Auxiliary Services Requirement Space 1 Pertemuan 10

advertisement

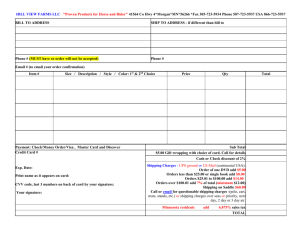

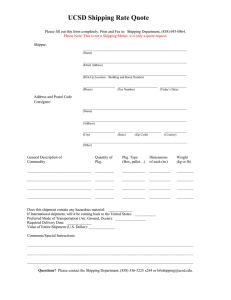

Auxiliary Services Requirement Space Pertemuan 10 1 Auxiliary Services Requirement Space Manufacturing departments need support services, and these services need space. There are many service functions to consider in a manufacturing plant but the activity centers that require a lion’s share of space are: Shipping and Receiving Storage Warehousing Maintenance and Tool Room Utilities, Heating, and Air Conditioning 2 Shipping and Receiving While shipping and receiving are two separate departments, they have very similar people, equipment, and space requirements. These functions could be placed next to each other or across the plant from each other. The placement of the shipping and receiving departments have a significant effect on the flow of material in the plant. 3 Shipping and Receiving Advantages Common Equipment Common Personnel Improved Space Utilization Reduced Facility Costs Disadvantages Space Congestion Poor Material Flow Lost Materials Poor Communication 4 Shipping and Receiving Material Handling issues. . . Dock Loaders 5 Trucking Industry’s Effect The trucking industry is organized nationally to deliver raw materials and parts to industry in the morning and pick up shipments in the afternoon. This is know as less than truck load quantities (LTL). Full truck loads are handled differently. 6 Receiving Department Functions 1. 2. 3. 4. 5. 6. 7. Assist in locating a trailer at the receiving dock door Assist in the unloading of materials Record the receipt of the number of containers Open, separate, inspect, and count the received materials Develop an overage, shortage, or damage reports as required Create a receiving report Route incoming material 7 Receiving Department Facilities Dock Doors – Dock Plates, Levelers, and Boards – Aisles – Outside Areas – Offices – and service rates Quantity is dependent on arrival used to bridge the door to floor space Tools Size aisles based upon materials and handling equipment required loading dock Area around the outside of the Receiving offices are usually small (allow 100 sq. ft. / clerk) 8 Receiving Area 65’ T U R N I N G A I S L E S Office 22’ 45’ 11’ Parking Area 9’ Door 5’ Aisle Maneuvering Area Road Trailer parking can consume 65’ from the plant wall Maneuvering space is usually 45’ Roadways are 11’ one way or 22’ for two-way traffic 9 Receiving Area 10 Shipping and Receiving 11 Shipping Department Functions 1. 2. 3. 4. 5. 6. 7. Packaging finished goods for shipping Addressing cartons or containers Weighing each container Collecting orders for shipping (staging) Spotting trailers Loading trailers Creating bills of lading 12 Packaging Workstation 13 Packaging Workstations Pack Bench Packing Workstation 14 Determining Shipping Space Q: The shipping department is estimating the required shipping space for a new line of toolboxes. The company projects a maximum of 2,000 units per day shipping in an 8 x 8 x 18 inch box. The toolboxes will be packaged in the work cell. Uncle Bob’s Freightliner will be using a 40 ft long trailer. How many trailers and how much staging space will be required per day? A: (8 x 8 x 18) / (1,728 cu. in. per ft.) = .66 cu. ft. = .66 cu. ft. x 2,000 units = 1,333 cu. ft. per day A trailer is 8’ wide x 40’ long x 7’ high = 2,240 cu. ft. Number of trailers per day = 1,333 cu. ft. / 2,240 cu. ft. = 0.6 trailers per day 15 Determining Shipping Space A: One dock door will be required to meet the expected one day demand. It should be noted that we are utilizing only 60% of the trailer capacity: (1,333 / 2,240) x 100% = 59.5% or 60% Internal staging requirements will be a space of: 8’ x 40’ x 60% = 192 sq. ft. Compensating for the extra space needed for aisles and offices (not inclusive of packing. . . handled in the work cell) 192 sq. ft. x 200% = 384 sq. ft. or 400 sq. ft. 16 Storage Stores is a term used to denote an area set aside to hold raw materials, parts, and supplies. There are many different types: Raw Materials Stores Finished Parts Stores Office Supplies Stores Maintenance Supplies Stores Janitorial Supply Stores 17 Storage Maintenance Supply Stores Example 18 Storage The space requirements for stores is dependent on the stated inventory policy of the company. It may be as simple as “Provide space to store a one-month supply.” Another method is the ABC philosophy. . . Inventory Class A B C Percentage of Parts 20% 20% 60% Percentage Inventory of $ Policy 80% 1 wk. supply 15% 2 wks. supply 5% 1 mth. supply 19 Just-in-Time Inventory Storage Just in time (JIT) is the inventory policy that has begun to roll across the United States after a very successful beginning in Japan. This is a special type of inventory that can affect the plant layout in many ways: Adjust or eliminate receiving, receiving reports, etc. Eliminate quality control checks Eliminate or greatly reduce stores area requirements 20 Storage Goals JIT will not be considered in this course because designing a layout for a non-JIT system is more difficult and, unfortunately, is more common. The goals of any stores department should be: To maximize the use of the cubic space To provide immediate access to everything (selectively) To provide for the safekeeping of the inventory including damage and count control 21 Warehousing Warehousing is the storage of finished products. As in the storeroom, the area requirement will depend on management policy. Additional issues include seasonality of products. These may require outside warehousing during peak times. A warehouse can be a department or an entire building. 22 Warehousing Three basic warehousing functions: To safekeep the finished product To maintain some stock of every product sold by the company To prepare customer orders for shipment 23 Warehousing 24 Warehousing Cantilever Racks Carton Flow Rack Carousel Rack 25 Pallet Position Example Q: A company wants to store a single part number consisting of 5,000 cartons each containing 20 cartons. How many pallet positions are needed if the pallets are stored three high? A: Number of pallets required = total cartons / cartons per pallet = 5,000 / 20 = 250 pallets Number of pallet positions = total pallets / stored height = 250 / 3 = 83.33 = 84 pallet positions 26 Maintenance and Tool Room The maintenance and tool room function is to provide and maintain production tooling. These functions vary widely from one company to another. Tool rooms may not exist is some plants because all tools are purchased from outside sources. 27 Maintenance and Tool Room Maintenance is service to the company’s equipment. A mobile service cart may be used, but more commonly, a central maintenance area would include equipment, machine overhead areas, maintenance supplies, and spare parts storage. 28 Maintenance and Tool Room Maintenance can account for 2 to 4 percent of the plant personnel. An extreme may be upwards of 33 percent (paper mills). As a rule of thumb, allow 400 sq. ft. of space for each maintenance employee. This would allow for everything except maintenance stores, which were covered previously. 29 Determining Tool Room Space Q: Our toolbox plant historically used 0.13702 hours per unit of the rate of 100 percent. History indicates that 85 percent equipment performance is more realistic. Determine the number of maintenance personnel required as well as the amount of space allocated for the tool room. Assume production projections of 2,000 toolboxes per day and 3% maintenance. A: 0.13702 / .85 = 0.16120 hours each 0.16120 x 2,000 units per day = 322.4 hours of production people Each person works 8 hours per day, so 41 production people are required 41 x 3% = 1.2 maintenance people Space = 2 x 400 sq. ft. = 800 sq. ft. for the tool room 30 Maintenance and Tool Room Add a 10 x 10 ft. controlled storeroom for tools and supplies to most plant layouts. This 100 sq. ft. storage area is just a minimum size area for controlling supplies. Therefore in the previous example, total square footage for maintenance will be 900 sq. ft. 31 Utilities Heat, air conditioning, electrical panels, air compressors, etc. must be considered when determining space. These areas must be kept separate from normal traffic – electrical panels should be fenced off, heaters must be kept clean, air compressors require special noise handling. There are few rules of thumb concerning these. . .safety should take precedence when placing these into the facility plan. 32 Questions? 33