Model Predictive Control of Hybrid Systems Alberto Bemporad

advertisement

Model Predictive Control

of Hybrid Systems

Model Predictive Control

of Hybrid Systems

Controller

Alberto Bemporad

Reference

r(t)

Dip. di Ingegneria dell’Informazione

Università degli Studi di Siena

•

•

Università degli Studi di Siena

Facoltà di Ingegneria

Receding Horizon Philosophy

– minimize |y à r| + ú|u|

Input

u(t)

Output

y(t)

Measurements

bemporad@dii.unisi.it

http://www.dii.unisi.it/~bemporad

http://www.dii.unisi.it/~bemporad

• At time t :

Solve an optimal

control problem over a

finite future horizon p :

Hybrid System

•

MODEL: a model of the plant is needed to predict the future

behavior of the plant

PREDICTIVE: optimization is based on the predicted future

evolution of the plant

CONTROL: control complex constrained multivariable plants

Receding Horizon - Example

r(t)

Predicted outputs

Manipulated

Inputs

t t+1

MPC is like playing chess !

u(t+k)

t+p

– subject to constraints

u min ô u ô u max

y min ô y ô y max

t+1 t+2

t+p+1

• Only apply the first optimal move u ã (t)

• Get new measurements, and repeat the optimization

at time t +1

Advantage of on-line optimization: FEEDBACK!

1

MPC for Hybrid Systems

past

Closed-Loop Stability

future

Model

Predictive (MPC)

Control

Predicted

outputs y(t+k|t)

Manipulated

Inputs u(t+k)

t t+1

t+T

• At time t solve with respect to

the finite-horizon open-loop, optimal control problem:

(Bemporad, Morari 1999)

• Apply only u(t) =uã(t) (discard the remaining optimal inputs)

Proof: Easily follows from standard Lyapunov arguments

• Repeat the whole optimization at time t+1

Stability Proof

Hybrid MPC - Example

Switching System:

"

x(t + 1) = 0.8

Lyapunov function

cos ë(t) à sinë(t)

sinë(t)

cos ë(t)

#

ô õ

x(t) + 0 u(t)

1

y(t) = [ 0 1 ] x(t)

ù

if [1 0]x(t) õ 0

3

ë(t) =

ù

à if [1 0]x(t) < 0

3

Constraint:

Open loop:

Closed loop:

y(t), r(t)

u(t)

à 1 ô u (t) ô 1

time t

time t

Note: Global optimum not needed for convergence !

2

MIQP Formulation of MPC

(Bemporad, Morari, 1999)

Optimal Control of Hybrid Systems:

Computational Aspects

Mixed Integer Quadratic Program (MIQP)

(Bemporad, Borrelli, Morari, 2000)

Mixed-Integer Program Solvers

• Mixed-Integer Programming is NP-hard

Phase transitions have been found in

computationally hard problems.

• Introduce slack variables:

ïxk

ïuk

• Set

õ kQy(t + k|t)k∞

õ kRu(t + k)k∞

ø,[ïx1 ,

. . .,

ïxN , ïu1 ,

y

min |x|

ïxk

ïxk

ïuk

ïuk

BUT

min ï

s.t. ï õ x

ïõ àx

[Qy(t + k|t)]i

õ

õ à [Qy(t + k|t)]i

õ [Ru(t + k))]i

õ à [Ru(t + k))]i

i = 1, . . ., p,

i = 1, . . ., p,

i = 1, . . ., m,

i = 1, . . ., m,

4000

50 var

40 var

20 var

3000

2000

1000

0

2

3

4

5

6

7

8

Ratio of Constraints to Variables

(Monasson et al., Nature, 1999)

k = 1, . . ., T à 1

k = 1, . . ., T à 1

k = 0, . . ., T à 1

k = 0, . . ., T à 1

• General purpose Branch & Bound/Branch & Cut solvers available

for MILP and MIQP (CPLEX, Xpress-MP, BARON, GLPK, ...)

More solvers and benchmarks: http://plato.la.asu.edu/bench.html

• No need to reach global optimum (see proof of the theorem),

although performance deteriorates

. . ., ïTà1 , U, î, z]

min J(ø, x (t)) =

Mixed Integer Linear Program

(MILP)

Cost of Computation

MILP Formulation of MPC

ø

Tà1

X

ï xi + ïui

k=0

s.t.Gø ô W + Sx (t)

Good for large sampling times (e.g., 1 h) / expensive hardware …

… but not for fast sampling (e.g. 10 ms) / cheap hardware !

3

On-Line vs. Off-Line Optimization

min J(U, x(t)),

U

Tà1

P

kQy(t + k + 1|t)k∞ + kRu(t + k)k∞

k=0

MLD model

subj. to

x(t|t) = x(t)

x(t + T|t) = 0

Explicit Form of

Model Predictive Control

• On-line optimization: given x(t), solve the problem at each time step t

Mixed-Integer Linear Program (MILP)

via Multiparametric Programming

• Off-line optimization: solve the MILP for all x(t)

min J(ø, x (t)), f 0 ø

ø

s.t.Gø ô W + F x (t)

multi-parametric Mixed Integer Linear Program (mp-MILP)

Linear MPC

Example of Multiparametric Solution

Multiparametric LP ( ø ∈ R2 )

40

• Linear Model:

CR{1,2,3}

CR{1,4}

60

CR{1,3}

20

• Constraints:

CR{2,3}

x2 0

- 20

• Optimal control problem (quadratic performance index):

- 40

- 60

- 60

- 40

- 20

0

20

40

60

x1

4

Linear MPC

Multiparametric Quadratic Programming

(Bemporad et al., 2002)

• Substitution:

• Optimization problem:

(quadratic)

(linear)

Convex QUADRATIC PROGRAM (QP)

• Objective: solve the QP for all

• Assumption:

Linearity of the Solution

x0∈ X

solve QP to find

(always satisfied if QP

problem originates from

optimal control problem)

Determining a Critical Region

• Impose primal and dual feasibility:

identify active constraints at

linear inequalities in x !

form matrices

by collecting

active constraints

KKT

optimality

conditions:

From (1) :

From (2) :

In some neighborhood of x0, λ and U are explicit

affine functions of x !

• Remove redundant constraints

• x0

critical region CR0

CR0

CR0 = {Ax ô B}

x-space

X

à,W

à ,S

à

• CR0 is the set of all and only parameters x for which G

is the optimal combination of active constraints at the optimizer

5

Multiparametric QP

R2

x-space

RN

R2

CR0 = {Ax ô B}

R3

•x0

CR0

R1

Multiparametric QP

Ri = {x ∈ X : Aix > Bi, Ajz ô Bj, ∀j < i}

R4

{CR0 , R1 , . . ., RN}

Theorem:

is a partition of X ò Rn

X

X ← Ri

Mp-QP – More efficient method

(Tøndel, Johansen, Bemporad, 2003)

x2

R4

{CR0 , R1 , . . ., RN}

Theorem:

is a partition of X ò Rn

Note: while CR0 is characterizing a set of active constraints, Ri is not

X

X

Keep track of the CR already

explored, don’t split CRs

Mp-QP Properties

x2

CR

CR

Ri = {x ∈ X : Aix > Bi, Ajz ô Bj, ∀j < i}

X

Ri

The recursive algorithm terminates after a finite

number of steps, because the number of combinations

of active constraints is finite

x2

RN

x-space

Proceed iteratively: for each region

repeat the whole procedure with

•x0

CR0

R1

CR0 = {Ax ô B}

R3

CR

continuous,

piecewise affine

x1

x1

x1

The active set of a neighboring region is found by using

the active set of the current region + knowledge of the

type of hyperplane we are crossing:

⇒ The corresponding constraint is added to the

active set

convex, continuous,

piecewise quadratic,

C1 (if no degeneracy)

Corollary: The linear MPC controller is a continuous

piecewise affine function of the state

⇒ The corresponding constraint is withdrawn from

the active set

6

Complexity Reduction

2.5

2.5

CR1

CR2

CR3

CR4

CR5

CR6

CR7

CR8

CR9

2

1.5

1

• System: y(t) =

CR1

CR2

CR3

CR4

CR5

CR6

CR7

2

1.5

1

s2

ô

x(t + 1) = 1

0

u(t)

sampling + ZOH

Ts=1 s

1

0.5

õ

ô õ

1 x(t) + 0 u(t)

1

1

0 ] x(t)

y(t) = [ 1

0.5

0

• Constraints: à 1 ô u(t) ô 1

0

-0.5

-0.5

-1

-1

-1.5

• Control objective: minimize

-1.5

-2

-2.5

-2.5

Double Integrator Example

P∞

t=0

1 2

y 0 (t)y(t) + 100

u (t)

-2

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

2.5

-2.5

-2.5

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

u t+k = KLQ x(t + k|t) ∀k õ N u

2.5

• Optimization problem: for Nu=2

(cost function is

normalized by

max λ(H))

Regions where the first component of the solution is the same

can be joined (when their union is convex). (Bemporad, Fukuda, Torrisi,

Computational Geometry, 2001)

mp-QP solution

Complexity

Nu=5

Nu=4

Nu=3

Nu=2

CPU time

40

20

0

0

# Regions

Nu=6

5

10

15

20

15

20

300

200

100

0

0

5

10

# free moves

7

Complexity

• Worst- case complexity analysis:

M,

Pq

Nr ô

( q ) = 2q

`=0 `

PMà1

k=0

k!qk

Extensions

• Tracking of reference r(t) : îu(t) = F(x(t), u(t à 1), r(t))

combinations of active constraints

upper-

bound to the number of regions

• Numerical Tests:

• Rejection of measured

disturbance v(t) :

îu(t) = F(x(t), u(t à 1), v(t))

• Soft constraints:

u(t) = F(x(t))

Number of regions in the state-space

partition

y min à ï ô y(t + k|t) ô y max + ï

• Variable constraints:

u min(t) ô u(t + k) ô u max(t)

y min(t) ô y(t + k|t) ô y max(t)

Computation time (s)

[Matlab 5.3, Pentium II 300MHz]

• Linear norms:

ClosedClosed-Loop MPC and Hybrid Systems

u(t) = F(x(t), u min(t), . . ., y max(t))

min J(U, x(t)),

U

Pp

k=0

kQy(t + k|t)k ∞ + kRu(t + k)k ∞

(Bemporad, Borrelli, Morari, IEEE TAC, 2002)

MPC Regulation of a Ball on a Plate

Task:

•

Tune an MPC

controller by

simulation, using the

MPC Simulink

Toolbox

•

Get the explicit

solution of the MPC

controller.

•

Validate the controller

on experiments.

DHA

Motivation:

Use hybrid techniques to analyze closed-loop MPC systems !

(Bemporad, Heemels, De Schutter IEEE TAC, 2002)

8

Ball&Plate Experiment

General Philosophy: (1) MPC Design

• Step 1: Tune the MPC controller (in simulation)

y

x

γ

δ

α'

β'

α

β

•

Specifications:

Angle:

-17 deg … +17deg

Plate:

-30 cm …+30 cm

Input Voltage: -10 V… +10 V

Computer: PENTIUM166

Sampling Time:30 ms

•

Model:

LTI 14 states

Constraints on inputs and states

E.g: MPC Toolbox for Matlab

(Bemporad, Morari, Ricker, 2003)

MPC Tuning

General Philosophy: (2) Implementation

• Step 2: Solve mp

MPC

QP and implement Explicit

Sampling time:

Prediction horizon:

Free control moves:

Ts = 30 ms

p = 50

m=2

m

Output constraint horizon:

1 (soft constraint)

Input constraint horizon:

1 (hard constraint)

Weight on position error:

5

Weight on input voltage changes:

E.g: Real-

y

u

p

1

T

ime Workshop + xPC Toolbox

9

Explicit MPC Solution

MPC Regulation of a Ball on a Plate

x: 22 Regions, y: 23 Regions

Controller:

Design Steps:

x-MPC: sections at αx=0, αx=0, ux=0, rx=18, rα=0

o

•

Tune an MPC

controller by

simulation, using

the MPC Simulink

Toolbox .

•

Get the explicit

solution of the

16

1

6

6

1

16

MPC controller.

9 Validate the

controller on

experiments.

Region 1:

LQR Controller (near Equilibrium)

Region 6:

Saturation at -10

Region 16: Saturation at +10

Comments on Explicit MPC

MILP Formulation of MPC

(Bemporad, Borrelli, Morari, 2000)

• Multiparametric Quadratic Programs (mp-QP) can be solved efficiently

• Model Predictive Control (MPC) can be solved off-line via mp-QP

• Introduce slack variables:

min |x |

• Explicit solution of MPC controller u = f(x) is Piecewise Affine

ïxk

ïuk

õ kQy(t + k|t)k∞

õ kRu(t + k)k∞

x

Eliminate heavy on-line computation for MPC

x

ïxk

ïxk

ïuk

ïuk

min ï

s.t. ï õ x

ïõ àx

õ [Qy(t + k|t)]i

õ à [Qy(t + k|t)]i

õ [Ru(t + k))]i

õ à [Ru(t + k))]i

i = 1, . . ., p,

i = 1, . . ., p,

i = 1, . . ., m,

i = 1, . . ., m,

k = 1, . . ., T à 1

k = 1, . . ., T à 1

k = 0, . . ., T à 1

k = 0, . . ., T à 1

u

• Set ø , [ ï1 , . . . , ï N y, ï1 , . . . , ïTà 1 , U, î, z ]

min J(ø, x (t)) =

Make MPC suitable for fast/small/cheap processes

Mixed Integer Linear Program

(MILP)

ø

Tà1

X

ï xi + ïui

k=0

s.t.Gø ô W + Sx (t)

10

Multiparametric MILP

Solutions via Dynamic Programming

(Borrelli, Bemporad, Baotic, Morari, 2003)

(Mayne, ECC 2001)

min

ø={ø c ,ød}

f 0øc + d0ød

s.t. Gøc + Eød ô W + Fx

ø c ∈ Rn

ø d ∈ {0, 1} m

• mp-MILP can be solved (by alternating MILPs and mp-LPs)

(Dua, Pistikopoulos, 1999)

• Theorem: The multiparametric solution

ø ã (x) is piecewise affine

• Explicit solutions to finite

- time optimal control

problems for PWA systems can be obtained using a

combination of

• Dynamic Programming

• Multiparametric Linear (1

- norm, ∞

norm), or

or Quadratic (squared 2

- norm) programming

• Corollary: The MPC controller is piecewise affine in x

Note: in the 2-norm case,

the partition may not be polyhedral

Hybrid Control - Example

Switching System:

"

x(t + 1) = 0.8

Hybrid Control Example

(Revisited)

#

cos ë(t) à sin ë(t)

sin ë(t)

cos ë(t)

ô õ

x(t) + 0 u(t)

1

y(t) = [ 0 1 ] x(t)

ù

if [1 0]x(t) õ 0

3

ë(t) =

ù

à if [1 0]x(t) < 0

3

Closed loop:

y(t), r(t)

u(t)

Constraint: à 1 ô u (t) ô 1

Open loop:

time t

time t

11

Hybrid MPC - Example

• MLD system

• mp

-

State x (t)

2 variables

Input u(t)

1 variables

Aux. binary vector δ(t)

1 variables

Aux. continuous vector z(t)

4 variables

mp-MILP Solution

Prediction Horizon T=2

M

ILP optimization problem

P

minn 1o J(v10, x(t)), 1k=0 kQ1(v(k) à ue)k∞ + kQ2(î(k|t) à îe)k∞ + kQ3(z(k|t) à ze)k∞ + kQ4(x(k|t) à xe)k∞

v

0

subject to constraints

to be solved in the region

à5

à5

ô x1 ô

ô x2 ô

5

5

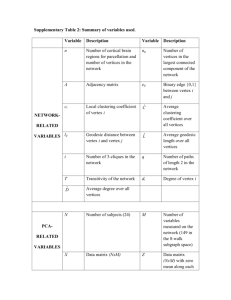

• Computational complexity of mp

-

M

ILP

Linear constraints

Continuous variables

Binary variables

Parameters

Time to solve mp-MILP

Number of regions

PWA law

84

20

2

2

3 min

7

ñ MPC law

Linear constraints

Continuous variables

Binary variables

Parameters

Time to solve mp-MILP

Number of regions

84

20

2

2

3 min

7

mp-MILP Solution

X2

Hybrid Control Example:

Traction Control System

X2

X1

Prediction Horizon T=3

X1

Prediction Horizon T=4

12

Simple Traction Model

Vehicle Traction Control

• Mechanical system

Improve driver’s ability to control a vehicle

under adverse external conditions (wet or icy roads)

ò

ó

üt

1

üc à beωe à

gr

Je

üt

vç v =

mv rt

ωç e =

• Manifold/fueling dynamics

üc = biüd(t à üf)

• Tire torque τt is a function of

slip ∆ω and road surface

Model

nonlinear, uncertain,

constraints

adhesion coefficient µ

Controller

suitable for real-time

implementation

∆ω =

Hybrid Model

Tire Force Characteristics

Nonlinear tire torque τt =f(∆ω , µ)

Torque

Longitudinal Force

PWA Approximation

(PWL Toolbox, Julian, 1999)

Slip Target

Zone

Maximum

Braking

Slip

Maximum

Cornering

Maximum

Acceleration

Steer Angle

Tire Slip

Longitudinal

Force

Lateral

Force

Torque

ra

µ

Tire Forces

te

La

Wheel slip

∆ω

MLD hybrid framework + optimization-based control strategy

ce

or

lF

ωe vv

à

gr rt

Mixed-Logical

µ

Slip

HYSDEL

(Hybrid Systems

Description Language)

Dynamical (MLD)

Hybrid Model

(discrete time)

13

MLD Model

Performance and Constraints

• Control objective:

min

PN

k=0

subj. to.

State x(t)

9 variables

Input u(t)

1 variable

Aux. Binary vars δ(t)

3 variables

Aux. Continuous vars z(t)

4 variables

|∆ω(k|t) à ∆ωdes|

MLD Dynamics

• Constraints:

• Limits on the engine torque: à 20Nm ô ü d ô 176Nm

• Logic Constraint:

• Hysteresis

The MLD matrices are automatically

generated in Matlab format by HYSDEL

Experimental Apparatus

Experimental Apparatus

14

Experiment

Hybrid Control Example:

Cruise Control System

• >500 regions

• 20ms sampling time

• Pentium 266Mhz +

Labview

Hybrid Control Problem

Renault Clio 1.9 DTI RXE

Hybrid Model

• Vehicle dynamics

mẍ = F e à F b à ìxç

xç

= vehicle speed

Fe =

traction force

Fb =

brake force

discretized with sampling time

T s = 0.5 s

• Transmission kinematics

GOAL:

command gear ratio, gas pedal,

and brakes to track a desired

speed and minimize consumption

ω=

Rg(i)

xç

ks

Fe =

Rg(i)

M

ks

ω

= engine speed

M=

i

engine torque

= gear

15

Hybrid Model

• Engine torque

Hybrid Model

• Gear selection: for each gear #i,

+

à Cà

e (ω) ô M ô Ce (ω)

define a binary input

gi ∈ {0, 1}

C+

e (ω)

• Max engine torque

• Gear selection (traction force):

Fe =

180

Rg( i)

M

ks

depends on gear #i

define auxiliary continuous variables:

160

http://www.renault.fr

Piecewise-linearization:

120

(PWL Toolbox, Julián, 1999)

100

requires: 4 binary aux variables

4 continuous aux variables

• Min engine torque

IF gi = 1 THEN F ei =

140

Rg(i)

M

ks

ELSE 0

F e = F eR + F e1 + F e2 + F e3 + F e4 + F e5

80

60

1000

2000

3000

4000

Cà

e (ω) = ë1 + ì 1 ω

• Gear selection (engine/vehicle speed):

ω=

Rg( i)

xç

ks

similarly, also requires 6 auxiliary continuous variables

Hysdel Model

Hybrid Model

• MLD model

x(t + 1) = Ax(t) + B1 u(t) + B2 î(t) + B3 z(t)

y(t) = Cx(t) + D1 u(t) + D2 î(t) + D3 z(t)

E 2 î(t) + E 3 z(t) ô E 4 x(t) + E 1 u(t) + E 5

x, v

• 2 continuous inputs: M, F b

• 6 binary inputs: gR, g1 , g2 , g3 , g4 , g5

• 1 continuous output:v

• 2 continuous states:

• 16 auxiliary continuous vars:

• 4 auxiliary binary vars:

(vehicle position and speed)

(engine torque, brake force)

(gears)

(vehicle speed)

(6 traction force, 6 engine speed,

4 PWL max engine torque)

(PWL max engine torque breakpoints)

• 96 mixed-integer inequalities

http://control.ethz.ch/~hybrid/hysdel

16

Hybrid Controller

Hybrid Controller

• Max-speed controller

• Max-speed controller

Velocity (km/h)

Gear

200

max J(u t, x(t)),v(t + 1|t)

ut

ú

MLD model

subj. to

x(t|t) = x(t)

Fraction of Max Torque (Nm)

1

1

150

4

0.5

0.5

250

100

3

50

2

0

1

Linear constraints

Continuous variables

Binary variables

Parameters

Time to solve mp-MILP

(Sun Ultra 10)

Number of regions

v(t)

0

0

200

MILP optimization problem

Brakes (Nm)

5

-0.5

-0.5

150

0

50

100

0

50

100

-1

0

50

-1

100

0

50

100

100

96

18

10

1

Road Slope (deg)

Engine speed (rpm)

1

50

Engine Torque (Nm)

6000

Power (kW)

200

60

5000

50

0.5

0

150

4000

x (t)

45 s

11

0

40

3000

( x (t ) is irrelevant)

100

30

2000

20

-0.5

50

1000

-1

0

50

Time (s)

Hybrid Controller

100

10

0

0

100

0

0

50

Time (s)

0

100

0

50

Time (s)

100

Hybrid Controller

• Tracking controller

min J(u t, x (t)),|v(t + 1|t) à vd(t)| + ú|ω|

• Tracking controller

min J(u t, x(t)),|v(t + 1|t) à vd (t)| + ú|ω|

ut

ú

MLD model

subj. to

x(t|t) = x (t)

50

Time (s)

Velocity (km/h), Desired velocity (km/h)

120

ut

Gear

Fraction of Max Torque (Nm)

5

Brakes (Nm)

10000

1

100

8000

4

0.5

80

6000

60

250

3

0

4000

40

2

200

0

MILP optimization problem

Linear constraints

Continuous variables

Binary variables

Parameters

Time to solve mp-MILP

(Sun Ultra 10)

Number of regions

98

19

10

2

27 m

49

vd(t)

150

0

100

200

1

0

100

200

2000

-1

0

100

200

0

0

100

200

ú = 0.001

100

6

50

00

-0.5

20

40

80

120

v(t)

160

200

6000

5000

2

4000

0

3000

-2

2000

-4

1000

-6

0

100

Time (s)

Engine Torque (Nm)

Engine speed (rpm)

Road Slope (deg)

4

200

0

0

Power (kW)

200

100

100

50

0

100

Time (s)

200

0

-100

-50

-200

-100

0

100

Time (s)

200

0

100

200

Time (s)

17

Hybrid Controller

Hybrid Controller

• Smoother tracking controller

• Smoother tracking controller

Velocity (km/h), Desired velocity (km/h)

120

min J(u t, x(t)),| v(t + 1 |t) à vd (t)| + ú| ω|

ut

|v(t + 1|t) à v(t)| < T samax

subj. to

MLD model

x(t|t) = x(t)

Gear

Fraction of Max Torque (Nm)

5

100

8000

4

0.5

80

6000

60

3

0

2

-0.5

20

Linear constraints

Continuous variables

Binary variables

Parameters

Time to solve mp-MILP

(Sun Ultra 10)

Number of regions

100

19

10

2

200

28 m

54

0

0

150

vd(t)

6

100

50

00

4000

40

250

MILP optimization problem

Brakes (Nm)

10000

1

40

80

120

v(t)

160

200

100

200

1

0

100

200

2000

-1

0

6000

4

5000

2

4000

0

3000

-2

2000

200

-6

0

0

100

200

Power (kW)

200

100

100

50

0

0

-50

-100

-4

0

Engine Torque (Nm)

Engine speed (rpm)

Road Slope (deg)

100

1000

100

Time (s)

200

0

-200

0

100

Time (s)

200

0

100

Time (s)

200

-100

0

100

200

Time (s)

18