Low-Cost Hinge for Deployable Structures

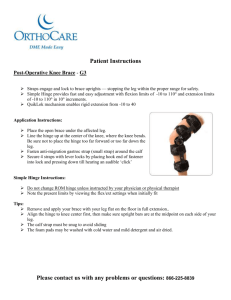

advertisement