Successful Applications Converting 3M Technology into Selection Guide

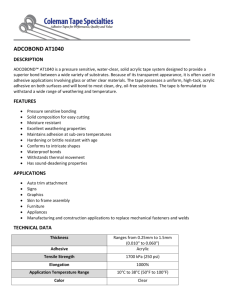

advertisement