERSIBLE

DRILL SHIP

(DP RIG)

TABLE 2 – OTHER OFFSHORE MOORING INFO. SOURCES

POSTER COLOR CODE KEY

23

Spread Moored

SINGLE POINT MOORING

RTM

Riser Turret Mooring

R2R

Rope to Rope Connector

R2C

Rope to Chain Connector

SALM Single Anchor Leg Mooring

SCM

Spread Catenary Mooring

SEA

Suction Embedded Anchor

SEMI

Semi Submersible

SEPLA Suction Embedded Plate Anchor

SM

Spread Mooring

SP

Suction Pile

STM

Spread Taut Mooring

STP

Submerged Turret Mooring

TLP

Tension Leg Platform

VLA

Vertical Loaded Anchor

Anchor Pile

Chain-Poly-Wire

Chain & Wire

Catenary Anchor Leg Mooring

Chain To Rope Connector

Chain To Chain Connector

Drag Embedded Anchor

Driven Pile

External Turret

Floating Production Storage & Offloading

High Holding Power

Internal Turret

Jacket Soft Yoke

Mobile Offshore Drilling Unit

108

5

25% 50% 75% 100%

Philippines

24

28%

Turret Moored

Country/Region

AP

C&P&W

C&W

CALM

C2R

C2C

DEA Dr. P

ET

FPSO

HHP IT

JSY

MODU

POSTER

12

72%

0%

Information Accuracy: We have attempted to use correct and current, as of press time, information for the mooring systems and equipment described herein. No installed, sanctioned,

nor pending application was intentionally excluded. We have summarized the capability and operating experience by acting as a neutral party and integrator of information. Information

has been collected from public sources, company brochures, personal interviews, phone interviews, press releases, industry magazines, vendor-supplied information, and web sites. No

guarantee is made that information is accurate or all-inclusive. Neither University of Houston nor Offshore Magazine guarantees or assumes any responsibility or liability for any party’s

use of the information presented. If any information is found to be incorrect, not current, or has been omitted, please send comments to: jchristi@central.uh.edu and gksheridan@uh.edu.

3

Spread Moored

Figs. 1, 2, & 3 Courtesy: BRIDON

0%

Brazil

5

ABS: Judy Murray, John Stiff and Kenneth Huang; Aker Solutions: Tom Plank, and John-Otto Nilsen; Balltec: Martin Bell, and Emma Corrie; Bardex: Stephen Jones; Bluewater

Industries, Inc: Jamie Armstrong; Bridon: Chris Leonard, Tony Tarabochia, and Troy Rybicki; Bruce Anchor: David Ledgerwood; C-Ray Media: Connie Gray, Nanette McNair,

Samara Barks, and Jalil Whitmore; DCL Mooring & Rigging: Rick Hall Doris, and Richard D. Haun; Delmar US: Even Zimmerman, and Robert Garrity; First Subsea: Valerie

Pylypiw, and Greg Campbell-Smith; Grahherne: Richard D’Sourza and Sai Majhi; InterMoor: Jonathon Miller, Florence Kosmala, and Todd Veselis; Lankhorst Ropes: Geeske

Terpstra; LeBeon Manufacturing: Aurelien Le Floch, and Clement Mochet; MODEC: Ken Turner; National Oilwell Varco: Charyl Smerek, Geir Hovde, and Tatjana Tanya Brestovac;

Parker Hannifin Corporation: Brian Compton, and Eldon E. Thomas; Pennwell: Jessica Tippee, Mary Sumner, Roger Kingswell, and Daniel Bernard; Quest Offshore: Matt Gross,

and Paul Hillegeist; Sigma Offshore: Allan Millmaker; Tex Ocean: Donnie Newman; Vrhof Anochors: Erik Rykers, and Thomas Agnevall

22

Fig. 10: Mooring Chain & Suction Piles Ready for Loadout & Installation

Fig. 9: Studded Mooring

Chain used at mud line

& host facility. Chain

actual field life performance is 15–20 years

vs. typical design life of

20 to 25 years.

20

University of Houston and Offshore Magazine wish to acknowledge the following individuals and companies who continue to support our efforts

to educate and inform the oil and gas industry on the status of mooring systems.

Tendon Moored

25% 50% 75% 100%

0%

Fig. 1: Catenary System

1,500 M

4,921 ft.

01

ACKNOWLEDGEMENT OF THE CONTRIBUTORS

21

11

3. MOORING CHAIN

93%

Turret Moored

Courtesy: BRIDON

20

10

7%

Courtesy: Royal Lankhorst

99

9

Spread Moored

Courtesy: Royal Lankhorst

20

100%

Australia

23

24

97

Spread Moored

Turret Moored

19

18

Fig. 3: Comparison of Typical Mooring Configurations

& Line Type by Water Depth

2,000 M

6,562 ft.

19

2

25% 50% 75% 100%

Fig 3: Sheathed Jacket around

spiral strand increases service life

> 20 years.

95

Canada/US Atlantic

Polyester Fiber Rope

Chain/Wire Rope

2,500 M

8,202 ft.

6%

0%

20

The usage of polyester fiber rope

(green squares) is a growing

trend for mooring systems on

Past

Future

deepwater production facilities

installations.

19

25% 50% 75% 100%

9/12/13 9:18 AM

66%

Tendon Moored

17

3,000 M

9,842 ft.

28%

Turret Moored

6

Fig. 7: Cross Section of

Lankhorst’s MODULINE Polyester Fig. 8: Cross Section of

Fiber Rope

Polyester Mooring Lines.

93

1

Tendon Moored

TABLE 1 – ABBREVIATIONS

Spread Moored

15

Fig. 5 – Lankhorst’s Polyester Fiber Rope on Deployment Reel Offshore

Indonesia

22

16

14

8

100%

25% 50% 75% 100%

Courtesy: Royal Lankhorst

19

25

particle filter layer to limit the ingress of abrasive particles and marine

finish on load bearing elements enhances the resistance to yarn on yarn

abrasion ensures long term performance for field life in excess of 20 years.

GRAPH 1: CHAIN/WIRE ROPE VS. POLYESTER ROPE USAGE MOORING SYSTEM TREND

91

4

Peru

10%

0%

Increasing Performance Life of Fiber Rope – The inclusion of a

Fig 2: Spiral Strand galvanized or

coated high tensile wire. Service

life span up to 15 Years.

19

25% 50% 75% 100%

50%

89

7

Courtesy: Bridon

40%

19

4

25% 50% 75% 100%

Malaysia

Tendon Moored

0%

1455 West Loop South, Suite 400

Houston, TX 77027

Tel: 713-963-6200 Fax: 713-963-6296

www.offshore-mag.com

0%

Tendon Moored

Tendon Moored

E

25% 50% 75% 100%

• Polyester rope gives a "softer" mooring system than steel wire rope; and therefore host motions are more compliant and riser friendly.

• Better Vortex Induced Motion (VIM) response to loop currents than Chain-Wire-Chain system.

• Affords smaller SCR departure angles.

• Allows the use of a significantly smaller turret buoy on FPSOs for enhanced safety and project viability.

• Up to 50% reduction in costs compared to conventional catenary mooring system.

• Approximately 80% reduction in wet weight of tension members (i.e. ropes) when converting from Wire to Polyester. The vertical mooring force on the

platform is reduced by 50%. This reduction in wet weight and forces therefore increases usable payload.

• Up to 50% reduction in mooring pre-tension.

• Polyester rope does not corrode and there is no need for corrosion allowances on the diameter of the polyester like there is on chain and wire.

87

N

0%

Turret Moored

0%

I

25% 50% 75% 100%

Spread Moored

D - DISCONNECTABLE

P -PERMANENT

The University of Houston

www.uh.edu Tel: 713 743 2255

4800 Calhoun Road Houston, TX

77004-2693

Z

Tendon Moored

Tendon Moored

0%

78%

21

Turret Moored

A

Turret Moored

Turret Moored

Spread Moored

G

50%

100%

3

A

25% 50% 75% 100%

Turret Moored

22%

Advantages of Polyester for Mooring Lines

19

0%

Spread Moored

Colombia/Venezuela

Spread Moored

E-Mail Comments, Correction or Additions to: jchristi@central.uh.edu and gksheridan@uh.edu

M

Tendon Moored

50%

Fig. 4: Components of Typical Polyester Fiber Rope for Deepwater Mooring Fig. 6: Lankhorst’s Fiber Rope with Torsional Reference Lines

85

Tendon Moored

25% 50% 75% 100%

0%

100%

Turret Moored

Spread Moored

2. FIBER ROPE (Typically Polyester)

Fig. 1: Wire Rope for Deepwater

MODU (Drilling Rigs) Mooring Lines

Cross Section (6 x 34) – Life span

up to 10 Years.

19

25% 50% 75% 100%

0%

100%

Turret Moored

9%

Tendon Moored

Spread Moored

1. WIRE ROPE

83

25% 50% 75% 100%

41%

Turret Moored

Tendon Moored

Spread Moored

China/Vietnam

20

19

32%

Turret Moored

50%

India

18

81

Spread Moored

Caspian Sea

16

19

Prepared by: Manoochehr Bozorgmehrian, Manjunath Terwad, and Vani Aparna Peri – Former Graduate Students, University of Houston

With Assistance From: Jack Christiansen and Galina Sheridan of the University of Houston, College of Technology, Petroleum Technology Initiative,

www.uh.edu/technology/pti; Kurt Albaugh of Repsol E&P USA; David Davis, Mary Sumner and Jessica Tippee of Offshore Magazine;

Jonathan Miller of InterMoor; and Amy Hendrix GIS Consultant

25%

68%

Adriatic/Italy

14

79

2

0%

25% 50% 75% 100%

0%

Spread Moored

Tendon Moored

34%

Tendon Moored

OCTOBER 2013

Turret Moored

75%

Angola

12

19

9%

Turret Moored

Trends & Technology

Spread Moored

57%

Nigeria

10

DelSys_OSmaps_1310 1

MOORING LINE CONFIGURATIONS

77

Spread Moored

Spanish Mediterranean

MOORING LINE COMPONENT TYPES: WIRE ROPE, POLYESTER FIBER ROPE, AND CHAIN

19

8

9/30/13 9:58 AM

75

GOM

1

www.delmarus.com ï 1-337-365-0180

EMAS_OSmaps_1310 1

19

MOORING SYSTEMS FOR OFFSHORE

FLOATING INSTALLATIONS

DELMAR

Delmar Systems

PROVEN MOORING SOLUTIONS FOR FPSO AND FLNG

WWW.LONDONMARINE.CO.UK

OMNI MAX ™

7/9/13 9:34 AM

68ñ2 0 1 3

...count on the

leader in offshore mooring

19

IntermRev_OSmaps_1310 1

Learn more

about our

deepwater

installation

vessels at

mcdermott.com

DRIVEN PILE

© 2013 McDermott International, Inc. All rights reserved.

19

45 years

90% more thrust with 6 new thrusters

200% improved station keeping

50% more power with 4 new engines

Subsea lowering up to 480 tons to 11,500 ft.

(+/-) 8.2 feet heave compensation

Main fixed crane capacity 4,189 ST

SUCTION PILE

Enhanced to deliver

greater reliability

& versatility

Mooring Foundations Subsea

www.in

www.intermoor.com

intermoor.com

for all your mooring

installation needs

TORPEDO PILE

DB50

When experience

counts....

Water Depth (Meters & Feet)

INNOVATIVE

MOORING

SOLUTIONS

Technical expertise. Practical

know-how. Delivered worldwide.

9/30/13 9:56 AM

Courtesy: BP

Mooring Integrity

Management Services

Control inspection and maintenance costs

Extend mooring system life

Minimize mooring failures and downtime

Manage degraded and damaged moorings

www.amogconsulting.com

AmoCon_OSmaps_1310 1

9/16/13 11:43 AM