This article was published in an Elsevier journal. The attached... is furnished to the author for non-commercial research and

advertisement

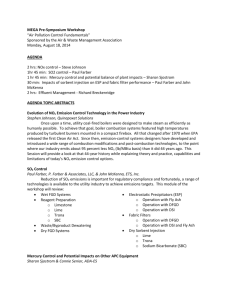

This article was published in an Elsevier journal. The attached copy is furnished to the author for non-commercial research and education use, including for instruction at the author’s institution, sharing with colleagues and providing to institution administration. Other uses, including reproduction and distribution, or selling or licensing copies, or posting to personal, institutional or third party websites are prohibited. In most cases authors are permitted to post their version of the article (e.g. in Word or Tex form) to their personal website or institutional repository. Authors requiring further information regarding Elsevier’s archiving and manuscript policies are encouraged to visit: http://www.elsevier.com/copyright Author's personal copy Chemical Engineering Science 63 (2008) 782 – 790 www.elsevier.com/locate/ces Evaluation of mercury sorbents in a lab-scale multiphase flow reactor, a pilot-scale slipstream reactor and full-scale power plant Jiang Wu a,b , Yan Cao a , Weiguo Pan b , Minqiang Shen b , Jianxing Ren b , Yuying Du b , Ping He b , Du Wang b , Jingjing Xu b , Andy Wu a , Songgeng Li a , Ping Lu c , Wei-Ping Pan a,∗ a Institute for Combustion Science and Environmental Technology, Western Kentucky University, KY 42101, USA b School of Energy and Environmental Engineering, Shanghai University of Electric Power, Shanghai 200090, PR China c School of Power Engineering, Nanjing Normal University, Nanjing 210042, PR China Received 19 September 2006; received in revised form 22 August 2007; accepted 13 September 2007 Available online 6 October 2007 Abstract Due to its adverse effects on human health and ecosystem, mercury emission from the coal-fired utility boiler has been generating more and more concern. Sorbent injection upstream of the electrostatic precipitator (ESP) or bag-house has been deemed one of the recommended mature technologies to reduce mercury emission. Before a sorbent is used in practice, its mercury capture ability needs to be evaluated, but has until recently only been demonstrated in bench-, pilot- or full-scale experiments separately. In this paper, a lab-scale multiphase flow reactor and a pilot-scale slipstream reactor were set up and conducted such evaluation on the two scales. After that, some kinds of sorbents were injected at a full-scale power station. The experimental results show that the lab- and pilot-scale reactor systems in this paper can provide accurate information of sorbent evaluation under flue gas atmosphere. There was significant difference between the mercury removal efficiency of tested sorbents, varying from 98.3% down to 23%. SO2 in the flue gas was shown to inhibit mercury oxidization and capture. The sorbents have higher mercury capturing efficiency with higher injection rate and longer residence time when other conditions were held constant. In the pilot-scale, four injection ports vertical to the flue gas flow direction could help improve mixture of sorbent and flue gas so that the mercury removal efficiency became higher. The pilot-scale data can be used to predict the full-scale results. Some of the chemical and physical mechanisms responsible for the mercury removal of the sorbents were identified. 䉷 2007 Elsevier Ltd. All rights reserved. Keywords: Mercury; Removal efficiency; Evaluation; Mercury sorbent; Lab-, pilot- and full-scale; Prediction 1. Introduction As reported by the U.S. Environmental Protection Agency (EPA), the Canadian Council of Minister of Environment (CCME) and the European Commission, the major anthropogenic source of mercury emissions, which are among the most toxic pollutants to human health and the ecosystem, is from coal-fired power plants (Brown, 1999; US EPA, 1998; Pavlish et al., 2004; Keating et al., 1997). Coal contains naturally occurring mercury that varies in concentration with both the type of coal and its place of origin. The U.S. EPA has determined that mercury emitted from utility power plants ∗ Corresponding author. Tel.: +1 270 745 2272; fax: +1 270 745 2221. E-mail address: wei-ping.pan@wku.edu (W.-P. Pan). 0009-2509/$ - see front matter 䉷 2007 Elsevier Ltd. All rights reserved. doi:10.1016/j.ces.2007.09.041 should be controlled and it has set the final regulation on mercury emission from coal-fired power generation on March 15, 2005 (US Environmental Protection Agency, 2005). This decision will affect both economic and environmental aspects of the U.S. U.S. EPA announced the Clean Air Interstate Rule (CAIR) that will cap emissions of sulfur dioxide (SOx ) and nitrogen oxides (NOx ) and also mercury (Hg) from coal-fired power plants. This is a market-based cap-and-trade program, which will reduce electric utility mercury emissions by nearly 70% from 1999 levels when fully implemented. Sorbent injection upstream of the ESP or bag-house is one of the recommended methods for mercury emission control. Sorbent injected into the flue gas ducts absorbs both of the elemental and oxidized mercury in flue gas, then the ESP captures the sorbent and fly ash simultaneously. However, the mercury capturing efficiency Author's personal copy J. Wu et al. / Chemical Engineering Science 63 (2008) 782 – 790 of sorbents is extremely important to avoid increasing the ESP load and to control the cost of adsorbent. Before a sorbent is used in practice, its mercury capturing ability needs to be evaluated. However, such evaluation has until recently only been demonstrated in bench-, pilot- or full-scale experiments separately (Cao et al., 2004; Wu et al., 2006a,b; Yan et al., 2004). In this paper, a lab-scale multiphase flow reactor and a pilot-scale slipstream reactor were set up and evaluated mercury capture by the injection of some commercial sorbents. After that, some kinds of sorbents were chosen to inject at a full-scale power station to test their mercury capturing efficiency. 2. Experimental Two phases of testing were conducted on the lab-scale multiphase flow reactor to evaluate the mercury capture efficiency of the commercial sorbents. In the first phase, elemental mercury generated by a special Cav-Kit䉸 , which provides a stable mercury concentration, was introduced to the lab-scale multiphase flow reactor. An on-line Hg analyzer, semi-continuous emission monitor (Hg-SCEM) (Kellie et al., 2004; Wu et al., 2005), was adopted to get the quasi-real-time mercury concentration in the flue gas. The change of the mercury concentration with sorbent injection was monitored. The adopted Hg analyzer uses gold amalgamation cold-vapor atomic fluorescence to measure Hg (0) concentrations. A proprietary flue gas-conditioning system was used to remove acid gases and reduce any Hg (2+) present to Hg (0) for subsequently measuring total mercury. The online instrument measures Hg (0) and Hg (T) continuously by switching from channel to channel. The selected bituminous coal ash was injected together with the sorbents into the lab-scale reactor so that the real working conditions of the sorbents were simulated. The sorbent feeding and ash separation are very important for the experiments. The feeding system was optimized and suitable transfer gas was added so that the sorbent could be injected smoothly, and a cyclone and inertial filter were added to remove the ash. Compressed air and simulated flue gas consisted of 9.8% of O2 , 9.5% of CO2 and 1106 ppm of SO2 were used as the carrier gases, respectively, for the lab-scale multiphase flow reactor. The dimensions of this reactor are listed in Table 1. The tubular reactor is a 0.05 m I.D. stainless steel pipe. Its length is 1.22 m. To protect the stainless steel pipe and eliminate its effect on mercury due to possible oxidization and absorption of mercury, a 0.04 m I.D. ceramic pipe is inserted into this stainless steel pipe. The multiphase flow reactor is heated up by two electric furnaces. A thermocouple is inserted into the reactor to monitor the inside temperature. A two-channel temperature controller is utilized to control the furnaces to the Table 1 Dimensions of lab-scale multiphase flow reactor Stainless steel pipe I.D. (m) Ceramic pipe I.D. (m) Total length (m) Length of heating section (m) 0.05 0.04 1.016 0.914 783 desired temperatures. The gaseous products flowed out the multiphase flow reactor from the outlet in the bottom end of the stainless steel pipe, where they entered the gaseous sampling system. The schematic of lab-scale multiphase flow reactor is shown as Fig. 1. In the pilot-scale slipstream testing facility, the flue gas was directly introduced from the air pre-heater duct of utility boiler to simulate the real flue gas atmosphere for sorbent evaluation. The pilot-scale slipstream reactor was set up in a selected power station in Kentucky that burns medium-sulfur bituminous coal. The pilot-scale slipstream reactor is shown as Fig. 2. The flue gas was taken out from the duct into the slipstream reactor and then went back to the duct so that real flue gas was attained. Some insulation tape was put on the surface of the duct connecting the duct and slipstream reactor. The position and thickness of the insulation tape are adjustable so that the temperature inside the slipstream reactor can be adjusted to expected value. The temperature inside the multiphase reactor and the residence time of the flue gas in the reactor were controlled by adjusting the insulation tape and use of the cooling fan. The temperature inside the slipstream reactor kept very well, and the temperature difference between the two ends of the slipstream reactor was around 1 ◦ C. A special feeder was designed to make the sorbent enter the reactor easily and distribute evenly. In the second phase of the experiments on the lab-scale multiphase flow reactor, the reactor was taken to the power station where the pilot-scale slipstream reactor was set up. The flue gas was taken out directly from the air pre-heater duct of the utility boiler and introduced into the multiphase reactor to investigate the real flue gas atmosphere for sorbent evaluation. The flue gas was taken out from the duct into the multiphase 5 10 8 6 9 4 7 16 3 18 17 11 19 2 12 13 14 1 15 1. Simulated flue gas 2. Regulator 4. Cavkit Box 5. Carrier gas 7. Flue gas port 8. Thermocouple 10. Feeder Controller 11.Tube flow reactor 13. Temperature controller 14. Mini cyclone 16. Mercury injection port 17. CEM analyzer 19. Computer 3. MFC 6. Flowmeter 9. Mini screw feeder 12. Electric furnace 15. Solid collection vessel 18. Conversion Unit Fig. 1. The schematic of lab-scale multiphase flow reactor. Author's personal copy 784 J. Wu et al. / Chemical Engineering Science 63 (2008) 782 – 790 Pilot-scale Slipstream Reactor Lab-scale Multi-phase Reactor Flue Gas from Air Preheater A-A A A reactor and returned back to the boiler duct through the pilotscale slipstream reactor. The process that introduces real flue gas into the lab-scale multiphase reactor is shown as Fig. 2. Several kinds of sorbents were tested at both of the two phases on the lab-scale multiphase reactor and the pilot-scale slipstream reactor under different residence time, sorbent injection rate and temperature. The injection system was also optimized to improve the mixture and capturing process. The residence time was 1–2.5 s and temperature inside the reactors was 150–170 ◦ C. Sorbent injection changed from 3.85 × 10−5 .7.7×10−5 kg/m3 in the lab-scale, and 5.13×10−5 .2.57× 10−4 kg/m3 in the pilot-scale experiments. Mercury Concentration, ng / Nm3 Fig. 2. The schematic diagram of pilot-scale slipstream reactor. 12000 Start injection Hg (T) 8000 4000 Stop injecting 0 14:24 16:48 Time (date) 19:12 Fig. 3. The history of Hg concentration changing during sorbent injection on lab-scale multi-phase flow reactor. 3. Results and discussion 3.1. Definition of mercury adsorption efficiency During the first phase of the lab-scale experiments on the multiphase flow reactor, elemental mercury was introduced with the flue gas into the multiphase flow reactor and residual Hg concentration changed during the sorbent injection. A typical curve of mercury concentration at the lab-scale multiphase flow reactor during sorbent injection is shown as Fig. 3. It demonstrates that the mercury concentration begins to drop as soon as sorbent injection starts and gradually returns to the original concentration level when sorbent injection ends; however, it is difficult to recover completely possibly because of fine sorbent build-up on the wall of the reactor and inertial filter. To describe the phenomena, maximum and minimum mercury adsorption efficiency can be defined as max = (Ci − Cmin )/Ci × 100% (1) and min = (C0 − Cmin )/Ci × 100%, (2) where Ci is concentration of the injected mercury, Cmin is the lowest concentration of the mercury in the flue gas after sorbent injection, and C0 is the recovered concentration of the mercury after ending sorbent injection. They are shown as Fig. 4. According to the experimental data, max is a function of both of the characteristics of a sorbent and the experimental Author's personal copy J. Wu et al. / Chemical Engineering Science 63 (2008) 782 – 790 Ci Ci C0 Cmin Fig. 4. The schematic of Hg concentration changing during sorbent injection. conditions. For a given experimental run, a sorbent may have different max and min . This is possibly a result of the sorbent sticking to the wall of the reactor or sorbent accumulating in the horizontal duct of the reactor so that the contact time of the sorbent with the flue gas is longer than the calculated residence time. min can be adopted to study the mechanism of the sorbent adsorption. When the sorbent is injected into the reactor, it will be distributed by the aerodynamic effect and start to fly in the reactor. The mercury inside the reactor will possibly collide with the sorbent and adhere to the surface of the sorbent, and the mercury will be oxidized not depending on the characteristics of the sorbent. The mercury on the sorbent surface will enter the sorbent inside or just adhere to the surface. This process is physical and/or chemical sorption, and it can be called flying adsorption. On the other hand, some sorbent may collide with the horizontal tube or the wall of the reactor and stick on its surface and accumulate. The accumulated sorbent will go on adsorbing mercury as soon as there is a chance since it has more mercury capturing capability after flying adsorption. This is the main reason why the mercury concentration could not recover its original level even after ending sorbent injection for some time. It will take a very long time for this recovering process. The yielding mechanism of the difference between max and min will be described in a separated paper. This paper focuses on max , and it will be called mercury removal efficiency in this paper. During the second phase of experiments on the lab-scale reactor and experiments on the pilot-scale slipstream reactor, elemental and oxidized mercury in the flue gas are both introduced into the reactors, and their concentration dropped during the sorbent injection and recovered gradually when sorbent injection was ended. The specific process is shown in Fig. 5. The relevant definition of mercury adsorption efficiency is also applied to the second phase of testing. 3.2. Mass balance calculation During sorbent injection, mercury was introduced into the multiphase flow reactor and it would be adsorbed by the injected sorbent and would stay in bottom container, horizontal tube, cyclone or went out together with the flue gas. This process is so complex that mercury mass balance calculation needs to be conducted to help understand mercury transportation. The sorbent was injected together with the selected representative bituminous coal fly ash from a power station at a ratio of 4.4:1000, so the mercury in the ash is also a mercury source in the material balance calculation. The compressed air 785 or simulated flue gas was believed to be mercury-free. The ash in the horizontal tube was found to be so little that it could be ignored. Although there was a bottom container and minicyclone to collect the ash, a part of ash still escaped with the flue gas, so the ratio of injected ash to the sum of bottom ash and cyclone ash was adopted as a reference. Based on the above analysis, the mercury mass balance was calculated as MHg, input = CHg, gas phase, introduced × Minjected MHg, output = CHg, + YHg, in ash ash , (3) gas phase, introduced + (YHg, × (1.0 − ) × Q × t in bottom ash × Mbottom ash in cyclone ash × Mcyclone ash )/(Mbottom ash ash ) × Minjected ash , (4) + Mcyclone R = MHg, × Q × t + YHg, output /MHg, input , (5) where the flow rate Q was 8.33 m3 /s and injected ash was 0.05 kg. The calculated mercury mass balance results for 18 experimental runs of sorbent injection tests show that the recovery of mercury ranged from 90% to 110%; so the experimental data are acceptable. On the other hand, most of them are under 100%. This is possibly because the little ash together with the injected sorbent escaping with the flue gas was fine and contained more mercury; however, such ash entered the exhaust and was lost to the atmosphere. During the second phase of experiments on the lab-scale reactor and experiments on the pilot-scale slipstream reactor, the ash collected at the bottom and cyclone was insufficient to analyze the mercury concentration in it; so the mercury mass balance was not calculated for these experiments. 3.3. Sorbent adsorption efficiencies under different injection conditions Different sorbents were injected under varying conditions on the lab-scale multiphase flow reactor. The residence time was 1–2.5 s, temperature inside the reactors was 150–170 ◦ C, and sorbent injection rate was 3.85 × 10−5 .7.7 × 10−5 kg/m3 . In the first phase, compressed air and simulated flue gas were used as carrier gases in the multiphase flow reactor and real flue gas was introduced into the reactor during the second phase. The experimental results in the first phase show that different sorbents have different mercury removal ability, ranging from 98.3% to 23.0%. A part of the experimental results is shown as Table 2. It demonstrates that, compared with compressed air, simulated flue gas inhibited the mercury removal efficiency. It was possibly because SO2 in the simulated reduced mercury oxidization and capture. On the other hand, longer residence time and higher injection rate help improve the mercury removal. The temperature inside the multiphase flow reactor also has effect on the mercury adsorption efficiency, and sorbent has higher mercury adsorption efficiency at lower temperature. Author's personal copy J. Wu et al. / Chemical Engineering Science 63 (2008) 782 – 790 Mercury Concentration, ng / Nm3 786 20000.00 start injection HgT Hg (0) 15000.00 10000.00 start injection 5000.00 stop injection stop injection 0.00 19:12 21:36 0:00 2:24 Time (date) Fig. 5. The changing history of Hg concentration during sorbent injection in flue gas. Table 2 Experimental results on the lab-scale multiphase flow rate Injected sorbent Carrier gas Temperature inside the reactor (◦ C ) Residence time (s) Sorbent injection rate (∗ 10−5 kb m3 ) Hg (0) adsorption efficiency (%) A1 A1 A1 Compressed air Simulated flue gas Simulated flue gas 150 150 150 1 1 2.5 3.85 5.78 7.70 84.1 77.6 82.1 B1 B1 Compressed air Simulated flue gas 150 150 1 2.5 3.85 7.70 32.9 50.1 C1 C1 Compressed air Compressed air 150 170 1 1 3.85 5.13 98.3 97.0 Fig. 6. Hg adsorption at difference SO2 in the flue gas. According to the data in Table 2, we can get Hg adsorption efficiencies at different SO2 concentration in the flue gas and at different residence time. They are shown in Figs. 6 and 7. The mercury adsorption efficiency of the sorbent C1 changed much when the SO2 concentration changed from 2 ppm in the air to 1000 ppm. For sorbent A1, its mercury adsorption efficiency reduced from 84.1% to 77.6% when the SO2 concentration changed from 2 ppm in the air to 1106 ppm in the simulated flue gas even the injection rate was increased from 3.85 × 10−5 to 5.78 × 10−5 kg/m3 . When residence time increased to 2.5 s and injection rate increased to 7.7 × 10−5 kg/m3 , the mercury adsorption of sorbent A1 in the simulated flue gas was still lower than that in the compressed air. It shows that SO2 has big inhibition on mercury adsorption Author's personal copy J. Wu et al. / Chemical Engineering Science 63 (2008) 782 – 790 787 Fig. 7. Hg adsorption at difference residence time. Hg adsorption efficiency 120 100 C1 E B (%) 80 60 40 20 0 Hg (T) at flue gas Hg (0) at flue gas injection condition Hg (0) at compressed air Fig. 8. Hg adsorption efficiencies at different injection conditions. ability. The mercury adsorption efficiency of sorbent B1 increased much when residence extended from 1.0 to 2.5 s; however, there was little mercury adsorption efficiency change of sorbent A1 when residence time changed. This is possibly due to different physical and chemical characteristics of the sorbents. In the second phase, real flue gas from the utility duct was introduced into the multiphase flow reactor. The experimental data were compared with that in the first phase, and the results are shown in Fig. 8. The temperature inside the reactor was 170 ◦ C, the residence time was 1.0 s, and the sorbent injection rate was 5.13 × 10−5 kg/m3 . It was shown that different types of sorbents have different mercury removal efficiency. This was possibly due to different physical and chemical characteristics of the sorbents. The typical SEM (scanning electron microscopy) results for sorbent C1 are shown as Fig. 9. The SEM analysis results show that there is bromine as well as carbon in the sorbent C1. The main content of sorbent B was carbon and no halogen was in the sorbent B. The carbon mainly adsorbs the oxidized mercury. It is easy to yield chemical bond between bromine and elemental mercury, so bromine can help sorbent to improve elemental adsorption efficiency. Fig. 8 demonstrates that sorbent C1 mainly adsorb elemental mercury and sorbent B adsorb more oxidized mercury than elemental mercury, and that the sorbent C1 has much higher mercury adsorption efficiency than that of sorbent B. The bromine helps to improve the mercury adsorption efficiency. The sorbent E is a non-carbon based sorbent, and there were aluminum, silicon, sulfur, chlorine, calcium, manganese, iron, copper, and other inorganic contents instead of carbon in it. The main mercury adsorption mechanism of the sorbent E may be its porosity and specific surface area. At the same time, chlorine in sorbent E helps capture and oxidize elemental mercury through chemical bond to improve the mercury adsorption Author's personal copy 788 J. Wu et al. / Chemical Engineering Science 63 (2008) 782 – 790 Fig. 9. SEM results for sorbent C1. efficiency, so that sorbent E has higher mercury removal ability than sorbent B. There was also chlorine in sorbent D, which can help explain why it has high adsorption efficiency on elemental mercury. The sorbent has lower mercury adsorption efficiency in real flue gas than that in the compressed air. This was possibly because SO2 , NOx and other contents in the flue gas inhibited the mercury capture and/or oxidization by the sorbent. During experiments on the pilot-scale slipstream reactor, the sorbent injection feeder was modified. Before modification, the sorbent entered the reactor with one port vertical to the reactor and its injection direction was same as the flue gas flow. After modification, the sorbent entered the reactor through four ports uniformly distributed at each side of the reactor and their injection directions were vertical to the reactor and vertical to the flue gas flow. When the residence time, temperature inside the reactor and injection rate were kept at 1.0 s, 170 ◦ C and 2.57 × 10−4 kg/m3 , respectively, the experimental results of different sorbent injection before and after the sorbent injection feeder modification were shown in Table 3. It demonstrated that the capture efficiencies of the total mercury and elemental mercury of all the sorbents were improved at different levels after the sorbent injection system modification. It was possibly because the modified sorbent injection system enhanced the mixture between the sorbent and mercury and lengthened their contact and reaction time, which helped the process of mercury capturing of the sorbents. On the other hand, the mercury removal efficiency with 2.57 × 10−4 kg/m3 sorbent injection at the pilot slipstream reactor was similar to that with 5.13 × 10−5 .7.7 × 10−5 kg/m3 at full-scale. It may be because the aerodynamic field inside the pilot-scale slipstream reactor needs to be further optimized to improve the distribution of the injected sorbent and mercury capturing process, and it is in consideration. The changing of mercury removal efficiency with the injection rate on the pilot-scale slipstream reactor is shown in Fig. 10. It shows that the mercury removal efficiency will be higher when the injection rate increased; however, the increasing extent became less and less. Different type of sorbent has different mercury adsorption efficiency relative to its own physical and chemical characteristics. For the purpose of comparison, the Hg adsorption efficiency of standard PAC, as derived from the literature (Withum et al., 2005) is plotted in Fig. 10 along with our experimental results. The PAC was injected at Pleasant Prairie Power Plant (PPPP) combusting sub-bituminous coal. The shape of the PAC curve follows the same trend as that of the data in the present paper. The difference in magnitude of Hg removal between PAC and adsorbents C1, D and E is reflective of experimental conditions, particularly adsorbent injection efficiency. The sorbent C1 is carbon based and its removal efficiency on mercury total attained on the pilot-scale slipstream reactor with injection rate of 2.57 × 10−4 kg/m3 is 49.6%. The removal efficiency of PAC on mercury total at the full-scale power station with injection rate of 7.7 × 10−5 kg/m3 is 56.0%. The absolute difference between them is 6.4% and the relative difference is 11.4%. The injection rate is one of the reasons. The sorbent injection rate of 2.57 × 10−4 kg/m3 at the pilot-scale slipstream reactor was around equal to 5.13 × 10−5 .7.7 × 10−5 kg/m3 at the full scale. In fact, the removal efficiency of PAC on mercury total at the full-scale power station with injection rate of 5.13 × 10−5 kg/m3 is 50.0%, which is close to 49.6% at the pilot scale slipstream reactor. At the same time, the coal type and boiler operation conditions may make part contribution to the difference. Sorbent E was chosen to conduct injection test at a power station burning bituminous coal. The sorbent injection port was as before ESP. The mercury concentration changing with the sorbent injection was monitored by Hg SCEM and Ontario hydro (OH) method. The injection rate was around 7.7 × 10−5 kg/m3 . The mercury removal efficiency was 41.4% on Hg (0) and 35.4% on Hg (T). The result attained on the pilot-scale slipstream reactor with injection rate of 2.57×10−4 kg/m3 was 36.1% and 46.2%. The comparison between them was shown as Fig. 11. It demonstrates that the data of mercury removal efficiency attained from pilot-scale slipstream reactor can be used to predict the results at the full-scale power station. For Author's personal copy J. Wu et al. / Chemical Engineering Science 63 (2008) 782 – 790 789 Table 3 Experimental data for the pilot-scale tests Injected sorbent Hg(VT) capture efficiency (%) after feeder modification Hg(VT) capture efficiency (%) before feeder modification Hg(0) capture efficiency (%) after feeder modification Hg(0) capture efficiency (%) before feeder modification C1 D E 49.6 14.5 36.1 40.1 10.5 28.8 63.5 80.1 46.2 50.1 67.0 36.4 Fig. 10. The mercury removal efficiencies at different injection rates (pilot-scale). Hg Capturing Efficiency (%) 100 90 Lab-scale with compressed air Pilot-scale with real flue gas Power Plant with real flue gas Lab-scale with simulated flue gas 80 70 60 50 40 30 20 10 0 Hg (0) adsorption Hg (T) adsorption injection condition Fig. 11. The mercury removal efficiencies of sorbent E at different scales. the removal efficiency on the mercury total, the absolute difference between them is 5.3% and the relative difference is 12.8%. Considering relationship between the sorbent injection rate (2.57 × 10−4 kg/m3 ) at the pilot scale slipstream reactor and that at the full scale (5.13 × 10−5 .7.7 × 10−5 kg/m3 ), the difference may be less. Together with the comparison result between sorbent C1 injected on the pilot-scale slipstream reactor and PAC injected Author's personal copy 790 J. Wu et al. / Chemical Engineering Science 63 (2008) 782 – 790 on the full-scale power station, the predicted results are with around 6% of absolute difference and 12% or less of relative difference. 4. Conclusions 1. The sorbent injection tests on the lab-scale multiphase flow reactor and pilot-scale slipstream reactor systems could simulate the working conditions of the full-scale power plant and provide accurate information of sorbent evaluation in the flue gas atmosphere. The data of mercury removal efficiency attained from pilot-scale system can be used to predict the results at the full-scale power plant, and the relative difference is around 12%. 2. There was significant difference between the mercury removal efficiencies of tested sorbents, varying from 98.3% down to 23%. It is due to different physical and chemical characteristics of the sorbents and different reaction conditions. The halogen in the sorbent can help improve the mercury capture efficiency. The coal type and boiler operation parameters may impact the mercury removal efficiencies. SO2 in the flue gas may inhibit the mercury oxidation and capturing. 3. The mercury capturing efficiency of the sorbents is affected by the injection rate, residence time and mixture between the sorbent and flue gas. The tested sorbents had higher mercury capture efficiency with higher injection rate and longer residence time when other conditions were held constant. At the pilot-scale slipstream reactor, four injection ports vertical to the flue gas flow direction could help improve mixture of sorbent and flue gas so that the mercury removal efficiency became higher. Notation C Hg (0) Hg (2+) Hg (T) M ppm Q R t Y concentration, kg/m3 elemental mercury oxidized mercury mercury total mass, kg Parts per million flow rate, m3 /s ratio, % injection duration time, s concentration, kg/kg Greek letter mercury adsorption efficiency Acknowledgments This work was partially supported by the U.S. Department of Energy (Cooperative Agreement No. DE-FC26-03NT41840), Key Fund of Shanghai Science Technology Committee (Grant No. 062312059), Shanghai Pujiang Program (07PJ14045) and Shanghai Leading Academic Discipline Project (No. P1302). The authors would like to thank Mr. John Smith, Martin Cohron, and Stan Herren for their help during the setup of the reactor systems. References Brown, T.D., 1999. Mercury measurement and its control: what we know, have learned, and need to further investigate. Journal of the Air and Waste Management Association 49 (6), 628–640. Cao, Y., Liu, X., Liu, K.L., Yang, H., Riley, T.R., Pan, W.P., 2004. The labscale sorbent injection testing on mercury capture with follow-up solid–gas mixture. Preparation Paper—American Chemical Society, Fuel Chemistry 49 (2), 918. Keating, M.H., Mahaffey, K.R., Schoeny, R., Rice, G.E., Bullock, O.R., Ambrose, R.B. Jr., Swartout, J., Nichols, J.W., 1997. Mercury study report to Congress, EPA-452/R-97-003 through 010’U.S. Environmental Protection Agency. Office of Air Quality Planning and Standard and Office of Research Development, Research Triangle Park, NC, vols. I–VIII. Kellie, S., Duan, Y., Cao, Y., Chu, P., Mehta, A., Carty, R., Liu, K., Pan, W., Riley, J., 2004. Mercury emissions from a 100-MW wall-fired boiler as measured by semi-continuous mercury monitor and Ontario hydro method. Fuel Progressing Technology 85, 487–499. Pavlish, J.H., Holmes, M.J., Benson, S.A., Crocker, C.R., Galbreath, K.C., 2004. Application of sorbents for mercury control for utilities burning lignite coal. Fuel Progressing Technology 85, 563–576. U.S. EPA,1998. A study of hazardous air pollution emissions from utility steam generating units: final report to Congress; EPA-453/R-98-004a. U.S. EPA Office of Air Quality Planning and Standards, U.S. Government Printing Office, Washington, DC. U.S. Environmental Protection Agency, 2005. Clean air mercury rules. Accessed on December 2005. http://www.epa.gov/mercuryrule/index.htm. Withum, J.A., Tseng, S.C., Locke, J.E., 2005. Mercury emissions from coalfired facilities with SCR-FGD systems. DOE/NETL’s Mercury Control Technology R&D Program Review, July 12–14, 2005. Wu, J., Chen, B., Yang, H., Cao, Y., He, B., Wu, A., Pan, W.P., 2005. Comparison between dry and wet based mercury SCEM. The 30th International Technical Conference on Coal Utilization and Fuel Systems, April 17–21, 2005. Wu, J., Cao, Y., Li, S., Cui, H., Lu, P., Pan, W.P. 2006a. Evaluation of mercury sorbents on a lab-scale multi-phase flow reactor and on a pilotscale slipstream reactor. 232nd ACS National Meeting, San Francisco, CA, September 10–14, 2006. Wu, J., Cao, Y., Wu, A., Li, S., Pan, W.P., 2006b. Evaluation of mercury sorbents in a lab-scale multi-phase flow reactor. The 9th Annual EPA, DOE, EPRI, EEI Conference on Clean Air, Mercury, Global Warming and Renewable Energy. The Westin La Paloma, Tucson, Arizona, USA, January 22–25, 2006. Yan, R., Liang, D.T., Tsen, L., Wong, P.Y., Lee, Y.K., 2004. Benchscale experimental evaluation of carbon performance on mercury vapor adsorption. Fuel 83, 2401–2409.