OSU Memorial Union Save Energy Now Industrial Assessment Report For

advertisement

Save Energy Now

Industrial Assessment Report

For

OSU Memorial Union

26th and Jefferson

Corvallis, OR 97331

INDUSTRIAL ASSESSMENT CENTER

OREGON STATE UNIVERSITY

INDUSTRIAL ASSESSMENT CENTER

Sponsored by

U.S. Department of Energy

Managed by

Center for Advanced Energy Systems

Rutgers University

Assessment Report No. 2001

December 17, 2008

Joseph F. Junker, Assistant IAC Director

________________________________

Peter Hanslits, Lead Analyst

________________________________

Assessment Participants

Bryan Kilgore

Elsie Deland

Yuming Qui

Justin Olson

Dr. George Wheeler

IAC Director

Batcheller Hall 341

Corvallis, OR

97331-2405

(541) 737-2515

Motor Analyst

Lighting Analyst and Safety Officer

Chiller Analyst

Energy Analyst

Joseph F. Junker

Assistant Director

Batcheller Hall 344

Corvallis, OR

97331-2405

(541) 737-5034

PREFACE

The work described in this report is a service of the Oregon State University Industrial

Assessment Center (IAC). The project is funded by the U.S. Department of Energy’s Office of

Energy Efficiency and Renewable Energy (EERE) Industrial Technologies Program and

managed by Rutgers University Center for Advanced Energy Systems.

The primary objective of the IAC is to identify and evaluate opportunities for energy

conservation, waste minimization, and productivity improvements through visits to industrial

sites. Data is gathered during a one-day site visit and assessment recommendations (ARs) are

identified. Some ARs may require additional engineering design and capital investment. When

engineering services are not available in-house, we recommend that a consulting engineering

firm be engaged to provide design assistance as needed. In addition, since the site visits by IAC

personnel are brief, they are necessarily limited in scope and a consulting engineering firm could

be more thorough.

We believe this report to be a reasonably accurate representation of energy use, waste generation,

and opportunities in your building. However, because of the limited scope of our visit, the U.S.

Department of Energy, Rutgers University, and the Oregon State University Industrial

Assessment Center cannot guarantee the accuracy, completeness, or usefulness of the

information contained in this report, nor assume any liability for damages resulting from the use

of any information, equipment, method or process disclosed in this report.

Pollution prevention recommendations are not intended to deal with the issue of compliance with

applicable environmental regulations. Questions regarding compliance should be addressed to

either a reputable consulting engineering firm experienced with environmental regulations or to

the appropriate regulatory agency. Clients are encouraged to develop positive working

relationships with regulators so that compliance issues can be addressed and resolved.

The assumptions and equations used to arrive at energy, waste, and cost savings for the

recommended ARs are given in the report. We believe the assumptions to be conservative. If you

do not agree with our assumptions you may follow the calculation methodologies presented

using revised assumptions to develop your own estimates of energy, waste, productivity, and cost

savings.

Please feel welcome to contact the IAC if you would like to discuss the content of this report or

if you have another question about energy use or pollution prevention. The IAC staff that visited

your building and prepared this report is listed on the preceding page.

TABLE OF CONTENTS

1.

Introduction....................................................................................................................... 1

2.

Executive Summary .......................................................................................................... 2

3.

Assessment Recommendations ......................................................................................... 5

4.

AR No. 1.

Pipe Insulation ........................................................................................ 5

Justin Olson

AR No. 2.

Chiller ..................................................................................................... 6

Yuming Qui

AR No. 3.

Winter HVAC ........................................................................................ 7

Peter Hanslits

AR No. 4.

Oven Exhaust Fan .................................................................................. 8

Bryan Kilgore

AR No. 5.

Skylights ................................................................................................. 9

Elsie Deland

AR No. 6.

Halogen Lights ..................................................................................... 10

Elsie Deland

Calculation Methodology ............................................................................................... 11

AR No. 1.

AR No. 2.

AR No. 3.

AR No. 4.

AR No. 5.

AR No. 6.

Pipe Insulation ...................................................................................... 11

Chiller ................................................................................................... 14

Winter HVAC ...................................................................................... 21

Oven Exhaust Fan ................................................................................ 27

Skylights ............................................................................................... 30

Halogen Lights ..................................................................................... 35

APPENDIX

A. Utilities ........................................................................................................................... 41

A.1. Energy Definitions .................................................................................................. 41

A.2. Energy Conversions ................................................................................................ 46

A.3. Energy Accounting ................................................................................................. 47

A.4. Energy Use .............................................................................................................. 55

B. Motors ............................................................................................................................. 59

B.1. Boiler Motor Definitions ......................................................................................... 59

B.2. Motor Inventory ...................................................................................................... 63

B.3. Motor Applications ................................................................................................. 64

B.4. Motor Use Summaries ............................................................................................ 65

B.5. Motor Economics .................................................................................................... 65

B.6. Motor Performance ................................................................................................. 66

B.7. Motor Power Factor ................................................................................................ 67

C. Lighting........................................................................................................................... 68

C.1. Lighting Worksheet Definitions.............................................................................. 68

C.2. Lighting Inventory .................................................................................................. 74

D. Refrigeration ................................................................................................................... 76

D.1. Refrigeration Worksheet Definitions ...................................................................... 76

1. INTRODUCTION

This report describes how energy is used in your building, and includes our recommendations on

cost effective steps you can take to reduce your energy and waste costs. The contents of this

report are based on our recent visit to your building. The report is divided into 4 major sections

and 4 appendices:

1. Introduction. The purpose, contents and organization of the report are described.

2. Executive Summary. Your energy use and waste generation costs, energy and waste

savings, and our recommendations are summarized here with details in the following

sections.

3. Assessment Recommendations. This section contains our Assessment Recommendations

(AR), briefly highlights the current and proposed systems and summarizes the cost savings

available upon implementation. Some of our recommendations will require a significant

investment to implement, while others will cost little or nothing. We have grouped our

recommendations by category and then ranked them by payback period.

4. Calculation Methodologies. This section includes detailed calculations for the Assessment

Recommendations (AR). It includes any data that was collected during the audit, assumptions

we use to estimate savings, our estimate of implementation cost, and the simple payback. We

have grouped the calculations in the same order as the AR’s in Section 3.

Appendix A: Utilities. Your utility bills and energy use by process are summarized and plotted

in detail. Due to the changes in rate schedules and adjustments our calculations are an

approximation and may not be exactly consistent with your bills. When available, we also

include water and solid waste bills.

Appendix B: Motors. Motors are typically a large energy user. This section contains your motor

information including: nameplate information, area of the plant the motor is located in, and

monthly energy use in each section of the plant.

Appendix C: Lighting. The number and type of lighting fixtures are recorded for each area.

This appendix also includes the Lighting Worksheet Definitions, which describe the symbols and

terminology used in our lighting calculations. The lighting power and annual energy use for each

plant area are summarized in the Lighting Inventory worksheet.

Appendix D: Refrigeration. This appendix includes the Refrigeration Worksheet Definitions,

which describes the accompanying Refrigeration Energy Savings worksheets. The worksheet

uses bin weather data to model the refrigeration compressor’s operating conditions.

1

2. EXECUTIVE SUMMARY

This section includes a summary of energy use and waste generation in your building, our

recommendations, and total energy, waste, and cost savings of all recommendations if

implemented.

Recommendation Summary. The following is a brief explanation of each of the

recommendations made in this report. If all 6 recommendations are implemented, the total cost

savings will be $29,430 and will pay for costs in 0.3 years.

AR No. 1: Pipe Insulation

Insulate exposed hot steam and chilled water lines. This will reduce energy lost through these

pipe surfaces by 92%.

AR No. 2: Chiller

Reduce the minimum R-22 discharge (head) pressure on both chiller units. This will reduce

chiller operation costs by 25% through a reduction in compressor energy use.

AR No. 3: Winter HVAC

Turn off five major air handling units during winter night time hours. This will reduce total

building steam use by 31% and reduce fan energy use by 33%.

AR No. 4: Oven Exhaust Fan

Turn off the Pangea oven exhaust fan at night and during the summer. This will reduce electrical

costs for this fan by 43% and will reduce conditioned air exhaust when cooling or heating is

needed.

AR No. 5: Skylights

Install photo sensor/timer units on T8 fixtures in skylights to reduce operating hours. Replace

yellow glass with clear glass to allow more light into hallways. This will reduce lighting costs by

46% in this area.

AR No. 6: Halogen Lights

Replace Halogen fixtures in the ballroom with Compact Fluorescent fixtures. This will reduce

energy usage in this area by 58%.

2

Our recommendations are summarized in the following table.

Assessment Recommendation Summary

Energy

Cost

Implementation

AR#

Description

1

Pipe Insulation

2

Chiller

3

Winter HVAC

4

Oven Exhaust Fan

5

Skylights*

6

Halogen Lights*

Totals

(MMBtu) Savings

44.0

$631

415.3

$5,700

1,301.3 $24,414

58.0

$789

20.6

$415

39.7

$483

1,878.9 $32,432

Cost

$298

$6,000

$0

$100

$1,040

$2,533

$9,963

Payback

(years)

0.5

1.5

Immediate

0.1

2.5

5.2

0.3

*Includes Incentives

Total savings are the sum of the savings for each recommendation. Some of the

recommendations may interact. Therefore, actual savings may be less than the total indicated

above. In our calculations we indicate where we have assumed that other recommendations will

be implemented in order to provide a realistic estimate of actual savings. Total savings, including

interactions among recommendations, can be better estimated after you select a package of

recommendations.

Savings Summary. Total cost savings are summarized by energy cost savings. We then

normalize savings as a percentage of annual building energy costs. For example, Energy Cost%

is energy cost savings divided by the total energy cost from the Utility Summary.

Savings Summary

Source

Qty.

Units

Cost Savings

Energy Cost %

$32,432

17.7%

Energy 1,878.9 MMBtu

Existing Energy Use Summary. We used your utility bills to determine annual energy use for

all fuels. From these bills we summarized annual energy consumption at your plant in the

following table.

Energy costs and calculated savings are based on the incremental cost of each energy source. The

incremental rate is the energy charge first affected by an energy use reduction and is taken from

your utility rate schedules. For example, electrical use and savings include energy (kWh),

demand (kW), reactive power charges (KVARh or power factor), and other fees such as basic

charges, transformer rental, and taxes. However, if a recommendation does not affect your

electrical demand, such as turning off equipment at night, then we use the cost of electrical

energy alone. The fuel costs we used can be found in the Energy Accounting Summary in

Appendix A.

3

Existing Energy Use Summary

Source

Electric Energy

Natural Gas

Steam

Totals

Qty.

1,972,560

10,890

4,067,500

Units

kWh

Therms

lbs

4

MMBtu Energy %

Cost

Cost %

6,732

57.5%

$91,527 50.0%

1,089

9.3%

$12,244

6.7%

3,880

33.2%

$79,316 43.3%

11,702

100.0% $183,087 100.0%

3. Assessment Recommendations

AR No. 1

Pipe Insulation

Recommendation

Insulate exposed piping that is significantly hotter or colder than ambient temperature. This will

reduce energy lost through pipe surfaces by 92%.

Assessment Recommendation Summary

Energy Savings

(MMBtu)

44.0

Cost

Savings

$631

Implementation

Cost

$298

Payback

(years)

0.5

Background

About 33 feet of exposed pipe runs in the commons and bookstore maintenance rooms. Uninsulated pipes contribute to energy losses in heating and cooling systems.

Proposal

Insulate bare piping with suggested insulation to reduce

further energy losses. Insulating these lines will save

energy. Typical types of insulation used for pipes are

listed below:

•

•

•

•

Polystyrene

High density fiberglass shaped for pipes or flat

sections

Blankets of fiberglass or mineral wool

Spray-on foam (Primarily on cooling systems)

We have recommended polystyrene with an aluminum

jacket. This type of insulation results in a payback period

of 0.6 years.

Photo courtesy of The Boiler Burner

For detailed calculation, see Pipe Insulation - Calculation Methodology later in this report.

5

AR No. 2

Chiller

Recommendation

Reduce the approach temperature on both of the chiller cooling towers. This will reduce

compressor energy use while maintaining your chilled water temperature.

Assessment Recommendation Summary

Energy

Energy

Cost

Implementation Payback

(MMBtu) (kWh)* Savings

Cost

(years)

415.3

121,800 $5,700

$6,000

1.1

*1 kWh = 3,410 Btu

Background

Chillers use a refrigerant loop to chill water and transfer the heat to ambient air. The chiller

compressor pressurizes refrigerant, raising its temperature and pressure, then pumps refrigerant

to the condenser where refrigerant condenses into a liquid, rejecting heat. The approach

temperature difference between chiller refrigerant and water approaching the condenser is a good

indicator of whether excess compression is required at the compressor. Your condenser’s

minimum approach temperature is approximately 54 °F. We recommend an approach

temperature of 20 °F.

Proposal

Reduce condenser approach temperature.

This will reduce compressor energy use

while maintaining chilled water

temperature. It is likely that the chiller heat

exchangers will have to be cleaned to lower

approach temperature without effecting

chiller capacity.

As detailed in the Chiller - Calculation

Methodology, there is a 1.1 year payback

with $6,000 implementation cost.

6

AR No. 3

Winter HVAC

Recommendation

Turn off the five major air handling units during winter night time hours. The estimated

reduction in total building steam use is 31% and the estimated reduction in electricity usage for

these five fans is 33%.

Assessment Recommendation Summary

Energy

Steam Energy Net

Implementation

(MMBtu) (lbs)** (kWh)* Savings

Cost

1,301.3 1,273,843 25,251 $24,414

$0

*1 kWh = 3,410 Btu

**1 lb Steam = 903 Btu

Payback

(years)

Immediate

Background

Five major HVAC units currently run constantly throughout the year. During the summer,

HVAC fans are needed at night to circulate cool outside air into the building for a night flush.

However, during the winter, these fans exhaust steam heated air to the outside while bringing in

chilled air that must be heated. While HVAC is needed during the day for circulation, nighttime

usage can be eliminated. Turning off major HVAC units at night during the winter will

significantly reduce building costs without negatively effecting air quality.

Proposal

Turn off five major air handling units at night during

the winter. This action is expected to result in

significant energy savings without negatively effecting

building comfort.

As detailed in the Winter HVAC - Calculation

Methodology, there is an immediate payback with no

implementation cost.

Image courtesy of www.jmcmechanical.com

7

AR No. 4

Oven Exhaust Fan

Recommendation

Turn off the Pangea oven exhaust fan at night and during the summer. This will reduce fan

electrical costs by 43% and loss of conditioned air when cooling or heating is needed. The

heating and cooling savings are not taken into account in this recommendation.

Assessment Recommendation Summary

Energy

Energy

Cost

Implementation Payback

(MMBtu) (kWh)* Savings

Cost

(years)

58.0

17,010

$789

$100

0.1

*1 kWh = 3,410 Btu

Background

The kitchen oven exhaust fan runs constantly, even at night and during the summer when the

ovens are not running. During these times the oven exhaust fan is unnecessarily exhausting

conditioned air and consuming energy.

Proposal

Turn off Pangea oven exhaust fan during nights

throughout the year and keep exhaust fan off during

the summer when the ovens are not running. This

should save approximately 43% of the energy

consumed by exhaust fan.

As detailed in the Oven Exhaust Fan - Calculation

Methodology, cost savings will pay for

implementation costs in 0.1 years.

Image Courtesy of: www.greenheck.com

8

AR No. 5

Skylights

Recommendation

Install photo sensor/timer units on T8 fixtures in skylights to reduce operating hours. Replace

yellow glass with clear glass to allow more light into hallways. This will reduce lighting costs by

46% in this area.

Assessment Recommendation Summary

Energy

Energy

Cost

Implementation Payback**

(MMBtu) (kWh)* Savings

20.6

6,574

$415

*1 kWh = 3,410 Btu

**Cost after incentives

Cost**

$1,492

(years)

3.6

Background

While visiting your building we observed 15 skylights with yellowed glass. Each skylight

contained a T8 fixture that was lit during our visit.

Proposal

We recommend installing a photo sensor/timer unit for each skylight T8 fixture and replacing

yellow glass panes in skylights with clear glass panes. Installing photo sensor/timer units will

reduce the time each light is on and installing clear glass will allow more natural light into the

second floor hallway so the T8 fixtures will be unnecessary on sunny days.

As detailed in the Skylights - Calculation Methodology, there is a 3.6 year payback with $1,492

implementation cost after incentives.

9

AR No. 6

Halogen Lights

Recommendation

Replace halogen fixtures in the ballroom with compact fluorescent fixtures. This will reduce

lighting energy usage in this area by 58%.

Assessment Recommendation Summary

Energy

Energy

Cost

Implementation Payback**

(MMBtu) (kWh)* Savings

39.7

12,650

$483

*1 kWh = 3,410 Btu

**Savings after incentives

Cost**

$2,533

(years)

5.2

Background

While visiting your facility we observed 45 halogen lights in the ballroom. According to

maintenance and a report prepared by an outside source, the halogen lights are 450 watt mini

candelabra lights. We observed them operating on a dimmer at 80% output.

Proposal

Replace candelabra base sockets with mogul base sockets that

will accommodate 150 watt non-dimmable compact fluorescent

bulbs. This will reduce energy consumption and heat produced

by the fixtures. Dimmable compact fluorescent bulbs and

fixtures are available and will save additional energy when

dimmed. They also cost more, so implementation costs will

increase.

As detailed in the Halogen Lights - Calculation Methodology,

there is a 5.2 year payback with $2,553 implementation cost.

Photo courtesy of Amazon.com

10

4. Calculation Methodology

AR No. 1

Pipe Insulation

Calculation Methodology

Recommendation

Insulate exposed piping that is significantly hotter or colder than ambient temperature. This will

reduce energy lost through pipe surfaces by 92%.

Assessment Recommendation Summary

Energy Savings

Cost

(MMBtu)

Savings

44.0

$631

*1 kWh = 3,410 Btu

Implementation

Cost

$298

Payback

(years)

0.5

Data Collected Summary

The bookstore maintenance room (BMR) and commons maintenance room (CMR) contain bare

piping with energy loss. The following table summarizes data collected from those locations.

Bare Pipe Data*

Length Diameter Surface Temp. Ambient Temp.

Area

Description

(in.)

(in.)

(˚F)

(˚F)

BMR Unidentified

84.0

3.8

185˚

88˚

BMR Unidentified

34.3

3.8

210˚

88˚

CMR Steam

28.5

17.0

200˚

85˚

CMR Steam

58.0

4.5

200˚

85˚

CMR Unidentified

49.0

2.3

150˚

85˚

*Only bare pipes with significant temperature differential from ambient are included

Savings Analysis

Uninsulated pipes contribute to energy losses in heating and cooling systems. The system must

make up for heat losses due to radiation and convection. Reducing the heat transfer coefficient

by adding insulation will yield energy and cost savings. Note that the following calculations

assume that the fluid or gas temperature in the pipe is constant.

We used 3E+ software, a free insulation calculation tool prepared by the North American

Insulation Manufacturer’s Association and made available by U.S. Department of Energy, to

compare current and proposed energy losses and cost savings for several insulation thicknesses.

11

Cost savings are based on a steam energy cost of $0.0195/lb. The following table shows different

thicknesses taking the Bookstore Maintenance Room piping at 185˚F as an example.

Energy Savings Summary for Bookstore Maintenance Room

Energy

Insulation

Surface

Energy

Cost

Thickness Temperature Efficiency

Cost

Heat Loss Savings

(inches)

(°F)

(%)

($/ft/yr) (Btu/ft/yr) ($/ft/yr)

Bare

184.9

$27.86 1,860,000

0.5

132.4

80.7

$5.39

359,200

$22

1.0

120.6

87.1

$3.59

239,400

$24

1.5

114.1

90.4

$2.68

178,400

$25

2.0

109.7

92.5

$2.11

140,200

$26

2.5

106.6

93.8

$1.72

114,300

$26

Cost savings (CS) can be found as:

CS

=

=

=

=

Cost savings

FT x EC

7 ft x $26/ft

$182

FT

= Feet of pipe to be insulated

= 7 ft

EC

= Energy cost savings from 3E plus software using 2.0 inch thick insulation

= $26/ft

Where,

Total savings for all bare piping is summarized in the table below. 3E+ calculated each scenario

and the best result was chosen (as in example above).

Area

BMR

BMR

CMR

CMR

CMR

Total

Description

Unidentified

Unidentified

Steam

Steam

Unidentified

Total Cost Savings Summary

New

Energy Cost

Insulation Surface Temp Efficiency

Savings

Thickness

(˚F)

(%)

($/ft)

2.0

109.7

92.4

$26

2.5

110.5

94.1

$35

2.0

110.1

84.2

$30

2.0

110.1

84.2

$30

2.5

98.3

82.4

$15

12

Pipe

Length

(ft.)

7.0

4.9

2.4

4.8

4.0

32.3

Energy

Cost

Savings

$182

$172

$73

$145

$59

$631

Cost Analysis

Implementation costs include material costs for the following insulation:

•

•

•

Insulation Layer 1: Polystyrene, Varied

Outer Jacket Material: Aluminum, oxidized, in service

Outer Surface Emittance 0.1

We used RSMeans Building Construction as an estimation tool of installation cost for the

insulation. The insulation costs from RSMeans Building Construction ($2.87 /ft) seemed low

from previous experience, so we added additional costs of $10/ft for installation to maintain a

conservative estimate.

Area

BMR

BMR

CMR

CMR

CMR

Total

Total Cost Summary

Pipe Length

Description

(ft.)

Unidentified

7.0

Unidentified

4.9

Steam

2.4

Steam

4.8

Unidentified

4.0

Cost

($/ft)

12.9

12.9

12.9

12.9

12.9

Insulation

Cost

$91

$63

$31

$62

$51

$298

Cost savings will pay for implementation in 0.6 years.

Incentive Summary

Incentives don’t apply to energy efficiency projects with less than a one year payback. However,

if this project is combined with another that creates a total project payback of greater than one

year, then some energy incentives may apply.

13

AR No. 2

Chiller

Calculation Methodology

Recommendation

Reduce the approach temperature on both of the chiller cooling towers. This will reduce

compressor energy use while maintaining your chilled water temperature.

Assessment Recommendation Summary

Energy

Energy

Cost

Implementation Payback

(MMBtu) (kWh)* Savings

Cost

(years)

415.3

121,800 $5,700

$6,000

1.1

*1 kWh = 3,410 Btu

Data Collected Summary

From building personnel

• Chillers don’t run in between October and February

Assumptions

• Chiller heat exchangers will require a thorough cleaning or additional capacity

From nameplates and observation

Chiller Nameplate and Observed Operating Conditions Summary

East Chiller

West Chiller

Manufacturer

Carrier

Carrier

Horsepower

35

40

Cooling Tower Type

Wet

Wet

Minimum Approach Temperature

54 °F

54 °F

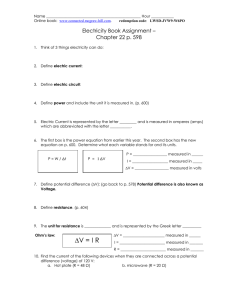

Currently, the chiller system consists of three separate loops.

1. The chilled loop carries chilled water from the chiller evaporator to the end use, where

the chilled water gains energy by absorbing heat. The chilled water then exhausts heat

into the chiller evaporator.

2. The refrigerant loop carries low energy refrigerant to the chiller evaporator where the

refrigerant absorbs energy from the chilled water. The high energy refrigerant travels

through a compressor and exhausts energy at the chiller condenser. The refrigerant then

travels through the expansion device back to the evaporator again.

14

3. The cooling loop carries low energy cooling water to the chiller condenser where it gains

energy. The cooling water then travels to the cooling tower where it exhausts energy to

the atmosphere. The following diagram is of the chiller system.

Chiller System

End Use

Chilled Loop

Chiller Evaporator

Energy Flow

Refrigerant

Loop

Chiller

Compressor

Chiller Condensor

Cooling Loop

Cooling Tower

The heat exchangers referenced in this recommendation are in the chiller condenser. If the heat

exchanger in the chiller condenser cannot be changed, changes in the cooling tower controls and

maintenance might achieve similar results.

15

From regional weather data

Ambient Temperature Data between September and February 1

Outside Wet Bulb

Winter Hours at this

Outside Wet Bulb

Winter Hours at this

Temperature

Temperature

Temperature

Temperature

(°F)

(Hours)

(°F)

(Hours)

68

13

44

992

67

40

40

811

65

86

36

590

63

158

31

318

61

240

26

163

58

349

20

42

56

473

15

8

53

710

11

2

48

882

7

1

Savings Analysis

A chiller spreadsheet developed by the Oregon State University Industrial Assessment Center is

used to calculate chiller energy and cost savings. The spreadsheet uses weather data, current

operating conditions and proposed operating conditions to find compressor energy savings.

Annual cost savings are calculated by finding the cost savings associated with energy savings.

CS

=

=

=

=

Cost Savings

EC x ES

$0.0464 /kWh x 121,800 kWh

$5,700

EC

=

=

Incremental Energy Cost

$0.0464 /kWh

ES

=

=

=

=

Energy Savings

E+W

62,500 kWh + 59,300 kWh

121,800 kWh

E

=

=

East Chiller Energy Savings

62,500 kWh

W

=

=

West Chiller Energy Savings

59,300 kWh

Where,

Where,

1

Data is collected at and compiled by Salem Airport between the years of 1948 and 1985

16

Chiller Energy Savings are found using the spreadsheets at the end of the Chiller – Calculation

Methodology. Spreadsheet terminology is described in Refrigeration Appendix D.

Total annual cost savings are summarized in the following Savings Summary table:

Savings Summary

Source

Quantity Units Energy (MMBtu)

East Chiller Energy Use

62,500 kWh

213.1

West Chiller Energy Use

59,300 kWh

202.2

121,800 kWh

Total

415.3

Cost Savings

$2,900

$2,800

$5,700

Cost Analysis

Based on the chiller loop temperatures and the refrigerant temperatures, the heat exchangers are

not achieving a sufficiently low condenser approach temperature. Installing larger heat

exchangers would greatly improve heat exchanger performance, but this is not cost effective. We

assume a professional cleaning should improve chiller performance enough to accommodate a

lower approach temperature.

IC

=

=

=

=

Implementation Cost

HC x N

$3,000 /Heat Exchanger x 2 Heat Exchangers

$6,000

HC

=

=

Cost to Professionally Clean the Heat Exchanger

$3,000 /Heat Exchanger

N

=

=

Number of Heat Exchangers

2 Heat Exchangers

Where,

Total implementation costs are summarized in the following Implementation Summary table:

Implementation Summary

Source

Quantity

Units

$/Unit Cost

Heat Exchanger Cleaning Costs

2 Heat Exchangers $3,000 $6,000

Savings will pay for implementation in 1.1 years.

17

Note

If the current chiller heat exchangers are undersized, it may not be possible to reduce approach

temperature even with a thorough cleaning. In this case, larger heat exchanger will greatly

increase implementation costs and payback period.

During our first visit to your building, we observed anomalous chiller behavior including a

cooling water loop approach temperature of over 80 °F. To preserve a conservative estimate in

our calculations, we assume that the approach temperature is constant at 54 °F, the temperature

we observed during our second visit to your building.

18

EAST REFRIGERATION ENERGY SAVINGS

Report:

Application:

Buildings:

Bin Data:

2001

Refrigeration

Bookstore Maintenance Room

Salem, OR

Operating Conditions

Minimum Condensing Temperature (Tm):

Approach Temperature Difference (DT):

Compressor Energy (EC):

Condenser Fan Horsepower (Hp):

Fan Power (FP):

Average Fan Use Factor (UFe):

Fan Energy (FE):

Total Energy Usage:

Total Energy Cost:

Bin Calculation

Dry

Bulb

We t

Bin

Bulb

(Tdb)

(Twb)

107

73

102

72

97

69

92

68

87

67

82

65

77

63

72

61

67

58

62

56

57

53

52

48

47

44

42

40

37

36

32

31

27

26

22

20

17

15

12

11

7

7

2

2

-3

-1

-8

-8

-13

-13

Totals

Cooling

Wate r

Ente ring

Conde nse r (Tcw)

88

87

84

83

82

80

78

76

73

71

68

63

59

55

51

46

41

38

38

38

38

38

38

38

38

Refrigerant:

Energy Cost (E$):

Annual Hours:

Existing

70

54

156,870

3

1.6

100.0%

9,300

166,170

$7,710

Approach

Te mp

Hours

(H)

0

0

2

13

40

86

158

240

349

473

710

882

922

811

590

318

163

42

8

2

1

0

0

0

0

5,810

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

Exist

Cond

Temp

(Tce)

142

141

138

137

136

134

132

130

127

125

122

117

113

109

105

100

95

92

92

92

92

92

92

92

92

Prop

Cond

Temp

(Tcp)

127

122

117

112

107

102

97

92

87

82

77

72

70

70

70

70

70

70

70

70

70

70

70

70

70

Energy and Cost Savings

Compressor Energy Savings (CES):

Fan Energy Increase (FEI):

Total Energy Savings (ES):

Total Cost Savings (CS):

Implementation Cost (IC):

Simple Payback:

Deg-hr

Savings

(DHS)

0

0

42

325

1,160

2,752

5,530

9,120

13,960

20,339

31,950

39,690

39,646

31,629

20,650

9,540

4,075

924

176

44

22

0

0

0

0

232,000

Savings

%

(E%)

0.0%

0.0%

0.0%

0.1%

0.2%

0.5%

1.0%

1.6%

2.4%

3.5%

5.5%

6.8%

6.8%

5.4%

3.6%

1.6%

0.7%

0.2%

0.0%

0.0%

0.0%

0.0%

0.0%

0.0%

0.0%

39.9%

R22

$0.04640 /kWh

5,810

Proposed

70

20

94,370

3

1.6

85.3%

7,900

102,270

$4,750

Compress

Savings

kWh

(CES)

0

0

11

88

313

743

1,493

2,462

3,769

5,492

8,627

10,716

10,704

8,540

5,576

2,576

1,100

249

48

12

6

0

0

0

0

62,500

Savings

0

34

62,500

0.0

0.0

14.7%

1,400

63,900

$3,000

Fan

Increase

kWh

(FEI)

kWh

kWh

Total

Savings

kWh

(ES)

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

(8)

(2)

0

0

0

0

0

0

62,500

0

62,500

$2,900

$3,000

1.0

19

Units

°F

°F

kWh/yr

hp

kW

0

0

11

88

313

743

1,493

2,462

3,769

5,492

8,627

10,716

10,704

8,540

5,576

2,576

1,100

249

56

14

6

0

0

0

0

62,500

kWh/yr

kWh/yr

kWh/yr

/yr

years

WEST REFRIGERATION ENERGY SAVINGS

Report:

Application:

Buildings:

Bin Data:

2001

Refrigeration

Bowling Chiller Room

Salem, OR

Refrigerant:

Energy Cost (E$):

Annual Hours:

Operating Conditions

Minimum Condensing Temperature (Tm):

Approach Temperature Difference (DT):

Compressor Energy (EC):

Condenser Fan Horsepower (Hp):

Fan Power (FP):

Average Fan Use Factor (UFe):

Fan Energy (FE):

Total Energy Usage:

Total Energy Cost:

Bin Calculation

Dry

Cooling

Bulb

Wet

Water

Bin

Bulb

Entering

(Tdb)

(Twb)

Condenser (Tcw)

107

73

88

102

72

87

97

69

84

92

68

83

87

67

82

82

65

80

77

63

78

72

61

76

67

58

73

62

56

71

57

53

68

52

48

63

47

44

59

42

40

55

37

36

51

32

31

46

27

26

41

22

20

38

17

15

38

12

11

38

7

7

38

2

2

38

-3

-1

38

-8

-8

38

-13

-13

38

Totals

Energy and Cost Savings

Compressor Energy Savings (CES):

Fan Energy Increase (FEI):

Total Energy Savings (ES):

Total Cost Savings (CS):

Implementation Cost (IC):

Simple Payback:

R22

$0.04640 /kWh

5,810

Existing

70

54

173,370

3

1.6

100.0%

9,300

182,670

$8,480

Approach

Temp

Hours

(H)

0

0

2

13

40

86

158

240

349

473

710

882

922

811

590

318

163

42

8

2

1

0

0

0

0

5,810

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

54

Exist

Cond

Temp

(Tce)

142

141

138

137

136

134

132

130

127

125

122

117

113

109

105

100

95

92

92

92

92

92

92

92

92

Prop

Cond

Temp

(Tcp)

108

107

104

103

102

100

98

96

93

91

88

83

79

75

71

70

70

70

70

70

70

70

70

70

70

Deg-hr

Savings

(DHS)

0

0

68

442

1,360

2,924

5,372

8,160

11,866

16,082

24,140

29,988

31,348

27,574

20,060

9,540

4,075

924

176

44

22

0

0

0

0

194,000

Savings

%

(E%)

0.0%

0.0%

0.0%

0.1%

0.2%

0.5%

0.9%

1.4%

2.0%

2.8%

4.2%

5.2%

5.4%

4.7%

3.5%

1.6%

0.7%

0.2%

0.0%

0.0%

0.0%

0.0%

0.0%

0.0%

0.0%

33.4%

Proposed

70

20

115,470

3

1.6

85.3%

7,900

123,370

$5,720

Compress

Savings

kWh

(CES)

0

0

20

132

406

873

1,603

2,435

3,541

4,799

7,203

8,948

9,354

8,228

5,986

2,847

1,216

276

53

13

7

0

0

0

0

57,900

Savings

Units

0 °F

34 °F

57,900 kWh/yr

0.0 hp

0.0 kW

14.7%

1,400 kWh

59,300 kWh

$2,800

Fan

Increase

kWh

(FEI)

0

0

0

0

0

0

0

0

0

0

0

0

(192)

(371)

(372)

(241)

(140)

(39)

(8)

(2)

0

0

0

0

0

(1,400)

57,900 kWh/yr

(1,400) kWh/yr

59,300 kWh/yr

$2,800 /yr

$3,000

1.1 years

20

Total

Savings

kWh

(ES)

0

0

20

132

406

873

1,603

2,435

3,541

4,799

7,203

8,948

9,546

8,599

6,358

3,088

1,356

315

61

15

7

0

0

0

0

59,300

AR No. 3

Winter HVAC

Calculation Methodology

Recommendation

Turn off the five major air handling units during winter night time hours. This will reduce total

building steam use by 31% and fan energy use by 33%.

Assessment Recommendation Summary

Energy

Steam

Energy

Net Implementation Payback

(MMBtu)

(lbs)**

(kWh)* Savings

Cost

(years)

1,301.3

1,273,843

25,251 $24,414

$0

Immediate

*1 kWh = 3,410 Btu

**1 lb Steam = 903 Btu

Data Collected Summary

From building personnel

• Building occupancy is minimal between midnight and 6 am

• HVAC during the winter is to provide circulation, not for temperature control

• The building switches between heating and cooling in October and April

• The entire MU is wired at 230 Volts

• Steam costs $0.0195/lb Steam for the 2008/2009 school year

• Bowling Unit runs at 13.6 Amps (live)

• Bookstore Supply Fan #7 runs at 10.1 Amps (live)

• Bookstore Exhaust Fan #2 runs at 9.8 Amps (live)

• Ballroom Unit runs at 21 Amps (live)

• Lounge Unit runs at 21 Amps (live)

From previous reports

• Lounge unit draws heated supply air from the attic

• Steam enthalpy is 903 Btu/lb Steam

Assumptions

• Building heating set-point is 60 °F

• Bookstore Supply Unit #7, Bowling Unit and Ballroom Unit are running at rated airflow

• Live amp readings accurately reflect conditions throughout winter

21

The following table summarizes current winter operating conditions.

Current Winter Operating Conditions Summary

Live Amps Volts kW CFM

Winter Operating Hours

Bookstore Supply Unit #7

10.1

230

2.3 20,000

4,380

Bookstore Exhaust Unit #2

9.8

230

2.2 18,000

4,380

Bowling Unit

13.6

230

3.1

7,500

4,380

Ballroom Unit

21.0

230

4.8 10,000

4,380

Lounge Unit

21.0

230

4.8 13,000

4,380

kWh

10,074

9,636

13,578

21,024

21,024

The following table summarizes average temperature conditions between 1 am to 8 am from

October to April.

Midnight to 8 am Winter Heat Load Summary 2

Building Setpoint Outside Temperature Temperature Difference Winter Hours at this Temperature

(°F)

(°F)

(°F)

(Hours)

60

57

3

43

60

52

8

149

60

47

13

269

60

42

18

336

60

37

23

288

60

32

28

212

60

27

33

95

60

22

38

37

60

17

43

15

60

12

48

5

60

7

53

0

Savings Analysis

For the purpose of this analysis winter is assumed to be a 6 month period when the building

requires heating. Current energy use is calculated using a building set-point of 60 °F. We

propose reducing the winter operating hours of the air handling units by eight hours each night.

This recommendation doesn’t change the maximum power value, so there are no demand

savings. We calculate electrical savings first, then savings from space heating reductions.

2

Data is collected at and compiled by Salem Airport between the years of 1948 and 1985

22

Electrical savings are calculated as the difference between current and proposed electrical energy

use. The Ballroom Unit is taken as an example:

Electrical Savings for the Ballroom Unit

EC

=

=

=

=

Electricity Cost Savings

ES x IE

7,047 kWh x $0.0464/kWh

$327

ES

=

=

=

=

Energy Savings

CE – PE

21,024 kWh – 13,977 kWh

7,047 kWh

IE

=

=

Incremental Energy Cost

$0.0464/kWh

CE

=

=

=

=

Current Winter Energy Usage

CH x CP

4,380 hrs x 4.8 kW

21,024 kWh

PE

=

=

=

=

Proposed Winter Energy Usage

PH x PP

2,912 hrs x 4.8 kW

13,977 kWh

CH

=

=

Current Winter Operating Hours

4,380 hrs

CP

=

=

Current Power

4.8 kW

PH

=

=

=

Proposed Winter Operating Hours

(24 hrs/day – 8 hrs/day) x 182 days/winter

2,912 hrs

PP

=

=

Proposed Power

4.8 kW

Where,

Where,

Where,

23

The following table summarizes existing electrical conditions, proposed electrical conditions and

electrical savings during winter.

Winter Operating Conditions and Electrical Savings Summary

Operating Hours

kW

kWh

Existing Bookstore Supply Unit #7

4,380

2.3

10,074

Existing Bookstore Exhaust Unit #2

4,380

2.2

9,636

Existing Bowling Unit

4,380

3.1

13,578

Existing Ballroom Unit

4,380

4.8

21,024

Existing Lounge Unit

4,380

4.8

21,024

Proposed Bookstore Supply Unit #7

2,912

2.3

6,698

Proposed Bookstore Exhaust Unit #2

2,912

2.2

6,406

Proposed Bowling Unit

2,912

3.1

9,027

Proposed Ballroom Unit

2,912

4.8

13,977

Proposed Lounge Unit

2,912

4.8

13,977

Savings

1,468

0.0

25,251

Cost

$467

$447

$630

$975

$975

$310

$298

$418

$648

$648

$1,172

Heating Savings for major Air Handling Units

We propose to eliminate fan operating hours between midnight and 8 am. This will effectively

eliminate steam heating in these units during these hours. Savings are determined by calculating

the energy required to raise the temperature of outside air to the building set-point during these

hours.

Previous HVAC reports noted that the Lounge Unit draws heated air from the attic that is used

during the winter without requiring additional heating. Also, the Bookstore Exhaust Unit #2 is

not taken into account as no heating occurs within it.

HC

=

=

=

=

Heating Cost Savings

SS x IS

1,345,787 lbs Steam x $0.0195/lb Steam

$26,242

SS

=

=

=

=

Steam Savings

HS ÷ SE

1,215,246,240 Btu ÷ 903 Btu/lb Steam

1,345,787 lbs Steam

IS

=

=

Incremental Steam Cost

$0.0195/lb Steam

Where,

24

Where,

HS

=

=

=

=

Heating Savings

CP x AT x SA x ℓ x 60 min/hr

0.24 Btu/lb-°F x 28,852 °F-hrs x 37,500 cfm x 0.078 lb/ft3 x 60 min/hr

1,215,246,240 Btu

SE

=

=

Steam Enthalpy

954 Btu/lb Steam

CP

=

=

Specific Heat of Air in btu/lbm-degF

0.24 Btu/lb-°F

AT

=

=

Annual Temperature Difference Hours

=

28,852 °F-hrs

SA

=

=

=

=

System Airflow

BU + BS + BA

10,000 cfm + 20,000 cfm + 7,500 cfm

37,500 cfm

ℓ

=

=

Air Density

0.078 lb/Ft3

Where,

∑(60° - T )× H

Where,

Variable Declaration and Winter Temperature Hours between Midnight and 8 am

Temperature Outside Temperature

Hours Spent at this Outside Temperature

Variable

(°F)

Hours Variable

(Hours)

Ta

57

Ha

43

Tb

52

Hb

149

Tc

47

Hc

269

Td

42

Hd

336

Te

37

He

288

Tf

32

Hf

212

Tg

27

Hg

95

Th

22

Hh

37

Ti

17

Hi

15

Tj

12

Hj

5

BU

=

=

Bowling Unit Airflow

10,000 cfm

25

BS

=

=

Bookstore Supply Unit Airflow

20,000 cfm

BA

=

=

Ballroom Unit Airflow

7,500 cfm

Total savings including electrical and heating are summarized in the following table.

Electrical Energy

Electrical Demand

Heating

Total

Savings Summary Table

Quantity

Units

Energy (MMBtu)

25,251 kWh

86.1

0 kW

1,273,843 lbs Steam

1,215.2

1,301.3

Cost

$1,172

$0

$26,242

$27,414

Cost Analysis

An additional cost associated with this recommendation is the labor cost of turning off the air

handling units at night and turning them back on in the morning. From building personnel, there

is maintenance staff onsite as early as 6 am and as late as midnight. Usually, we expect turning

motors on and off to be within normal maintenance duties. However, as this is not an industrial

facility, we assume that $3,000 annually will cover additional labor hours. Total Cost savings

including annual costs are calculated below.

Net Savings Summary Table

Cost Savings

Annual Labor Cost

Net Savings

$27,414

($3,000)

$24,414

There is no immediate implementation cost associated with this recommendation.

Note

A programmable logic controller or a direct digital controller can perform the task of turning the

air handling units on and off at the appropriate hours automatically. This will eliminate the

annual labor cost while increasing the implementation cost. This is not included in the cost

analysis as we were unable to find a price for a suitable controller.

26

AR No. 4

Oven Exhaust Fan

Calculation Methodology

Recommendation

Turn off the Pangea oven exhaust fan at night and during the summer. This will reduce fan

electrical costs by 43% and loss of conditioned air when cooling or heating is needed. The

heating and cooling savings are not taken into account in this recommendation.

Assessment Recommendation Summary

Energy

Energy

Cost

Implementation Payback

(MMBtu) (kWh)* Savings

Cost

(years)

58.0

17,010

$789

$100

0.1

*1 kWh =3,410 Btu

Data Collected Summary

The following data was collected during our visit

• Marathon motor on main Pangea oven exhaust fan

• 7.5 Horse power

• 1760 RPM

• 208 volts

• Operates 24/7, even when ovens are not running

• During the summer and at night, the ovens are not used

Assumptions

• Estimated motor efficiency: 86.5% (based on generic motor efficiency table)

• Estimated load factor: 70%

• Proposed operating hours: 4,980 hrs (based on turning fans off during the 3 summer

months and 6 hours each night)

27

Savings Analysis

Annual cost savings are calculated by finding the difference between the current and proposed

conditions. We neglect any demand savings incurred to maintain conservative cost savings.

ES

=

=

=

=

Energy Savings

EC x ES

$0.0464/kWh x 17,010 kWh

$789

EC

=

=

Incremental Energy Cost

$0.0464 /kWh

ES

=

=

=

=

Energy Savings

CE – PE

39,420 kWh – 22,410 kWh

17,010 kWh

CE

=

=

=

=

Current Energy

P x CH

4.5 kW x 8,760 hrs

39,420 kWh

PE

=

=

=

=

Proposed Energy

P x PH

4.5 kW x 4,980 hrs

22,410 kWh

P

=

=

=

=

Power Usage

(HP x C x LF) ÷ EF

(7.5 hp x 0.746 kW/hp x 0.70) ÷ 0.865

4.5 kW

CH

=

=

Current Hours

8,760 hrs

PH

=

=

Proposed Hours

4,980 hrs

HP

=

=

Horse Power

7.5 hp

Where,

Where,

Where,

Where,

28

C

=

=

Energy Conversion

0.746 kW/hp

LF

=

=

Load Factor

70%

EF

=

=

Motor Efficiency

86.5%

Total annual cost savings are summarized in the following Savings Summary table:

Source

Energy Use

Saving Summary

Quantity Units

Energy (MMBtu)

17,010

kWh

58.0

Cost Savings

$789

Cost Analysis

Turning off the exhaust fan requires only an attentive operator. The power switch is located

behind a refrigerator, but is reachable. Moving the power switch to a location that is accessible is

advised. The cost of moving one power switch will be about $100 for one hour of electrician

work and material.

Cost Summary

Source

Quantity Units

$/Unit

Electrician

1

hrs

50.0

Material

Total

Cost

$50

$50

$100

Cost savings will pay for implementation costs in 0.1 years.

Note

An electronic controller will be more reliable than employee operated switch. However, we did

not include this option in the cost analysis as the savings did not warrant a controller.

29

AR No. 5

Skylights

Calculation Methodology

Recommendation

Install photo sensor/timer units on T8 fixtures in skylights to reduce operating hours. Replace

yellow glass with clear glass to allow more light into hallways. This will reduce lighting costs by

46% in this area.

Assessment Recommendation Summary

Energy Energy

Cost

Implementation Payback

(MMBtu)

20.6

(kWh)

6,574

Savings

$415

Cost

$1,995

(years)

4.8

*1 kWh = 3,410 Btu

Estimated Incentive Summary

ETO

BETC2

Net

Net Payback

Incentive Tax Credit

Cost

(years)

$499

$456

$1,040

2.5

1

Energy Trust of Oregon Incentive

2

Oregon Department of Energy Business Energy Tax Credit

1

Data Collected Summary

The following data was collected during our visit

• 15 Skylights

• Each skylight contains a T8 fluorescent fixture

• Fixtures operate 4,969 hrs unnecessarily annually

Assumptions

• We assume each fixture runs constantly

Savings Analysis

Energy and maintenance cost savings for installing photo sensors are calculated using the Install

Photo Sensor/Timer Units worksheet following this calculation. The lighting worksheet’s

terminology is described in Appendix C.

30

Energy savings are estimated using power, current operating hours, and proposed operating

hours per year. Energy cost savings are estimated with an incremental energy cost of

$0.0464/kWh.

CS

=

=

=

=

Energy Cost Savings

EC x ES

$0.0464/kWh x 6,574 kWh

$305

EC

=

=

Incremental Energy Cost

$0.0464/kWh

ES

=

=

=

=

Energy Savings

CE – PE

12,264 kWh –5,690 kWh

6,574 kWh

CE

=

=

Current Energy Consumption

12,264 kWh

PE

=

=

Proposed Energy Consumption

5,690 kWh

Where,

Where,

Reducing light operating hours will decrease maintenance costs, as estimated in the Install Photo

Sensors table at the end of this calculation methodology. The maintenance material savings total

$60 per year, while maintenance labor savings total $50 per year. Therefore, the total

maintenance savings sum to $111 annually. Total annual cost savings are summarized in the

following Savings Summary table:

Saving Summary

Energy

Source

Quantity Units (MMBtu) Cost

Energy Use

6,574 kWh

22.4

$305

Maintenance Material

$60

Maintenance Labor

$50

Total

22.4

$415

31

Cost Analysis

Implementation costs for photo sensors and clear glass panes include material and installation

costs. Each skylight requires 1 photo sensor/timer unit and 24 glass panes. Labor costs were

conservatively estimated at one hour per sensor installation with a typical electrician’s wage of

$50 per hour and one hour per skylight for glass panes with a typical maintenance wage of $15

per hour.

Cost Summary

Item

Units Cost/Unit Total

Photo Sensors/Timers

15

$20

$300

Glass Panes

360

$2

$720

Electrician

15

$50

$750

Installation

15

$15

$225

Total

$1,995

Incentive Summary

Energy Trust cash incentives are available to help pay for implementation of energy saving

measures if they save at least 10% of the energy used in a system. Incentives can be anticipated

to equal the minimum of 25% of total project cost, $0.12 per kWh saved, or $1 per therm saved.

CI

Where,

TES

TC

=

=

=

=

=

ETO Cash Incentive

Minimum of

TES x $0.12

Minimum of

6,574 x $0.12

Minimum of

$789

$499

=

=

Total Energy Savings

6,574 kWh

=

=

Applicable Implementation Cost

$1,995

or

or

or

0.25 x TC

0.25 x $1,995

$499

You may also be eligible for the Oregon Business Energy Tax Credit. If a project reduces system

energy use by at least 10%, the incentive can be expected to equal 35% of project costs after

applying other incentives. However the tax credit accrues over a 5 year period (10%, 10%, 5%,

5%, and 5%), or over one year for projects with implementation costs of less than $20,000. The

Oregon Department of Energy also allows “pass through” of a onetime lump value, which is

25.5% of project costs over $20,000 and 30.5% of project costs under $20,000. As this is a

reasonable estimate for the 35% tax credit’s net present value, we will use 30.5% as the value of

the tax credit in our analysis and estimate of the “payback” period.

32

BTC

=

=

=

=

Business Energy Tax Credit

(TC – CI) x 0.305

($1,995 – $499) x 0.305

$456

The following table summarizes implementation costs before and after incentives.

Incentive Summary

Description

Pre-incentive Cost

Energy Trust Incentives

Business Energy Tax Credit

Total after Incentives

Cost

$1,995

($499)

($456)

$1,040

Savings will pay for implementation costs in 2.5 years after incentives.

33

Install Photo Sensor/Timer Units

Report Number:

PLANT DATA

Building:

Area:

Lamp Replacement Time:

Ballast Replacement Time:

Fixture Replacement Time:

M emorial Union

2nd Floor Hallways

1/6 hours

1/2 hours

1

hours

Existing

$4.75 /kW-mo.

$0.04640 /kWh

$15.00 /hour

$50.00 /hour

Proposed

Savings

4 Ft T8 Elec.

15

8,760

100%

3

1

$62.95

4 Ft T8 Elec.

15

4,064

100%

3

1

$62.95

0

4,696

0%

0

0

$0.00

F32-1

4 Ft T8 C.T.

45

20,000

$1.94

32

2,710

44%

$38.24

$49.08

F32-1

4 Ft T8 C.T.

45

20,000

$1.94

32

2,710

20%

$17.74

$22.77

0

0

$0.00

0

0

0

$20.50

$26.31

T32-5

4 Ft F32T8

15

75,000

$42.65

0%

93

12%

$74.72

$43.80

T32-5

4 Ft F32T8

15

75,000

$42.65

0%

93

5%

$34.67

$20.32

0

0

$0.00

0

0

0

$40.06

$23.48

FIXTURES

FIXTURE CODE

Description:

Quantity:

Operating Hours:

Output Factor:

Lamps per Fixture:

Ballasts per Fixture:

Fixture Cost:

2001

Incremental Demand Cost:

Incremental Energy Cost:

Recommended Foot-candles:

M aintenance Labor Rate:

Electrician Labor Rate:

OFT8-2

Units

OFT8-2

hours

LAMPS

LAM P CODE

Description:

Quantity:

Life:

Lamp Cost:

Watts per Lamp:

Lumens:

Replacement Fraction:

Annual Lamp Replacement Cost:

Annual M aintenance Labor Cost:

hours

watts

BALLASTS

BALLAST CODE

Description:

Quantity:

Life:

Ballast Cost:

Ballast Factor:

Input Watts:

Replacement Fraction:

Annual Ballast Replacement Cost:

Annual M aintenance Labor Cost:

hours

watts

POWER AND ENERGY

Power:

Energy Use:

1.4

12,264

1.4

5,690

0.0

6,574

kW

kWh

LIGHT LEVEL CHECK

Total Lumens:

Foot-candles:

Lighting Efficiency:

121,950

0

0.0

121,950

0

0.0

0

0

0 Lum./W

ANNUAL OPERATING COST

Demand Cost:

Energy Cost:

M aintenance M aterial Cost:

M aintenance Labor Cost:

Total Operating Cost:

$80

$569

$113

$93

$855

34

$80

$264

$52

$43

$439

$0.00

$305.00

$60.55

$49.79

$415.34

AR No. 6

Halogen Lights

Calculation Methodology

Recommendation

Replace Halogen fixtures in the ballroom with Compact Fluorescent fixtures. This will reduce

energy usage in this area by 58%.

Assessment Recommendation Summary

Energy

Energy

Cost

Implementation Payback

(MMBtu)

39.7

(kWh)*

12,650

Savings

$483

Cost

$4,860

(years)

10.1

*1 kWh = 3,410 Btu

Estimated Incentive Summary

ETO

BETC2

Net

Net Payback

Incentive

Tax Credit

Cost

(years)

$1,215

$1,112

$2,533

5.2

1

Energy Trust of Oregon Incentive

2

Oregon Department of Energy Business Energy Tax Credit

1

Data Collected Summary

The following data was collected during our visit

• 45 recessed cans

• 1 Halogen T4 E11 fixture per recessed can

Assumptions

• The lights operate 1,340 hrs annually

Savings Analysis

Energy and maintenance cost savings for installing motion sensors and replacing metal halide

lights are calculated using the “Replace Halogen Fixtures with Compact Fluorescents”

spreadsheet that follows this calculation summary. Lighting spreadsheet terminology is described

in Appendix C.

35

Energy savings are estimated using power, current fixture wattages, and proposed fixture

wattages, and operating hours. Energy cost savings are estimated with an incremental energy

cost of $0.0464/ kWh.

ES

=

=

=

=

Energy Cost Savings

(CE – PE) x EC

(21,762 kWh – 9,112 kWh) x $0.0464/ kWh

$587

CE

=

=

Current Energy Consumption

21,762 kWh

PE

=

=

Proposed Energy Consumption

9,112 kWh

EC

=

=

Energy Cost

$0.0464/ kWh

Where,

Installing compact fluorescent fixtures will also lead to a decrease in fixture maintenance labor

costs by extending the life of lamps. Annual labor savings are $56. However, the increased cost

of lamps will increase material costs by $160 annually, totaling $104 of annual increased

maintenance costs. Total annual cost savings are summarized in the following Savings Summary

table:

Savings Summary

Source

Energy Use

Maintenance Material

Maintenance Labor

Total

Energy

Quantity Units MMBtu

12,650 kWh

39.7

39.7

Cost

$

$587

($160)

$56

$483

Cost Analysis

The cost of replacing the halogen fixtures with Compact Fluorescent fixtures is based on the cost

of material and installation per fixture. There are a total of 45 fixtures that need replaced. We

estimate that it will take an electrician one hour to install each fixture at a wage of $50 per hr.

36

The costs are summarized in the table below:

Item

150 Watt Mogul CFL

Mogul Base Socket Assembly

Electrician

Total

Cost Summary

Quantity

Units

45

Lamps

45

Fixtures

45

Hours

Cost/Unit

$46

$12

$50

Total Cost

$2,070

$540

$2,250

$4,860

Incentive Summary

Energy Trust cash incentives are available to help pay for implementation of energy saving

measures if they save at least 10% of the energy used in a system. In this case, the 10% savings

is met. Incentives can be anticipated to equal the minimum of 25% of total project cost, $0.12 per

kWh saved, or $1 per therm saved.

CI

Where,

TES

TC

=

=

=

=

=

ETO Cash Incentive

Minimum of

TES x $0.12

Minimum of

12,650 x $0.12

Minimum of

$1,518

$1,215

=

=

Total Energy Savings

12,650 kWh

=

=

Total Implementation Cost

$4,860

or

or

or

0.25 x TC

0.25 x $4,860

$1,215

You may also be eligible for the Oregon Business Energy Tax Credit. If a project reduces system

energy use by at least 10%, the incentive can be expected to equal 35% of project costs after

applying other incentives. However, the tax credit accrues over a 5 year period (10%, 10%, 5%,

5%, and 5%), or over one year for projects with implementation costs of less than $20,000. The

Oregon Department of Energy also allows “pass through” of a onetime lump value, which is

25.5% of project costs over $20,000 and 30.5% of project costs under $20,000. As this is a

reasonable estimate of the net present value of the 35% tax credit, we will use 30.5% as the value

of the tax credit in our analysis and estimate of the “payback” period.

BTC

=

=

=

=

Business Energy Tax Credit

(TC – CI) x 0.305

($4,860 – $1,215) x 0.305

$1,112

37

The following table summarizes implementation costs before and after incentives.

Incentive Summary

Description

Pre-incentive Cost

Energy Trust Incentives

Business Energy Tax Credit

Total after Incentives

Cost

$4,860

($1,215)

($1,112)

$2,533

Savings will pay for implementation costs in 5.2 years after incentives.

38

Replace Halogen Fixtures with Compact Fluorescents

PLANT DATA

Building:

Area:

Lamp Replacement Time:

Ballast Replacement Time:

Fixture Replacement Time:

Memorial Union

Ballroom

1/6 hours

1/2 hours

1

hours

Report Number:

Incremental Energy Cost:

2001

$0.04640 /kWh

Maintenance Labor Rate:

Electrician Labor Rate:

$15.00 /hour

$50.00 /hour

FIXTURES

Existing

Proposed

FIXTURE CODE

Description:

Quantity:

Operating Hours:

Output Factor:

Lamps per Fixture:

Fixture Cost:

HF450

CF150

450 Watt Halogens

45

1,340

80%

1

$0.00

150 Watt CF

45

1,340

100%

1

$11.95

0

0

-20%

0

($11.95)

H450

450 Watt Halogens

45

2,000

$6.19

450

8,000

67%

$186.63

$75.07

C150

150 Watt Compact Fluor

45

8,000

$46.06

150

8,000

17%

$347.18

$18.77

0

(6,000)

($39.87)

300

0

1

($160.55)

$56.31

Savings

Units

hours

LAMPS

LAMP CODE

Description:

Quantity:

Life:

Lamp Cost:

Watts per Lamp:

Lumens:

Replacement Fraction:

Annual Lamp Replacement Cost:

Annual Maintenance Labor Cost:

hours

watts

POWER AND ENERGY

Power:

Energy Use:

20.3

21,762

6.8

9,112

13.5

12,650

$1,010

$187

$75

$1,272

$423

$347

$19

$789

$587.00

($160.55)

$56.31

$482.76

kW

kWh

ANNUAL OPERATING COST

Energy Cost:

Maintenance Material Cost:

Maintenance Labor Cost:

Total Operating Cost:

IMPLEMENTATION COST

Materials:

Labor:

Total Implementation Cost:

$2,610

$2,250

$4,860

SIMPLE PAYBACK

10.1

39

years

40

APPENDIX A

UTILITIES

A.1 Energy Definitions

An essential component of any energy management program is tracking energy. When utility

bills are received, we record energy use and cost in a spreadsheet and get the appropriate graphs.

A separate spreadsheet may be required for each type of energy used, such as oil, gas, or

electricity. A combination might be merited when both gas and oils are used interchangeably in a

boiler. In such a case we suggest using a common energy unit for a cost-benefit analysis that can

represent most fuel options: the Btu.

We have prepared a utility spreadsheet analysis based on the information provided by you or

your utility companies. The worksheets are in section A.3, Energy, Waste, and Production

Accounting. They show how energy is used and help identify potential energy savings.

We use specific terminology and calculations in analyzing and discussing your energy, water,

and waste expenses. Energy related terms and calculations are detailed below followed by those

for waste and water.

Electricity Definitions:

Average Energy Cost. The total amount billed for 12 months of energy, divided by the total

number of energy units. Each energy type (oil, gas, electricity, propane, etc.) has its own average

energy cost. The average cost per energy unit includes the fees, taxes and unit cost.

Average Energy Cost = (Total Billed $) ÷ (Total Energy Units)

Average Load Factor. The ratio of annual electrical energy use divided by the average kilowatts

(kW) and the hours in a year.

Average Load Factor = (Total kWh) ÷ (Average kW x 8,760 hrs)

Average Load Factor expresses how well a given electrical system uses power. A higher load

factor yields lower average energy cost.

An example of how load factor applies: A large air compressor has high electric demand for

small periods of time and is not a large energy user. It will usually have low load factor and